Exploring the intricate workings of an all-terrain vehicle reveals the importance of each individual component in ensuring optimal performance. A comprehensive understanding of these elements enhances maintenance practices and promotes longevity. Whether you are a seasoned enthusiast or a novice owner, familiarizing yourself with the various sections can lead to more informed decisions when it comes to repairs and upgrades.

Every all-terrain machine comprises several interconnected systems, each designed for specific functions. Recognizing how these systems interact not only aids in troubleshooting but also empowers users to enhance their vehicle’s capabilities. The ability to visualize the arrangement and relationship of these components is crucial for effective management and restoration.

In this section, we will delve into a detailed overview of the essential elements that make up these rugged machines. By examining the layout and function of each part, you will gain insight into how to maintain and optimize your vehicle for any adventure ahead. Let’s embark on this informative journey to uncover the core of what makes these machines a reliable choice for exploration and work.

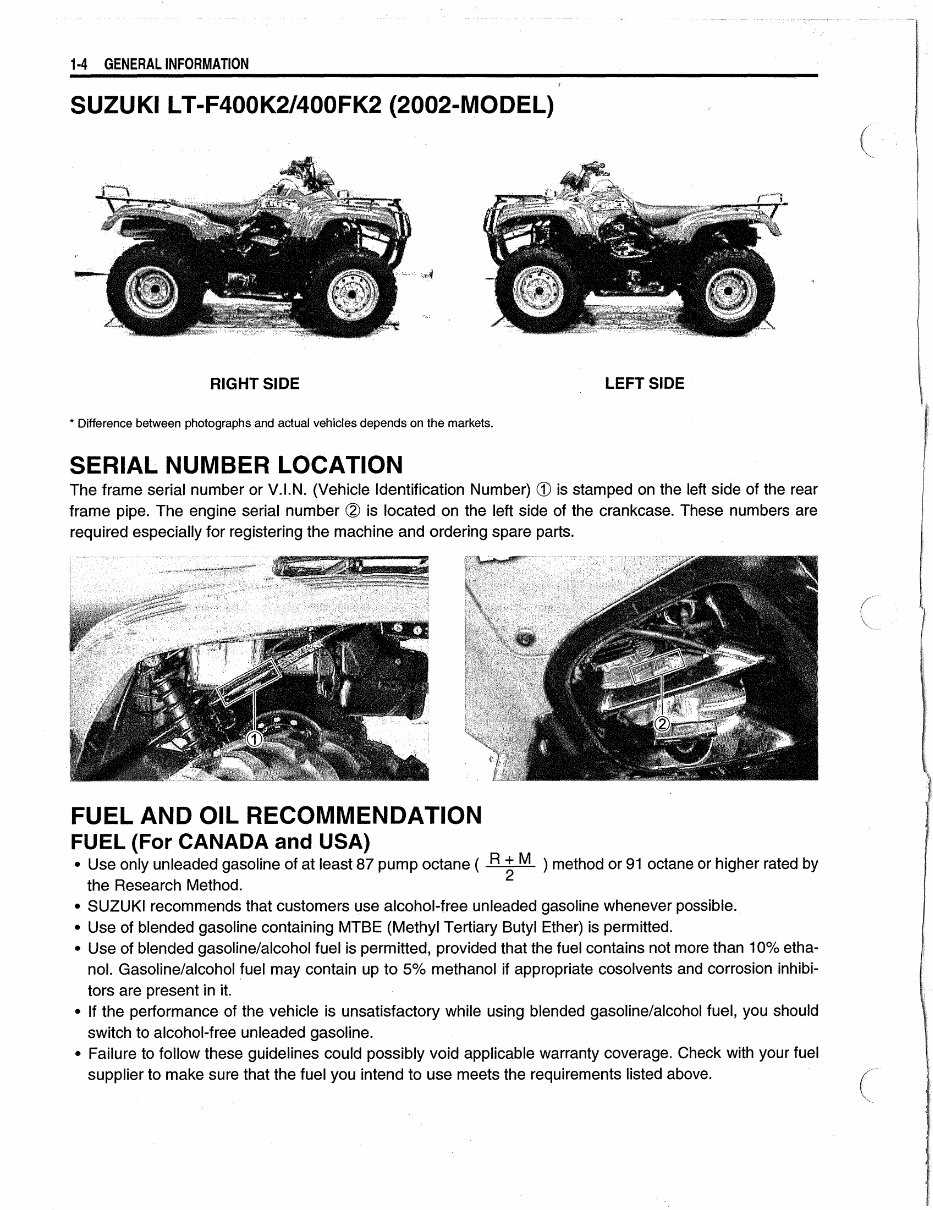

Overview of 2002 Suzuki Eiger 400 4×4

This section provides a comprehensive look at a specific all-terrain vehicle model known for its ruggedness and reliability. It highlights the features that make it suitable for various outdoor activities, as well as its overall performance and design aspects.

Key Features

The vehicle is equipped with a powerful engine that delivers exceptional torque, ensuring it can handle tough terrains with ease. Its sturdy frame and suspension system enhance stability, allowing for a smooth ride even on uneven surfaces. The design incorporates user-friendly controls, making it accessible for both novice and experienced riders.

Performance and Utility

Known for its versatility, this machine is ideal for both recreational and work purposes. It boasts impressive towing capabilities, making it suitable for hauling equipment or trailers. Additionally, the efficient fuel system maximizes range, providing riders the ability to explore remote areas without frequent refueling.

Key Components and Their Functions

Understanding the essential elements of an all-terrain vehicle is crucial for optimal performance and maintenance. Each component plays a significant role in the overall functionality, contributing to a seamless driving experience. Below are some of the vital parts and their respective functions.

- Engine: The heart of the vehicle, responsible for generating power and enabling movement.

- Transmission: This mechanism transfers power from the engine to the wheels, allowing for speed control and direction changes.

- Suspension System: Aids in absorbing shocks and maintaining stability while traversing uneven terrain.

- Braking System: Ensures safe stopping by providing the necessary friction to slow down or halt the vehicle.

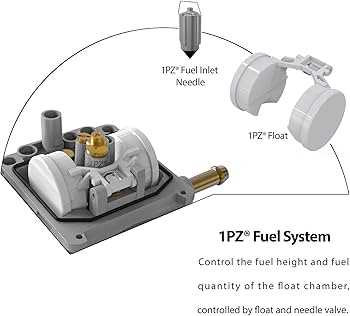

- Fuel System: Delivers the required fuel to the engine, supporting efficient combustion and performance.

- Electrical System: Powers essential components like lights, ignition, and various electronic features within the vehicle.

- Exhaust System: Channels harmful gases away from the engine and reduces emissions for a cleaner operation.

Each of these parts is interconnected, and understanding their functions can aid in troubleshooting issues, enhancing the lifespan of the vehicle, and ensuring a reliable ride.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficient functioning of your vehicle. By adhering to a systematic maintenance routine, you can prevent unexpected issues and enhance overall performance. Below are some key strategies to help maintain optimal condition.

- Regular Oil Changes: Changing the oil at recommended intervals helps lubricate engine components and prevent wear.

- Check Fluid Levels: Regularly inspect and top off essential fluids, including coolant, brake fluid, and transmission fluid.

- Tire Maintenance: Ensure proper tire pressure and tread depth to enhance handling and fuel efficiency.

- Brake System Inspection: Regularly check brake pads, rotors, and fluid to ensure safe stopping power.

- Air Filter Replacement: Replacing the air filter as needed promotes optimal airflow to the engine and improves fuel efficiency.

Additionally, keeping an eye on the electrical system and battery health can prevent electrical failures. Performing routine checks and addressing issues promptly will lead to a more reliable driving experience.

- Inspect Belts and Hoses: Look for any signs of wear or cracking and replace them as necessary.

- Regularly Clean the Vehicle: Keeping the exterior and interior clean protects against corrosion and wear.

- Follow the Manufacturer’s Maintenance Schedule: Adhering to guidelines provided in the owner’s manual ensures that important tasks are not overlooked.

By implementing these practices, you can enhance the performance and reliability of your machine, ensuring a smoother and more enjoyable ride.

Identifying Common Wear Issues

Understanding the signs of wear and tear is essential for maintaining optimal performance and longevity of your all-terrain vehicle. Over time, various components may experience fatigue, leading to potential operational problems. Recognizing these issues early can prevent more significant damage and costly repairs.

Typical Areas of Concern

Several components are particularly prone to wear, including the suspension system, brakes, and drive train. The suspension is crucial for stability and comfort, so inspect for any signs of damage or deterioration. Check for fluid leaks, as these can indicate failing seals or worn components. The braking system also requires attention; worn pads and discs can significantly affect safety and control. Lastly, the drive train should be monitored for unusual noises or vibrations, which may signal a need for maintenance.

Preventative Measures

Regular inspections and routine maintenance are key to mitigating wear. Cleaning and lubricating moving parts can help reduce friction and prolong component life. Additionally, adhering to recommended service intervals for fluids and filters can enhance overall performance and reliability. Being proactive in addressing minor issues can save time and resources in the long run.

Understanding the Parts Diagram

This section aims to elucidate the visual representation of components found in a specific utility vehicle. By interpreting these illustrations, users can gain valuable insights into the structure and arrangement of essential elements, facilitating more effective maintenance and repairs. A comprehensive grasp of these visuals empowers individuals to identify and understand the function of various pieces within the machine.

Such illustrations serve as vital tools for both novices and experienced enthusiasts. They provide clarity on the interconnectivity of each segment, illustrating how they work together to ensure optimal performance. Engaging with these resources can lead to enhanced troubleshooting skills, allowing for quicker identification of issues and appropriate solutions.

Moreover, familiarizing oneself with these representations fosters confidence when sourcing replacements or upgrades. Understanding the layout and specifications of components ensures that users make informed decisions, ultimately contributing to the longevity and reliability of their machinery.

Upgrading Parts for Enhanced Capability

Enhancing the performance and functionality of your vehicle can significantly improve its overall capability. By focusing on specific components, you can achieve better handling, increased power, and greater durability. This section will explore various upgrades that can elevate your machine’s capabilities, ensuring it can tackle any terrain or challenge with ease.

Key Areas for Enhancement

- Suspension System: Upgrading the suspension can provide better stability and comfort. Consider options such as adjustable shocks or heavy-duty springs.

- Engine Performance: Enhancing the engine with aftermarket components, such as performance air filters and exhaust systems, can increase horsepower and torque.

- Tires and Wheels: Investing in high-quality, off-road tires can improve traction and handling. Lightweight alloy wheels can also reduce unsprung weight, enhancing performance.

Installation Tips

- Research compatible upgrades to ensure proper fit and functionality.

- Consult a professional mechanic for installation if you lack the necessary skills or tools.

- Regularly maintain and inspect upgraded components to ensure longevity and reliability.

By carefully selecting and upgrading crucial components, you can significantly enhance the overall performance and capability of your vehicle, allowing you to conquer new challenges with confidence.

How to Access Replacement Parts

Finding the right components for your vehicle is essential for maintaining its performance and longevity. Understanding where to look and how to obtain these items can significantly streamline the repair process. Here are several effective methods for sourcing necessary replacements.

Authorized Dealers

One of the most reliable ways to access genuine components is through authorized dealerships. These establishments typically offer:

- Original manufacturer items that ensure compatibility.

- Expert advice from knowledgeable staff regarding installation and maintenance.

- Warranty options for added peace of mind.

Online Retailers

The internet provides a vast selection of suppliers where you can find both new and used components. When shopping online, consider the following:

- Research reputable websites with positive reviews.

- Verify return policies and shipping options to avoid complications.

- Check for compatibility information to ensure the selected items fit your vehicle model.

By utilizing these resources, you can efficiently locate the necessary replacements to keep your vehicle in optimal condition.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right tools at your disposal is crucial for achieving optimal results. The following items can significantly streamline the process and ensure that repairs are conducted efficiently and effectively.

Essential Hand Tools

A variety of hand tools are necessary for performing basic tasks. Commonly used implements include wrenches, screwdrivers, and pliers. These tools allow for easy manipulation of fasteners and components, making it simpler to access and replace worn or damaged parts.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be required. For instance, socket sets are invaluable for dealing with larger bolts and nuts, while torque wrenches help ensure that all fasteners are tightened to the manufacturer’s specifications. Furthermore, an oil filter wrench can make the process of changing fluids much more straightforward.

Step-by-Step Repair Procedures

This section outlines a systematic approach to troubleshooting and fixing common issues in an all-terrain vehicle. By following these detailed steps, you can ensure effective repairs while minimizing the risk of errors. Each procedure emphasizes the importance of proper tools and safety precautions to achieve optimal results.

Preparation and Safety Measures

Before starting any repair, gather the necessary tools and parts, ensuring that everything is in working order. It’s essential to wear appropriate safety gear, including gloves and goggles, to protect yourself during the process. Make sure to work in a well-ventilated area and consult the owner’s manual for specific guidelines related to your vehicle.

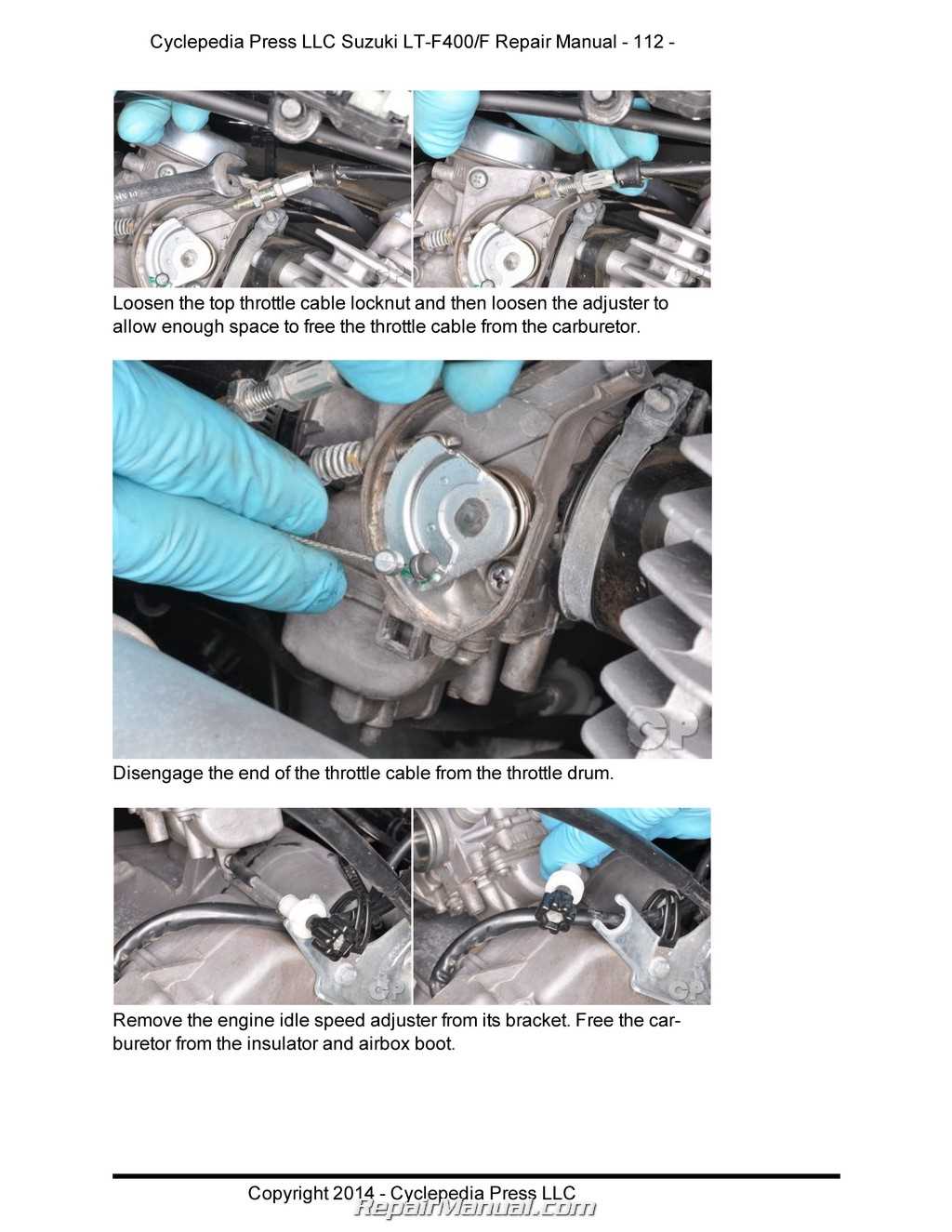

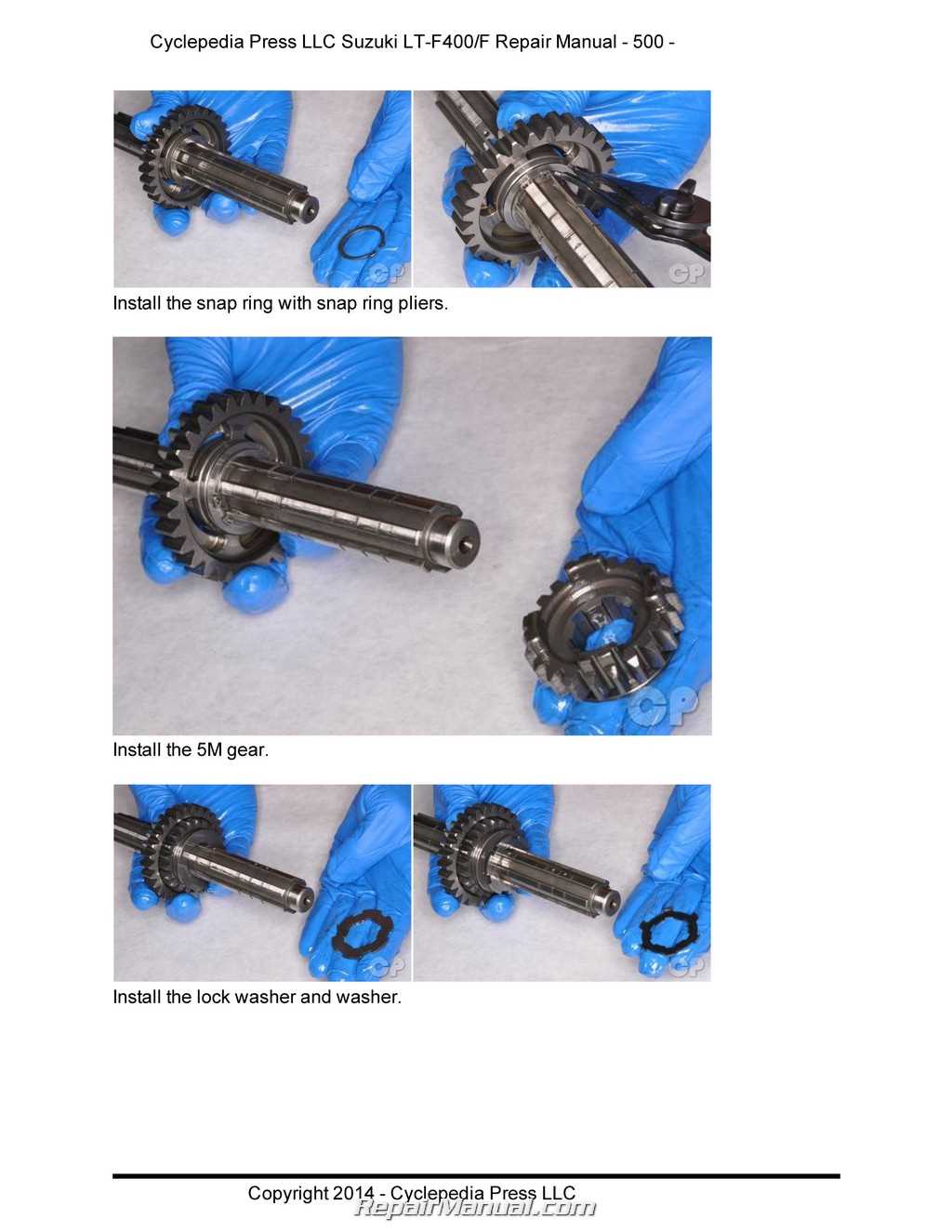

Disassembly and Inspection

Begin by carefully removing the components that need attention. Take note of the arrangement and connections of each part to facilitate reassembly. Inspect each component for wear or damage, documenting any issues that require further action. Cleaning parts before reassembly can enhance performance and longevity.

Safety Guidelines During Maintenance

Ensuring safety during upkeep and repairs is crucial for both the individual performing the work and the equipment itself. Adhering to proper protocols can prevent accidents, enhance the longevity of the machinery, and ensure optimal performance. Following these guidelines will help create a secure environment for maintenance tasks.

Preparation and Planning

- Review the owner’s manual for specific safety instructions related to the equipment.

- Gather all necessary tools and replacement components before beginning work.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

Safe Work Practices

- Always perform maintenance on a flat, stable surface to prevent accidents.

- Ensure the engine is turned off and cool before starting any work.

- Disconnect the battery to prevent accidental starts while servicing electrical components.

- Use jack stands or ramps when lifting the equipment to ensure it is secure and stable.

- Keep the work area clean and free of clutter to minimize hazards.

By following these guidelines, individuals can help ensure a safe and efficient maintenance experience, contributing to the reliable operation of the machinery.

Where to Find Expert Advice

When seeking guidance for maintenance and repairs, it’s essential to tap into reliable resources. Expert insights can significantly enhance your understanding and ensure that you make informed decisions regarding your vehicle’s upkeep. Whether you’re looking for troubleshooting tips or detailed instructions, various avenues are available to assist you.

Online Forums and Communities

Engaging with online forums dedicated to off-road enthusiasts can be highly beneficial. These platforms often host discussions where experienced individuals share their knowledge and experiences. By participating in these communities, you can ask specific questions and receive tailored advice from those who have faced similar challenges.

Professional Workshops and Manuals

Consulting professional service manuals or guides can provide in-depth information about maintenance procedures. These resources often include illustrations and detailed descriptions that can help clarify complex processes. Additionally, attending workshops led by qualified technicians can offer hands-on experience and expert tips, further enriching your understanding.