Understanding the various elements of a high-performance table saw is essential for efficient operation and maintenance. These machines are made up of multiple interconnected mechanisms that work together to ensure precise cutting and reliable performance. Whether you are a professional woodworker or a DIY enthusiast, knowing how the components fit and function is key to extending the lifespan of your equipment.

In this section, we will delve into the different mechanisms and features that contribute to the functionality of modern table saws. From the blade assembly to the safety systems, each element plays a crucial role in ensuring smooth and accurate operation. By familiarizing yourself with these details, you can make better decisions about maintenance and upgrades.

Additionally, we will cover the importance of routine checks and adjustments to keep your equipment in peak condition. This knowledge will not only help prevent downtime but also improve

Overview of the Table Saw

This high-performance table saw is a powerful tool designed for professionals and DIY enthusiasts alike. It delivers a combination of precision and durability, making it suitable for a variety of cutting tasks. The machine features a robust build, ensuring stability and accuracy during operation, while its portable design allows for easy transportation between job sites.

Efficiency is enhanced by the motor, which provides sufficient power for cutting through a wide range of materials, from hardwoods to sheet goods. The saw is equipped with safety mechanisms that protect the user without compromising performance. Additionally, adjustable features allow for precise cuts, making it versatile for different applications.

Whether you’re working on construction projects or fine woodworking, this tool offers a reliable solution for achieving professional results with ease.

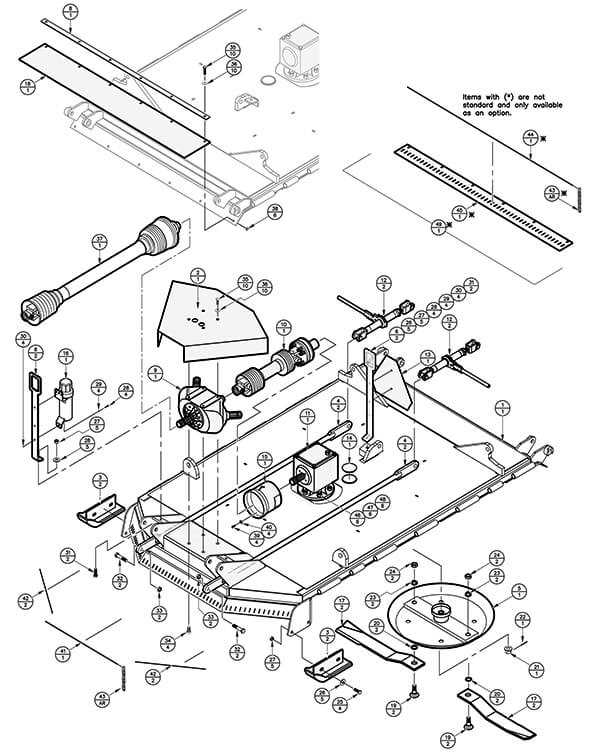

Main Components of the DWE7491RS

The key elements of this table saw are designed to ensure both precision and efficiency during operation. Each component plays a critical role in enhancing cutting performance and user safety, making the system both reliable and versatile for a variety of woodworking tasks.

| Component | Description | |||||||

|---|---|---|---|---|---|---|---|---|

| Motor Assembly | A powerful drive system that delivers high-speed rotations for clean and efficient cutting of various materials. | |||||||

| Rip Fence | This adjustable guide helps maintain straight and accurate cuts along the material’s length, ensuring consistent results. | |||||||

| Blade Guard | A protective cover that enhances safety by preventing contact with the spinning blade during operation. | |||||||

Blade Assembly and Installation GuideThe proper installation of the blade assembly is crucial for ensuring optimal performance and safety during operation. Understanding the steps involved in securely attaching the blade and checking its alignment can help you achieve smooth, efficient cutting. This guide will walk you through the process, highlighting the key actions to take and the tools required for a successful setup. Step 1: Before beginning, make sure the power to the tool is completely disconnected to avoid any accidental activation. Gather the necessary wrenches and other tools needed for the process. Step 2: Carefully position the blade onto the spindle, ensuring that the teeth are facing in the correct direction for the type of material you will be cutting. Use an appropriate washer to secure the blade Fence System: Key FeaturesThe fence system plays a crucial role in ensuring precision and stability during woodworking tasks. It provides reliable alignment, allowing for accurate cuts while maintaining the workpiece securely in place. This section will highlight the essential characteristics that make a high-quality fence system efficient and easy to use. Precision and Adjustability

One of the standout features of a good fence system is its precise alignment capabilities. The system should offer fine-tuning adjustments to ensure the material is perfectly positioned before each cut. This level of control enhances the accuracy and overall quality of your projects. Sturdiness and DurabilityA well-built fence system must also be robust and durable to withstand long-term use. Stability is key, as it helps maintain consistent results over time. Look for sys Motor Housing and Maintenance TipsProper care of the motor housing is crucial for ensuring long-term functionality and efficiency. Regular inspections and cleanings can help prevent wear and tear, while specific maintenance practices can extend the life of the tool’s components. Below are some essential tips to maintain the motor housing effectively. Inspecting the Motor Housing

Maintenance Routine

Effective onboard storage options are essential for keeping accessories organized and readily accessible during operation. These solutions ensure that users can easily store various tools and attachments without cluttering their workspace, enhancing efficiency and productivity. Incorporating designated compartments or bins within the equipment allows for seamless storage of smaller items such as blades, wrenches, and screws. This organized approach not only saves time when searching for necessary components but also minimizes the risk of losing essential accessories. Additionally, utilizing quick-release mechanisms or magnetic strips can further simplify the retrieval process, making it easier to switch between tasks swiftly. Furthermore, investing in durable storage solutions that withstand regular use can significantly extend the lifespan of both the accessories and the equipment itself. By prioritizing onboard storage, users can maintain an organized workspace that promotes safety and efficiency while working on various projects. Adjusting the Riving Knife for Safety

Ensuring the proper alignment and adjustment of the riving knife is crucial for maintaining safety during woodworking operations. The riving knife serves a critical role in preventing kickback by keeping the kerf open and guiding the workpiece through the cut. Start by checking the alignment of the riving knife with the saw blade to ensure they are parallel. This alignment helps in minimizing binding and ensures smooth operation during cuts. Use the adjustment mechanisms provided to make fine adjustments, ensuring the knife is neither too high nor too low relative to the blade. Additionally, verify that the riving knife is securely fastened and does not wobble during operation. A stable riving knife reduces the risk of material kickback, enhancing overall safety in the workshop environment. Regularly inspect and maintain the riving knife as part of your routine saw maintenance. This includes cleaning it from sawdust buildup and checking for any signs of wear or damage that could affect its functionality. Proper maintenance extends the lifespan of the riving knife and ensures consistent safety performance. Dust Collection Port Setup and UsageEffective dust management is essential for maintaining a clean workspace and ensuring optimal performance of your equipment. Setting up a dust collection system not only improves visibility but also enhances safety by reducing airborne particles. This section outlines the setup process and offers tips for maximizing the system’s efficiency. Setup StepsUsage Tips

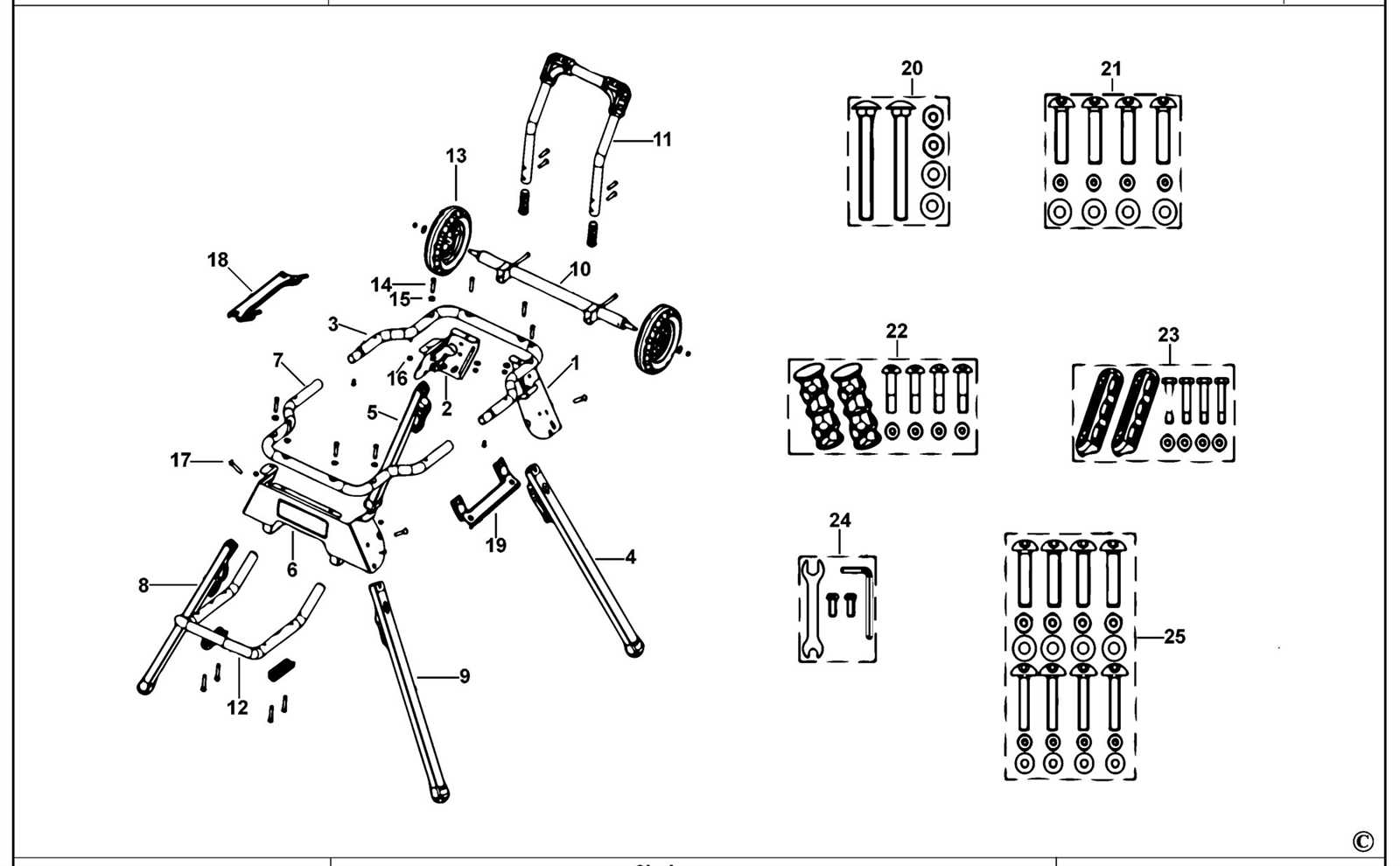

Table Extension Mechanism Explained

The table extension mechanism enhances functionality by providing additional workspace, allowing for more significant projects and improved accuracy. Understanding its components and operation is crucial for optimal use. This mechanism typically includes several key features:

Proper maintenance of these components can significantly extend their lifespan and improve performance. Power Switch and Safety FeaturesThe functionality and user safety of power tools are paramount, especially when dealing with high-performance equipment. A reliable power switch not only ensures ease of operation but also plays a critical role in protecting users from potential hazards. Understanding the various components and safety mechanisms can significantly enhance the overall experience while using these tools. Importance of the Power SwitchThe power switch serves as the primary interface for controlling the tool’s operation. Its design typically emphasizes accessibility and responsiveness, allowing for quick engagement and disengagement. Key aspects include:

Safety MechanismsIn addition to the power switch, various safety features are integrated to minimize risks. These include:

Understanding and utilizing these features can significantly enhance safety and effectiveness, ensuring a smoother operation and longer tool lifespan. Replacing the Throat Plate and BladesEnsuring optimal performance of your equipment often requires periodic replacement of essential components. The throat plate and cutting edges are crucial for achieving precise cuts and maintaining safety during operation. This section will guide you through the process of replacing these key elements effectively. Tools Needed

Step-by-Step ReplacementBegin by unplugging the device to ensure safety. Remove the screws securing the throat plate and lift it out gently. For blade replacement, loosen the bolts using the wrench and remove the old blade. Install the new blade, ensuring it is properly aligned and secured. Finally, reattach the throat plate, ensuring all screws are tightened securely. |