Understanding the structure and functionality of complex equipment can significantly improve both its maintenance and operation. This section focuses on the detailed examination of various internal mechanisms, emphasizing how individual elements work together to ensure optimal performance. By familiarizing yourself with the key components, you can ensure smooth functionality and tackle any issues that may arise during use.

In the following paragraphs, you will find an in-depth exploration of the essential elements that make up the system. We will walk through the major sections, highlighting their roles and explaining how they integrate to provide efficient operation. With a clear breakdown, servicing and troubleshooting will become a more straightforward process, making it easier to identify and address any challenges.

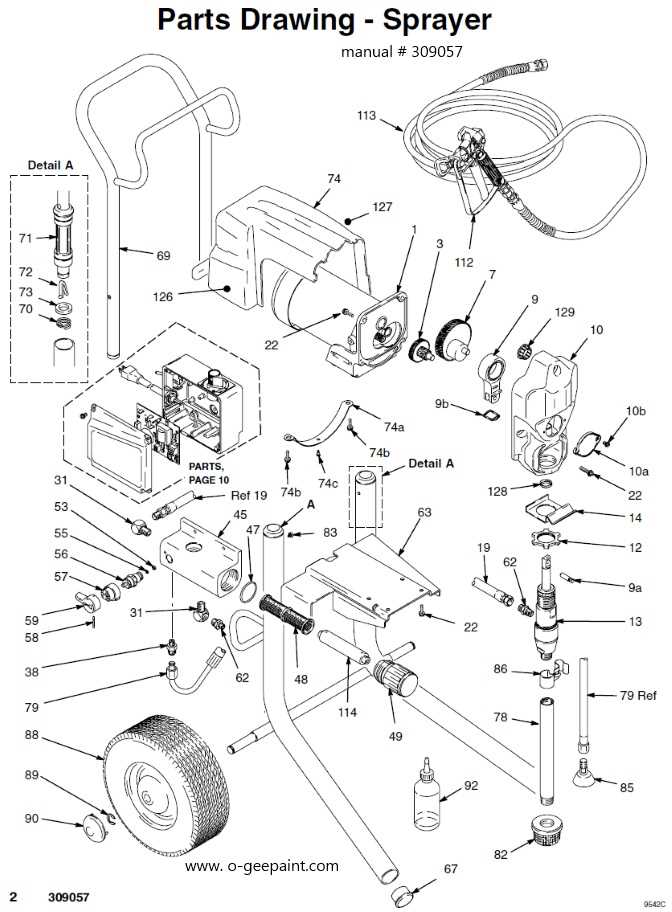

Overview of Graco 495 ST Pro Components

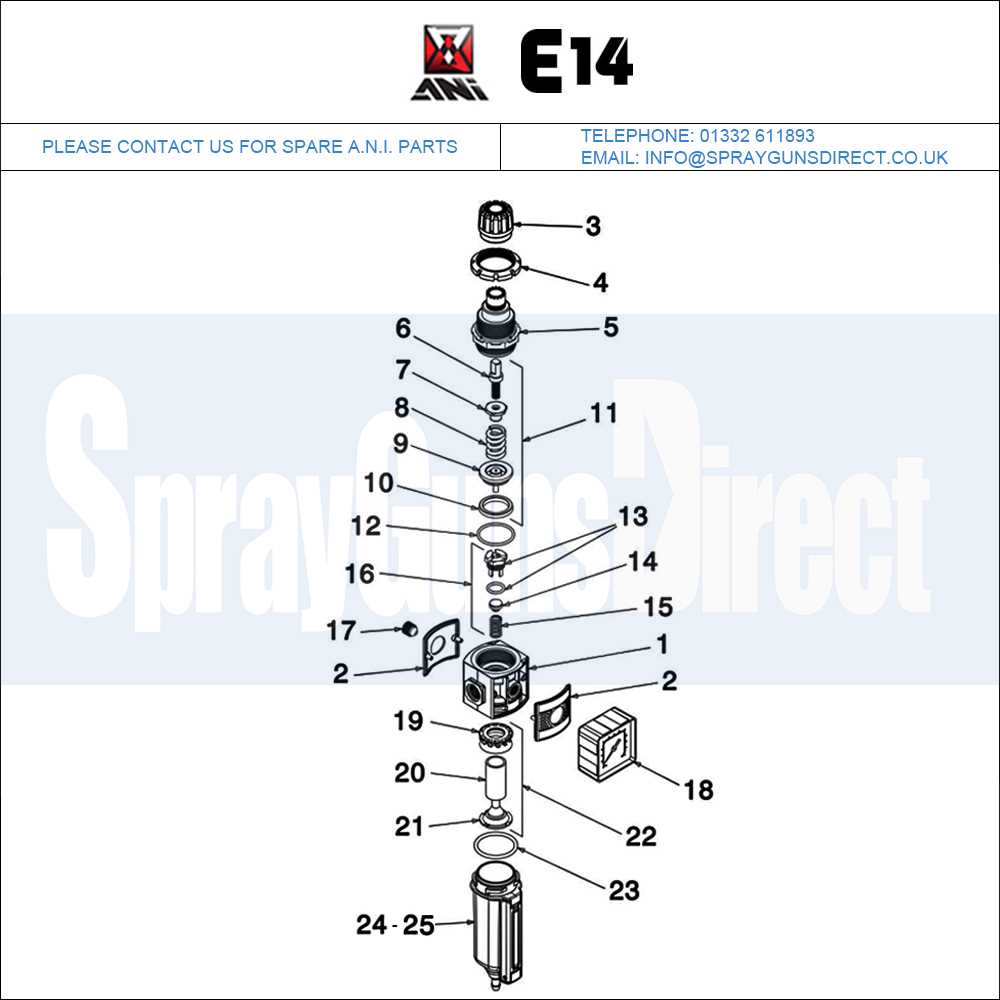

This section provides a detailed explanation of the main elements that make up this particular model of equipment. Each component plays a crucial role in ensuring smooth operation and reliability, offering users the ability to perform various tasks with efficiency. Understanding the arrangement of these elements helps in optimizing the performance and maintaining the longevity of the unit.

Key Structural Elements

The framework of this unit is built to offer stability and durability. The housing is designed to protect internal mechanisms while offering easy access for maintenance. Additionally, the design ensures efficient cooling, minimizing the risk of overheating during extended use.

Fluid and Control Systems

At the heart of this model is a sophisticated fluid management system that ensures consistent operation. The control unit allows for precise adjustments, providing users with the flexibility to tailor performance according to their specific needs. The integration of high-quality materials ensures that these systems function without interruption.

| Component | Function | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Frame | Supports and protects internal parts, providing stability | ||||||||||||||||||||

| Pump |

| Connection Type | Fitting Type | Usage | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Threaded Connection | Male/Female Couplings | Used for a tight and permanent fit in most systems | ||||||||||||

| Quick-Disconnect | Snap Fittings |

Motor and Power System Components

The motor and power system serve as the central force behind the machine’s operation, providing the necessary energy to drive the various processes. These components are essential for ensuring smooth and efficient functionality, allowing for precise and reliable performance over extended periods of use. Key Elements of the MotorThe motor operates as the primary source of mechanical power, converting electrical energy into motion. It plays a crucial role in maintaining consistent operation, ensuring that the system functions at optimal levels. With proper care and maintenance, this component remains highly effective and durable, delivering the required force to support all related tasks. Power Transmission and Regulation

The power system ensures the efficient transfer of energy from the source to the working mechanisms. This involves not only generating the needed power but also regulating its flow to prevent overloads or interruptions. The smooth coordination between the motor and power regulation systems guarantees the machine operates without strain, protecting both the equipment and the operator. Pressure Control and Adjustment ComponentsThis section discusses essential elements involved in regulating and fine-tuning pressure settings within various spraying systems. These components play a crucial role in achieving optimal performance and ensuring the correct application of materials.

Maintaining these elements in good condition is vital for efficient and effective operation. Regular inspection and timely replacements contribute to the longevity of the equipment and enhance the quality of the application process. Spray Gun Assembly and AccessoriesThe assembly of a spray application tool is crucial for achieving optimal performance and efficiency. This section will delve into the various components and supplementary items that enhance the functionality of the spray gun. Understanding these elements will aid in effective maintenance and operational excellence. Components OverviewThe spray application tool consists of several key components, including the handle, nozzle, and trigger mechanism. Each part plays a vital role in ensuring a smooth and controlled spray pattern. Regular inspection and replacement of worn-out elements can significantly improve performance and prolong the life of the equipment. Essential AccessoriesIn addition to the core assembly, various accessories can enhance the user experience. Items such as paint filters, fluid tips, and cleaning kits are essential for maintaining the quality of the application and ensuring seamless operation. Utilizing these accessories can lead to improved results and easier upkeep. Seals, Gaskets, and O-Ring Placement

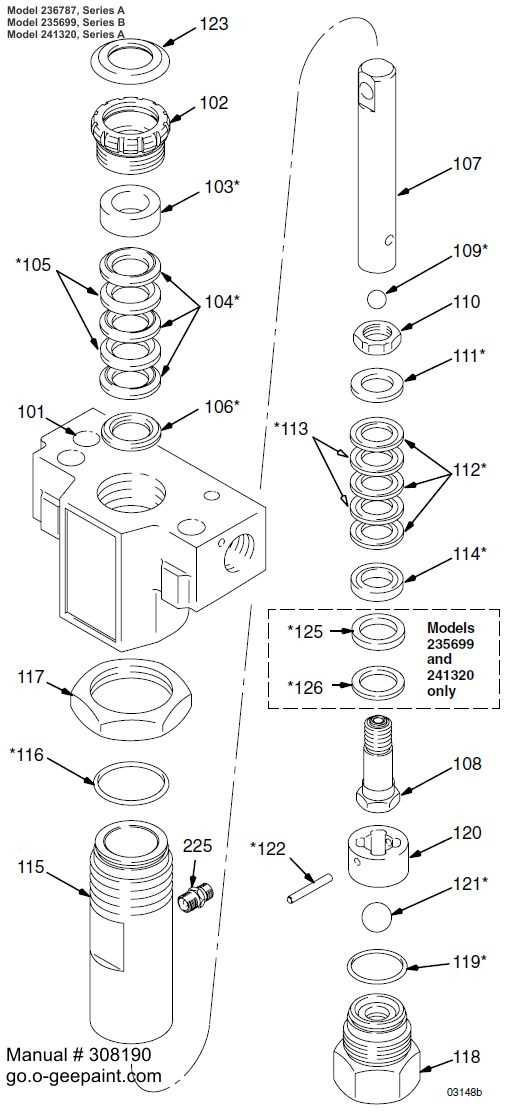

The effective operation of any machinery often hinges on the precise arrangement of seals, gaskets, and O-rings. These components play a crucial role in preventing leaks and ensuring a tight fit between various parts, contributing to overall efficiency and durability. Understanding their placement is essential for maintaining optimal performance. Seals are designed to create a barrier against fluids and gases, while gaskets serve as a cushion between surfaces to absorb vibrations and prevent wear. Proper installation of these elements is vital to avoid operational failures. O-rings, on the other hand, provide a simple yet effective sealing solution, commonly utilized in various joints and fittings. Maintenance and Replacement Parts GuideThis section provides essential information on upkeep and the necessary components for your equipment’s optimal performance. Regular maintenance and timely replacements are crucial to ensuring longevity and efficiency. Following these guidelines will help in sustaining the functionality and reliability of your device. Routine Maintenance Practices

Essential Components for ReplacementOver time, certain elements may need to be replaced to maintain high performance. Here are key components to consider:

By adhering to these maintenance recommendations and promptly replacing necessary components, you can enhance the reliability and performance of your equipment, ensuring it operates at its best for years to come. Troubleshooting Common Component Issues

Addressing problems with machinery components is crucial for maintaining optimal performance. Many issues can arise from wear and tear, improper use, or inadequate maintenance. This section outlines common difficulties encountered with various parts and offers solutions to effectively resolve them. Identifying Performance Problems

It is essential to recognize signs of malfunction to implement timely corrective measures. Common symptoms may include unusual noises, erratic operation, or reduced efficiency. These indicators often suggest underlying component issues that need attention. Resolution Steps

Once a problem has been identified, follow these systematic steps to address the issue:

Upgrades and Compatible Accessories

Enhancing your equipment can significantly improve its performance and versatility. This section explores various enhancements and accessories that can be seamlessly integrated with your existing setup, ensuring that you maximize efficiency and effectiveness. Essential EnhancementsConsider upgrading key components to boost productivity and streamline operations. High-performance nozzles and specialized hoses are excellent choices, allowing for improved flow rates and precision during use. Additionally, incorporating advanced filtration systems can prevent clogs and maintain optimal functionality. Versatile Accessories

To complement your setup, various accessories can be utilized. Extension poles facilitate reaching elevated areas with ease, while multi-functional sprayers enable a range of applications from fine misting to robust sprays. Emphasizing compatibility is crucial, as selecting accessories designed for your specific model ensures flawless integration and top-notch performance. |