When it comes to agricultural equipment, having a clear overview of the various components is essential for effective maintenance and operation. A comprehensive understanding of these elements ensures that machinery functions optimally, minimizing downtime and enhancing productivity.

Farm equipment consists of numerous interconnected parts, each serving a specific purpose. Familiarity with the layout and functions of these components can aid in troubleshooting and repairs, enabling users to address issues promptly and efficiently.

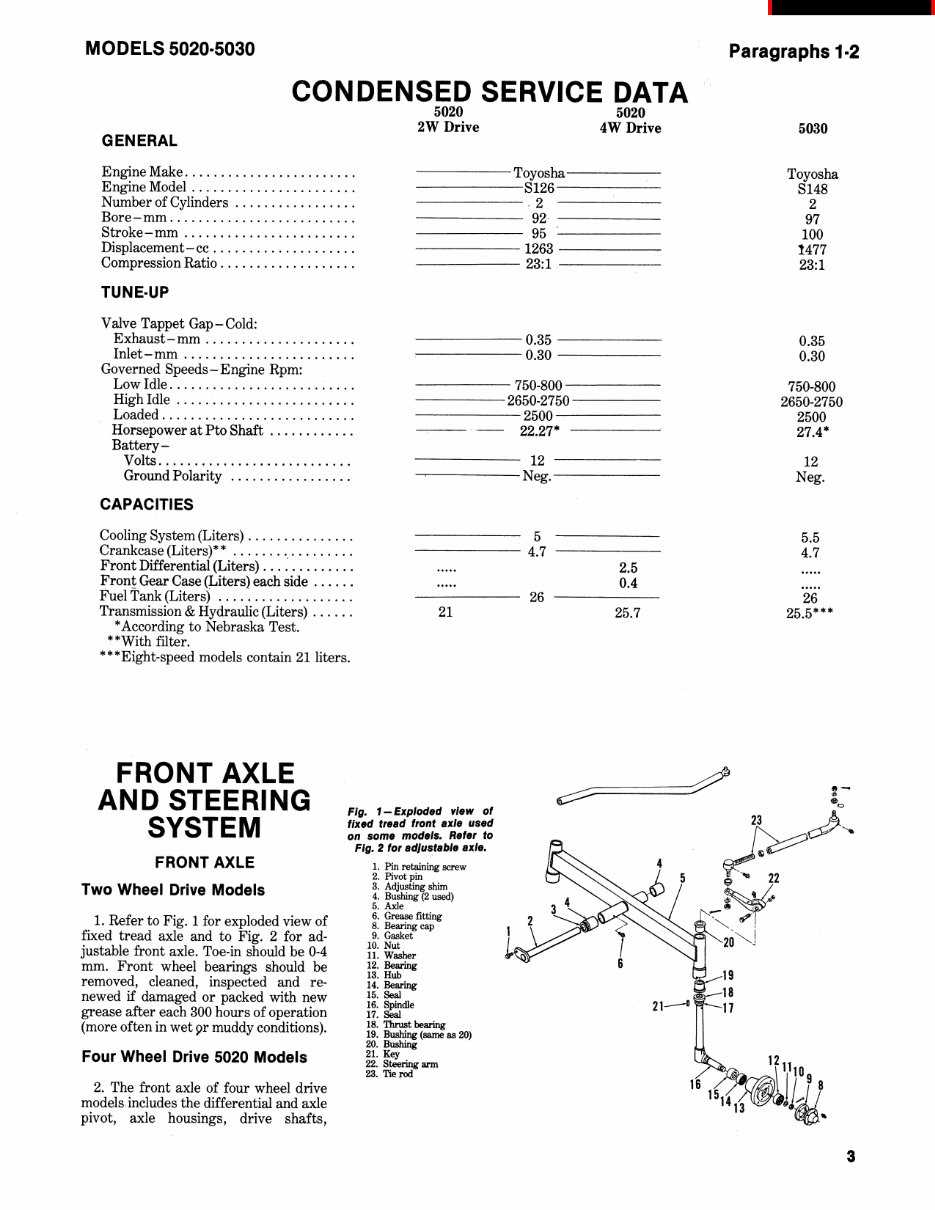

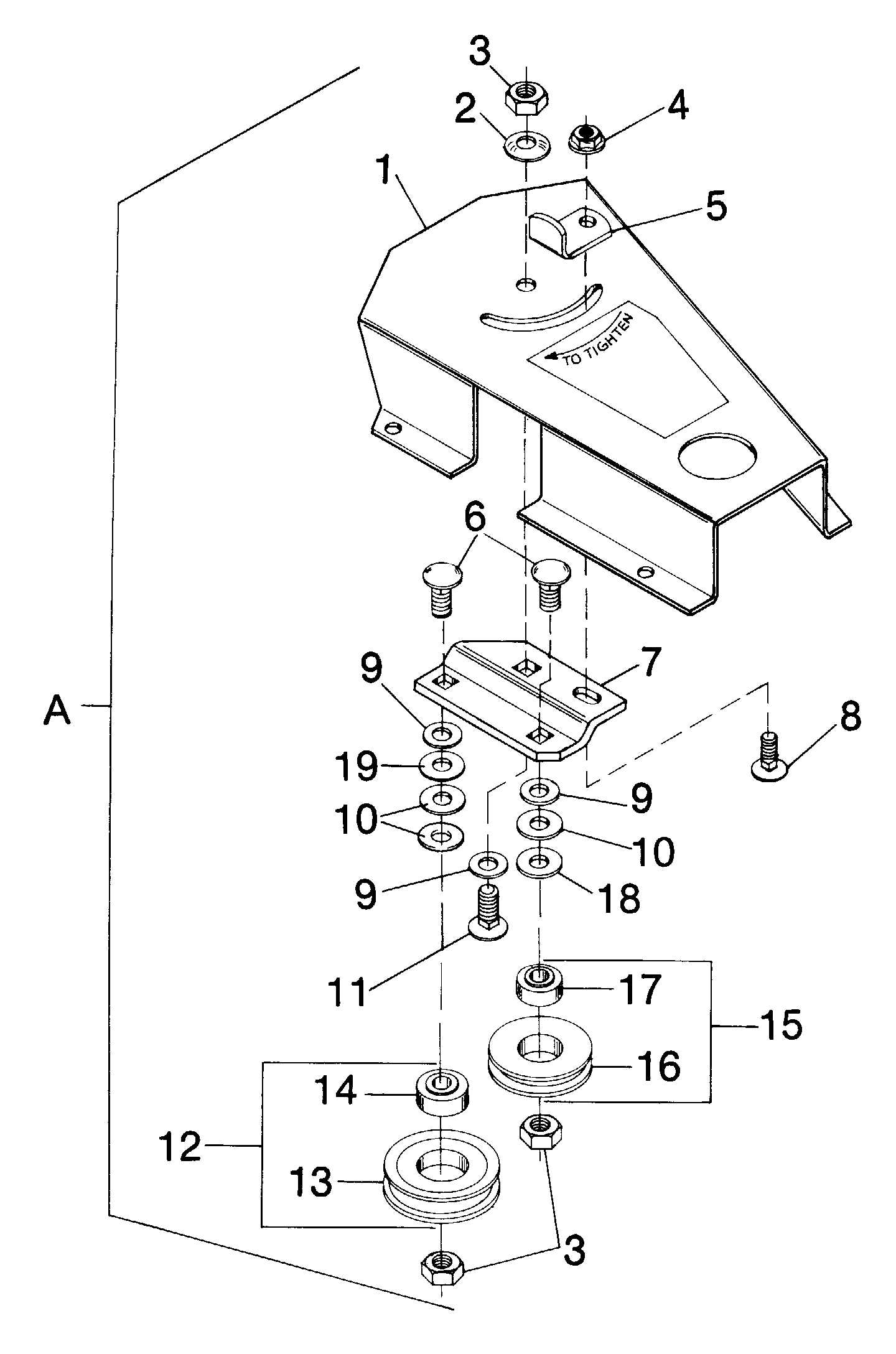

Additionally, visual representations of machinery layouts can provide valuable insights into the relationships between different elements. Such illustrations not only enhance comprehension but also serve as practical references for anyone looking to optimize their equipment’s performance.

This section aims to explore the various components of a specific agricultural machine, emphasizing the importance of each part in ensuring optimal functionality and performance. Understanding the assembly is crucial for both maintenance and troubleshooting, helping operators keep the equipment in excellent working condition.

Importance of Component Knowledge

Familiarity with the different elements of machinery enables users to perform effective repairs and enhancements. Each section contributes to the overall operation, and recognizing their roles helps in identifying potential issues before they escalate.

Overview of Essential Elements

| Component | Function |

|---|---|

| Engine | Powers the machine and drives the hydraulic systems. |

| Transmission | Transmits power from the engine to the wheels. |

| Hydraulics | Facilitates the movement of implements and attachments. |

| Chassis | Provides structural integrity and support for other components. |

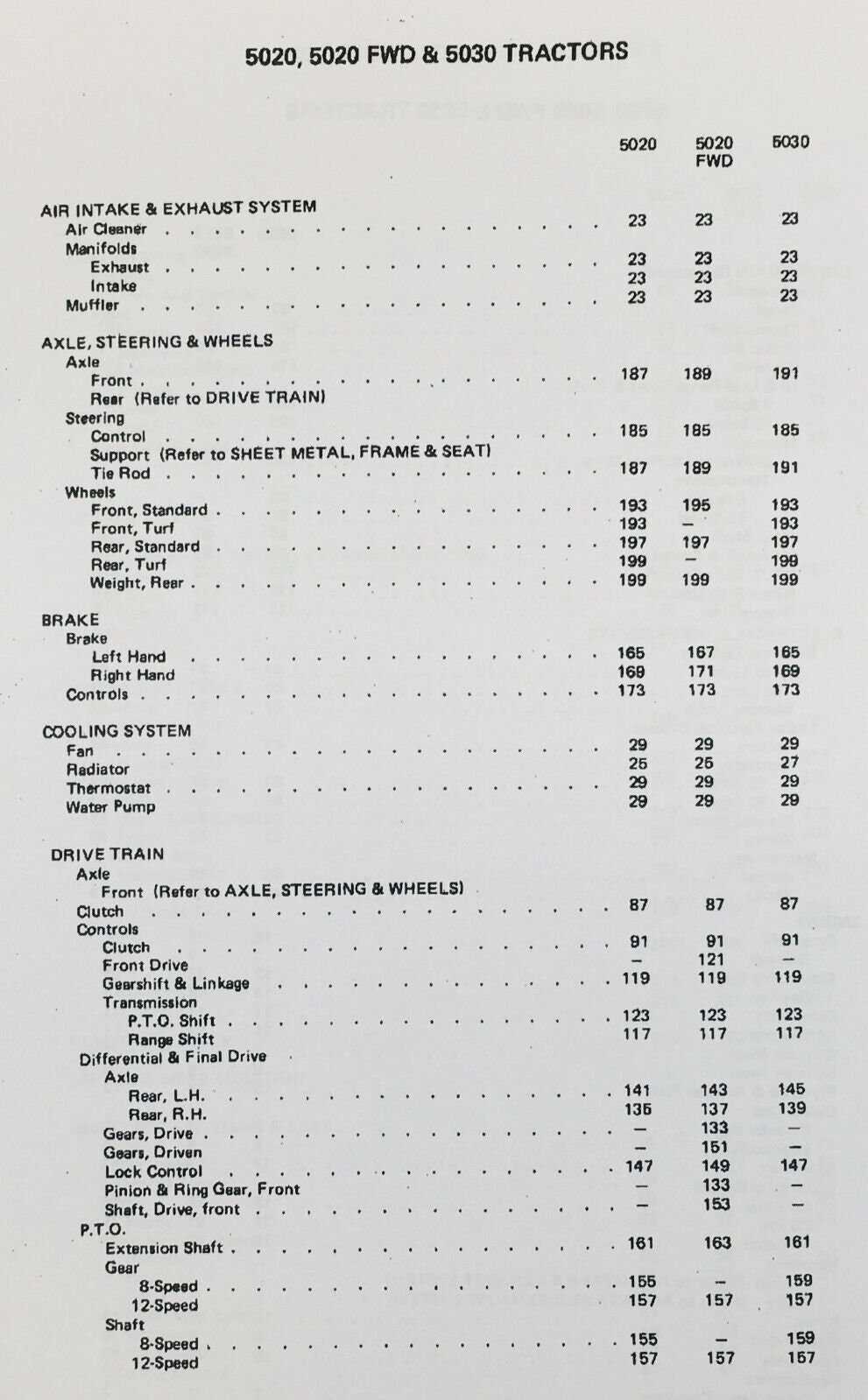

Key Components of the 5020 Model

This section explores the essential elements of the machine, highlighting their significance and interrelations. Understanding these components is crucial for maintaining optimal functionality and performance.

- Engine: The powerhouse that drives the entire unit, providing the necessary energy for various operations.

- Transmission: A critical mechanism that transfers power from the engine to the wheels, ensuring smooth movement and control.

- Hydraulic System: This system facilitates various functions, including lifting and moving attachments, enhancing versatility.

- Chassis: The structural frame that supports all components, ensuring stability and durability during use.

- Electrical System: An intricate network responsible for powering lights, instruments, and other electronic devices, crucial for operation.

Each of these parts plays a vital role in the overall efficiency and effectiveness of the equipment. Regular maintenance and understanding of their functions can lead to improved performance and longevity.

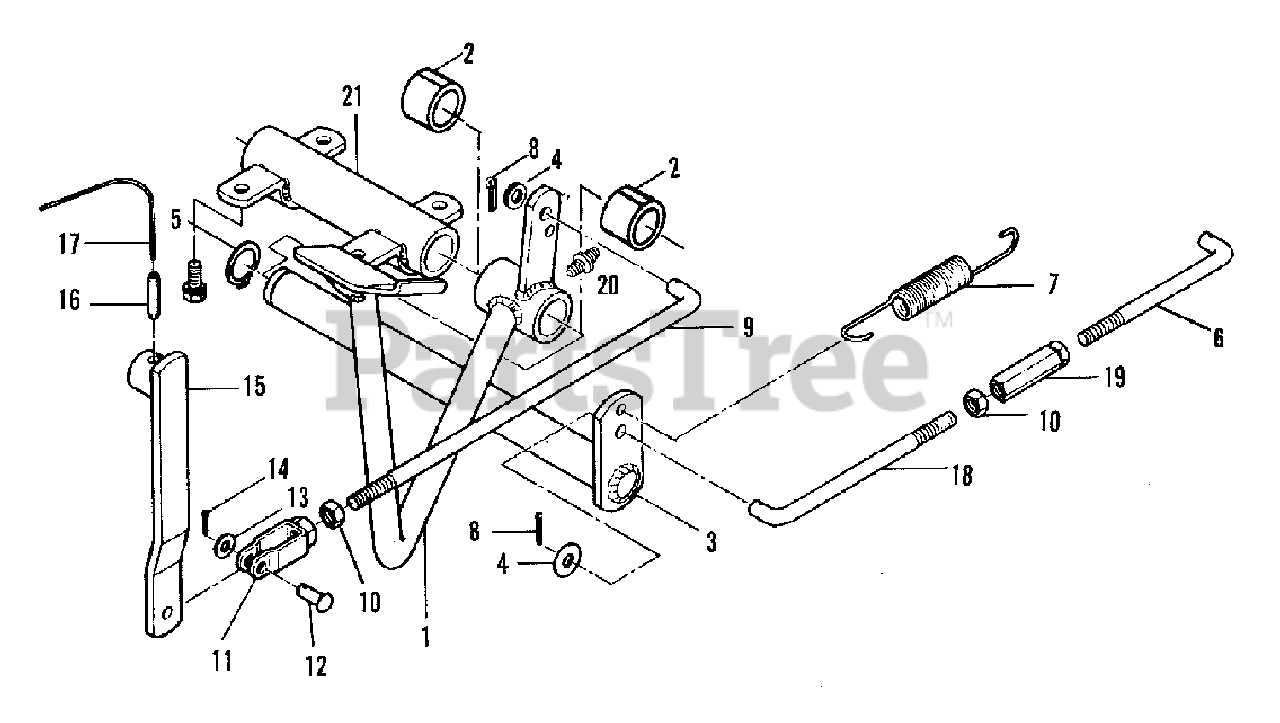

Importance of a Parts Diagram

Understanding the assembly and components of a machine is crucial for effective maintenance and repairs. A visual representation that outlines the various elements of a system enhances clarity and facilitates easier identification of each part. This organized depiction plays a significant role in ensuring that users can accurately locate and replace components as needed, ultimately improving the longevity and functionality of the equipment.

Enhanced Troubleshooting

Having access to a comprehensive visual reference simplifies the troubleshooting process. Users can quickly pinpoint malfunctioning components and determine the necessary replacements without unnecessary guesswork. This efficiency reduces downtime and enhances productivity in various operational settings.

Streamlined Maintenance Procedures

A clear illustration of machine components not only aids in repairs but also promotes routine maintenance. Users can follow a systematic approach to check, clean, and service different elements, ensuring optimal performance and preventing potential issues before they escalate. This proactive strategy ultimately saves time and resources.

Identifying Major Assemblies

Understanding the main components of machinery is crucial for efficient maintenance and repair. Recognizing the key structures allows operators and technicians to diagnose issues quickly and source the correct replacements. This knowledge contributes to better overall performance and longevity of the equipment.

Essential Components Overview

Each assembly plays a significant role in the functionality of the system. Key elements often include the engine unit, transmission system, and hydraulic components. Familiarity with these critical sections can enhance operational efficiency and ensure that any malfunctions are addressed promptly.

Common Assembly Identification Tips

When examining machinery, it’s beneficial to familiarize oneself with the layout and connection points of various assemblies. Visual inspection can reveal wear or damage, while maintenance manuals provide detailed insights into assembly configurations. Utilizing these resources can greatly aid in the identification and resolution of potential issues.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual representations simplify complex assemblies by showcasing individual components and their interconnections. Learning to interpret these visuals can significantly enhance your ability to identify necessary elements and execute repairs efficiently.

Key Elements of Technical Illustrations

- Labels: Each component is typically marked with a label that provides its identification number or name.

- Symbols: Various symbols may indicate different types of elements, such as electrical parts or hydraulic components.

- Connections: Lines or arrows often illustrate how different parts interact or are connected, highlighting the flow of operation.

Steps to Effectively Interpret Illustrations

- Begin by examining the legend or key, which explains the symbols and notations used in the visual representation.

- Identify the main assembly and its subcomponents, noting how they relate to one another.

- Cross-reference the labels with any accompanying documentation to ensure you understand each element’s role.

- Use the diagram to guide disassembly or reassembly, ensuring each component is correctly positioned.

Common Replacement Parts Explained

Understanding the components that often require substitution can significantly enhance the longevity and performance of machinery. This section outlines the essential elements that users typically need to replace over time, ensuring optimal functionality and reliability.

Key Components to Monitor

Several vital components should be regularly inspected and, if necessary, replaced to maintain efficient operation. These include items such as filters, belts, and hoses, which are crucial for the smooth running of the equipment. Neglecting these parts may lead to decreased performance and potential mechanical failures.

Signs Indicating the Need for Replacement

Awareness of specific indicators can aid in timely replacements. For instance, unusual noises, leaks, or reduced efficiency are clear signs that components may be worn out. Addressing these issues promptly can prevent more extensive damage and costly repairs in the future.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and optimal performance of machinery. By following a few simple guidelines, users can extend the lifespan of their equipment, reduce the likelihood of malfunctions, and improve overall efficiency.

Regular inspections play a crucial role in identifying potential issues before they escalate. Check components for signs of wear and tear, and replace any damaged parts promptly. Additionally, keeping the equipment clean prevents dirt and debris buildup, which can lead to operational problems.

It’s also important to follow the manufacturer’s recommendations for lubrication and servicing schedules. Using the correct lubricants helps maintain smooth operation and reduces friction between moving parts. Furthermore, ensuring that all fasteners are tightened to the specified torque can prevent loosening and subsequent damage.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect components | Monthly | Identify wear and prevent breakdowns |

| Clean equipment | Weekly | Prevent dirt buildup and enhance performance |

| Lubricate moving parts | As recommended | Reduce friction and extend life |

| Tighten fasteners | Monthly | Ensure stability and avoid damage |

Where to Find Authentic Parts

Locating genuine components for machinery can be a crucial aspect of maintenance and repair. Ensuring that you use original or certified replacements helps maintain the functionality and longevity of your equipment. Here are some effective strategies to consider when searching for these essential items.

- Manufacturer’s Website: The official site often provides a comprehensive catalog of available components, along with specifications and compatibility information.

- Authorized Dealers: Visiting authorized retailers can guarantee that you are purchasing certified replacements, often with a warranty.

- Online Marketplaces: Reputable platforms can be excellent sources for various components. Look for sellers with positive feedback and verified listings.

- Local Repair Shops: Establishing a relationship with local service providers can be beneficial. They may have connections or inventory for original components.

- Trade Shows: Attending industry events can provide opportunities to connect directly with manufacturers and suppliers, ensuring access to authentic items.

By utilizing these resources, you can enhance your chances of acquiring the right components for your machinery, ensuring optimal performance and reliability.

Upgrades for Enhanced Performance

Improving the functionality of machinery can lead to significant gains in efficiency and productivity. Various enhancements can be applied to optimize performance, ensuring the equipment meets the demands of challenging tasks. These modifications often focus on increasing power output, improving fuel efficiency, and enhancing overall reliability.

Engine Modifications: Upgrading the engine components can provide noticeable improvements in horsepower and torque. Replacing factory-installed elements with high-performance alternatives can enhance responsiveness and overall power delivery.

Transmission Improvements: Upgrading the transmission system can lead to smoother shifting and better power distribution. Enhanced gear ratios and more efficient components can help in achieving optimal performance across various operating conditions.

Hydraulic System Enhancements: Investing in superior hydraulic components can increase lifting capacity and operational speed. Improved hydraulic pumps and cylinders can lead to more efficient movement and greater versatility in applications.

Overall Maintenance: Regular maintenance and timely upgrades can prevent wear and tear, prolonging the life of the machinery. Implementing a proactive approach to equipment care will ensure that it operates at peak performance for years to come.

Troubleshooting Common Issues

When operating machinery, encountering difficulties is not uncommon. Understanding typical problems and their solutions can enhance performance and extend the lifespan of equipment. This section aims to guide users through frequent challenges and provide effective methods to address them.

One prevalent issue is engine performance problems. These may manifest as difficulty starting, stalling, or reduced power output. To resolve these, it’s essential to check the fuel supply and ensure that filters are clean and free from debris. Regular maintenance can help prevent such complications.

Another common concern is hydraulic system malfunctions. Symptoms might include unusual noises, slow operation, or leaks. Inspecting the fluid levels and examining hoses for any signs of wear or damage are critical steps in troubleshooting these problems. Addressing leaks promptly is vital for maintaining efficiency.

Lastly, electrical issues can arise, resulting in poor functionality or complete inoperability. Checking the battery connections and ensuring that wiring is intact can often solve these issues. Keeping electrical components clean and dry will contribute to reliable operation.

By being proactive and knowledgeable about these frequent challenges, users can effectively manage their equipment and minimize downtime.

Resources for Further Information

For those seeking additional insights and comprehensive guidance related to machinery components and maintenance, there are numerous valuable resources available. These materials can assist in understanding the intricacies of different models and their functionalities, offering a deeper knowledge base for enthusiasts and professionals alike.

Online Communities and Forums

Participating in online forums and communities can provide a wealth of shared experiences and knowledge. Users often discuss their challenges, solutions, and recommendations, making these platforms a great place to connect with others who have similar interests.

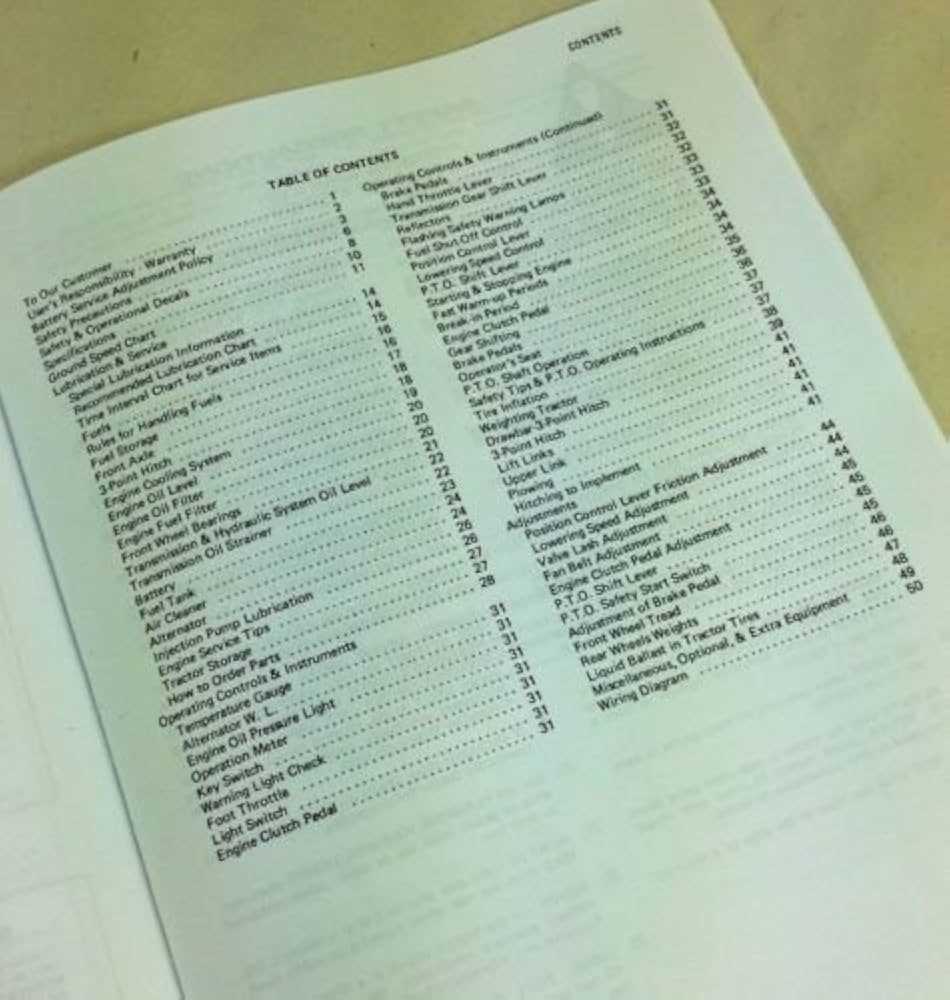

Technical Manuals and Guides

Accessing technical manuals and instructional guides is essential for detailed information. These documents often include troubleshooting tips, maintenance schedules, and specifications, ensuring users have the necessary details to effectively operate and care for their equipment.