The proper maintenance of your winter equipment is essential for optimal performance and longevity. Having a clear overview of the individual components can significantly enhance your ability to address any issues that may arise during usage. This section aims to provide a comprehensive look at the various elements involved in these machines, ensuring you have the knowledge needed to keep them running smoothly.

By exploring the intricate relationships between the different parts, you can better grasp how they function together. Recognizing the layout and design of each segment allows for easier troubleshooting and effective repairs. Ultimately, this understanding empowers you to delve into maintenance tasks with confidence and precision.

Whether you’re a seasoned user or a newcomer to winter equipment, familiarizing yourself with these components can lead to improved efficiency and reliability. This guide serves as a valuable resource for anyone looking to enhance their knowledge and skills in maintaining their machines.

Understanding John Deere Snow Blowers

Mastering the intricacies of outdoor equipment designed for winter maintenance can significantly enhance efficiency and performance. This section delves into the components and mechanisms that make these machines effective in tackling harsh weather conditions. Recognizing how each element functions contributes to smoother operation and better care.

| Component | Description |

|---|---|

| Engine | Powers the entire unit, providing the necessary force for operation. |

| Auger | Grabs and moves the accumulated material toward the discharge chute. |

| Chassis | The main frame that supports all other components, ensuring stability. |

| Discharge Chute | Directs the expelled material away from the working area, allowing for effective clearing. |

| Control Panel | Houses controls for operation, enabling adjustments for different conditions. |

Understanding these fundamental aspects can lead to improved maintenance practices and prolonged lifespan of the equipment, ensuring it remains a reliable ally during winter challenges.

Essential Components of Snow Blowers

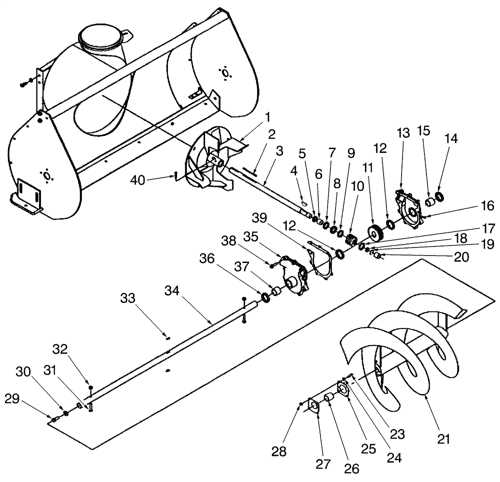

Understanding the fundamental elements of a snow-clearing machine is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the device functions efficiently during harsh winter conditions. A comprehensive knowledge of these key parts enables users to troubleshoot issues and enhance performance.

Auger: This spiral mechanism is responsible for gathering and breaking up the accumulated ice and snow. Its design allows for efficient movement of debris towards the impeller, ensuring swift removal.

Impeller: Acting as a powerful fan, the impeller propels the cleared material away from the machine. The effectiveness of this component directly impacts the distance and speed at which the snow is expelled.

Chassis: The sturdy framework supports all other elements and contributes to the overall stability of the equipment. A well-constructed chassis is essential for durability and ease of maneuverability.

Drive Mechanism: This component enables the machine to move forward or backward. Different systems, such as tracks or wheels, affect the device’s traction and control, particularly on slippery surfaces.

Control Panel: Located within easy reach of the operator, this interface allows for the adjustment of settings, such as speed and chute direction. An intuitive design can greatly enhance user experience.

Each of these elements is vital for optimal functionality and reliability. By familiarizing oneself with these components, users can ensure their equipment remains in peak condition throughout the winter months.

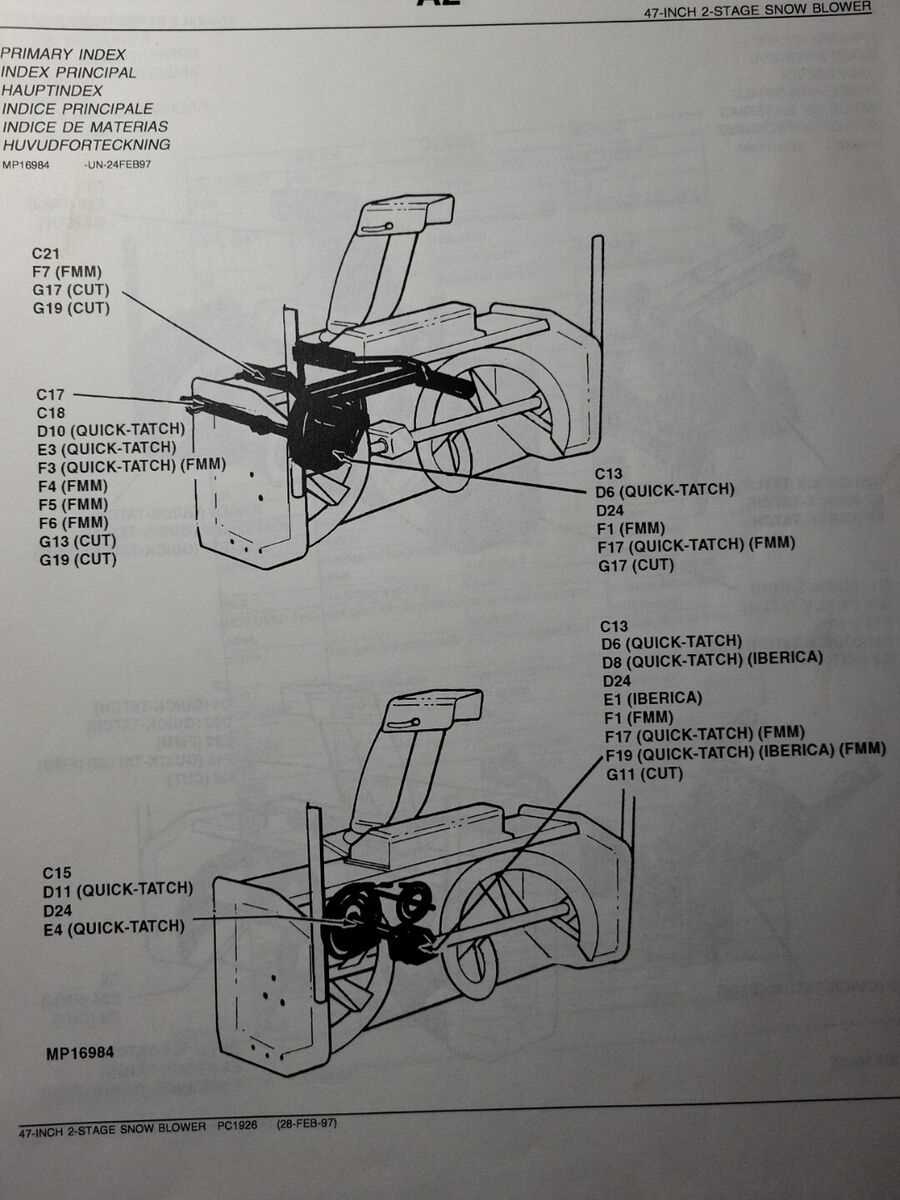

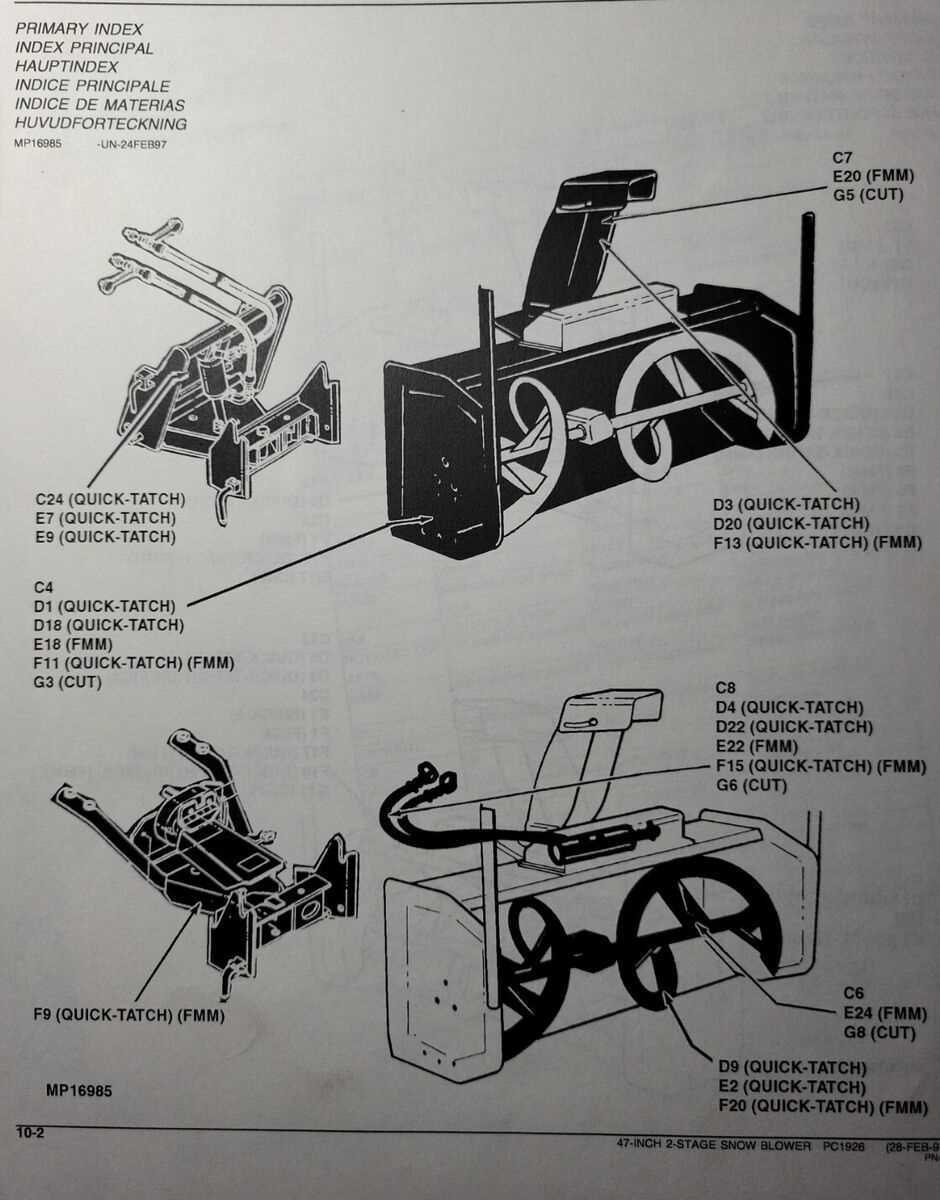

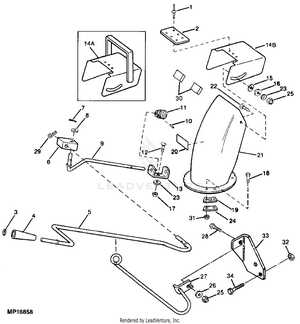

How to Read Parts Diagrams

Understanding visual schematics is crucial for effective maintenance and repair of machinery. These illustrations provide a clear representation of components and their interrelationships, enabling users to identify necessary elements and their functions. Familiarity with these visuals can greatly enhance the efficiency of repair tasks.

Key Elements to Note

- Labels: Each component is usually labeled with a unique identifier, making it easier to reference in manuals or parts lists.

- Connections: Arrows or lines may indicate how various parts are linked or interact with one another.

- Scale: Understanding the scale can help in visualizing the actual size of components in relation to each other.

Steps to Interpret the Illustration

- Examine the Legend: Start by checking the legend or key that explains symbols and colors used in the illustration.

- Identify Components: Locate the main parts, focusing on their shapes and placements.

- Trace Connections: Follow the lines or arrows to see how components are interconnected, which can reveal assembly sequences.

- Cross-Reference: Use the identifiers to cross-check with parts lists for detailed specifications.

Common Issues with Snow Blower Parts

When operating outdoor equipment designed for clearing snow, users often encounter a variety of challenges related to mechanical components. Understanding these frequent problems can significantly enhance the efficiency and longevity of the machine. From wear and tear to improper maintenance, each issue can lead to diminished performance.

Worn Belts: Over time, belts can fray or become loose, affecting the overall functionality. Regular inspection is crucial to ensure they are in good condition.

Clogged Augers: Ice and debris can accumulate, leading to blockages. It’s essential to clean the augers after each use to maintain optimal performance.

Fuel System Issues: Stale fuel can lead to starting problems. Using fresh fuel and proper storage techniques can mitigate these issues.

Electrical Failures: Battery and wiring problems can disrupt operation. Regular checks can help prevent unexpected breakdowns.

By delving into these common challenges, users can achieve the ultimate reliability from their outdoor clearing machines.

Maintaining Your Snow Blower

Proper upkeep of your equipment is essential to ensure its longevity and efficient performance. Regular maintenance can prevent minor issues from escalating into costly repairs and can enhance the overall functionality during the winter months. This section will guide you through essential care practices that keep your machine running smoothly.

Regular Inspections

Conducting routine checks is vital for identifying potential problems early. Look for signs of wear and tear, especially in critical components. Inspect belts, cables, and other moving parts for any signs of damage. Ensuring that all connections are tight and free from corrosion will help maintain optimal operation.

Cleaning and Storage

After each use, it’s important to clean your equipment thoroughly. Remove any accumulated debris and ice that could hinder performance. When the season ends, store the machine in a dry, sheltered area to protect it from the elements. Consider using a cover to prevent dust and moisture buildup during the off-season.

Emphasizing the significance of routine maintenance not only safeguards your investment but also ensures reliability when you need it most. Following these simple guidelines can make a substantial difference in the effectiveness and lifespan of your machinery.

Where to Find Replacement Parts

When it comes to maintaining outdoor machinery, sourcing the right components is crucial for optimal performance. Identifying reliable avenues for obtaining these essential items can make all the difference in keeping your equipment in top shape.

Authorized Dealers

One of the most dependable options is to visit authorized retailers. These establishments often provide genuine components, ensuring compatibility and durability. Always check their inventory for the specific items you need.

Online Marketplaces

Another great option is to explore various online platforms. Websites dedicated to outdoor equipment often feature extensive catalogs that allow users to delve into specifications and compare prices. Be sure to read reviews and verify seller credibility for the ultimate peace of mind.

Safety Tips for Snow Blower Use

Operating outdoor clearing equipment can be highly effective but comes with inherent risks. Adhering to safety guidelines is essential to ensure both personal safety and the optimal performance of the machinery. Following these tips will help you navigate winter conditions more securely.

1. Read the Manual: Always familiarize yourself with the manufacturer’s instructions. Understanding the specific features and safety mechanisms of your equipment is crucial for safe operation.

2. Wear Appropriate Gear: Dress in warm, waterproof clothing and sturdy footwear. Protective eyewear and gloves can safeguard against debris and cold exposure.

3. Inspect Before Use: Conduct a thorough check of the equipment prior to operation. Look for any signs of wear, damage, or loose components that could hinder performance or pose hazards.

4. Avoid Overloading: Do not attempt to clear excessive amounts of accumulation at once. Working in manageable sections prevents strain on both the machinery and the operator.

5. Stay Alert: Remain focused during operation. Distractions can lead to accidents, so ensure a clear workspace and limit interruptions.

6. Turn Off When Clearing Blockages: If a clog occurs, always turn off the equipment and disconnect the power source before attempting to remove any obstructions. This prevents accidental start-ups.

7. Keep Children and Pets Away: Ensure that family members and pets are at a safe distance during use. This reduces the risk of injury from flying debris or equipment operation.

8. Use Lights and Reflectors: When working in low visibility conditions, use external lights and reflectors to enhance visibility for yourself and others nearby.

By implementing these precautions, you can significantly reduce the risks associated with using outdoor clearing machinery and ensure a safer experience throughout the winter months.

Upgrading Your Snow Blower Components

Enhancing the performance of your winter machinery can significantly improve efficiency and durability. By carefully selecting upgraded elements, you can adapt your equipment to better handle harsh conditions and extend its lifespan. This process not only involves replacing worn-out components but also integrating advanced technology to boost functionality.

When considering enhancements, it’s essential to evaluate which elements will yield the most significant benefits. Below is a table outlining common components that can be upgraded, their potential improvements, and recommended options:

| Component | Potential Improvement | Recommended Options |

|---|---|---|

| Impeller | Increased throwing distance | High-performance impellers |

| Auger | Enhanced cutting efficiency | Heavy-duty auger systems |

| Skid Shoes | Improved ground contact | Adjustable metal skid shoes |

| Drive Belts | Smoother operation | Reinforced drive belts |

| Controls | Ease of use | Ergonomic control handles |

Investing in these upgrades not only enhances the efficiency of your equipment but also provides a more enjoyable and less strenuous experience during winter maintenance. By prioritizing quality and compatibility, you can ensure that your enhancements will yield the best results.

Repairing vs. Replacing Parts

When it comes to maintenance of equipment, a crucial decision often arises: should you fix a malfunctioning component or opt for a new one? This choice can significantly impact both performance and budget.

Repairing can offer several benefits:

- Cost-effectiveness

- Preservation of original functionality

- Reduced waste and environmental impact

On the other hand, replacing may be more advantageous in certain scenarios:

- Enhanced reliability and performance

- Access to the latest technology

- Long-term savings on repairs

Ultimately, evaluating the condition, cost, and potential longevity of each option can help determine the best course of action for maintaining equipment efficiency.

Customer Reviews on John Deere Parts

This section explores user feedback on components from a well-known manufacturer, providing insights into quality and performance. Customers share their experiences to guide potential buyers in making informed choices.

Positive Feedback

- Durability: Many users highlight the longevity of the components.

- Ease of installation: Reviewers appreciate straightforward assembly processes.

- Efficiency: Customers report improved performance after upgrades.

Areas for Improvement

- Availability: Some find it challenging to source specific items.

- Price: A few customers feel costs are on the higher side.

- Customer service: Instances of slow response times were noted.

Snow Blower Accessories to Consider

When it comes to optimizing your winter equipment, various enhancements can significantly improve functionality and efficiency. These add-ons can not only streamline your operations but also enhance performance during challenging weather conditions.

- Heated Handles: Keep your hands warm while operating in cold temperatures, ensuring better grip and control.

- Drift Cutters: These attachments help tackle heavy drifts, allowing for smoother navigation through deep accumulations.

- Skid Shoes: Adjustable shoes can protect surfaces while providing better maneuverability over uneven terrain.

- Light Kits: Illuminate your path during early mornings or late evenings, enhancing visibility and safety.

- Chute Deflector: Aimed to control the direction and distance of discharge, this accessory offers greater flexibility in clearing areas.

Choosing the right accessories can transform your winter maintenance tasks into a more manageable experience, allowing for efficient snow management all season long.