The intricate world of machinery relies on various elements that work in harmony to achieve optimal performance. Each component plays a vital role in the overall functionality, ensuring that operations run smoothly and efficiently. Understanding the arrangement and interconnection of these elements is essential for maintenance and repair tasks.

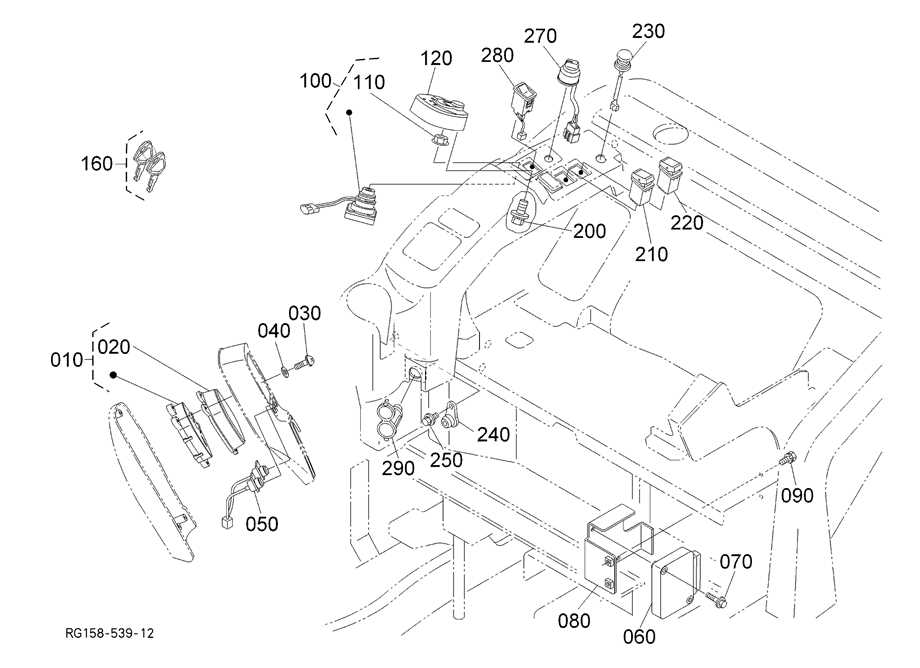

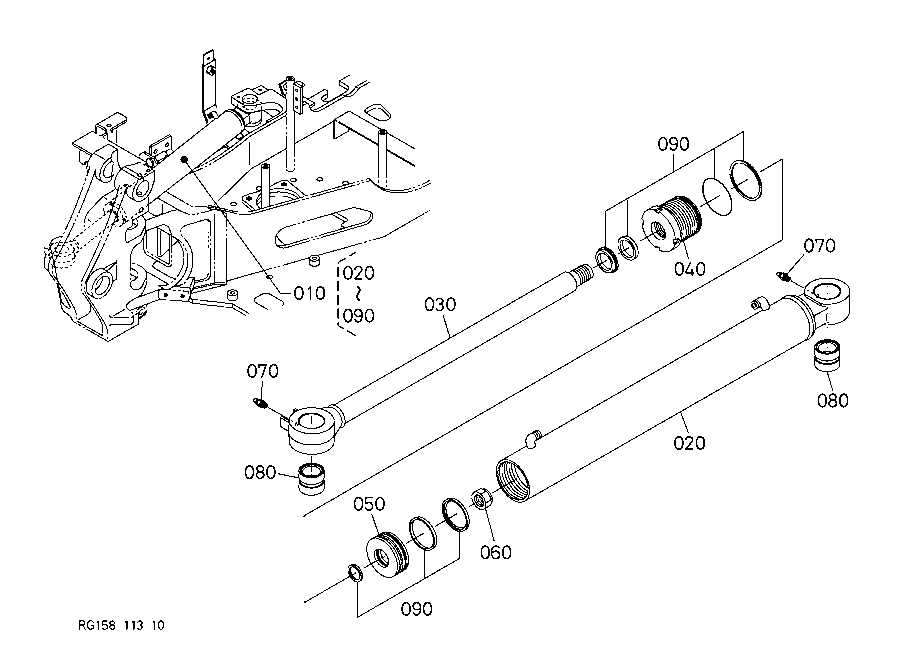

In this section, we will explore a comprehensive representation of the various components found within a specific model of compact excavator. By examining this schematic, readers will gain insights into the configuration and relationship of the individual parts, which is crucial for troubleshooting and enhancing operational efficiency.

Whether you’re a seasoned technician or a novice enthusiast, familiarizing yourself with the structure and layout of these components can significantly aid in the upkeep of your machinery. A clear understanding of how each element interacts will empower you to make informed decisions when it comes to repairs and upgrades.

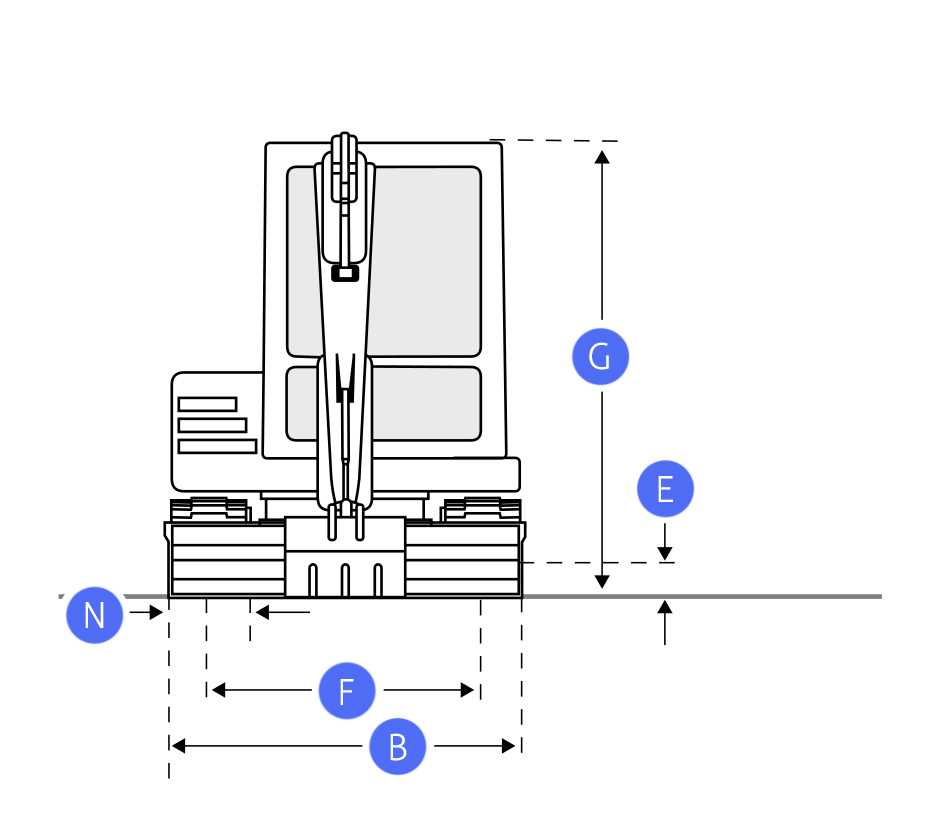

This section aims to provide a comprehensive overview of a compact excavator model designed for versatility and efficiency in various construction tasks. Understanding the key components and their functions is essential for effective maintenance and operation. This model stands out due to its compact size, allowing access to tight spaces while delivering powerful performance.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to operate the machine, ensuring optimal performance under load. |

| Hydraulic System | Responsible for powering the attachments and controlling the movement of the boom, arm, and bucket. |

| Chassis | The frame that supports all components and provides stability during operation. |

| Cab | Encloses the operator, offering protection and comfort while allowing for clear visibility of the work area. |

| Track System | Enables mobility over various terrains, ensuring stability and traction. |

Importance of Parts Diagrams

Understanding the components and their relationships within machinery is crucial for effective maintenance and repair. Visual representations serve as valuable resources for technicians, providing clarity on assembly and functionality. These illustrations enable users to quickly identify individual elements and their specific roles within the overall system.

Utilizing detailed schematics can lead to various benefits:

- Enhanced Clarity: Visual aids help clarify complex structures, making it easier to comprehend how different pieces interact.

- Efficient Troubleshooting: By pinpointing the exact location of components, users can diagnose issues faster and more accurately.

- Streamlined Repairs: Knowledge of part arrangements allows for quicker disassembly and reassembly, reducing downtime during maintenance.

- Improved Ordering Process: Understanding specific elements aids in accurate ordering, ensuring the correct replacements are obtained.

In summary, these visual tools not only facilitate better understanding but also enhance the overall efficiency of maintenance tasks. Employing them can lead to more effective management of machinery and prolong the lifespan of equipment.

Key Components of Kubota KX018-4

The functionality and efficiency of mini excavators greatly depend on their essential parts. Understanding these core elements is crucial for maintenance and performance optimization. This section delves into the primary components that contribute to the overall effectiveness of these machines.

Hydraulic System

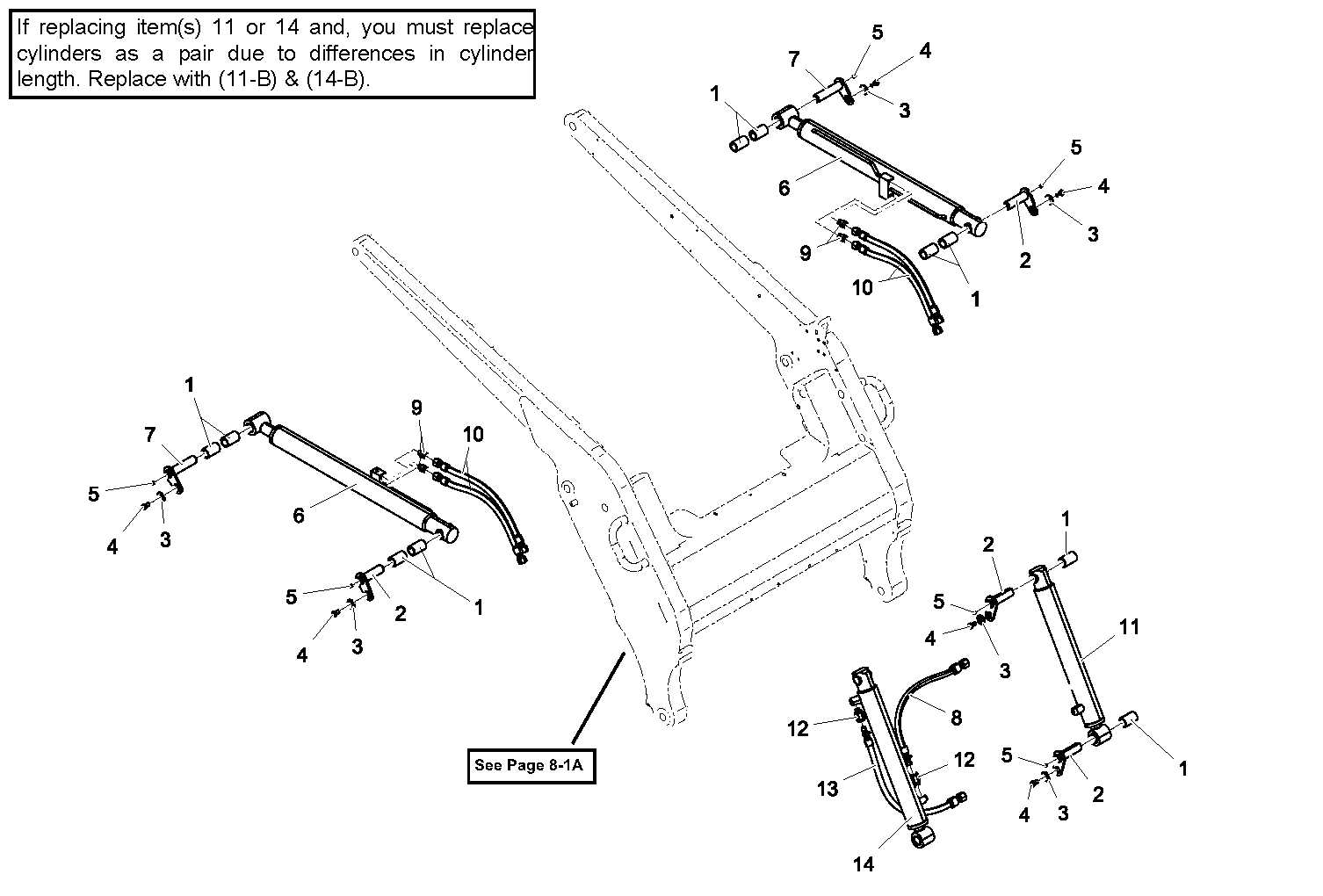

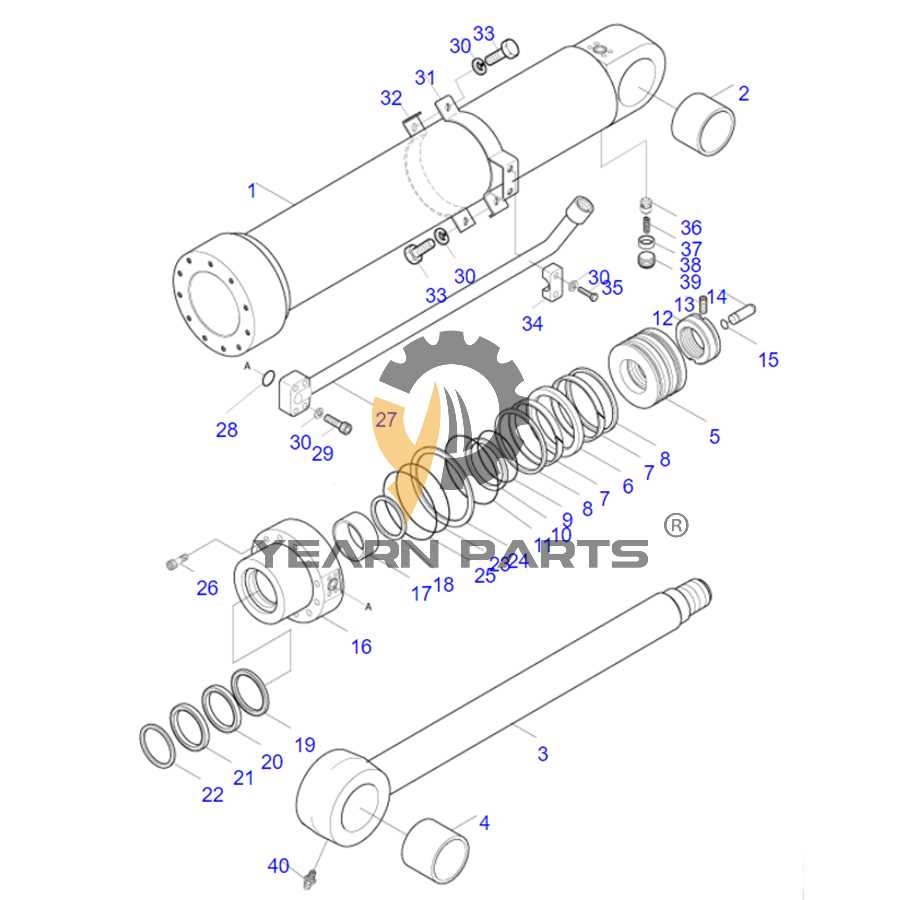

The hydraulic system plays a pivotal role in powering the various movements of the machine. It consists of pumps, cylinders, and hoses that work together to enable smooth operation. Regular checks and maintenance of this system are vital to ensure maximum performance and prevent potential breakdowns.

Engine and Transmission

The heart of the excavator is its engine, which provides the necessary power for operation. Coupled with an efficient transmission system, it ensures that the machine can handle various tasks with ease. Regular maintenance of the engine is essential for longevity and optimal performance.

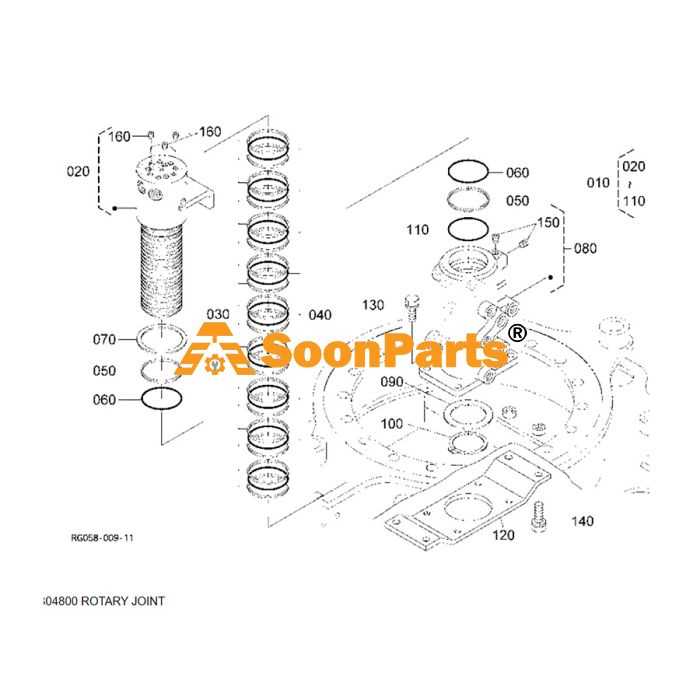

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in various machinery, enabling the efficient transfer of power through fluid movement. These systems rely on the principles of hydraulics to perform tasks that require significant force, making them essential for construction equipment, agricultural machines, and many industrial applications.

At their core, hydraulic systems consist of several key components that work together to facilitate fluid flow and pressure. The primary elements include pumps, valves, actuators, and hoses. Pumps generate the hydraulic fluid’s flow, while valves control this flow to direct it where it’s needed. Actuators, such as cylinders or motors, then convert the hydraulic energy into mechanical motion, enabling the machine to perform its intended functions.

The efficiency of these systems is influenced by various factors, including fluid viscosity, system pressure, and the design of the components. Understanding these elements is vital for diagnosing issues and ensuring optimal performance, ultimately contributing to the longevity and reliability of the equipment.

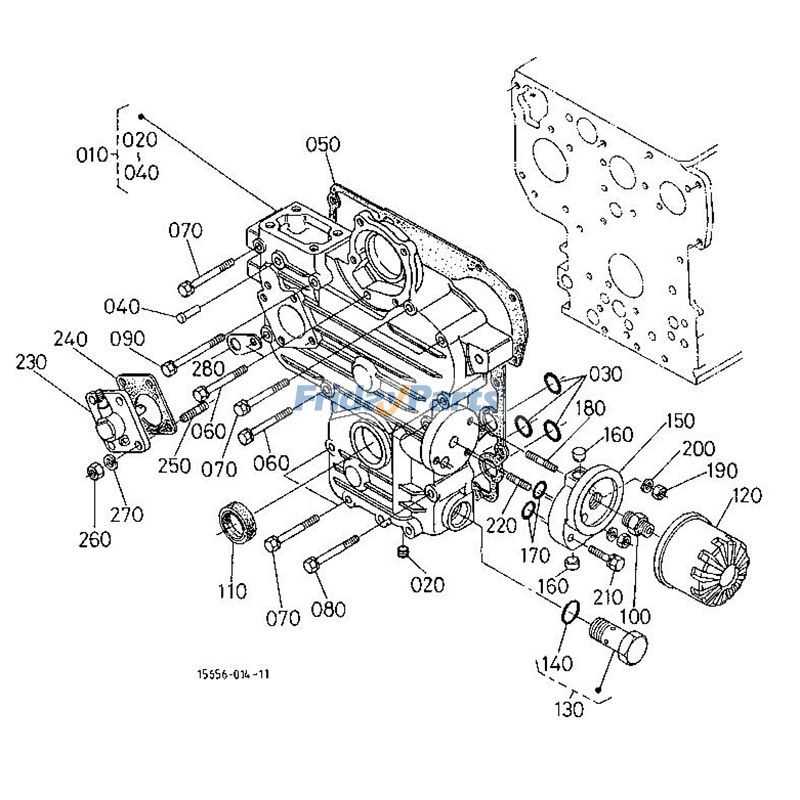

Engine Parts and Functions

The engine is the heart of any machinery, playing a vital role in converting fuel into mechanical energy. Understanding the various components and their respective functions is crucial for effective maintenance and repair. Each part works in harmony to ensure optimal performance, efficiency, and longevity of the equipment.

Key Components

Among the essential components are the cylinder block, which houses the cylinders and forms the core structure of the engine. The pistons move up and down within these cylinders, facilitating the combustion process. Additionally, the crankshaft converts the linear motion of the pistons into rotational motion, driving the overall machinery.

Supportive Elements

Supporting the primary functions are various elements such as the camshaft, responsible for operating the intake and exhaust valves, and the valve train, which ensures proper timing of the valve movements. Furthermore, the lubrication system minimizes friction between moving parts, enhancing the overall efficiency and durability of the engine.

Electrical System Components Explained

The electrical system in machinery plays a crucial role in its operation, providing the necessary power for various functions. Understanding the different elements that comprise this system is essential for effective maintenance and troubleshooting.

Key components of the electrical system include:

- Battery: Supplies electrical energy to start the engine and power electrical accessories.

- Alternator: Converts mechanical energy into electrical energy, recharging the battery while the engine is running.

- Starter Motor: Engages the engine to initiate combustion and start the machine.

- Fuses: Protect electrical circuits by breaking the connection in case of overloads, preventing damage.

- Wiring Harness: Connects various electrical components, allowing for efficient distribution of power and signals.

- Switches: Control the flow of electricity to different parts, enabling the operation of lights, ignition, and other systems.

Each of these components serves a specific function, contributing to the overall efficiency and reliability of the machinery. Regular inspection and maintenance of these parts are essential to ensure optimal performance and to prevent electrical failures.

Track and Undercarriage Details

The undercarriage and track system of compact machinery play a crucial role in ensuring optimal mobility and stability on various terrains. Understanding the components that make up this vital structure is essential for maintaining performance and extending the lifespan of the equipment.

Key elements of the undercarriage include the tracks, rollers, and frames that work together to provide effective weight distribution and traction. Tracks are designed to enhance grip and prevent slippage, while rollers facilitate smooth movement over uneven surfaces. Regular inspection of these components is vital for identifying wear and tear, ensuring the machine operates efficiently.

Moreover, the design and material quality of the undercarriage components significantly impact the overall durability and functionality. Ensuring that all parts are properly aligned and maintained can help avoid costly repairs and downtime, ultimately leading to enhanced productivity.

Maintenance Parts and Their Uses

Regular upkeep of machinery is essential for ensuring optimal performance and longevity. Various components play a crucial role in the maintenance process, each serving specific functions that contribute to the overall efficiency of the equipment. Understanding these elements is vital for operators and technicians alike.

Filters are among the most critical components, as they prevent contaminants from entering the engine and hydraulic systems. This ensures clean operation and helps avoid costly repairs due to dirt and debris.

Seals and gaskets are designed to prevent leaks, maintaining the integrity of fluids within the machinery. Their proper functioning is essential for sustaining hydraulic pressure and avoiding operational failures.

Belts and hoses connect various systems within the equipment, facilitating the transfer of power and fluids. Regular inspection and timely replacement of these items are necessary to avoid breakdowns and ensure seamless operation.

Lubricants are vital for reducing friction between moving parts, thereby enhancing efficiency and extending the lifespan of the machinery. Choosing the appropriate type of lubricant and applying it correctly is crucial for maintaining optimal performance.

By prioritizing the upkeep of these essential components, operators can significantly enhance the reliability and functionality of their machinery, leading to improved productivity and reduced downtime.

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original equipment manufacturer (OEM) components and aftermarket alternatives is crucial for anyone involved in machinery maintenance and repair. Each type offers unique advantages and potential drawbacks that can impact performance and longevity.

OEM components are made by the same manufacturer that produced the original machinery, ensuring compatibility and quality. On the other hand, aftermarket options are produced by third-party companies and can vary in quality and price. Here are some key considerations when evaluating these options:

- Quality Assurance: OEM products typically undergo rigorous testing, while aftermarket items may not always meet the same standards.

- Price Variability: Aftermarket alternatives often come at a lower cost, making them appealing for budget-conscious buyers.

- Warranty Coverage: OEM parts usually come with a warranty, providing added protection against defects.

- Availability: Aftermarket components may be more readily available, particularly for older models.

Ultimately, the choice between OEM and aftermarket items will depend on individual needs, preferences, and the specific application. Weighing the pros and cons of each can help ensure optimal performance and reliability in your machinery.

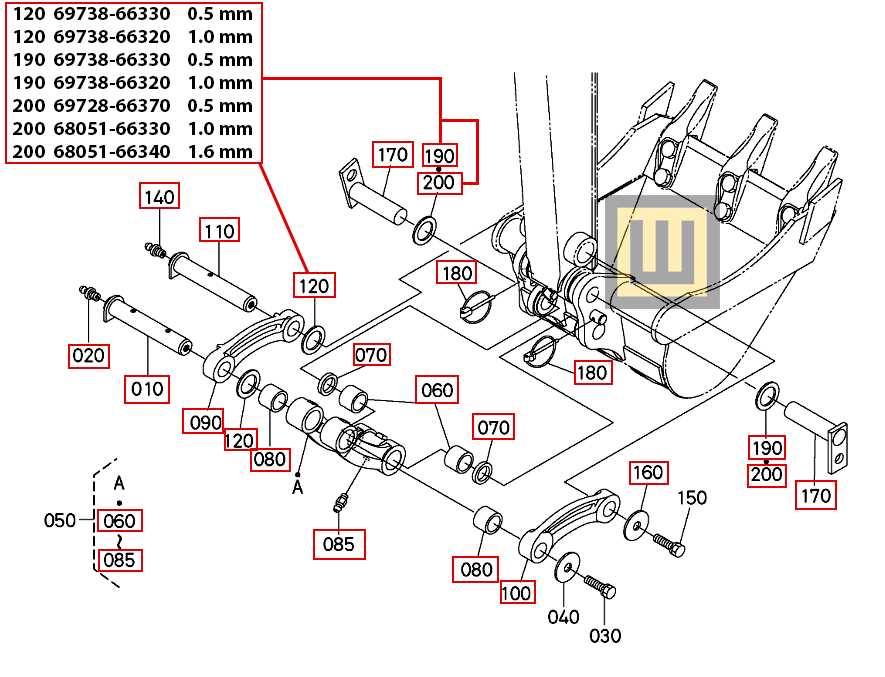

Common Replacement Parts for KX018-4

Maintaining the functionality of any machinery requires an understanding of the components that may need to be replaced over time. Regular use can lead to wear and tear, making it essential to know which elements are commonly substituted to ensure optimal performance. Below are some frequently replaced components that enhance the longevity and efficiency of this particular equipment.

| Component | Description | Signs of Wear |

|---|---|---|

| Tracks | Rubber tracks provide traction and stability. | Cracks, tears, or significant wear on the surface. |

| Bucket | Used for digging and moving materials. | Deformation or loss of sharpness on the cutting edge. |

| Hydraulic Filters | Essential for maintaining fluid cleanliness. | Restricted flow or discoloration of hydraulic fluid. |

| Oil Seals | Prevent leaks in hydraulic systems. | Visible leaks or a decrease in hydraulic pressure. |

| Belts | Transfer power to various components. | Cracks, fraying, or unusual noises during operation. |

Assembly and Disassembly Tips

Proper assembly and disassembly of machinery components are crucial for maintaining efficiency and longevity. Following a systematic approach ensures that all parts fit together seamlessly, reducing wear and preventing operational issues. Understanding the sequence of steps and utilizing the right tools can significantly simplify the process.

Preparation Steps

Before starting, ensure that you have all necessary tools and replacement components ready. It’s essential to organize your workspace to avoid misplacing parts. Take the time to review any manuals or guides related to the machinery to familiarize yourself with the components involved.

Disassembly Process

Begin the disassembly by systematically removing components in reverse order of assembly. Take note of how each part is attached to avoid confusion when reassembling. Keep small parts, such as bolts and washers, in a designated container to prevent loss. Document each step with photos or notes for future reference.

| Step | Action | Notes |

|---|---|---|

| 1 | Gather Tools | Ensure all necessary tools are available. |

| 2 | Review Manual | Understand the assembly sequence. |

| 3 | Remove Fasteners | Keep track of all small parts. |

| 4 | Document Steps | Take photos for reference. |

Benefits of Using Diagrams for Repairs

Visual representations serve as invaluable tools in the maintenance and restoration of machinery. They provide clarity and streamline the repair process, ensuring that technicians can swiftly identify components and their functions. Utilizing these visual aids can significantly reduce errors and enhance efficiency during repairs.

One of the primary advantages is the ability to visualize the assembly of parts. This makes it easier to understand complex systems and how various elements interact with one another. With a clear visual guide, technicians can quickly locate issues and determine the best approach for troubleshooting.

| Advantages | Description |

|---|---|

| Improved Clarity | Visual aids eliminate confusion by providing a clear picture of the components involved. |

| Reduced Errors | Having a visual reference minimizes the chances of mistakes during assembly or repair. |

| Time Efficiency | Quick identification of parts speeds up the overall repair process. |

| Enhanced Learning | Visuals assist technicians in grasping complex concepts and procedures more effectively. |

Incorporating visual tools into the repair workflow not only facilitates a smoother process but also empowers technicians with knowledge and confidence. This approach ultimately leads to higher quality repairs and prolonged equipment life.

Resources for Parts Acquisition

Finding the right components for machinery maintenance and repair is essential for ensuring optimal performance and longevity. Various sources can provide the necessary supplies, ranging from official dealers to online marketplaces. By exploring these options, users can make informed decisions and obtain the required items efficiently.

Official Dealers and Distributors

Authorized sellers offer a reliable way to acquire authentic components. They typically have access to the complete inventory of genuine replacements, ensuring quality and compatibility. Engaging with these suppliers can also provide insight into new arrivals and promotions.

Online Marketplaces and Forums

The internet hosts numerous platforms where users can buy and sell machinery supplies. Online marketplaces often feature a wide selection, making it easier to compare prices and find suitable options. Additionally, forums dedicated to machinery enthusiasts can provide recommendations for trusted sellers and valuable tips for sourcing hard-to-find items.