In the realm of machinery maintenance, having a clear visual representation of the various elements that make up a specific model is crucial for efficient repairs and upgrades. This resource aims to provide a comprehensive overview of how these components interact and function within the system, enhancing the user’s ability to identify and address potential issues.

By delving into detailed illustrations and descriptions, operators can gain invaluable insights into the arrangement and roles of each individual piece. This knowledge not only streamlines the process of locating the necessary items but also facilitates a deeper understanding of the overall mechanics involved.

Whether you are a seasoned technician or a novice user, familiarizing yourself with the intricacies of the machinery will empower you to make informed decisions regarding maintenance and enhancements. Effective troubleshooting and timely replacements can significantly extend the lifespan of your equipment, ensuring optimal performance for years to come.

Having precise visual representations of components is crucial for effective maintenance and repair in any machinery. These illustrations serve as essential guides, enabling users to identify individual elements and understand their arrangement within the overall structure. Clarity in these visuals can significantly impact the efficiency of repairs and replacements.

Accurate illustrations contribute to several key aspects of machinery management:

- Enhanced Understanding: Clear visuals help operators and technicians comprehend the design and functionality of various elements, promoting effective troubleshooting.

- Streamlined Repairs: When the layout of components is easily accessible, it reduces the time spent locating and fixing issues, leading to quicker turnaround times.

- Minimized Errors: Accurate visuals reduce the likelihood of mistakes during disassembly and reassembly, ensuring that parts are correctly installed and aligned.

- Improved Training: Visual aids are invaluable for training new personnel, allowing them to familiarize themselves with the equipment and its components more efficiently.

In conclusion, precise representations of machinery components are indispensable for maintaining optimal performance and longevity. Investing in high-quality visual resources is a fundamental step towards achieving operational excellence.

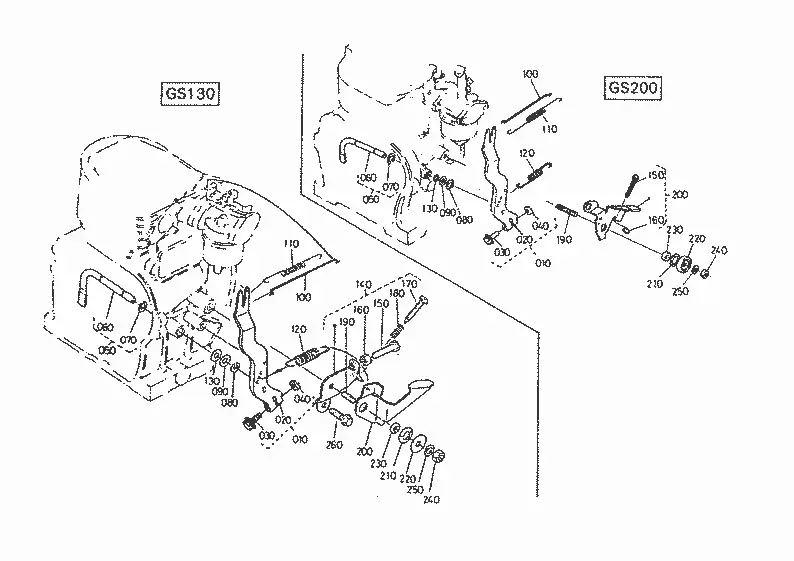

Common Components of GS130 Machinery

This section delves into the essential elements that make up the machinery designed for various agricultural and industrial applications. Understanding these fundamental components is crucial for efficient operation and maintenance, ensuring that the equipment performs at its best while meeting the demands of its tasks.

Main Elements

- Engine: The powerhouse responsible for driving the entire machine, converting fuel into mechanical energy.

- Transmission: This system facilitates the transfer of power from the engine to the wheels, allowing for varied speed and torque.

- Hydraulic System: A crucial component that enables the lifting and movement of heavy loads through pressurized fluid.

- Chassis: The framework that supports all other components, providing stability and structural integrity.

Supporting Features

- Cooling System: Prevents overheating of the engine and other critical components during operation.

- Fuel System: Ensures a steady supply of fuel to the engine, maintaining performance efficiency.

- Electrical System: Powers various electrical components, including lights and ignition systems.

- Cabin: The operator’s workspace designed for comfort and visibility, enhancing control over the machinery.

Familiarity with these primary and supporting features will aid users in understanding how to effectively operate and maintain their machinery, ultimately prolonging its lifespan and optimizing performance.

Step-by-Step Guide to Parts Identification

Understanding the components of machinery is essential for effective maintenance and repair. This guide provides a systematic approach to help you recognize and locate various elements of equipment, ensuring optimal performance and longevity. By following these steps, you can enhance your knowledge and skills in managing mechanical systems.

1. Gather Necessary Documentation

Start by collecting all relevant manuals, schematics, or catalogs related to the equipment. These resources often include detailed illustrations and descriptions that can assist in identifying individual components. Pay special attention to any sections that highlight assembly or disassembly procedures.

2. Utilize Identification Techniques

Once you have the documentation, employ the following techniques to pinpoint specific elements:

| Technique | Description |

|---|---|

| Visual Inspection | Examine the machinery closely for any labels or markings that indicate part numbers or specifications. |

| Cross-Referencing | Use the information from manuals to cross-reference with physical components, confirming their identities based on characteristics and dimensions. |

| Online Resources | Visit forums, manufacturer websites, or online marketplaces that specialize in mechanical equipment to find additional details and images. |

By systematically applying these strategies, you can effectively identify and understand the various elements within your machinery, paving the way for successful maintenance and repair efforts.

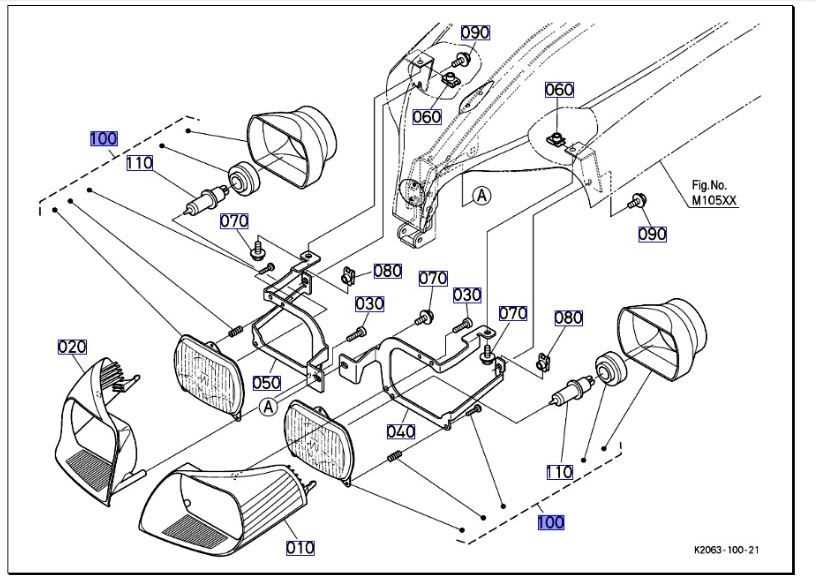

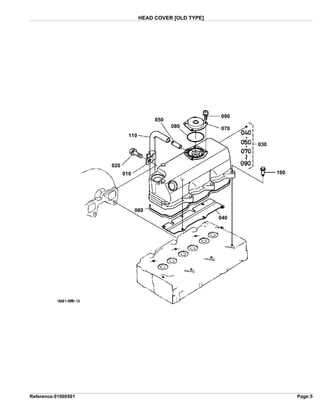

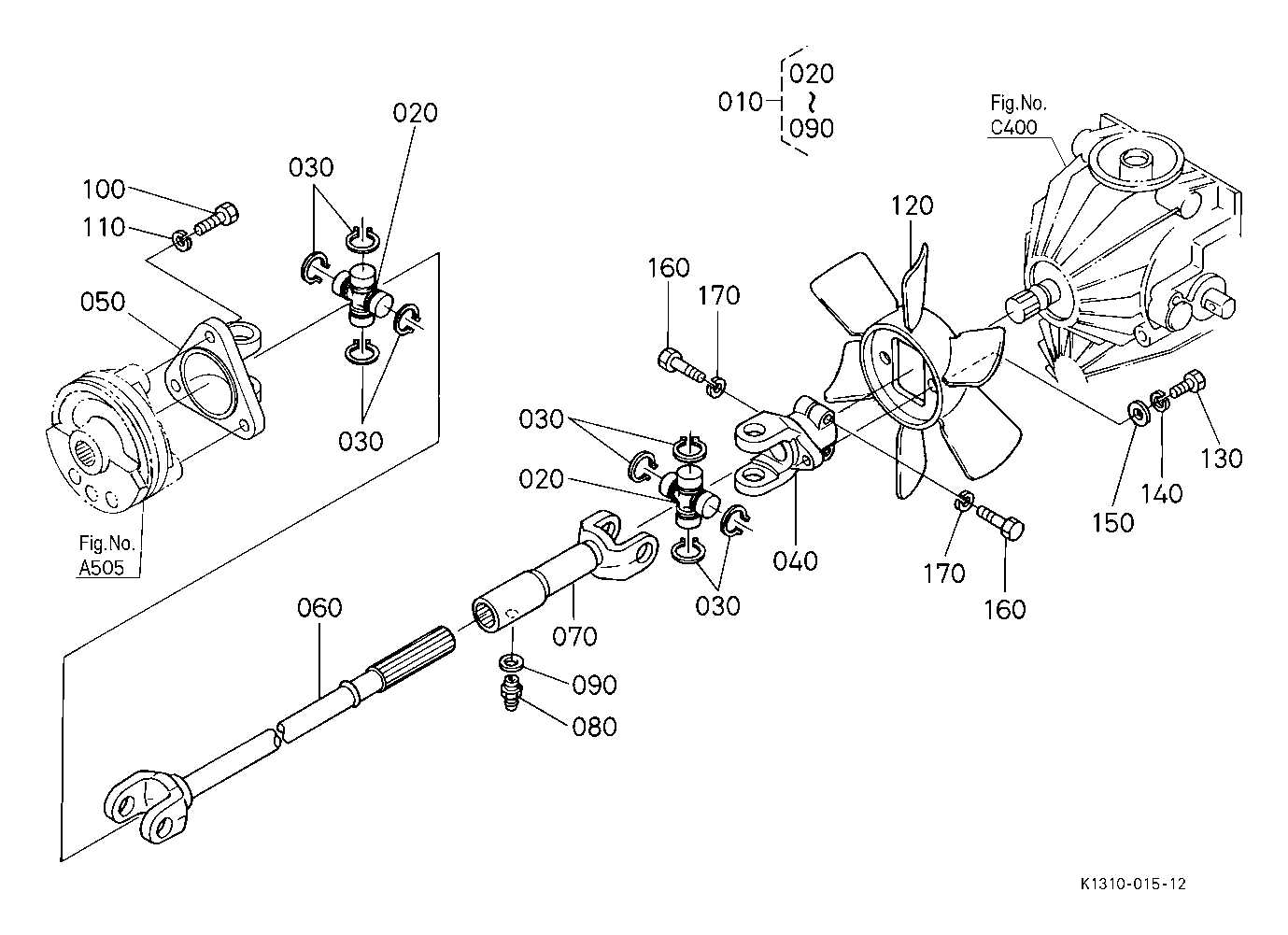

How to Read Parts Diagrams Effectively

Understanding component schematics is essential for successful maintenance and repair of machinery. These visual representations provide detailed information about the various elements of a system, allowing users to identify and locate specific items. Familiarizing oneself with these illustrations can significantly enhance the efficiency of troubleshooting and replacement processes.

Key Elements to Look For

When examining a schematic, pay attention to the following components:

| Element | Description |

|---|---|

| Symbols | Each icon represents a specific component, such as gears, bolts, or hoses. |

| Numbers | Reference numbers are usually associated with a list that details specifications or additional information. |

| Lines | Lines connect various components, illustrating how they interact within the system. |

| Shading | Differentiating shades can indicate various layers or sections, helping users navigate complex assemblies. |

Tips for Effective Interpretation

To enhance your ability to decipher schematics, consider the following strategies:

- Familiarize yourself with common symbols used in your specific industry.

- Always cross-reference numbers with accompanying lists to ensure accurate identification.

- Practice visualizing the physical layout based on the schematic to improve comprehension.

- Consult with experienced technicians or refer to manuals when unsure about specific components.

Common Issues in GS130 Parts Replacement

Replacing components in machinery can often lead to various challenges that users may encounter. Understanding these difficulties is essential for ensuring efficient maintenance and operation. Factors such as compatibility, sourcing quality materials, and installation procedures significantly influence the success of these replacements.

Compatibility Challenges

One of the primary issues that arise during the substitution of components is the compatibility with existing machinery. Variations in model specifications or outdated components may lead to difficulties in finding suitable replacements. It is crucial to verify that the selected items match the required specifications to prevent performance issues or damage to the system.

Quality of Replacement Items

The market is flooded with options for replacement components, but not all are created equal. Users must be cautious when selecting suppliers to ensure they obtain high-quality materials. Inferior products can lead to premature wear, decreased efficiency, and potential safety hazards. Conducting thorough research and reading reviews can assist in making informed choices.

Where to Find Official Parts Diagrams

Accessing authentic technical illustrations for machinery can greatly enhance the maintenance and repair process. These visual guides provide essential information regarding component placement and assembly, ensuring that users can perform tasks accurately and efficiently.

One of the best sources for these resources is the manufacturer’s official website. Most companies offer online platforms where users can browse through extensive catalogs that include technical illustrations for various models. Additionally, authorized dealers often have access to these resources and can provide them upon request.

Another valuable option is to consult dedicated online forums or communities. Enthusiasts and professionals frequently share links and files that include the necessary illustrations, making it easier for others to find the information they need. Engaging with these communities can also yield advice and insights from experienced users.

Lastly, consider investing in service manuals. These comprehensive guides not only feature visual representations but also include detailed explanations and troubleshooting tips, making them an indispensable resource for anyone looking to maintain their equipment effectively.

Benefits of Using Genuine Kubota Parts

Utilizing original components in machinery maintenance ensures optimal performance and longevity. When equipment requires servicing, the choice of replacement items can significantly impact functionality and reliability. Authentic elements provide assurance of quality, durability, and compatibility, fostering peace of mind for operators and owners alike.

One of the key advantages of selecting genuine components is superior quality. These items undergo rigorous testing and adhere to strict manufacturing standards, guaranteeing they meet the exact specifications required for seamless operation. This attention to detail minimizes the risk of malfunctions and extends the lifespan of the equipment.

Furthermore, employing original replacements often leads to improved efficiency. By maintaining the intended design and engineering, these components contribute to the machine’s overall effectiveness, enabling it to perform tasks more efficiently. This can result in significant cost savings over time due to reduced downtime and maintenance needs.

Additionally, using authentic components helps to maintain the warranty coverage of the machinery. Many manufacturers require the use of original items to uphold warranty claims, protecting the investment made by the owner. By adhering to these guidelines, operators can ensure they are covered in case of unforeseen issues.

In conclusion, the choice of genuine replacements not only enhances the operational integrity of equipment but also fosters trust in the manufacturer. Prioritizing quality, efficiency, and warranty protection ultimately supports better performance and satisfaction for all users.

Tips for Maintaining GS130 Equipment

Proper upkeep of machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps prevent costly repairs and downtime. Implementing a consistent maintenance routine can lead to better productivity and a smoother operational experience.

Regular Inspection

Conduct frequent checks on your equipment to identify any signs of wear or potential issues. Inspect critical components such as belts, filters, and fluid levels. Addressing minor problems promptly can prevent them from escalating into significant failures.

Routine Cleaning

Keep your machinery clean to enhance its performance. Remove dirt, debris, and other contaminants from the surfaces and moving parts. Regular cleaning helps prevent corrosion and ensures that all components function smoothly, extending the life of the equipment.

Comparing Aftermarket Parts with OEM Options

When it comes to machinery maintenance, selecting the right components is crucial for optimal performance and longevity. Two primary options exist for consumers: original equipment manufacturer (OEM) components and aftermarket alternatives. Each category presents unique advantages and disadvantages that can significantly impact the effectiveness and cost-efficiency of repairs.

Benefits of OEM Components

- Quality Assurance: OEM offerings are typically manufactured to meet strict specifications, ensuring compatibility and reliability.

- Warranty Protection: Most OEM products come with warranties that protect against defects and performance issues.

- Longevity: Original parts often provide enhanced durability, reducing the frequency of replacements.

Advantages of Aftermarket Alternatives

- Cost-Effectiveness: Aftermarket components are generally more affordable, making them an appealing choice for budget-conscious consumers.

- Variety: The aftermarket often offers a wider selection, allowing for more customization and upgrades.

- Availability: These options are typically easier to find, which can expedite repair times.

In conclusion, the choice between original and alternative components depends on individual priorities such as budget, performance needs, and personal preferences. Understanding the strengths and weaknesses of each category can aid in making an informed decision that best suits specific requirements.