In the realm of gardening machinery, a comprehensive understanding of individual elements is essential for effective maintenance and repair. Familiarity with the structure and functionality of each segment not only ensures optimal performance but also extends the lifespan of the equipment. This section aims to provide insights into the organization and relationship between various components, allowing users to navigate their machinery with confidence.

To facilitate a seamless interaction with these devices, detailed visual representations serve as invaluable resources. By examining the arrangement of different sections, users can identify potential issues and address them proactively. Moreover, such illustrations enhance the overall comprehension of how each part contributes to the machine’s efficiency.

Equipped with this knowledge, operators can better appreciate the intricacies of their tools, leading to more informed decisions during repairs or upgrades. Whether you are a seasoned professional or a hobbyist, grasping the layout of your equipment empowers you to maintain it effectively and ensures it performs at its best.

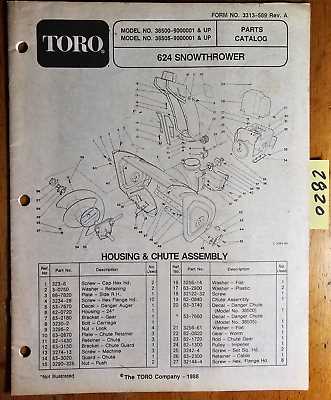

Toro 3650 Parts Overview

This section provides an in-depth look at the components and their functions for efficient maintenance and operation. Understanding each element’s role can significantly enhance performance and longevity.

Key Components

Essential elements include the engine assembly, cutting blades, and drive systems. Each plays a critical role in ensuring seamless functionality and optimal results.

Maintenance Insights

Regular inspection of these crucial parts is necessary to prevent wear and tear. Timely replacements not only improve efficiency but also ensure safety during use. Prioritize upkeep for the best outcomes.

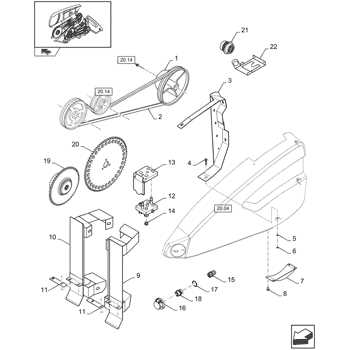

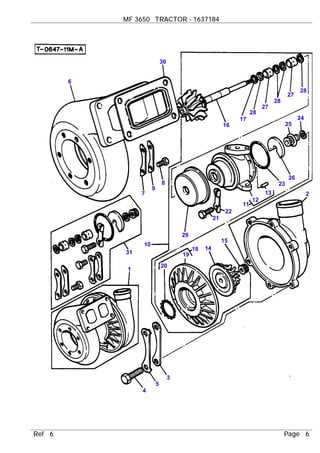

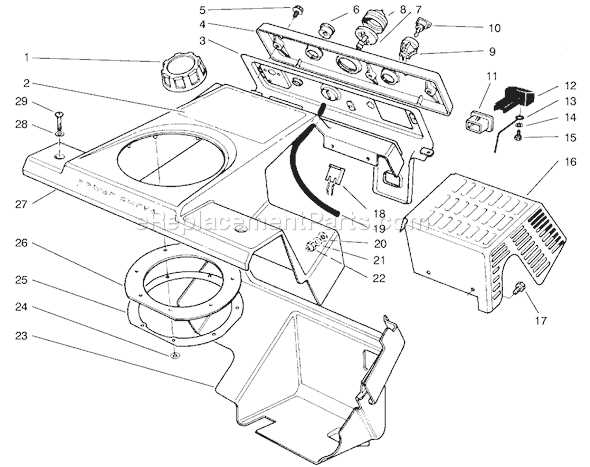

Understanding the Parts Diagram

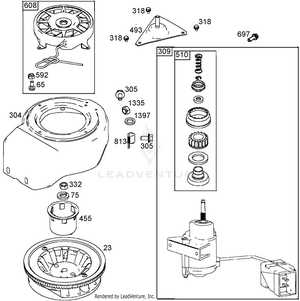

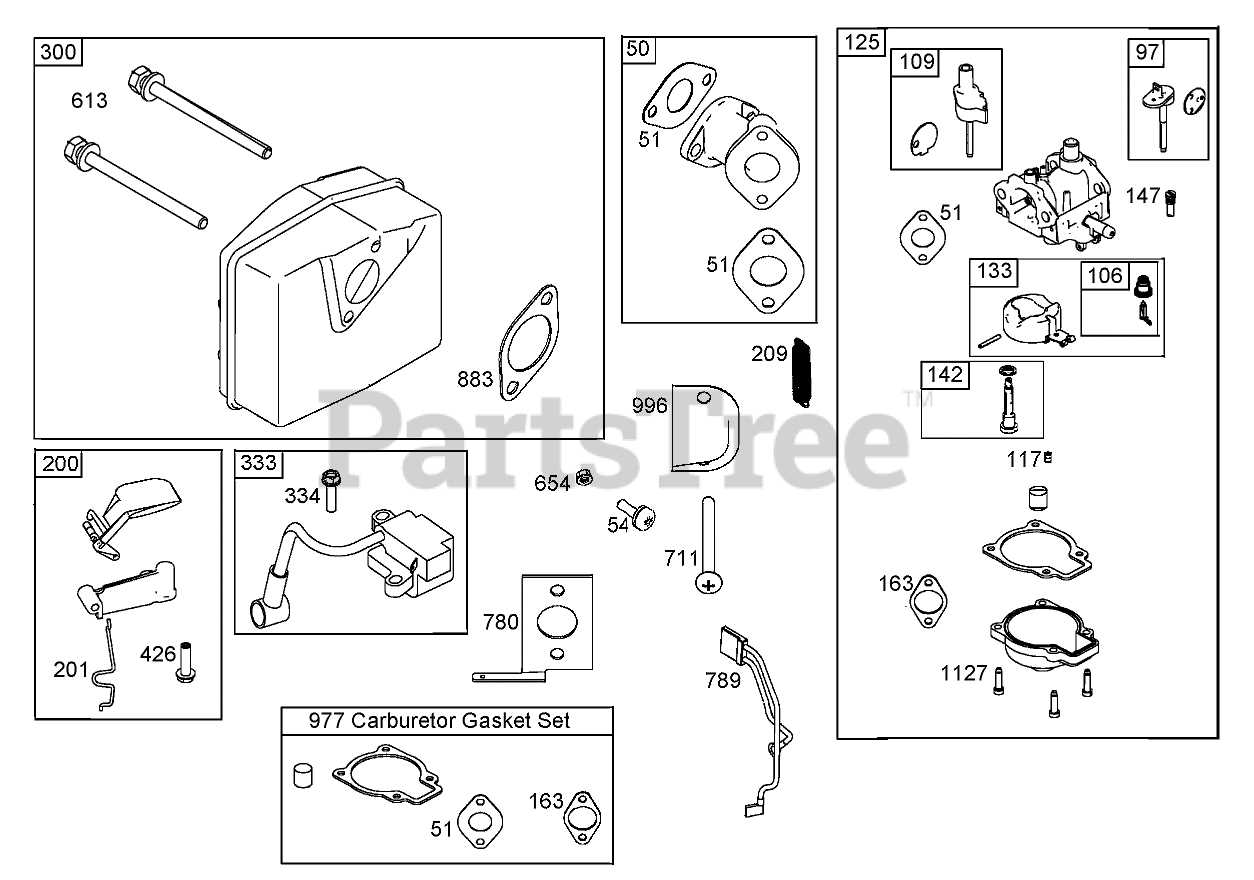

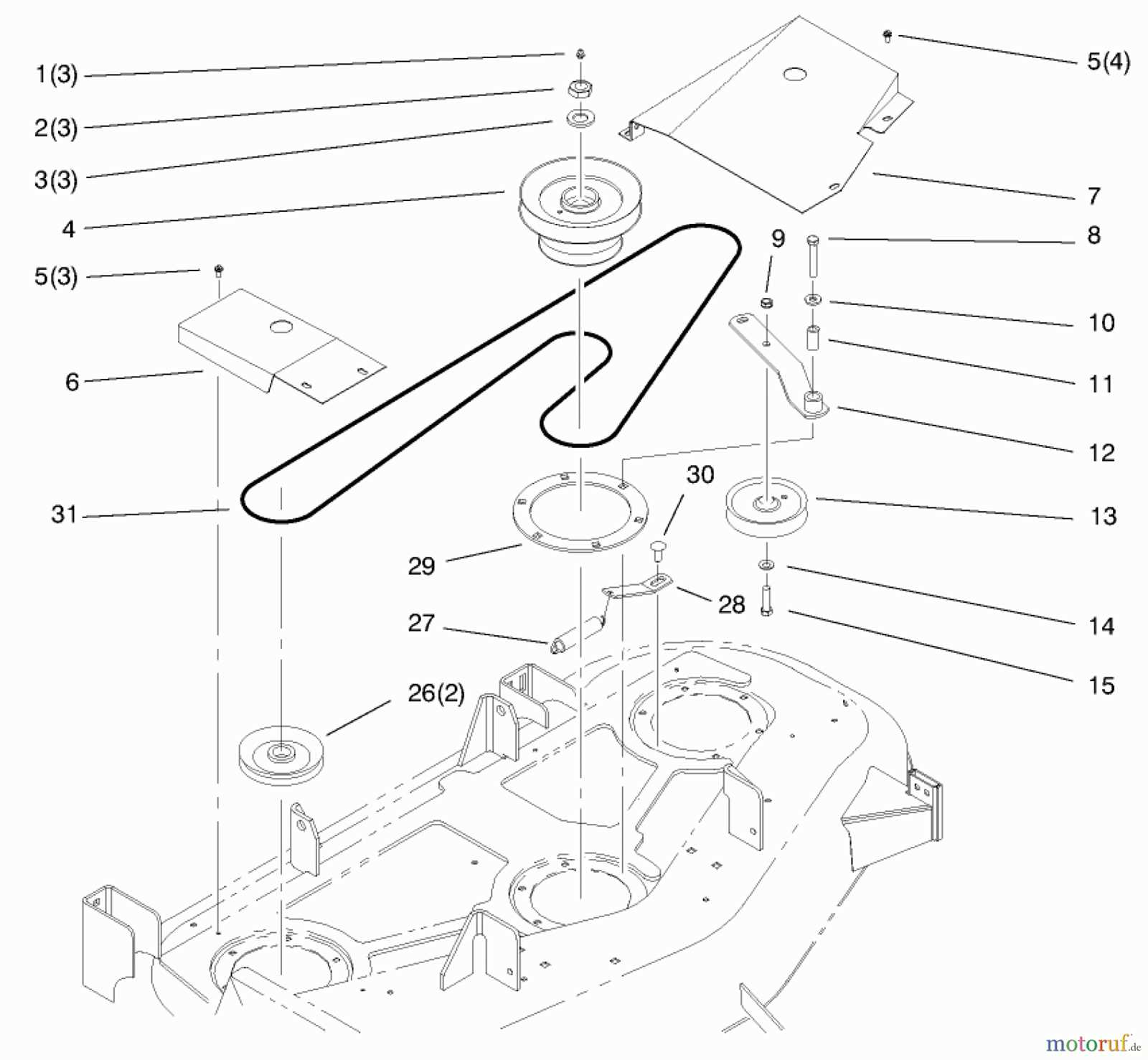

Having a clear visual representation of components is essential for effective maintenance and repair. This illustration serves as a guide to help users identify each element and understand how they fit together within the overall system. By familiarizing oneself with this layout, one can more easily troubleshoot issues and perform necessary replacements.

Components are often labeled to indicate their specific functions, which can significantly aid in understanding how each piece interacts with others. For example, knowing the location and purpose of various parts allows for quicker diagnostics and efficient repairs.

Moreover, the visual reference can simplify the process of ordering replacements. By recognizing the exact items needed, users can avoid confusion and ensure compatibility. Ultimately, a well-structured representation not only streamlines maintenance efforts but also enhances the longevity of the equipment.

Key Components of Toro 3650

Understanding the essential elements of this equipment is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and reliability, contributing to the overall functionality of the machine.

Main Functional Units

Among the various parts, several key units stand out due to their importance in the operation of the equipment. These components work in harmony to deliver superior results.

| Component | Function |

|---|---|

| Engine | Powers the machine and drives all operations. |

| Transmission | Transmits power from the engine to the wheels, enabling movement. |

| Deck | Supports the cutting mechanism and enhances stability during operation. |

| Control Panel | Allows the operator to manage various functions and settings easily. |

Additional Essential Features

Aside from the main units, several auxiliary features significantly enhance the overall performance and user experience. These elements are designed to improve functionality and ensure ease of use.

| Feature | Benefit |

|---|---|

| Safety Mechanisms | Protects the operator and prevents accidents during use. |

| Ergonomic Design | Enhances comfort and reduces fatigue for the operator. |

| Adjustable Settings | Allows customization for different tasks and conditions. |

| Durable Materials | Ensures longevity and resistance to wear and tear. |

How to Read the Diagram

Understanding a visual representation of components can greatly enhance your ability to manage and repair equipment. This guide will help you navigate through symbols, labels, and the overall layout effectively, allowing for a smoother experience in identifying parts and their functions.

Key Elements to Look For

Start by familiarizing yourself with the essential features, such as labels that indicate specific components. Each part will typically have a unique identifier, which is crucial for locating replacement options or troubleshooting issues. Pay attention to the connections between parts, as they often reveal how different elements interact with one another.

Interpreting the Symbols

Many illustrations use standardized symbols to represent various components. Learning these can save time and reduce confusion. Look for a legend or key, which provides explanations for each symbol, helping you to grasp the relationships and functions quickly.

Common Issues with Toro Parts

When it comes to maintaining outdoor equipment, users often encounter various challenges that can hinder performance. Understanding these frequent problems is essential for effective troubleshooting and ensuring the longevity of the machinery. From wear and tear to improper installation, several factors can contribute to malfunctions.

One of the most prevalent concerns is the degradation of components due to prolonged use. Over time, parts can become worn, leading to decreased efficiency and potential failure. Regular inspections are crucial to identify these signs early on.

Another common issue involves incorrect assembly. Many users may struggle with reassembling after repairs, resulting in misalignment or loose connections. This can lead to operational difficulties and may even cause further damage if not addressed promptly.

Furthermore, environmental factors can significantly impact the condition of the machinery. Exposure to moisture, dirt, and extreme temperatures can accelerate wear, making it vital to store equipment properly and perform routine maintenance.

Finally, using incompatible replacements can create additional complications. It’s essential to select suitable alternatives that meet the specifications to avoid compromising performance and safety.

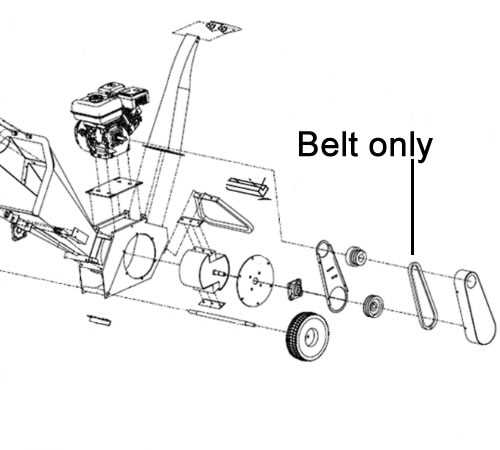

Replacement Parts for Toro 3650

Maintaining your equipment in optimal condition is crucial for ensuring longevity and efficiency. When specific components wear out or become damaged, it’s essential to find suitable replacements to keep your machinery running smoothly. This section focuses on available alternatives to enhance your device’s performance.

Common Components Needing Replacement

- Engines

- Blades

- Filters

- Wheels

- Belts

Where to Find Quality Alternatives

- Authorized dealers for genuine items

- Online marketplaces with user reviews

- Local repair shops that stock high-quality replacements

- Specialty retailers focusing on equipment maintenance

Choosing reliable substitutes ensures your machinery operates efficiently and safely, prolonging its service life.

Where to Buy Toro Parts

Finding components for your outdoor equipment can enhance its performance and longevity. Various sources offer these essential items, ensuring you can maintain your machinery effectively.

Authorized Dealers

Visiting licensed retailers guarantees access to genuine items, often accompanied by expert advice. These establishments typically have knowledgeable staff ready to assist with your specific needs.

Online Marketplaces

Many platforms provide a wide selection of aftermarket and original components. Websites often feature user reviews, allowing you to compare options and make informed decisions. Always check seller ratings for a reliable purchase experience.

Maintenance Tips for Toro 3650

Regular upkeep is essential for ensuring the longevity and optimal performance of your outdoor equipment. Following a systematic maintenance routine can prevent unexpected breakdowns and enhance efficiency. Here are some effective strategies to keep your machine running smoothly.

Routine Checks

- Inspect the air filter regularly. Clean or replace it as necessary to ensure proper airflow.

- Check the fuel system for leaks or blockages to maintain efficient fuel delivery.

- Examine the spark plug condition and replace it if it’s worn or fouled.

- Look over the blades for sharpness and signs of wear; sharpen or replace them as needed.

Seasonal Maintenance

- Before winter, store the machine in a dry location and ensure it’s cleaned thoroughly.

- Change the oil and oil filter to keep the engine lubricated and functioning well.

- In spring, inspect all belts and cables for any signs of fraying or damage, replacing them if necessary.

- After heavy usage periods, give the equipment a thorough inspection to address any issues that may arise.

Implementing these practices will help maintain your equipment in peak condition, ultimately prolonging its life and enhancing its performance. Regular attention to these details ensures reliability when you need it most.

Tools Needed for Repairs

When it comes to maintaining and fixing equipment, having the right instruments at your disposal is essential. This not only facilitates the repair process but also ensures that tasks are completed efficiently and effectively. From basic hand tools to specialized gear, each piece plays a crucial role in achieving optimal performance.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are vital for various adjustments and repairs. These instruments provide the leverage and precision needed to tackle different components and fasteners, making them indispensable for any maintenance task.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be required for specific tasks. This can include diagnostic tools, torque wrenches, and safety gear, which enhance both the quality of repairs and the safety of the technician. Investing in the right tools can significantly streamline the repair process.

Upgrades for Improved Performance

Enhancing machinery performance can significantly boost efficiency and longevity. By focusing on strategic modifications, users can unlock the ultimate potential of their equipment, ensuring optimal operation in various conditions.

Key Upgrades to Consider

- High-Performance Engine Components

- Enhanced Fuel Systems

- Advanced Suspension Systems

Benefits of Upgrades

- Increased Efficiency

- Improved Reliability

- Enhanced User Experience

Frequently Asked Questions about Parts

This section aims to address common inquiries related to components and their functionalities. Understanding these elements can enhance maintenance and performance.

- What are the key components of this machine?

Essential elements include the engine, transmission, and control systems.

- How can I identify a faulty part?

Look for unusual sounds, decreased efficiency, or visible wear and tear.

- Where can I find replacement components?

Authorized dealers, online retailers, and specialized stores are reliable sources.

- Is there a warranty on new components?

Most manufacturers offer warranties, but terms can vary widely.

- Can I install parts myself?

While some may be user-friendly, others may require professional assistance.