Understanding the key elements of a chainsaw’s internal structure is crucial for efficient maintenance and proper care. Each component has a specific function, working together to ensure the machine operates smoothly and reliably, whether for home or professional use.

This guide explores the various integral parts that make up the cutting tool, highlighting their roles and how they contribute to the overall functionality. We’ll also look into how these elements interact and the importance of each in keeping the equipment in top working condition.

By gaining insights into these essential details, users will be better prepared to perform regular check-ups and replacements, ensuring longer lifespan and optimal performance of their equipment.

Jonsered CS 2150 Parts Diagram

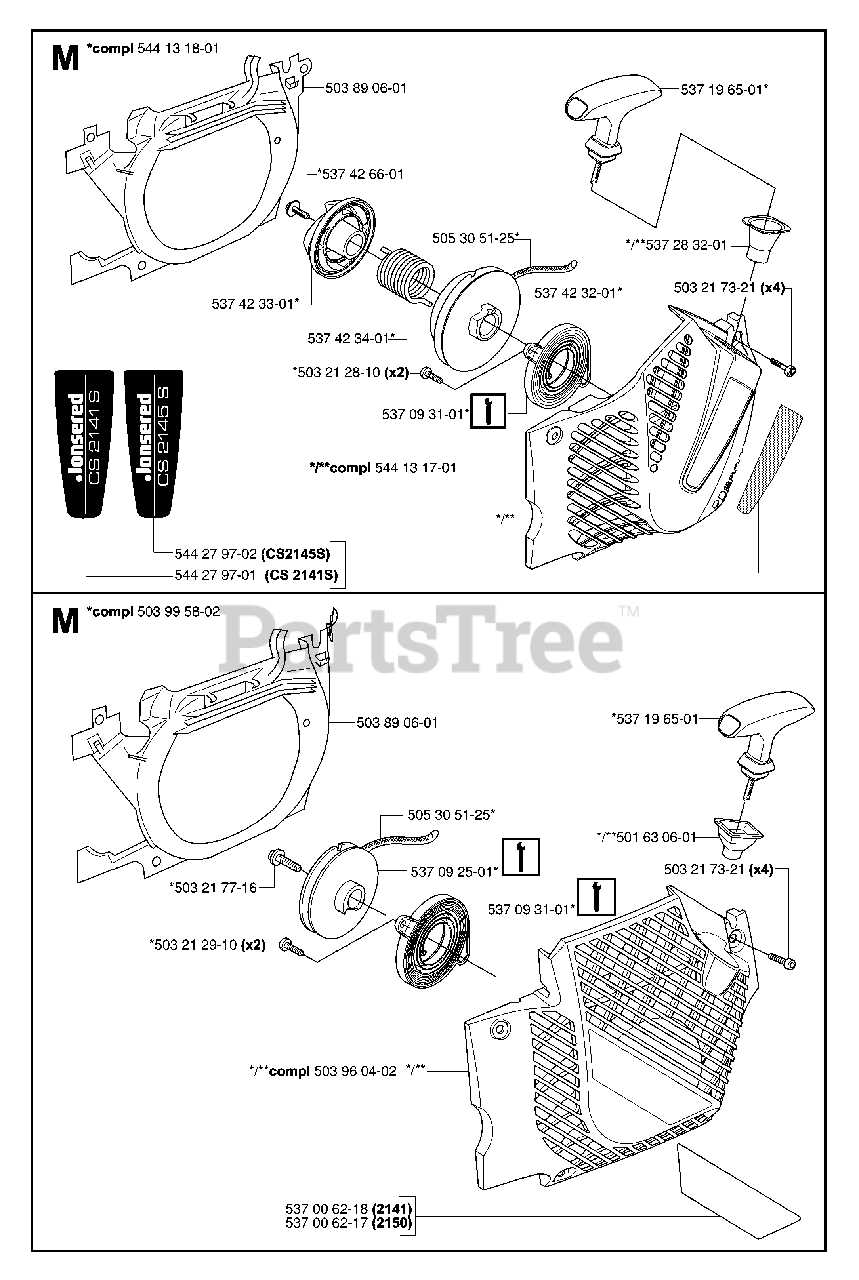

This section provides an overview of the key elements that make up the internal and external structure of this powerful machine. Understanding the various components is essential for proper maintenance and repairs. Each part has a specific role that contributes to the overall performance, ensuring smooth and efficient operation.

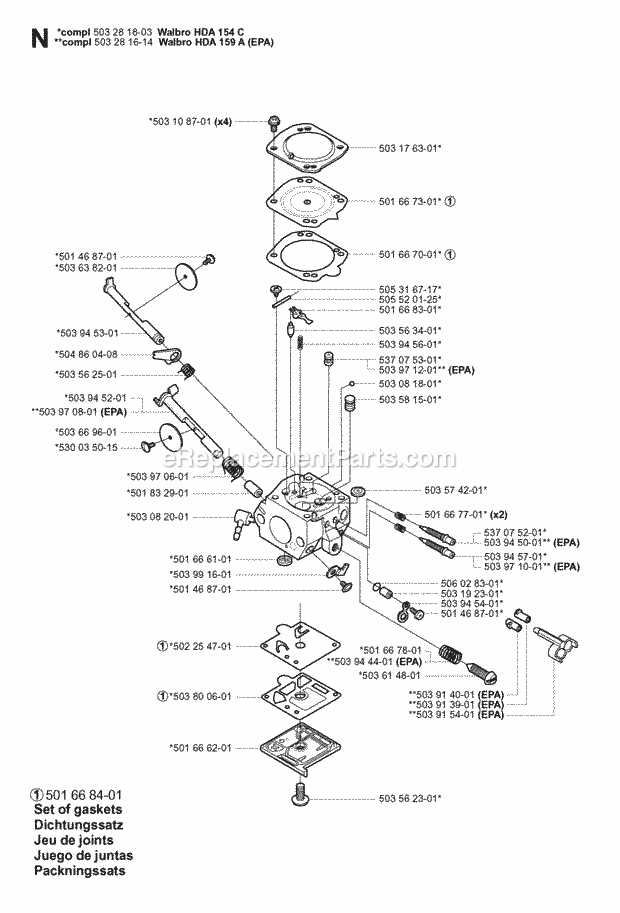

Engine and Mechanical Components

The heart of this model is its engine, surrounded by several critical mechanical elements. These include items responsible for fuel intake, exhaust, and overall power generation. Proper functioning of these systems is crucial to maintain efficiency and power output. Regular upkeep of these areas can p

Understanding Key Components of the Chainsaw

In order to properly maintain and use a chainsaw, it is essential to become familiar with its critical mechanisms. These components ensure smooth operation, safety, and overall performance of the tool.

Engine: The core of the machine, responsible for powering the cutting action, is a robust motor designed to handle high levels of stress and workload. A well-maintained engine directly impacts the chainsaw’s efficiency.

Guide Bar: This elongated metal structure guides the cutting chain during operation, providing stability and precision. Proper care of the guide bar ensures it remains free from wear and damage.

Cutting Chain: The sharpened loop responsible for the actual cutting. Regular sharpening and tension adjustments are necessary to keep th

How to Identify Wear and Tear

Recognizing the signs of deterioration is crucial for maintaining the efficiency and safety of your equipment. Various components can exhibit wear over time due to regular use and environmental factors. Understanding how to identify these signs will help you take appropriate action before more serious issues arise.

Visual Inspection

Conducting a thorough visual examination can reveal many indicators of wear. Look for the following:

- Cracks: Inspect parts for visible cracks or breaks that may compromise their integrity.

- Discoloration: Check for unusual color changes that could suggest overheating or material fatigue.

- Surface Damage: Notice any scratches, gouges, or rough patches that indicate excessive wear.

Functional Testing

In addition to visual checks, performing functional tests can help you assess the condition of different components:

- Operational Efficiency: Monitor how smoothly the equipment operates. Unusual noises or decreased performance can signal wear.

- Mobility: Ensure that all moving parts function without resistance. Any sticking or jamming should be addressed immediately.

- Fluid Leaks: Check for any leaks in hydraulic or lubrication systems, as these can indicate worn seals or gaskets.

Proper Maintenance for Longevity

Ensuring the durability of any mechanical equipment requires consistent care and attention. By implementing a systematic approach to upkeep, one can significantly enhance the performance and lifespan of the machinery. This section outlines essential practices that promote reliability and efficiency, ultimately safeguarding your investment.

Routine Checks and Cleaning

Regular inspections and cleaning are fundamental to maintaining optimal functionality. Debris accumulation can lead to performance issues and damage over time. It is advisable to adhere to a maintenance schedule that includes the following:

| Maintenance Task | Frequency |

|---|---|

| Inspect filters and air intakes | Every 10 hours of use |

| Clean exterior surfaces | After each use |

| Check fuel and oil levels | Before each use |

| Examine spark plug condition | Every 20 hours of use |

Seasonal Maintenance Practices

Seasonal tasks are crucial for ensuring that the equipment performs well throughout the year. During transitions between usage periods, focus on thorough inspections and necessary replacements to avoid potential breakdowns:

| Task | Season |

|---|---|

| Change oil and filter | Spring and Autumn |

| Sharpen cutting components | Before heavy usage |

| Store in a dry, safe place | During off-season |

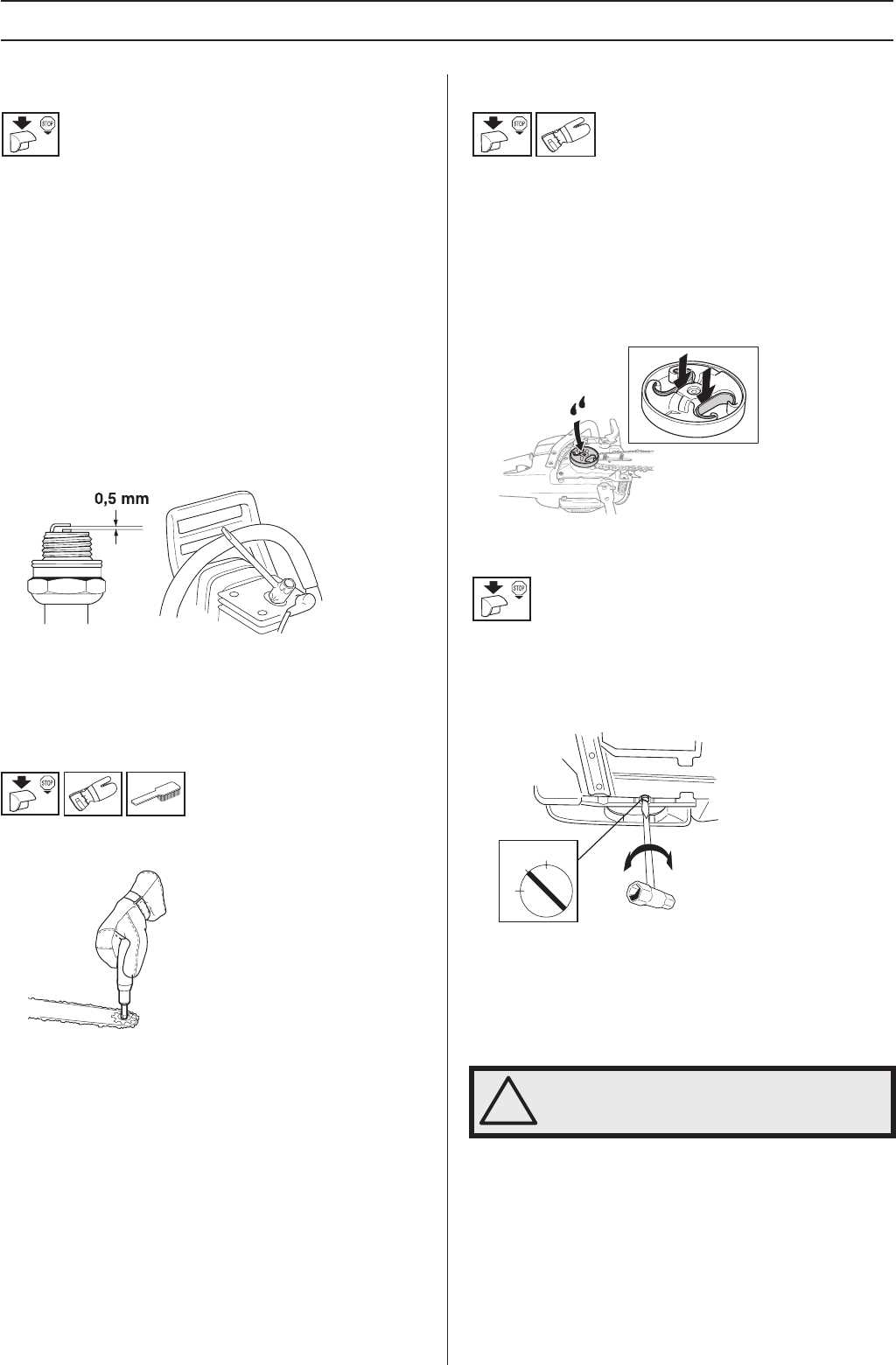

Assembly Guide for Chainsaw Parts

This section provides a comprehensive overview of how to assemble the components of a cutting tool effectively. Proper assembly is crucial for optimal performance and safety, ensuring that all elements fit together seamlessly for efficient operation.

When putting together the various components, it’s important to follow a systematic approach. Below is a simplified table outlining the essential steps and components involved in the assembly process.

| Step | Description |

|---|---|

| 1 | Begin by securing the handle and ensuring it is firmly attached to the main body. |

| 2 | Next, align the blade guard with the body, making sure it is positioned correctly for safety. |

| 3 | Attach the cutting chain, ensuring it is taut and properly positioned on the sprocket. |

| 4 | Finally, check all screws and bolts to ensure they are tightened securely, verifying that everything is in place. |

Following these steps will help ensure that the assembly process is smooth and that the tool operates safely and effectively.

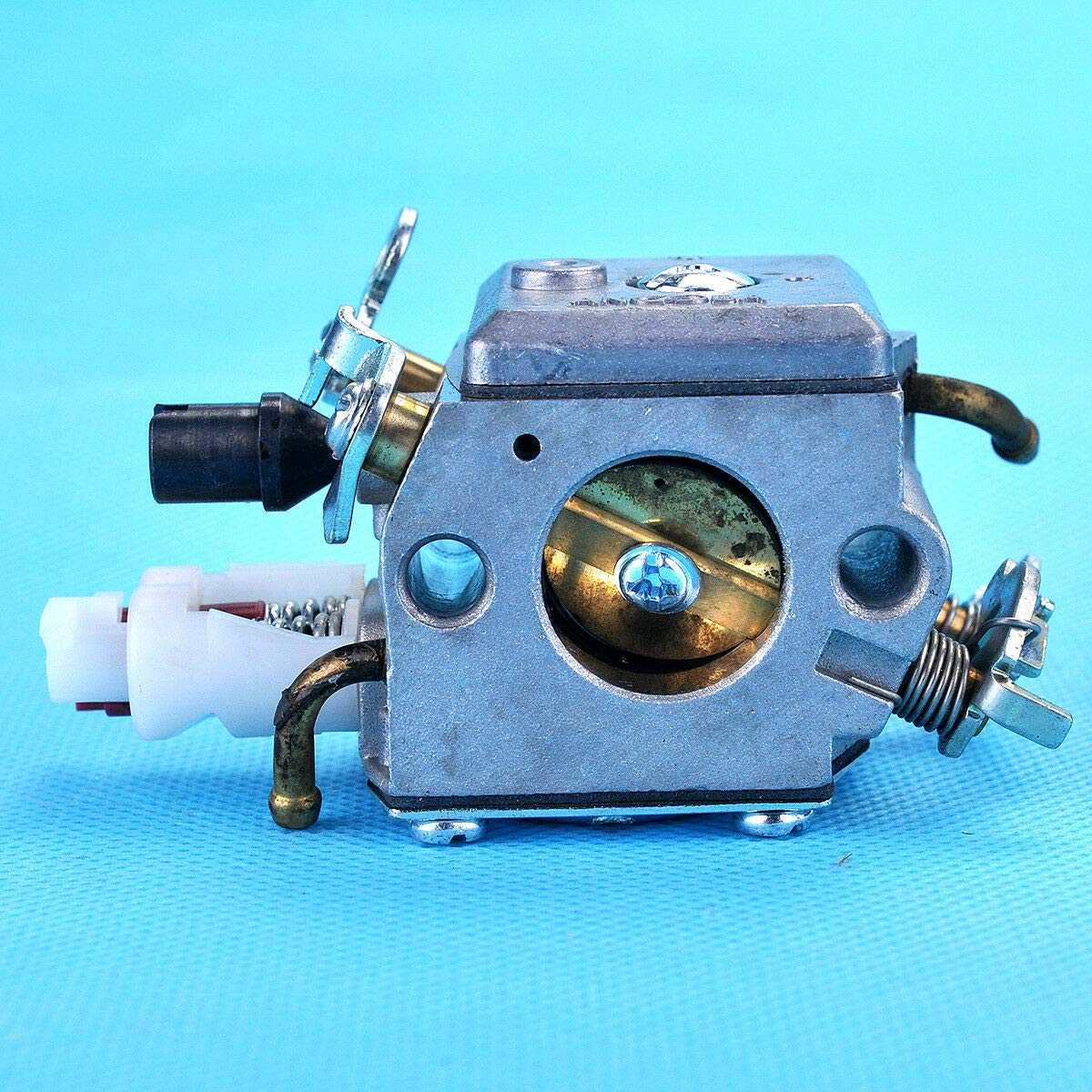

Common Replacement Parts Overview

When maintaining outdoor power equipment, understanding the frequently needed components is essential for optimal performance. This section highlights key elements that may require replacement over time, ensuring that your machinery operates smoothly and efficiently. Regular inspection and timely replacement of these components can enhance longevity and functionality.

Essential Components

Among the critical items to monitor are the fuel system elements, including filters and hoses, which are vital for proper operation. Additionally, ignition components such as spark plugs play a crucial role in starting and running the engine effectively. Keeping these elements in good condition is key to avoiding unexpected breakdowns.

Wear and Tear Items

Another category of components to consider includes those subject to wear and tear, such as chains, bars, and blades. These items can degrade with use and should be inspected regularly. Ensuring they are in good shape not only improves performance but also enhances safety during operation.

Essential Tools for Chainsaw Repairs

Proper maintenance and repair of a cutting device require specific instruments to ensure efficiency and safety. Having the right tools at your disposal can significantly enhance the repair process, allowing you to work effectively and confidently.

Wrenches and Sockets: These tools are essential for loosening and tightening bolts and screws. A complete set of different sizes will enable you to handle various components with ease.

Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are crucial for accessing different parts of the machine. They allow for precise adjustments and replacements.

Chain Breaker: This tool is vital for removing and repairing the cutting chain. It ensures that you can efficiently handle any issues that arise with the chain itself.

File: A sharpening file is necessary for maintaining the sharpness of the chain. Regular sharpening helps to enhance cutting performance and prolongs the life of the chain.

Protective Gear: Always wear safety equipment such as gloves, goggles, and ear protection. This ensures personal safety while performing repairs and maintenance tasks.

Equipping yourself with these essential tools will facilitate smooth repairs and upkeep, ensuring your device remains functional and reliable.

Troubleshooting Common Mechanical Issues

When dealing with machinery, encountering mechanical difficulties is a common occurrence. Understanding how to identify and resolve these issues can enhance the overall performance and longevity of your equipment. This section provides insights into the most frequent mechanical problems and offers practical solutions to address them effectively.

Identifying Power Problems: A frequent issue that operators face is a lack of power during operation. This may stem from various sources, including fuel supply issues, spark plug malfunctions, or air filter blockages. Inspecting these components regularly ensures that the machinery runs smoothly and efficiently.

Addressing Vibration and Noise: Excessive vibration or unusual noises can indicate underlying problems, such as loose parts or worn bearings. Tightening any loose screws and replacing damaged components can mitigate these symptoms, leading to a more stable and quieter operation.

Resolving Overheating: Overheating is another prevalent issue that can significantly impact performance. This often results from insufficient lubrication or blocked cooling systems. Regular maintenance, including checking oil levels and cleaning cooling fins, can help maintain optimal operating temperatures.

Ensuring Proper Alignment: Misalignment of moving parts can lead to increased wear and tear. Regularly checking and adjusting the alignment of components can prevent further damage and ensure smoother operation.

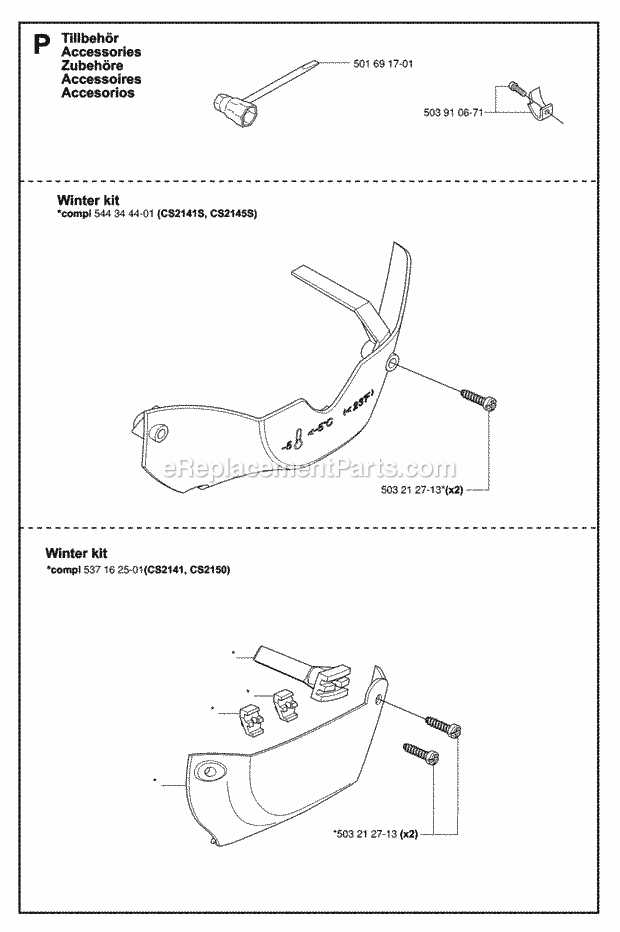

Compatible Accessories for Jonsered CS 2150

Enhancing the functionality of your chainsaw can significantly improve performance and ease of use. Selecting the right attachments can help you achieve optimal results in various cutting tasks, whether for professional landscaping or personal projects. This section explores essential accessories that can complement your equipment.

Essential Safety Gear

Using appropriate safety equipment is crucial for protecting yourself while operating machinery. Consider investing in high-quality protective gloves, safety goggles, and hearing protection. These items not only ensure your safety but also enhance your overall experience during operation.

Maintenance Tools

Regular maintenance is key to prolonging the lifespan of your chainsaw. Accessories such as sharpening kits, oiling tools, and cleaning brushes are essential for keeping your device in top condition. These tools will help you maintain efficiency and performance, allowing you to complete tasks with ease.

Where to Find Authentic Parts

When seeking genuine components for your equipment, it’s essential to identify reliable sources that offer high-quality items. Authentic parts ensure optimal performance and longevity, making it crucial to source them from reputable distributors and authorized retailers.

Authorized Dealers

One of the most dependable avenues for acquiring original components is through authorized dealers. These retailers are certified to sell genuine products, ensuring that you receive the exact specifications required for your machinery. Visiting the manufacturer’s website can help you locate these dealers easily.

Online Marketplaces

Numerous online platforms specialize in selling authentic components. Ensure to verify the seller’s credibility by checking reviews and ratings. Look for listings that clearly state the origin and authenticity of the items to avoid counterfeit products. Reliable online sources can often provide detailed descriptions and images, aiding in your purchasing decision.

Safety Tips for Parts Installation

When engaging in the installation of various components in machinery, adhering to safety guidelines is crucial. These practices ensure not only the effective operation of the equipment but also the well-being of the individual performing the task. Proper preparation and awareness can significantly reduce risks associated with assembly work.

Wear appropriate safety gear. Before beginning the installation process, ensure you have the necessary protective equipment. This includes gloves, goggles, and sturdy footwear. These items can shield you from potential hazards, such as sharp edges or falling objects.

Ensure the machine is powered off. Always disconnect power sources before attempting any maintenance or assembly. This precaution helps prevent accidental activation, which could lead to severe injuries during the process.

Read the instructions carefully. Familiarize yourself with the installation manual or guidelines relevant to the components being handled. Understanding the steps involved can prevent errors that might compromise the machinery’s functionality or safety.

Use the right tools. Selecting the appropriate tools for the job is vital for achieving a secure and efficient installation. Using incorrect tools can damage components or result in ineffective assembly.

Maintain a clean workspace. A tidy area minimizes distractions and hazards. Ensure that your workspace is free from clutter, which can lead to accidents or misplaced items during the installation.

Inspect components before installation. Always check the condition of the parts prior to assembly. Look for signs of wear or damage that could affect performance or safety. If any component appears compromised, replace it before proceeding.

By following these essential safety tips, you can create a secure environment for installing machinery components, reducing the likelihood of accidents and ensuring the longevity of your equipment.