In the realm of agricultural machinery, a comprehensive understanding of various components is crucial for optimal functionality and efficiency. Each machine is composed of numerous elements that work together harmoniously, ensuring that operations run smoothly. Recognizing these elements allows operators to maintain their equipment effectively, minimizing downtime and enhancing productivity.

The intricacies of machinery are often represented through detailed visuals that depict the interconnections and functions of each component. Such representations serve as valuable resources for both novice and experienced users, guiding them through maintenance and repair processes. A clear depiction helps demystify complex structures, making it easier to identify potential issues and implement solutions.

By exploring these representations, individuals can gain insight into the mechanisms that power agricultural tasks. This knowledge fosters a deeper appreciation for the engineering behind the machinery, ultimately leading to more informed decision-making regarding maintenance, upgrades, and repairs. Understanding the layout of components not only aids in troubleshooting but also contributes to a more efficient workflow in the field.

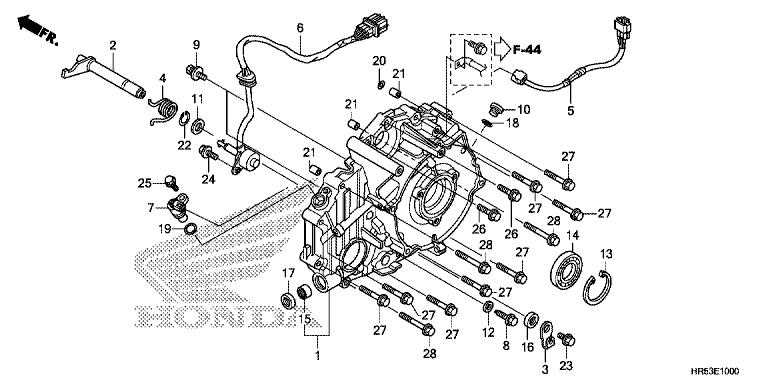

Understanding a component illustration is crucial for effective maintenance and repair. This visual representation simplifies the identification of individual elements and their relationships, making it easier to navigate complex machinery. By mastering this skill, users can enhance their troubleshooting capabilities and streamline their repair processes.

To effectively interpret a component illustration, follow these steps:

- Familiarize Yourself with the Layout: Examine the overall structure to understand how different elements are organized.

- Identify Key Symbols: Learn common symbols used in illustrations, such as lines indicating connections or arrows representing movement.

- Refer to the Legend: Utilize the legend or key provided, which explains the symbols and designations for clarity.

- Trace Connections: Follow lines or arrows to see how components interact and are connected, ensuring you understand the flow and functionality.

- Consult Documentation: If needed, refer to additional manuals or resources for detailed explanations on specific parts and their roles.

By applying these techniques, anyone can gain confidence in analyzing component illustrations, leading to more effective repairs and maintenance.

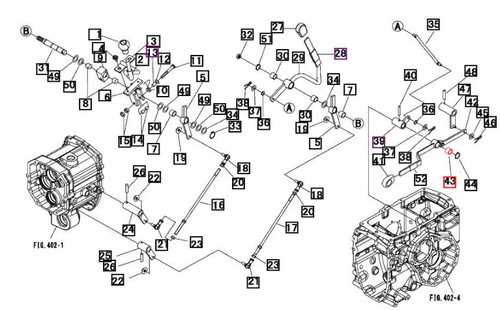

Identifying Hydraulic System Components

The hydraulic system in machinery plays a crucial role in facilitating powerful movements and operations. Understanding the various elements within this system is essential for effective maintenance and troubleshooting. Recognizing the specific components allows for better insight into how the entire mechanism functions.

Key components of the hydraulic system include:

- Pump: Converts mechanical energy into hydraulic energy, providing fluid under pressure.

- Reservoir: Stores hydraulic fluid, ensuring a steady supply for the system.

- Actuators: Devices such as cylinders or motors that convert hydraulic energy back into mechanical energy to perform work.

- Valves: Control the flow and direction of hydraulic fluid, managing the operation of the system.

- Hoses and Pipes: Facilitate the transport of hydraulic fluid between components, ensuring connectivity within the system.

Each of these elements is integral to the overall functionality of the hydraulic system. Proper identification and understanding of their roles contribute to efficient performance and longevity of the equipment.

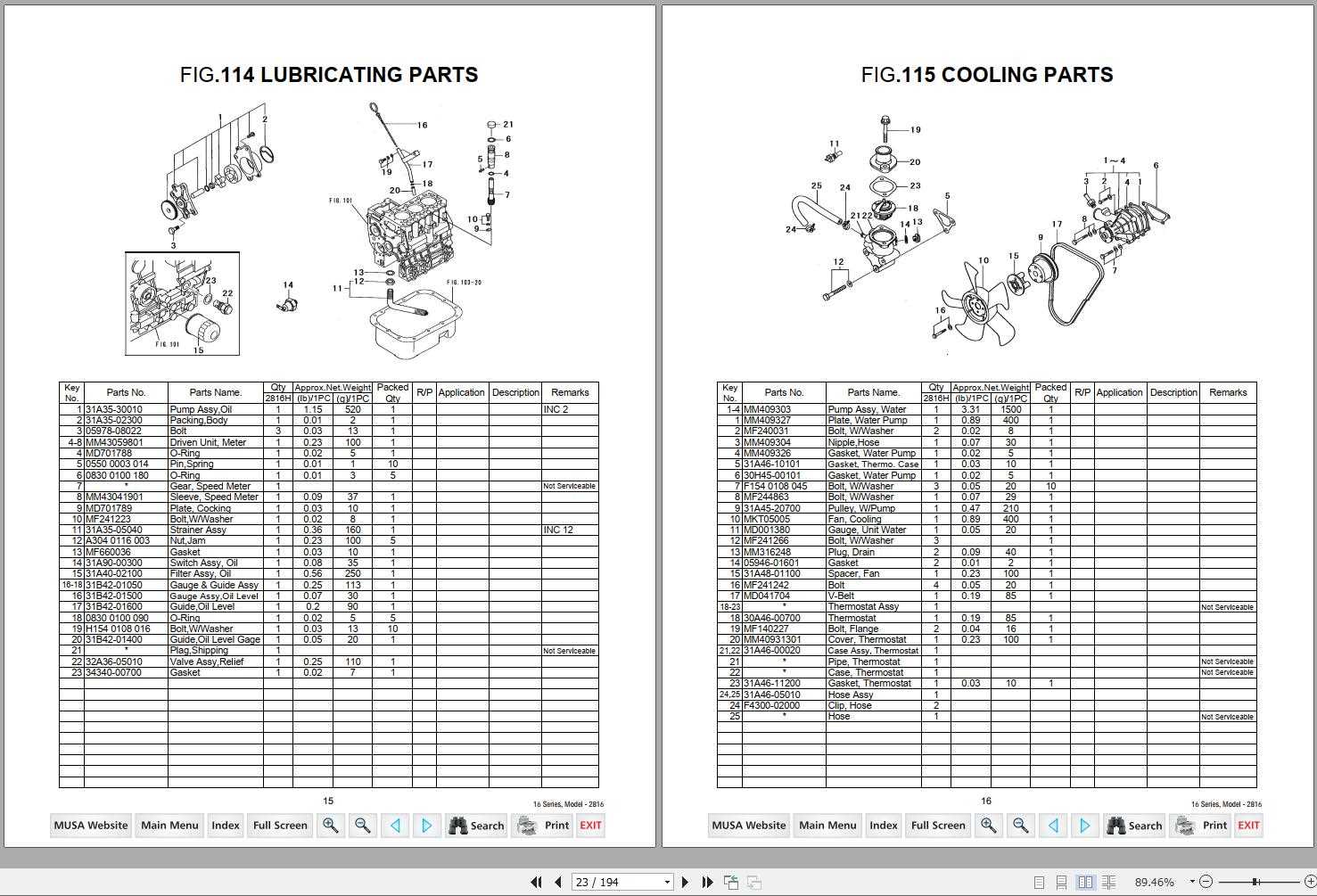

Engine Parts and Their Functions

Understanding the components of a power unit is essential for optimal performance and maintenance. Each element plays a crucial role in ensuring the smooth operation of the machinery. This section outlines various components and their specific functions within the engine system.

Cylinder Block

The cylinder block is the foundation of the engine, housing several critical components. It supports the cylinders and provides the necessary structure for other parts to be attached. Additionally, it contains passages for coolant and oil, helping to regulate temperature and reduce friction.

Camshaft

The camshaft is responsible for controlling the timing of the intake and exhaust valves. By converting rotational motion into linear motion, it ensures that the valves open and close at the correct intervals. This synchronization is vital for maintaining engine efficiency and performance.

Understanding these components is crucial for anyone involved in maintenance and repairs. By familiarizing oneself with the engine’s structure, one can better address potential issues and enhance the longevity of the machinery.

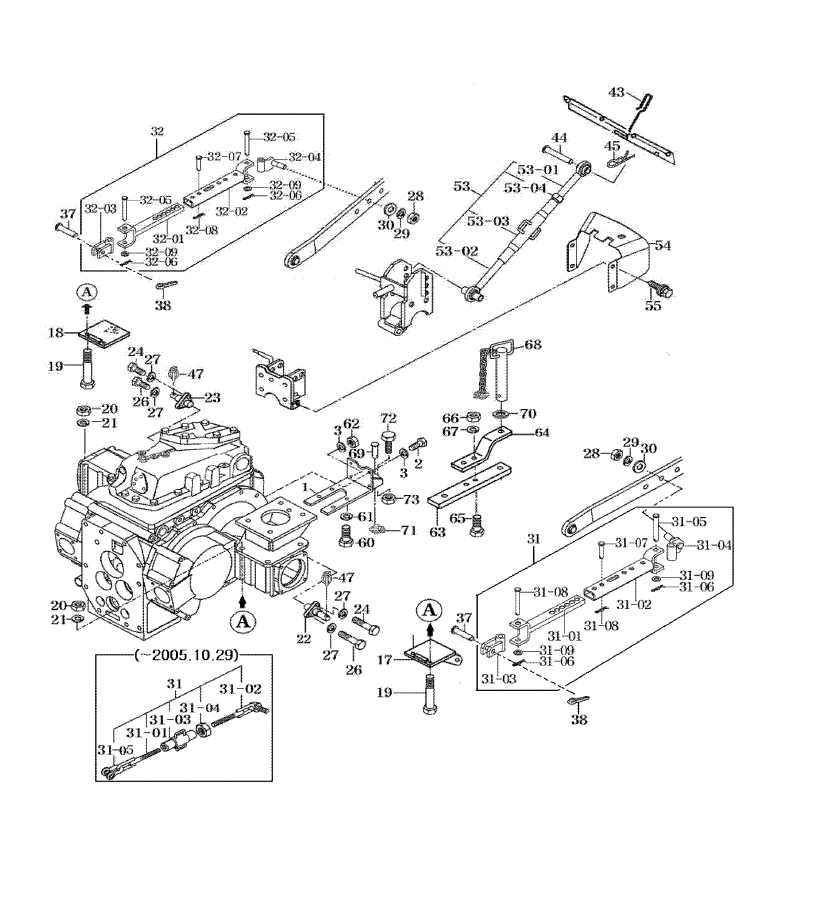

Transmission System Overview

The transmission system is a crucial component in any vehicle, responsible for transferring power from the engine to the wheels. This complex mechanism ensures that the machine operates efficiently, allowing for smooth movement and optimal performance under various conditions. Understanding its function and structure is essential for effective maintenance and troubleshooting.

Typically, the transmission system consists of several key elements that work in harmony. These components can vary in design and function but generally include:

| Component | Description |

|---|---|

| Gearbox | A series of gears that modify the torque and speed delivered to the wheels. |

| Clutch | A device that engages and disengages the engine from the transmission system, allowing for smooth gear shifts. |

| Drive Shaft | A rotating shaft that transmits power from the gearbox to the differential. |

| Differential | A mechanism that allows the wheels to rotate at different speeds, particularly during turns. |

Regular inspection and maintenance of the transmission system are vital to ensure longevity and reliability. This includes checking fluid levels, inspecting for leaks, and ensuring all components are functioning correctly.

Electrical System Components Explained

The electrical system in heavy machinery plays a crucial role in ensuring optimal performance and functionality. Understanding its components is essential for effective maintenance and troubleshooting. This section delves into the primary elements that make up the electrical network, highlighting their functions and significance.

- Battery: The energy source that powers the entire system, providing the necessary voltage for starting and operation.

- Alternator: This component generates electricity while the engine runs, recharging the battery and supplying power to various electrical systems.

- Starter Motor: Responsible for initiating the engine’s operation by converting electrical energy into mechanical energy.

- Wiring Harness: A network of wires that connects all electrical components, facilitating the flow of electricity throughout the system.

- Fuse Box: Houses fuses that protect the electrical system from overloads by breaking the circuit when necessary.

- Relays: Electromechanical switches that control high-power circuits with low-power signals, enhancing efficiency and safety.

- Switches: Devices used to open or close electrical circuits, allowing the operator to control various functions easily.

Each of these components plays a vital role in the seamless operation of the machinery, ensuring that all electrical functions work harmoniously together. Regular inspection and maintenance of these parts can prevent unexpected failures and enhance overall efficiency.

Maintenance Parts for Longevity

Ensuring the durability and efficiency of machinery requires attention to essential components that play a critical role in its operation. Regularly replacing or servicing these elements not only extends the lifespan of the equipment but also enhances performance, reducing the likelihood of unexpected failures.

One crucial aspect of upkeep involves checking and changing fluids, which safeguard internal mechanisms from wear and overheating. Moreover, inspecting and replacing filters is vital to maintain optimal performance and prevent contaminants from causing damage. Regular assessment of belts and hoses is also important, as these parts can deteriorate over time, potentially leading to operational disruptions.

Additionally, keeping an eye on electrical systems ensures reliable performance, as worn-out wiring or connections can lead to malfunctions. Investing time and resources in the upkeep of these fundamental components ultimately contributes to sustained efficiency and reliability, making it easier to tackle demanding tasks with confidence.

Aftermarket vs. OEM Parts

When it comes to equipment maintenance, the choice between aftermarket components and original equipment manufacturer (OEM) options is crucial. Each category offers distinct benefits and considerations that can influence the performance and longevity of machinery.

Aftermarket components are produced by third-party manufacturers and often come at a lower price point. These alternatives can provide comparable quality and performance but may vary significantly in reliability. On the other hand, OEM components are made by the original manufacturer and typically ensure a precise fit and optimal functionality, as they are designed specifically for the equipment in question.

Choosing between these options often depends on budget, availability, and the specific needs of the machinery. While aftermarket components can be appealing due to their cost-effectiveness, investing in OEM components may provide peace of mind and assurance of quality.

Tools Needed for Parts Replacement

When it comes to replacing components in machinery, having the right tools is essential for a smooth and efficient process. The proper equipment not only ensures that the job is done correctly but also helps prevent damage to both the new parts and the overall system. This section outlines the necessary tools that facilitate effective component exchange.

Essential Hand Tools

A variety of hand tools are indispensable for any replacement task. These typically include wrenches, screwdrivers, and pliers, which help in loosening and tightening fasteners securely. A reliable set of sockets can also enhance your ability to work on different sizes of bolts and nuts, making the process more efficient.

Power Tools and Equipment

In addition to hand tools, power tools can significantly expedite the replacement procedure. Electric or pneumatic wrenches can quickly remove stubborn fasteners, while drills assist in making necessary adjustments or modifications. Additionally, safety equipment, such as gloves and goggles, should not be overlooked to ensure a safe working environment.

Ordering Parts: A Step-by-Step Guide

Acquiring components for machinery can be a straightforward process if approached methodically. This guide outlines essential steps to ensure you receive the correct items efficiently, minimizing downtime and enhancing productivity.

-

Identify the Required Component

Before making a purchase, it’s crucial to pinpoint the specific component needed. Consult your equipment’s manual or identify the part number to avoid errors.

-

Research Suppliers

Explore various suppliers to find reliable sources. Look for vendors with positive reviews and a proven track record in supplying quality components.

-

Check Availability

Once you have identified potential suppliers, check the availability of the required component. Contact them directly or visit their websites for current stock information.

-

Compare Prices

Evaluate the prices offered by different suppliers. Don’t forget to consider shipping costs and delivery times as these can affect the total expense and timeframe.

-

Place Your Order

After selecting a supplier, proceed to place your order. Ensure that you provide accurate information regarding the item, including its specifications and part number.

-

Confirm Order Details

Once the order is placed, review the confirmation details. Verify that everything is correct, including the shipping address and payment information.

-

Track Your Order

After completing the purchase, monitor your order’s progress. Many suppliers provide tracking information, allowing you to stay updated on the delivery status.

Following these steps can streamline the process of obtaining essential components, ensuring that your equipment remains operational and efficient.

Troubleshooting Common Issues

Identifying and resolving frequent challenges in machinery operation can significantly enhance performance and longevity. This section aims to provide insights into typical problems users may encounter, along with practical solutions to address them effectively.

One common issue is difficulty in starting the engine, which may stem from various factors such as fuel supply problems or electrical faults. Checking the battery charge and ensuring proper fuel levels can often resolve this concern. Additionally, inspecting wiring connections for corrosion or damage is crucial.

Another prevalent problem involves unusual noises during operation. These sounds may indicate loose components or wear in mechanical parts. Regular maintenance checks and timely lubrication of moving elements can prevent such issues from escalating.

Furthermore, overheating is a critical issue that should not be overlooked. Ensuring the cooling system is functioning correctly and that there are no blockages in the air intake or radiator can help maintain optimal operating temperatures.

By following these troubleshooting guidelines, users can effectively manage and rectify common operational challenges, ensuring smoother functionality and extended service life.