In the intricate world of mechanical systems, having a clear visual representation of various elements is essential for both assembly and maintenance. This section delves into the significance of visual aids that elucidate the relationships and functionalities of individual components within a specific assembly. By breaking down complex structures into manageable parts, users can enhance their comprehension and efficiency when working with these systems.

Effective organization of the elements within a mechanical setup is crucial for troubleshooting and repair. When each part is clearly outlined, technicians and users alike can swiftly identify potential issues and make informed decisions about replacements or adjustments. This clarity not only streamlines workflows but also contributes to a greater understanding of the overall operation.

Moreover, utilizing a comprehensive reference for understanding these components promotes learning and skill development. As individuals become familiar with the different roles each element plays, they can cultivate a deeper appreciation for the engineering principles at work. Ultimately, this knowledge fosters innovation and improvement in design and functionality.

Understanding Ybsxs.1481hh Parts Diagram

In the realm of mechanical systems, the intricacies of components and their interrelationships are crucial for efficient operation. This section delves into the visual representation of elements that constitute a particular assembly, shedding light on their functions and connections. Grasping these representations enhances comprehension of the overall mechanism, facilitating better maintenance and troubleshooting.

Importance of Component Representation

Recognizing the significance of each individual piece within a system aids in understanding how they collectively contribute to functionality. This representation serves as a roadmap, guiding users through the complexities of assembly and ensuring all elements are accounted for. Additionally, it can assist in identifying potential issues and streamlining repairs.

How to Navigate the Visual Guide

Interpreting the visual guide requires an understanding of the symbols and notations employed. Familiarizing oneself with these can greatly enhance the ability to follow the layout and comprehend the relationships between the various elements. Attention to detail is paramount, as even minor discrepancies can lead to significant operational challenges. Embracing this knowledge empowers users to optimize performance and extend the longevity of their mechanical systems.

Overview of Ybsxs.1481hh Components

This section provides a detailed examination of the various elements that constitute the assembly in question. Understanding these components is crucial for anyone looking to grasp the functionality and operational mechanics involved.

Each individual piece plays a vital role, contributing to the overall performance and efficiency of the system. The intricate design ensures that all components work harmoniously, facilitating seamless interaction. Key elements include the framework, which serves as the backbone, and various modules that enhance specific functionalities.

Furthermore, maintenance and troubleshooting can be greatly improved by familiarizing oneself with these parts. Identifying the location and purpose of each element allows for quicker diagnostics and efficient repairs, ensuring the system operates at peak performance. An in-depth understanding of the structure ultimately leads to better management and optimization of the entire assembly.

How to Read the Parts Diagram

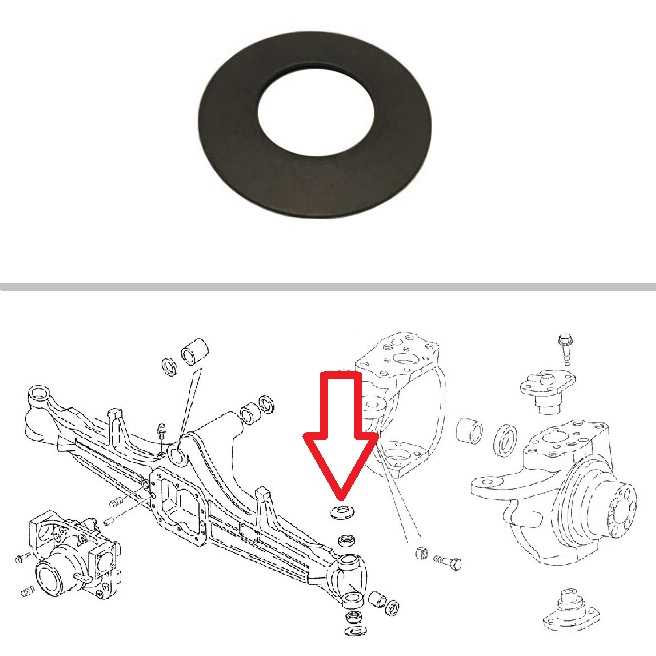

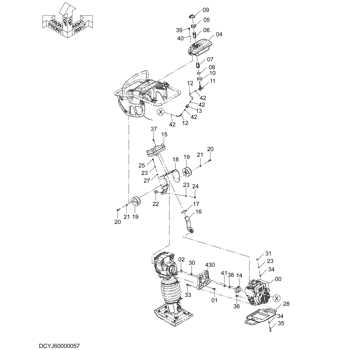

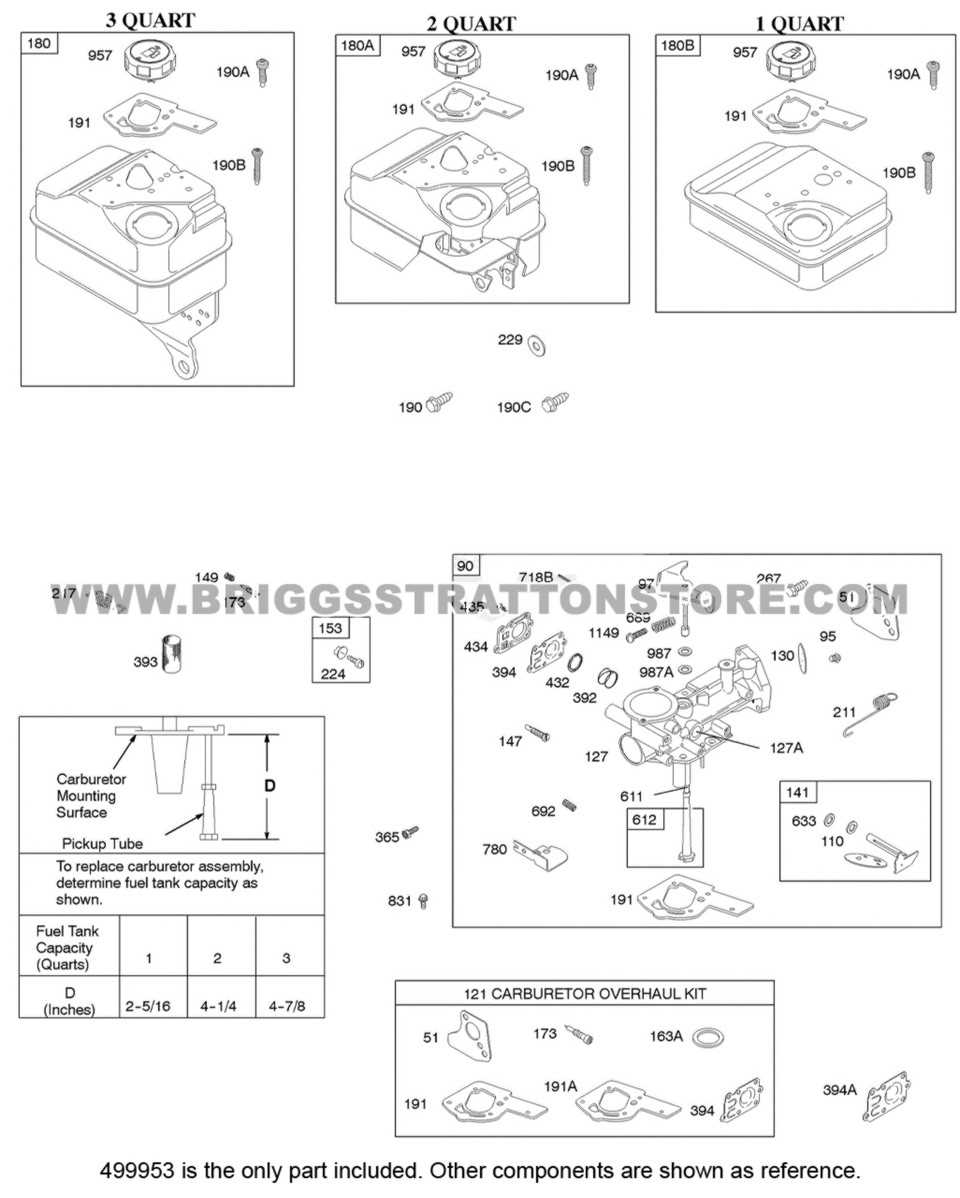

Understanding the layout of components in a mechanical assembly is essential for effective maintenance and repairs. This section provides insights into how to interpret the visual representation of different elements and their relationships within the system. Familiarity with this information can enhance your troubleshooting capabilities and ensure more efficient replacements when necessary.

Key Elements to Consider

- Labels: Each section is typically marked with specific identifiers that correspond to a part list.

- Connections: Observe how components are linked, as this can indicate the flow of function and potential areas for inspection.

- Scales: Pay attention to the scale used in the representation, as it helps determine the size of each element relative to others.

Steps to Interpret the Visual Representation

- Start by examining the overall layout to get a sense of the assembly structure.

- Identify the labeled sections that correspond to specific elements.

- Note the connections to understand how each component interacts with others.

- Refer to the accompanying list for detailed specifications or numbers associated with each element.

- Cross-reference any unfamiliar terms or symbols to clarify their meanings.

By following these guidelines, you can effectively navigate through complex layouts, making it easier to manage and repair your machinery.

Common Issues with Ybsxs.1481hh Parts

In any mechanical system, certain components are prone to wear and tear, leading to performance challenges. Understanding the frequent difficulties encountered with these elements can significantly enhance maintenance efforts and prolong the lifespan of the entire assembly.

One prevalent concern involves misalignment, which can cause excessive friction and ultimately result in premature failure. This misalignment may stem from improper installation or degradation over time, necessitating regular inspections to ensure optimal positioning.

Another common issue is the accumulation of debris and contaminants. Such buildup can obstruct functionality and hinder efficiency, emphasizing the importance of routine cleaning and servicing. Ensuring that all access points are clear can prevent potential malfunctions.

Additionally, wear from consistent usage often leads to reduced effectiveness. Monitoring these components for signs of fatigue or damage is crucial, as timely replacements can avert larger, more costly repairs down the line.

Lastly, improper lubrication can exacerbate friction-related issues. Ensuring adequate application of the correct lubricant is vital to maintaining smooth operation. Regularly checking lubrication levels can mitigate the risk of overheating and subsequent breakdown.

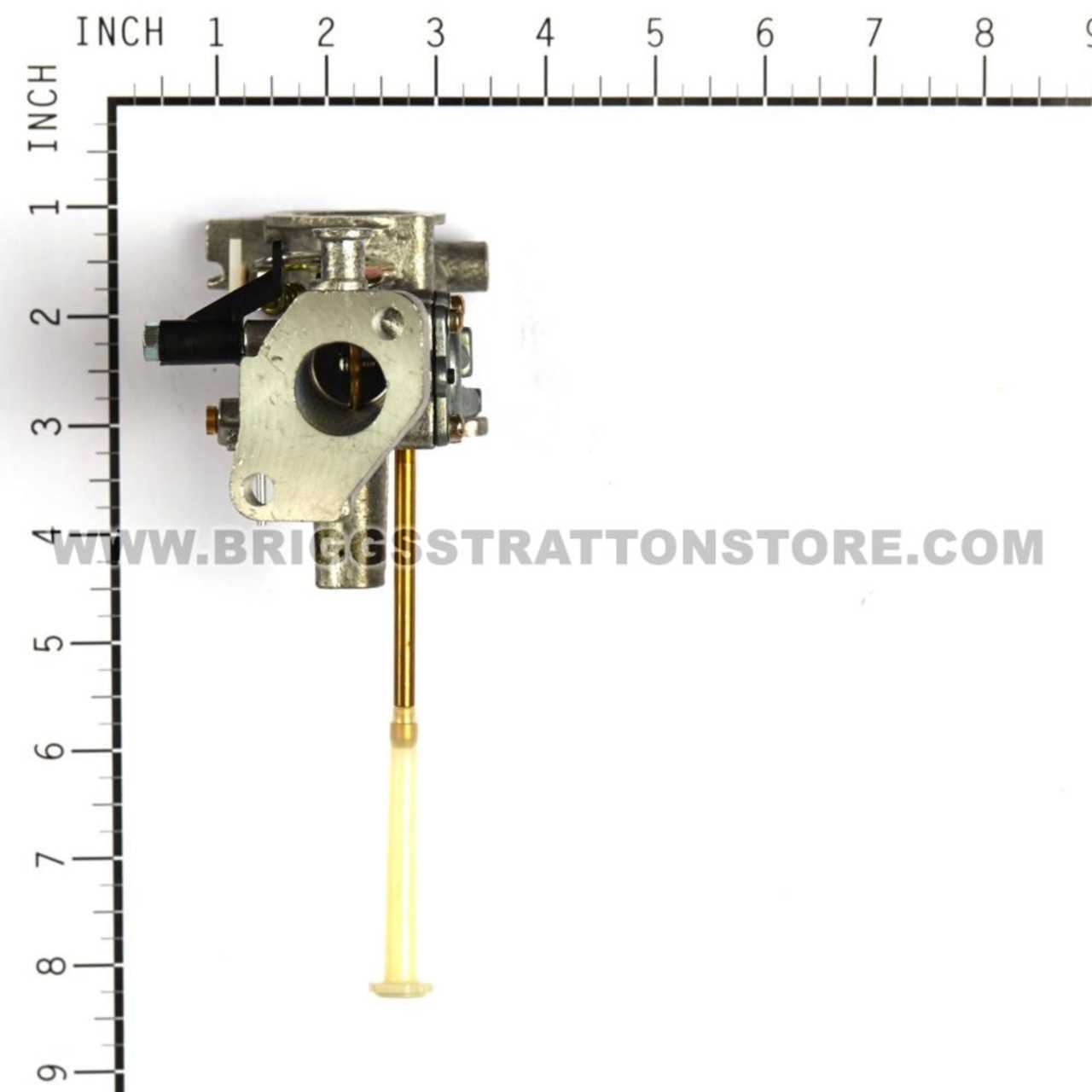

Replacement Parts for Ybsxs.1481hh

When maintaining or repairing your equipment, finding the right components is crucial for optimal performance. Whether you’re looking to replace worn-out items or upgrade specific elements, understanding the available options is essential.

Here are some common categories to consider when sourcing new elements:

- Electrical Components: These are vital for ensuring proper functionality. Look for quality alternatives to enhance efficiency.

- Mechanical Elements: Components that bear loads and enable movement should be durable and reliable. Consider high-grade materials for longevity.

- Fasteners and Connectors: Essential for securing various sections together, these should match the specifications for a perfect fit.

- Filters and Seals: Ensure that these items are compatible to maintain performance and prevent leaks.

When selecting replacements, it’s important to consult specifications and compatibility guides. This will help ensure you make informed decisions and maintain the integrity of your machine.

Additionally, consider sourcing from reputable suppliers to guarantee quality and reliability in your choices. Always check for warranties and return policies to safeguard your investment.

In summary, by understanding the different types of components available and focusing on quality and compatibility, you can effectively manage repairs and enhancements to your equipment.

Maintenance Tips for Ybsxs.1481hh

Ensuring the longevity and optimal performance of your equipment requires regular upkeep and careful attention to detail. By following a few straightforward guidelines, you can effectively maintain its functionality and minimize the risk of unexpected issues.

Routine Checks

- Inspect all components regularly for signs of wear or damage.

- Keep all connections secure and free from corrosion.

- Clean surfaces to prevent buildup of dust and debris.

Proper Usage

- Follow the manufacturer’s instructions for operation.

- Avoid overloading to prevent strain on the system.

- Monitor performance and address any anomalies promptly.

Implementing these practices will enhance reliability and extend the lifespan of your machinery, ensuring it operates smoothly for years to come.

Installation Guide for New Parts

This section provides a comprehensive guide for integrating new components into your system. Proper installation is crucial for optimal performance and longevity. By following the outlined steps, you can ensure a smooth integration process that enhances functionality.

Begin by gathering all necessary tools and equipment. Familiarize yourself with the specific requirements of the components you are working with, including compatibility and installation procedures. Refer to the provided resources to understand the unique features of each element.

Next, prepare the workspace to ensure a clean and organized environment. This minimizes the risk of damage and helps you keep track of all items involved in the process. Make sure to disconnect any power sources to avoid electrical hazards during the installation.

Follow the step-by-step instructions carefully, paying close attention to any specific recommendations or precautions. Proper alignment and securing of each piece are essential to avoid issues later. Utilize any included manuals or reference materials for additional guidance.

After the installation is complete, conduct a thorough inspection to ensure everything is correctly in place. Reconnect the power source and perform a test run to verify that all components are functioning as intended. If any issues arise, revisit the installation steps to identify and rectify any errors.

By adhering to these guidelines, you can successfully integrate new elements into your setup, leading to improved efficiency and performance.

Identifying Original vs. Aftermarket Parts

When it comes to maintaining or upgrading equipment, distinguishing between authentic components and alternative options is crucial. This decision affects not only performance but also longevity and safety. Understanding the differences can help consumers make informed choices and ensure optimal functionality.

Authentic components are typically manufactured by the original creator of the equipment, ensuring compatibility and adherence to quality standards. Conversely, alternative options are produced by third-party companies, which may vary in quality and reliability.

Several factors can aid in distinguishing between these two types of components:

| Criteria | Original | Aftermarket |

|---|---|---|

| Quality Assurance | Meets strict industry standards | Varies widely; may not meet specific requirements |

| Warranty | Often includes a manufacturer warranty | Warranty varies; may be limited or nonexistent |

| Cost | Generally more expensive | Usually less expensive, but quality can vary |

| Availability | Readily available through authorized dealers | Available from various suppliers and retailers |

| Performance | Designed for optimal performance and reliability | Performance may not match original specifications |

By carefully evaluating these aspects, consumers can make better decisions that align with their needs, ensuring that their equipment operates effectively and safely.

Tools Needed for Ybsxs.1481hh Repairs

When undertaking repairs for mechanical devices, having the right set of instruments is essential for achieving optimal results. A well-equipped toolkit not only streamlines the repair process but also enhances precision and efficiency. Below is a comprehensive list of essential tools required for effective maintenance and troubleshooting.

| Tool | Description |

|---|---|

| Wrench Set | Various sizes to secure or loosen bolts and nuts. |

| Screwdriver Set | Flathead and Phillips screwdrivers for removing and installing screws. |

| Pliers | Used for gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Multimeter | Measures voltage, current, and resistance for electrical troubleshooting. |

| Socket Set | Provides a variety of sizes for better access to fasteners. |

| Safety Goggles | Protective eyewear to safeguard against debris and chemicals. |

Frequently Asked Questions on Ybsxs.1481hh

This section addresses common inquiries related to the subject matter, aiming to provide clarity and assistance to users seeking detailed information. Below, you will find a compilation of prevalent questions along with their comprehensive answers, helping to enhance your understanding and experience.

What should I do if I encounter issues with the components?

If you face difficulties with any elements, it is advisable to consult the user manual for troubleshooting steps. Additionally, seeking guidance from customer support can offer personalized assistance tailored to your specific situation.

Where can I find replacement items for my setup?

Replacement items can typically be found through authorized retailers or official online platforms. Ensure you verify compatibility before making any purchases to avoid future complications.

Resources for Ybsxs.1481hh Owners

For individuals who own this specific model, having access to reliable information and tools is essential for maintaining and enhancing their experience. A comprehensive collection of guides, manuals, and support networks can significantly aid in understanding the intricacies of their equipment. Here, we present a selection of valuable resources tailored for owners seeking to maximize their utility and performance.

Official Support Channels

Reaching out to authorized service centers or the manufacturer’s customer support can provide tailored assistance and expert advice. These channels often have detailed documentation and troubleshooting guides available to owners. Engaging with official representatives ensures that any inquiries or concerns are addressed effectively and with the most current information.

Community Forums and Online Groups

Joining online forums and social media groups dedicated to enthusiasts of similar models can foster a sense of community and provide practical insights. These platforms allow owners to exchange experiences, share tips, and offer solutions to common challenges. Participating in discussions can lead to valuable connections and a deeper understanding of one’s equipment.