When working with off-road vehicles, having a clear understanding of the internal components and their arrangement is essential for proper maintenance and repair. A detailed visual guide of how different elements fit together helps owners and mechanics identify and troubleshoot issues more efficiently. Such references are invaluable for those looking to extend the lifespan of their machines or restore them to optimal performance.

Diagrams that illustrate the mechanical structure and connection of various system parts provide a comprehensive view, making it easier to locate and address problems. These visual aids break down complex systems into manageable segments, allowing users to follow the assembly process step by step. Knowing where each piece belongs can prevent costly errors during reassembly.

Exploring these visual layouts not only saves time but also enhances the understanding of the vehicle’s operation. Whether you’re replacing a worn-out component or fine-tuning the machine, having an accurate representation of the internal workings is crucial for maintaining its efficiency and performance.

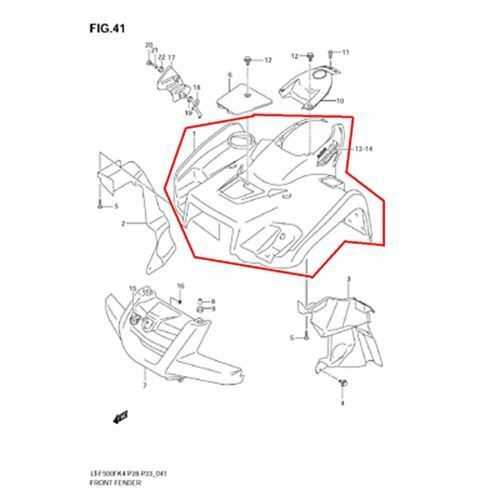

Overview of Suzuki Vinson 500 Components

The all-terrain vehicle consists of a variety of interconnected elements, each playing a critical role in ensuring efficient performance and durability. These components work in harmony to provide a balanced experience for the rider, combining strength, mobility, and reliability. A detailed understanding of these parts helps in proper maintenance, troubleshooting, and upgrades, which ultimately enhance the longevity and functionality of the vehicle.

Key System Areas

Each major system within the vehicle is designed for a specific function, contributing to the overall performance. These systems include the engine assembly, transmission system, suspension, braking components, and electrical components. Understanding each system’s individual components is crucial to maintaining optimal functionality and identifying potential issues before they become serious problems.

Commonly Replaced Components

Some elements of the vehicle experience more wear and tear than others due to frequent use. These include the tires, brake pads, air filter, and spark plugs. Regular inspection and timely replacement of these components help prevent operational disruptions and maintain the vehicle’s reliability in harsh conditions.

| Component | Function | Common Issues |

|---|---|---|

| Engine | Drives the vehicle and provides power | Overheating, oil leaks |

| Suspension | Ensures a smooth ride by absorbing shocks | Worn-out shocks, misalignment |

| Transmission | Transfers power from the engine to the wheels | Slipping gears, rough shifting |

| Brakes | Stops the vehicle when necessary | Worn-out brake pads, fluid leaks |

| Electrical System | Controls the ignition and lighting systems | Dead battery, faulty wiring |

Understanding the VIN Number on Suzuki ATVs

Each all-terrain vehicle (ATV) is assigned a unique identification number, which serves as its fingerprint in the world of motorsports and vehicle ownership. This alphanumeric code is essential for a range of purposes, from tracking the vehicle’s history to ensuring proper registration. Knowing how to read and interpret this number is crucial for owners, mechanics, and buyers alike.

The VIN provides valuable details about the vehicle’s manufacturing, specifications, and history. Each character or group of characters within the code conveys specific information. The following breakdown explains the significance of each section of the identification number:

- First Character(s): Indicates the country where the vehicle was manufactured.

- Second Character(s): Represents the manufacturer’s name or code, identifying the brand or company that produced the ATV.

- Third to Eighth Characters: Typically, these provide information about the vehicle’s model, engine type, and body style.

- Ninth Character: Serves as a check digit to verify the VIN’s authenticity and accuracy.

- Tenth Character: Denotes the model year of the ATV, helping to differentiate between different production years.

- Eleventh Character: This character indicates the manufacturing plant or location.

- Last Six Characters: Represent the serial number, which is unique to each vehicle and helps distinguish it from others.

Understanding the VIN number on your vehicle can simplify processes such as registration, insurance, and finding compatible parts. It also plays a critical role in verifying the authenticity and legality of the ATV, especially when buying or selling used models. Always ensure that the VIN on the vehicle matches official documents to avoid potential issues.

Essential Engine Parts in Suzuki Vinson

The performance and longevity of an all-terrain vehicle heavily depend on the key components within its power system. These elements are designed to ensure that the engine operates efficiently, providing the necessary power for various challenging tasks. Understanding the critical parts of the engine is essential for anyone looking to maintain or repair their vehicle.

Below is a list of the fundamental components that contribute to the smooth functioning of the engine:

- Cylinder Head – This is the top section of the engine, housing vital components such as valves and spark plugs. It plays a crucial role in the intake and exhaust processes.

- Crankshaft – A rotating part that converts the linear motion of the pistons into rotational energy, driving the vehicle’s wheels.

- Pistons – Located inside the engine’s cylinders, pistons move up and down, transferring force to the crankshaft.

- Timing Chain – This component ensures that the engine’s valves open and close at the correct time relative to the position of the pistons.

- Oil Pump – Responsible for circulating oil throughout the engine, lubricating moving parts and preventing overheating.

- Flywheel – A heavy, rotating part that helps maintain the engine’s rotational inertia and smoothens power delivery.

- Starter Motor – This motor is engaged to turn the engine over during startup, ensuring it begins operation.

- Carburetor – Regulates the air-fuel mixture before it enters the engine for combustion.

Each of these components is integral to the overall function of the engine, and their proper maintenance is key to keeping the vehicle running at its best. Regular checks and timely replacements will ensure optimal performance, avoiding costly repairs in the future.

Transmission System Explained for Vinson 500

The transmission system in an all-terrain vehicle (ATV) plays a crucial role in the transfer of power from the engine to the wheels, enabling efficient movement across diverse terrains. It is designed to ensure the rider can maintain control over speed and torque while adapting to various riding conditions. The complexity of this system lies in its ability to smoothly transition through different gears, providing both power and reliability under varying loads.

In this system, the key components work in harmony to transmit the engine’s output to the drivetrain. The assembly includes a clutch mechanism, a gearbox, and final drive elements. Each part is carefully engineered to function under the demanding conditions often faced by off-road vehicles, such as steep inclines, mud, and rough surfaces. Understanding how each component interacts is essential for maintaining optimal performance and longevity.

Clutch and Gearbox are at the heart of the transmission. The clutch allows for the smooth engagement and disengagement of the engine from the gearbox, enabling changes in gear ratio. This functionality ensures that power is delivered effectively depending on the vehicle’s speed and the driver’s intentions. The gearbox is responsible for altering the engine’s output to match the desired driving conditions, providing the necessary torque to the wheels when needed.

Final Drive consists of the components that directly connect the gearbox to the wheels, typically including the drive shaft or chain system. This part of the transmission system is essential for converting the rotational power generated by the engine into the movement of the vehicle. Maintaining these components is vital for preventing wear and ensuring smooth operation over time.

Overall, a well-maintained transmission system ensures that an ATV can operate efficiently in a wide range of environments, offering the rider both control and adaptability. Proper care and understanding of each element within the transmission contribute significantly to the overall performance and durability of the vehicle.

Front Suspension Setup and Maintenance

Proper setup and regular maintenance of the front suspension system are crucial for ensuring optimal handling, safety, and comfort when riding. The suspension plays a vital role in absorbing shocks from the terrain, providing stability, and maintaining tire contact with the ground. Whether you are riding on rough trails or smooth paths, keeping this system in top condition allows for better control and performance.

Adjusting the suspension correctly involves selecting the right spring rates, preload settings, and damping adjustments based on the rider’s weight, riding style, and the conditions of the terrain. Fine-tuning these factors ensures that the front end of the vehicle performs efficiently and smoothly during various maneuvers.

Regular inspection and maintenance are essential to prolong the life of the suspension components. Over time, seals, bushings, and shock absorbers may wear out or become damaged, leading to decreased performance. Ensuring that these parts are clean, lubricated, and replaced as necessary will help maintain smooth operation and prevent costly repairs in the future.

Taking the time to regularly check for wear and tear, adjusting suspension settings to suit specific needs, and replacing worn-out components will significantly enhance the riding experience and extend the longevity of the front suspension system.

Rear Suspension and Axle Components

The rear suspension and axle system of an ATV play a crucial role in providing stability, handling, and overall comfort. These components work together to absorb shocks, support the vehicle’s weight, and ensure smooth movement over rough terrain. The suspension system helps maintain tire contact with the ground, improving traction, while the axle system transmits power from the engine to the wheels, enabling efficient motion. Understanding the individual parts of this assembly is essential for proper maintenance and performance optimization.

The rear suspension typically includes shock absorbers, springs, and linkages that allow for controlled wheel movement. These elements are designed to reduce the impact of uneven surfaces and ensure a smooth ride. The shock absorbers dampen forces from bumps and dips, while the springs return the suspension to its resting position. Proper alignment and condition of these parts are essential for maintaining handling precision and preventing excessive wear.

The axle components are responsible for transmitting rotational force to the rear wheels. The axle shaft, along with its bearings and seals, supports the load and allows for smooth rotation while transferring power efficiently. Any damage to the axle can lead to performance issues, such as vibrations or uneven wheel movement. Regular inspection of the axle assembly ensures reliable performance and avoids potential breakdowns during use.

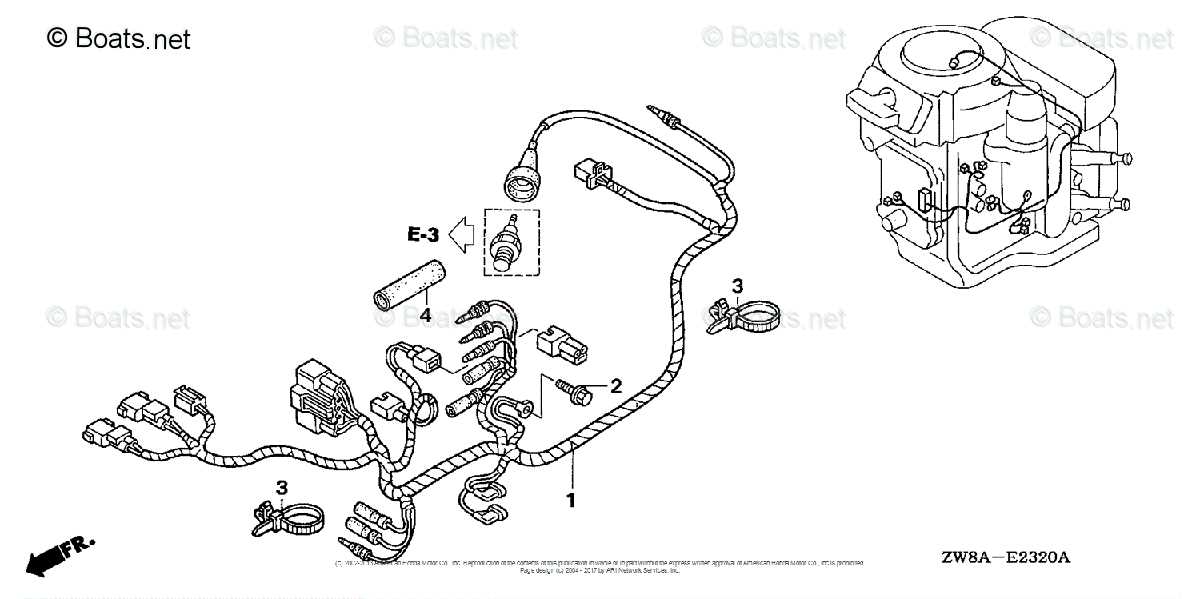

Electrical Wiring and Connection Diagrams

Proper understanding of electrical schematics is essential for troubleshooting, maintaining, and upgrading the electrical system of any off-road vehicle. These blueprints detail how each component is interconnected, ensuring that every circuit functions correctly. A comprehensive set of wiring diagrams simplifies identifying issues related to power distribution, sensor connections, and grounding, which are crucial for the overall performance and safety of the vehicle.

To maintain the electrical system effectively, it’s important to understand the following key elements:

- Power Distribution: Clear illustration of how the electrical energy is routed from the battery to various components like lights, ignition systems, and other accessories.

- Grounding Points: Diagrams highlight critical grounding locations, ensuring all circuits complete properly and preventing electrical faults.

- Component Connectivity: Detailed lines that represent the relationship between switches, sensors, relays, and other parts that rely on precise electrical connections.

- Fuses and Relays: Identifying fuse locations and relay connections helps in quick identification and replacement during repairs.

By understanding these diagrams, owners can ensure the longevity and reliability of the vehicle’s electrical components. It’s crucial to always consult the most accurate and updated wiring diagrams to avoid errors in repairs and upgrades.

Braking System Parts and Upgrades

The braking system is crucial for ensuring safety and control, whether navigating challenging trails or cruising at higher speeds. A well-maintained brake setup is essential for achieving optimal stopping power and preventing accidents. Understanding the components that make up this system, along with the potential for upgrading or modifying these elements, can significantly enhance performance and reliability.

Key components of the braking system include the brake pads, rotors, calipers, and master cylinder. Each of these elements plays a specific role in delivering effective stopping force. For instance, high-quality pads ensure consistent friction, while robust rotors offer durability and heat dissipation. Calipers, responsible for squeezing the pads onto the rotor, must be strong and precise to provide reliable braking performance.

Upgrading certain parts can provide noticeable improvements in braking efficiency. Swapping standard pads for high-performance variants made from materials like ceramic or carbon can result in better stopping power and reduced wear. Upgraded rotors with advanced cooling features help maintain braking performance under heavy use. Additionally, upgrading to a more powerful master cylinder can improve the responsiveness of the braking system, offering quicker and more controlled stops.

Other enhancements may involve switching to braided steel brake lines, which provide increased pressure resistance and less expansion, delivering more consistent braking force. In addition, hydraulic brake systems offer smoother operation and more precise control, especially in demanding conditions.

Ultimately, a well-upgraded braking system not only boosts performance but also ensures a safer and more enjoyable riding experience, especially when tackling varied terrains or demanding conditions.

Cooling System and Radiator Components

The cooling system plays a crucial role in maintaining the optimal operating temperature of an engine, preventing it from overheating during high-performance activities. Efficient heat dissipation is essential for ensuring that the engine runs smoothly and reliably over long periods. The radiator, along with other related components, works together to regulate the temperature, ensuring both performance and longevity.

Key Components of the Cooling System

The main elements of the cooling system include the radiator, coolant hoses, thermostat, and water pump. Each component works in harmony to circulate coolant throughout the engine, absorb heat, and expel it through the radiator. The coolant flows through the engine block, absorbing heat, and is then directed to the radiator where it releases the heat into the air. The water pump circulates the coolant, while the thermostat controls the temperature by regulating coolant flow.

Radiator and Its Function

The radiator is a core part of the cooling system, designed to transfer heat from the coolant to the surrounding air. It is typically made of metal or aluminum and contains numerous fins that increase the surface area for heat dissipation. A well-maintained radiator ensures that the engine temperature remains steady, avoiding overheating and potential damage. Leaks or blockages in the radiator can lead to cooling system failures, which is why regular inspection and maintenance are essential for optimal engine performance.

Fuel System and Carburetor Parts

The fuel delivery system is a crucial component for ensuring optimal engine performance. It consists of several key elements that regulate the flow of fuel from the tank to the combustion chamber, maintaining the correct air-fuel mixture for smooth operation. One of the most vital parts of this system is the carburetor, responsible for mixing air and fuel before it enters the engine. A properly functioning fuel system ensures better efficiency and longevity of the engine, while a malfunctioning one can lead to performance issues or even engine failure.

Fuel Delivery Components

The primary components involved in fuel delivery include the fuel tank, fuel lines, fuel pump, and filters. Each part plays a critical role in ensuring clean and consistent fuel supply to the engine. The fuel tank holds the gasoline, while the pump pushes the fuel through the lines to the carburetor. Filters are designed to catch any debris or impurities that could clog the fuel flow or damage the engine.

Carburetor Assembly

The carburetor is a finely tuned device that blends fuel with air in the correct ratio for efficient combustion. It includes several parts like the float, needle valve, throttle, and jets, each contributing to the overall mixture and engine performance. The float controls the fuel level within the carburetor bowl, while the needle valve regulates fuel intake. Throttles adjust the airflow, and jets determine the amount of fuel entering the engine. Fine adjustments to these components ensure the engine operates smoothly under varying conditions.

Handling and Steering Components on Vinson

The steering system and handling components are essential for maintaining control and stability while riding an all-terrain vehicle (ATV). These elements ensure that the rider has precise control over direction, responsiveness, and overall safety during operation. Proper understanding and maintenance of these parts are crucial for optimal performance and safe handling, particularly in challenging terrains.

Key Components

The steering and handling system of an ATV involves several interconnected components, each contributing to the overall maneuverability of the vehicle. The primary parts that work together for smooth operation include:

- Steering Column: Connects the handlebars to the rest of the steering mechanism, allowing the rider to change the direction of the front wheels.

- Handlebars: The interface through which the rider applies steering input, linked directly to the steering column.

- Ball Joints: Flexible connections that allow for movement between different parts of the steering mechanism, enabling precise control.

- Spindles: These rotate the front wheels in response to the rider’s steering input, making them essential for directional control.

- Steering Arms: Transfer the motion from the steering column to the spindles, facilitating the turning action.

Maintaining Control and Stability

For consistent and responsive handling, these components must be regularly inspected and maintained. Regular checks ensure that all parts are free of wear or damage that could compromise control. Additionally, adjusting the steering system can help fine-tune the ATV’s responsiveness to the rider’s input. Key maintenance tips include:

- Inspect the ball joints for signs of excessive wear or damage.

- Ensure the steering column is free of play or irregularities.

- Check the alignment of the front wheels and adjust if necessary.

- Lubricate moving parts to prevent rust and ensure smooth operation.

- Verify the condition of the handlebars and ensure they are properly secured.

Common Replacement Parts for Suzuki ATVs

Maintaining the performance and longevity of off-road vehicles requires regular attention to specific components that may wear out or become damaged over time. Ensuring timely replacement of these crucial elements helps keep your machine running smoothly and reliably in various conditions. Some of these components are more prone to wear due to their frequent use or exposure to harsh environments, while others are essential for the overall functionality of the vehicle.

Engine components such as the spark plugs, air filters, and fuel filters are often among the first to need replacement. These parts directly affect engine performance and fuel efficiency, making them vital for keeping your ride in top shape. The spark plug ensures proper ignition, while the air filter helps maintain a clean air supply to the engine, preventing debris from causing internal damage.

The braking system is another area where parts often need replacing. Brake pads, discs, and fluid all play a role in ensuring that your vehicle can stop effectively and safely. Over time, brake pads wear down, and discs can become warped, leading to decreased performance and potential safety risks.

Additionally, suspension parts such as shocks, springs, and bushings are critical for absorbing shocks and providing a smooth ride. These components can degrade from continuous use, leading to a rougher ride and less control over uneven terrain. Replacing worn-out suspension components is key for maintaining ride quality and stability.

Other common replacements include chain and sprocket sets, which can stretch or become worn, affecting the vehicle’s ability to transfer power from the engine to the wheels. Keeping these elements in optimal condition ensures efficient power delivery and improves overall performance.

Lastly, electrical components, such as the battery, lights, and wiring, can also require periodic attention. A faulty battery can leave your ATV inoperable, while damaged wiring or lights can hinder visibility and communication in low-light conditions.

By proactively replacing these commonly worn components, you can extend the lifespan of your off-road vehicle, reduce maintenance costs, and enjoy a smoother, safer ride on every adventure.