In the realm of mechanical systems, comprehending the intricate details of a power unit is essential for effective maintenance and repair. This section aims to illuminate the various elements that work in harmony to ensure optimal performance and longevity. By examining these components, one can gain insights into their roles and interconnections.

Visualization of these elements is crucial for troubleshooting and enhancing efficiency. An organized representation not only simplifies identification but also aids in understanding how each part contributes to the overall functionality. A detailed overview empowers technicians and enthusiasts alike to engage more confidently with the machinery.

Through careful analysis and exploration of these essential features, readers will discover the ultimate guide to mastering the complexities of their power units. This knowledge serves as a foundation for informed decision-making and effective problem-solving in the field.

Kubota D600 Engine Overview

This section provides a comprehensive look at a specific type of power unit renowned for its reliability and performance. Designed for various applications, it is a favored choice among operators seeking efficiency and durability. Understanding its components and functionality can significantly enhance maintenance and operational knowledge.

Key Features

The unit boasts several distinctive characteristics that contribute to its exceptional performance. Notable attributes include a robust construction, efficient fuel consumption, and ease of maintenance. These qualities make it suitable for both commercial and agricultural uses, allowing for versatile applications.

Applications

This versatile power source finds utility in numerous fields, from construction machinery to agricultural equipment. Its adaptability ensures that it meets the demands of various operational environments, providing reliability when it is needed most.

Key Features of D600 Engine

This section explores the remarkable characteristics that define this power unit, highlighting its efficiency and reliability. Understanding these features can enhance your appreciation for its engineering excellence and operational capabilities.

Compact Design

The compact layout allows for easy integration into various machinery. Its space-saving architecture does not compromise performance, making it suitable for diverse applications.

Fuel Efficiency

One of the standout attributes is its exceptional fuel economy. Optimized combustion processes ensure that energy is harnessed effectively, reducing operational costs while maximizing output. This efficiency contributes to a lower environmental impact.

Additionally, durability is a key aspect, as the robust construction withstands demanding conditions, ensuring longevity and reduced maintenance needs.

Understanding Engine Components

Grasping the intricacies of mechanical systems is essential for optimal performance and longevity. Each unit plays a vital role in the overall functionality, contributing to efficiency and reliability. Familiarity with these elements empowers users to maintain and troubleshoot effectively.

The fundamental components can be categorized as follows:

- Power Generation: This group includes items responsible for converting fuel into motion.

- Movement Control: Components that regulate the flow of energy and direction.

- Cooling System: Elements designed to manage heat and prevent overheating.

- Lubrication: Parts that reduce friction and wear between moving surfaces.

Understanding the function of each segment aids in recognizing potential issues before they escalate. Regular inspection and maintenance of these units can significantly enhance overall system performance.

Main Parts and Their Functions

Understanding the core components of a mechanical unit is essential for effective maintenance and optimal performance. Each element plays a crucial role, contributing to the overall functionality and efficiency of the system. Below, we explore the primary components and their respective roles.

Cylinder Block: This is the main structure that houses the combustion chambers and supports various internal components. It provides the foundation for the unit’s operation.

Piston: A vital component that moves up and down within the cylinder, facilitating the intake and exhaust processes. Its movement converts combustion energy into mechanical force.

Cylinder Head: This component covers the top of the cylinder block and contains important features like valves and spark plugs. It ensures proper sealing and aids in the combustion process.

Crankshaft: This part transforms the linear motion of the piston into rotational motion, ultimately powering the entire system. Its design is critical for maintaining balance and reducing vibrations.

Camshaft: Responsible for controlling the timing of valve openings and closings, the camshaft is essential for efficient airflow in and out of the combustion chambers.

Fuel Injector: This component atomizes the fuel and delivers it into the combustion chamber, ensuring optimal mixing with air for efficient combustion.

Cooling System: Comprising various elements, this system regulates temperature, preventing overheating and maintaining performance during operation.

Each of these components interacts seamlessly to ensure the smooth operation of the mechanical system, highlighting the importance of regular checks and maintenance for longevity and efficiency.

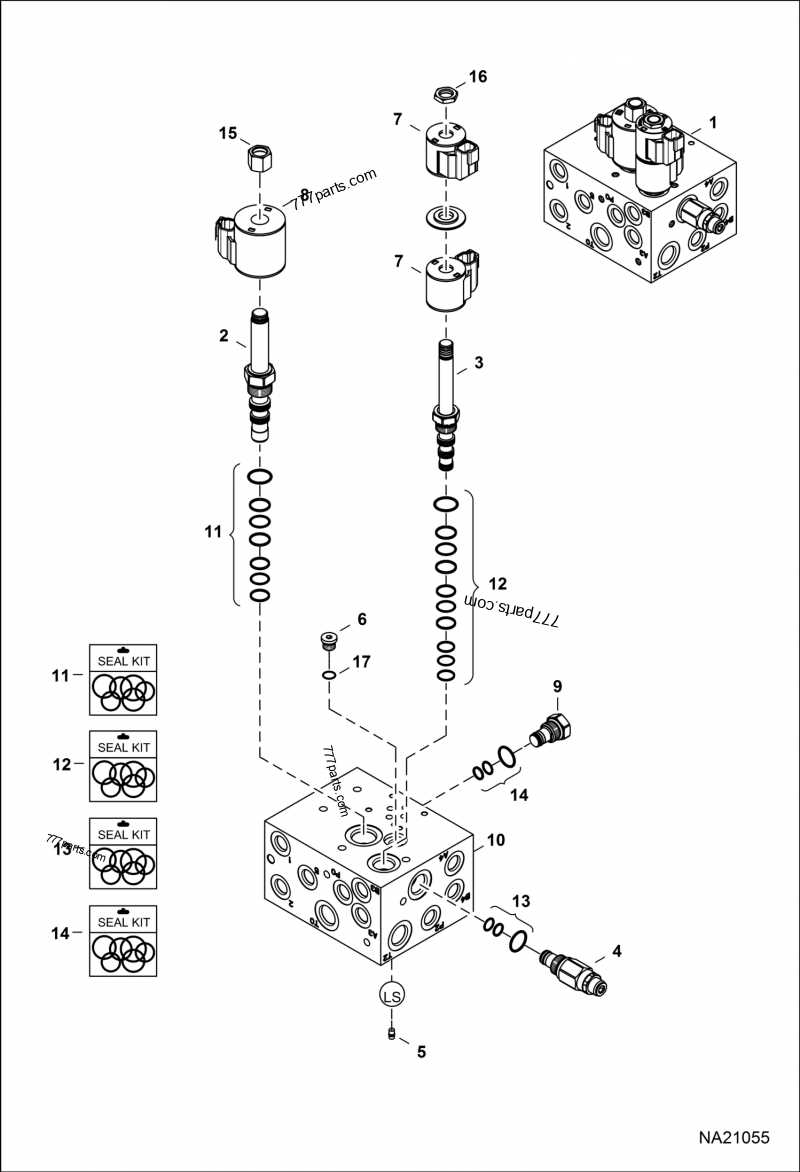

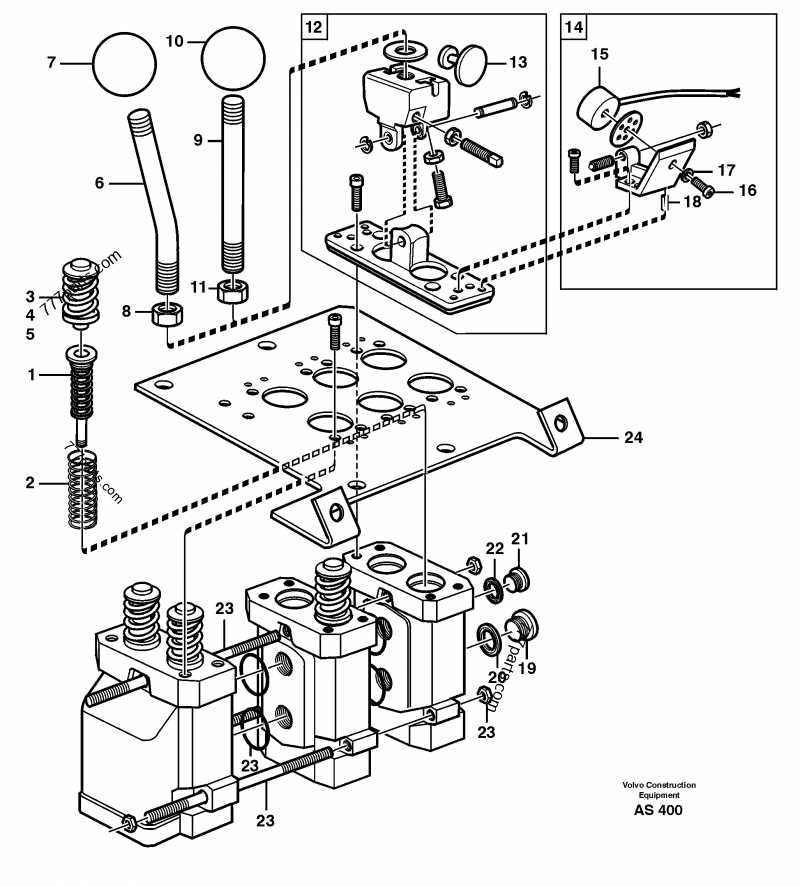

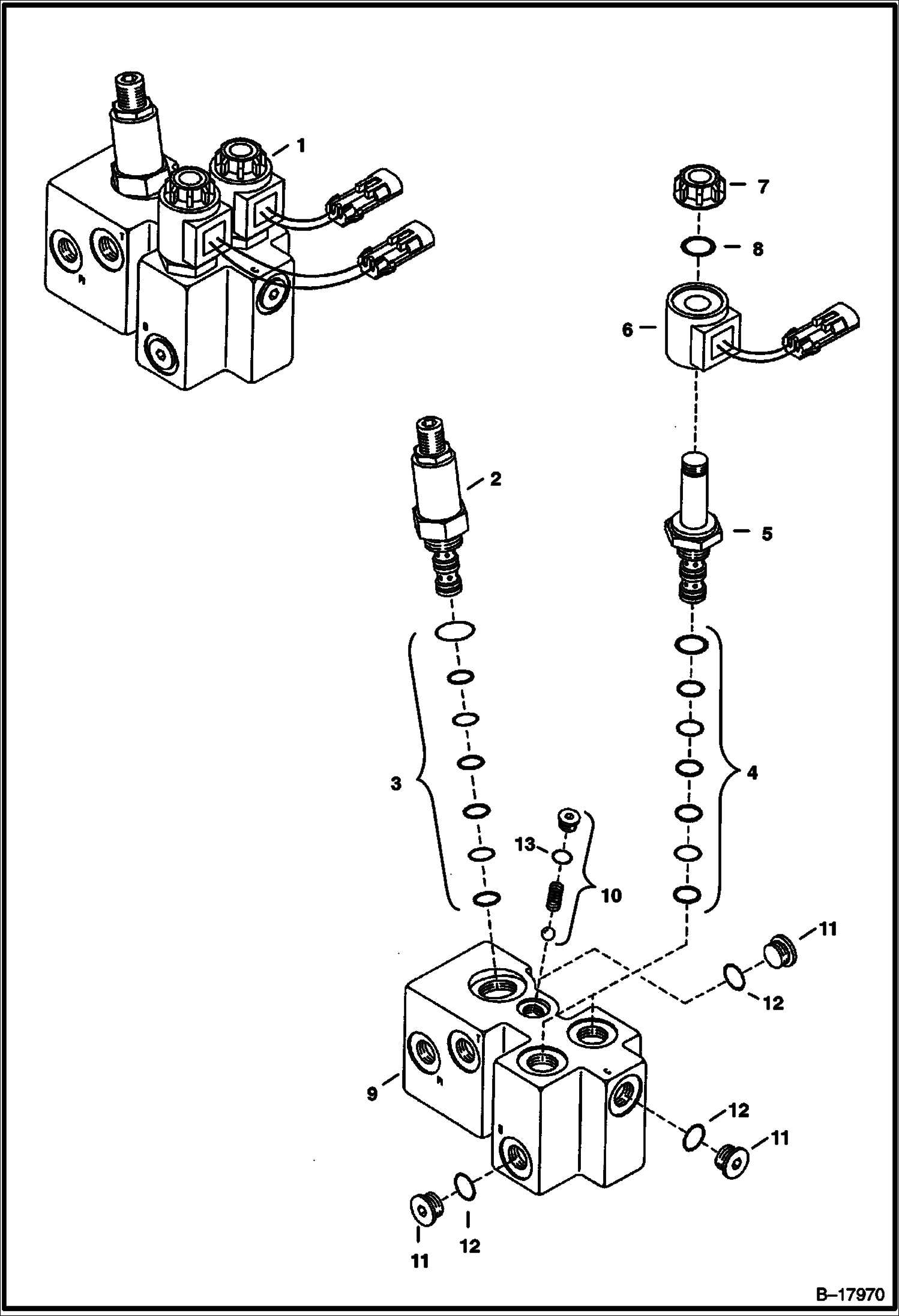

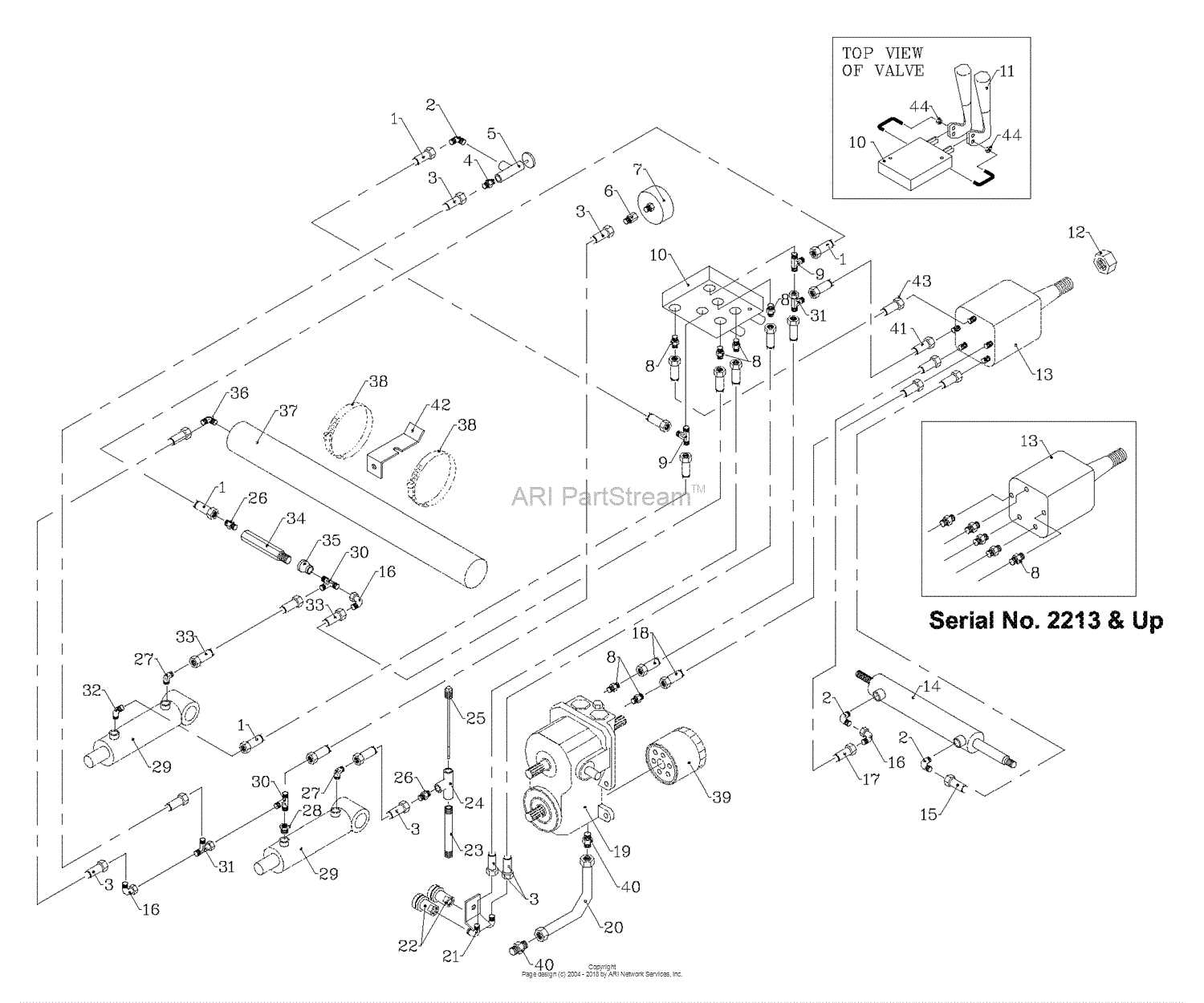

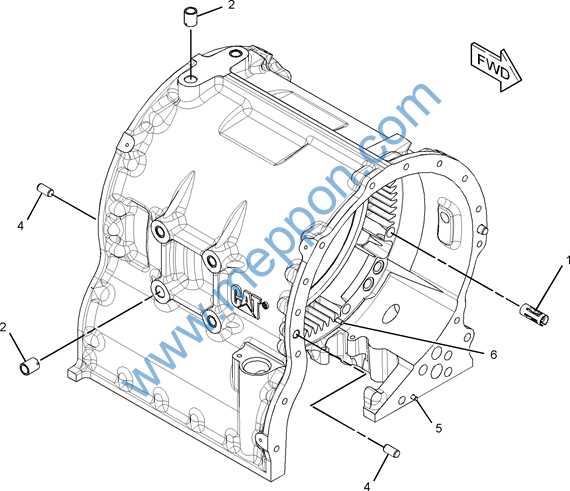

Importance of Engine Diagrams

Visual representations of mechanical systems are essential tools for understanding the intricate relationships between various components. They serve as invaluable resources for both professionals and enthusiasts, facilitating better comprehension of how individual elements work together. By providing clarity and enhancing communication, these visuals play a crucial role in maintenance, troubleshooting, and education.

Moreover, having access to accurate illustrations allows for efficient repairs and upgrades. Technicians can quickly identify potential issues, minimizing downtime and ensuring optimal performance. Furthermore, detailed depictions support learning, making it easier for newcomers to grasp complex concepts and develop their skills.

In summary, these graphical tools not only streamline processes but also foster a deeper appreciation for the mechanics involved, ultimately leading to enhanced reliability and innovation in the field.

How to Read Engine Diagrams

Understanding visual representations of mechanical assemblies is crucial for anyone working with machinery. These illustrations serve as valuable guides, providing insights into the components and their interconnections. Mastering how to interpret these visuals can significantly enhance your troubleshooting and repair skills.

Key Components to Identify

- Symbols: Familiarize yourself with common symbols used in illustrations. Each symbol typically represents a specific element, such as a valve or a piston.

- Labels: Pay attention to labels that indicate the names or functions of various components. These can provide essential information about the assembly.

- Connections: Observe how parts are connected. Lines often represent mechanical linkages or fluid pathways, which are vital for understanding functionality.

Steps for Effective Reading

- Start by reviewing the legend or key, if available. This will clarify any symbols or abbreviations used.

- Identify the main components before diving into details. This will help you grasp the overall structure.

- Follow the flow of the illustration systematically. Look for arrows or lines that indicate movement or interaction between parts.

By honing your ability to read these visuals, you’ll improve your capacity to diagnose issues and execute repairs efficiently.

Common Issues with D600 Engines

Various challenges can arise with this type of machinery, often stemming from wear and tear or improper maintenance. Understanding these potential problems can help operators take proactive measures to enhance performance and longevity.

Frequent Problems

Operators may encounter issues such as overheating, reduced power output, or fuel inefficiency. Regular inspections and timely repairs are crucial to prevent these complications from escalating.

Maintenance Tips

Adhering to a structured maintenance schedule can significantly reduce the likelihood of encountering severe malfunctions. Key areas to focus on include lubrication, filter replacements, and cooling system checks.

| Issue | Symptoms | Solutions |

|---|---|---|

| Overheating | High temperature readings, steam | Check coolant levels, inspect radiator |

| Power Loss | Slow acceleration, poor response | Examine fuel system, clean air filters |

| Fuel Inefficiency | Frequent refueling, low mileage | Regular maintenance, use quality fuel |

Maintenance Tips for Longevity

Ensuring the long-lasting performance of machinery requires a commitment to regular care and attention. Implementing effective maintenance strategies can significantly enhance the reliability and efficiency of your equipment over time. This section outlines essential practices that can help you achieve optimal performance and extend the lifespan of your machinery.

Regular Inspections

Conducting routine assessments is crucial for identifying potential issues before they escalate. Consider the following:

- Check fluid levels regularly to ensure optimal functioning.

- Inspect filters and replace them as necessary to maintain cleanliness.

- Look for signs of wear or damage in components and address them promptly.

Proper Cleaning

Keeping your equipment clean can prevent dirt and debris from causing significant damage. Follow these cleaning tips:

- Use appropriate cleaning agents to remove grime without harming surfaces.

- Pay special attention to cooling systems and air intake areas.

- Ensure all vents and drains are clear to promote proper airflow.

Where to Find Replacement Parts

Finding suitable components for machinery can be a challenge, but various resources make this task easier. Whether you’re a professional or a hobbyist, knowing where to look can save you time and money.

Online Marketplaces

Numerous online platforms offer a wide selection of components. Websites like eBay and Amazon often have listings from various sellers, allowing you to compare prices and quality. Make sure to check user reviews to ensure reliability.

Specialized Retailers

Visiting retailers that focus on agricultural and industrial equipment is another effective strategy. These businesses often carry a comprehensive inventory and can provide expert advice. Additionally, many of them offer warranties, which can give you peace of mind with your purchase.

Local Repair Shops may also be a valuable resource. They often have connections with suppliers and can help you locate hard-to-find items. Networking within local communities can also lead to recommendations for reliable sources.

Benefits of Genuine Kubota Parts

Using authentic components offers numerous advantages that enhance the overall performance and longevity of machinery. These elements are designed with precision, ensuring compatibility and efficiency that aftermarket alternatives often fail to deliver.

Quality Assurance

Genuine components are manufactured to meet strict quality standards. This ensures reliability and reduces the likelihood of failures, ultimately saving time and money on repairs.

Optimal Performance

When utilizing authentic items, users can expect peak functionality. These components are engineered specifically for their intended use, providing superior performance and enhancing the overall operational capacity of the equipment.

Aftermarket vs. OEM Components

When it comes to selecting replacement items for machinery, the choice between original manufacturer components and those produced by third-party suppliers is crucial. Understanding the differences in quality, cost, and performance can significantly influence maintenance strategies and overall operational efficiency.

Advantages of OEM Components

- Designed specifically for compatibility with your machinery.

- Manufactured under strict quality control standards.

- Often come with warranties that ensure reliability.

Benefits of Aftermarket Options

- Tend to be more cost-effective, offering significant savings.

- May provide enhanced features or improved performance.

- Available from a wide range of suppliers, increasing accessibility.

Ultimately, the decision should be based on the specific needs and preferences of the user, balancing cost with quality and performance requirements.

Using Diagrams for Repairs

Visual aids play a crucial role in simplifying complex maintenance tasks. By utilizing illustrations, technicians can quickly identify components and their interconnections, leading to more efficient troubleshooting and repairs. Such tools not only enhance understanding but also minimize the risk of errors during assembly or disassembly.

Benefits of Visual Aids

Clarity: Illustrations provide a clear representation of intricate systems, making it easier to locate specific items.

Improved Efficiency

Utilizing visual tools saves time by allowing users to follow a structured approach, reducing the likelihood of missteps and ensuring a smoother repair process.