The world of aquatic machinery is vast, and understanding its components is crucial for optimal performance. Enthusiasts and professionals alike benefit from a thorough knowledge of the key elements that contribute to the functionality of a 60 HP engine.

In this section, we will examine the intricate relationships between various components, shedding light on their roles and how they interact to ensure a seamless operation on the water. A comprehensive overview will provide insights into maintaining and troubleshooting these essential machines.

By delving into the specifics, readers will discover the ultimate guide to enhancing their equipment’s efficiency, ensuring every outing is both enjoyable and trouble-free. Join us as we navigate through this essential information.

Understanding 60 HP Mariner Outboard Motors

When it comes to small watercraft propulsion, a reliable power unit is essential for optimal performance. The 60 HP engine is designed to provide a balanced blend of power and efficiency, making it suitable for various boating activities. This section explores key features, components, and maintenance tips to ensure longevity and reliability.

Key Features

- Lightweight design for improved fuel efficiency

- Robust construction to withstand harsh marine conditions

- High torque output for quick acceleration

- Quiet operation for a more enjoyable experience on the water

Essential Components

- Fuel system: Ensures proper delivery of fuel for optimal combustion.

- Ignition system: Provides the necessary spark for engine operation.

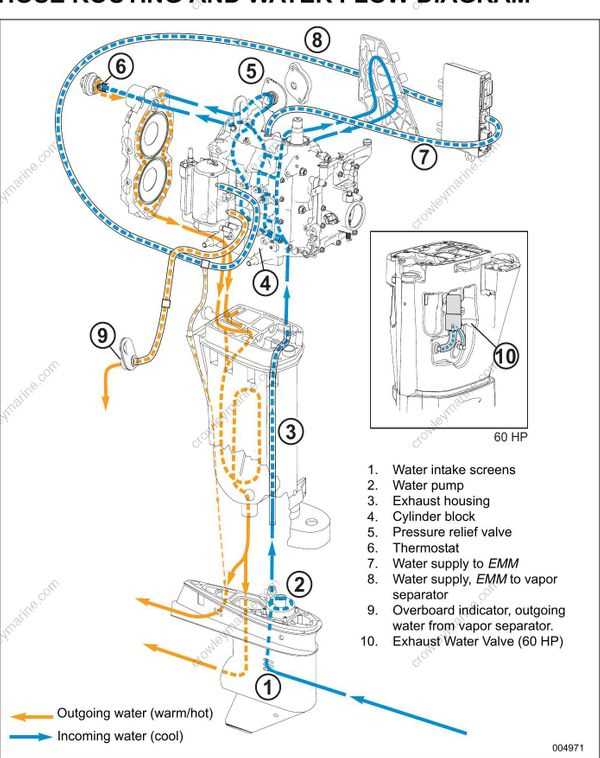

- Cooling system: Prevents overheating, ensuring smooth performance.

- Exhaust system: Manages emissions and noise levels.

Regular maintenance of these components is crucial for ensuring the unit operates efficiently and reliably. Understanding the mechanics behind each feature can help in troubleshooting common issues and enhancing overall performance.

Key Components of Outboard Engines

Understanding the essential elements of marine propulsion systems is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and reliability on the water.

Powerhead: This is the powerhouse of the system, housing the engine itself and responsible for generating thrust through combustion.

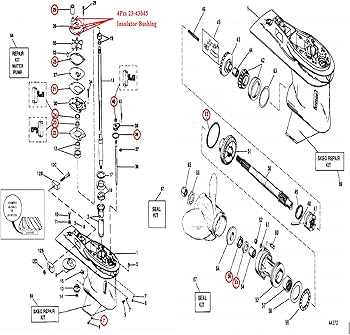

Lower Unit: This section contains the gears and shaft that transfer energy from the engine to the propeller, facilitating movement through the water.

Propeller: A critical component that converts rotational energy into forward motion, its design influences speed and fuel efficiency.

Fuel System: This encompasses the tank, lines, and injectors, delivering the necessary fuel for combustion while maintaining optimal performance.

Cooling System: Essential for preventing overheating, this system circulates water to dissipate heat generated during operation.

Electrical System: Comprising the battery, wiring, and ignition components, this system powers the engine and ensures smooth starting and operation.

By delving into these components, one can appreciate their interconnected roles in ensuring a seamless and efficient maritime experience.

Importance of Regular Maintenance

Routine care is essential for the longevity and efficiency of any machinery. By ensuring that all components function smoothly, owners can avoid costly repairs and unexpected breakdowns. Regular upkeep not only enhances performance but also contributes to safety and reliability during use.

Benefits of Consistent Upkeep

Engaging in systematic maintenance allows for early detection of potential issues. Identifying problems before they escalate can save time and resources, ultimately prolonging the lifespan of the equipment. Furthermore, it helps maintain optimal performance, ensuring that operations run as efficiently as possible.

Impact on Performance and Safety

Safety is a crucial factor that cannot be overlooked. Well-maintained machinery reduces the risk of accidents and injuries, providing peace of mind to users. Additionally, regular inspections and care lead to improved performance, which can enhance the overall experience and functionality, making every task more enjoyable and effective.

Common Issues with 60 HP Models

When operating 60 HP engines, several frequent challenges can arise that may affect performance and reliability. These issues often stem from mechanical wear, fuel system inefficiencies, or electrical failures, leading to reduced functionality. Identifying and addressing these common problems is essential for maintaining optimal operation.

One prevalent concern is overheating, which can result from inadequate cooling system maintenance. Regular checks of the water pump and thermostat can help prevent this issue. Additionally, fuel contamination can lead to starting difficulties or erratic running, making it crucial to use clean fuel and inspect filters regularly.

Another significant challenge is electrical system malfunctions, which can disrupt ignition and overall engine performance. Ensuring that connections are secure and that the battery is in good condition can mitigate these risks. By understanding these common issues, operators can take proactive measures to ensure the longevity and efficiency of their 60 HP units.

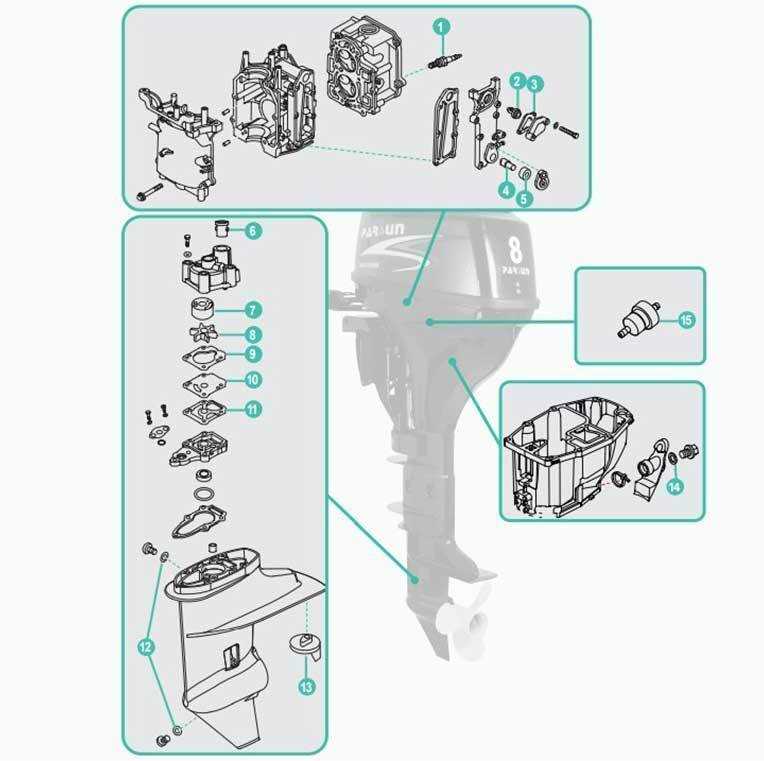

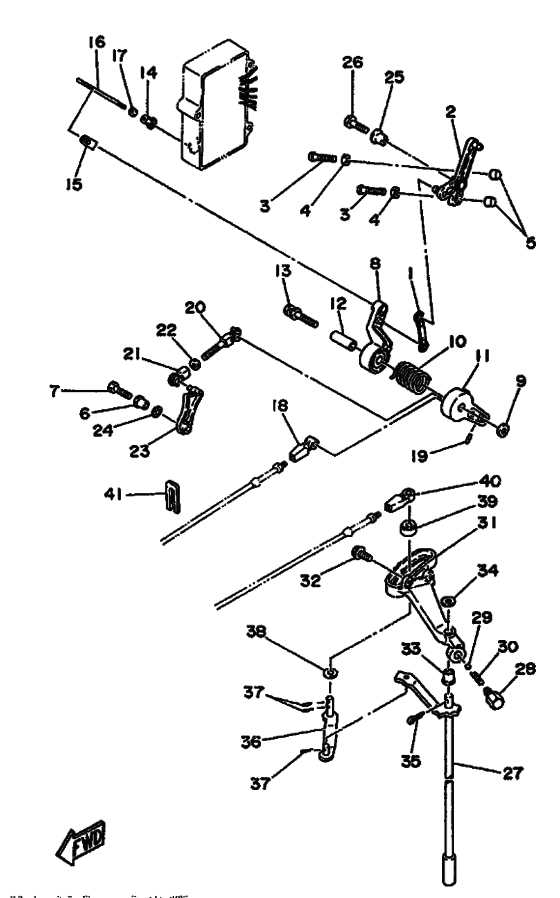

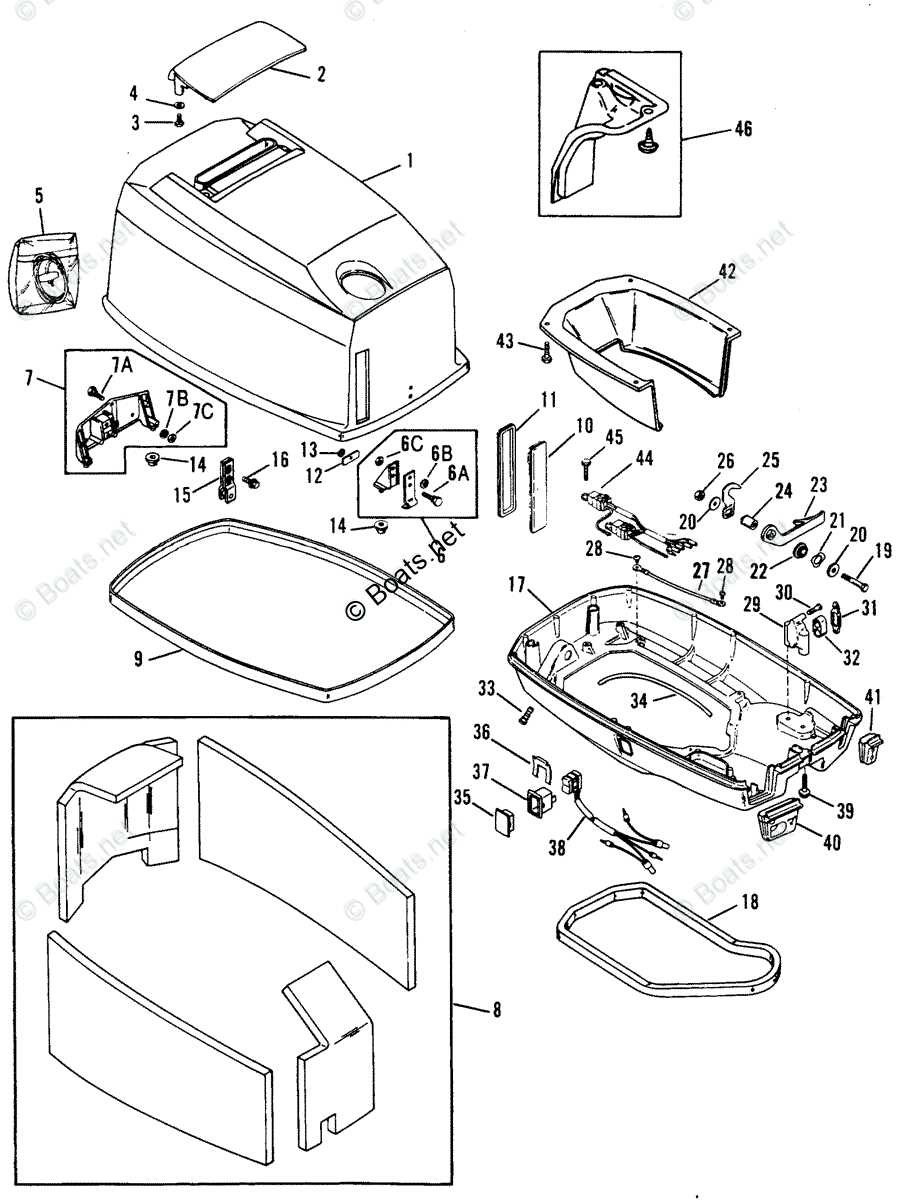

Parts Diagram Overview

This section provides an insightful look into the components of a 60 hp marine engine, illustrating how each piece contributes to overall functionality. Understanding these elements is crucial for maintenance and repairs, ensuring optimal performance on the water.

| Component | Description |

|---|---|

| Powerhead | The heart of the engine, responsible for generating thrust. |

| Gearcase | Encases the gearing mechanism that transfers power to the propeller. |

| Fuel System | Delivers the necessary fuel mixture to the combustion chamber. |

| Cooling System | Regulates temperature to prevent overheating during operation. |

| Electrical Components | Includes wiring, ignition, and other elements essential for operation. |

How to Read an Outboard Diagram

Understanding technical illustrations is crucial for effective maintenance and repairs. These visual guides provide an organized representation of components and their relationships, enabling users to identify parts easily. Familiarity with common symbols and notations is essential for navigating these resources successfully.

First, begin by examining the overall layout. Typically, you will find various sections dedicated to specific areas, such as the engine, fuel system, and electrical components. Familiarize yourself with these sections to gain a better understanding of where each element is located.

Next, pay attention to the labels. Each component is usually marked with a unique identifier, which can often be cross-referenced in accompanying manuals. Take note of these references, as they will guide you in sourcing replacement items or understanding functionality.

Another critical aspect is the connection lines. These lines represent relationships and flow between components, such as fuel or electrical pathways. Understanding these connections can help you diagnose issues effectively. Observe how different parts interact and the direction of flow indicated by arrows.

Finally, remember that practice makes perfect. The more you engage with these visuals, the more intuitive reading them will become. Take your time and refer to various resources until you feel comfortable navigating these essential tools for maintenance and troubleshooting.

Essential Tools for Repairs

When it comes to maintaining and fixing marine engines, having the right equipment is crucial for ensuring efficiency and precision. Whether you are a seasoned technician or a passionate DIY enthusiast, understanding the necessary tools can greatly enhance the repair process. Below is a comprehensive list of essential instruments that can help you tackle various maintenance tasks effectively.

| Tool | Description |

|---|---|

| Socket Set | Includes various sizes of sockets to loosen or tighten bolts and nuts securely. |

| Wrench Set | Essential for gripping and turning fasteners in tight spaces. |

| Screwdriver Set | Variety of types and sizes for different screw heads, allowing for versatile use. |

| Pliers | Useful for gripping, twisting, or cutting wires and small components. |

| Multimeter | Instrument for measuring voltage, current, and resistance, crucial for electrical diagnostics. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications to prevent damage. |

| Inspection Mirror | Helps view hard-to-reach areas, providing better access for troubleshooting. |

| Cleaning Supplies | Essential for maintaining cleanliness and removing debris from components. |

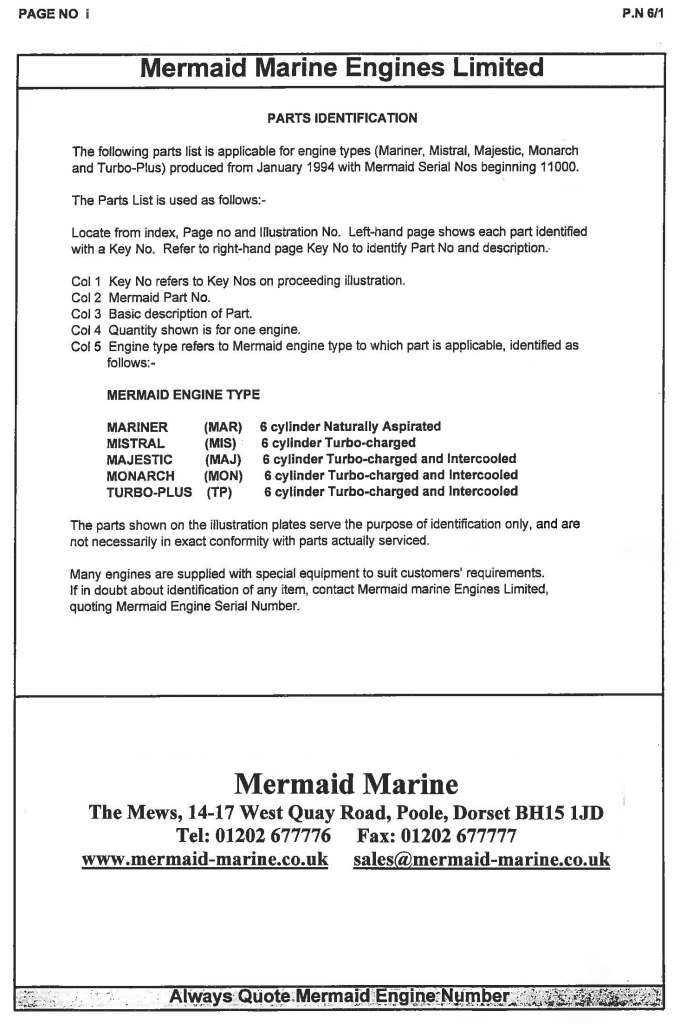

Finding Replacement Parts Online

Locating suitable components for your marine engine can be a straightforward process if you know where to look. The internet offers a plethora of resources that can assist you in identifying the exact pieces you need for maintenance or repairs. With the right tools and strategies, you can streamline your search and ensure you get quality items.

Utilizing Online Marketplaces

One of the most effective ways to find what you’re looking for is by exploring various online marketplaces. These platforms often feature a vast selection of components, along with user reviews and ratings that can guide your purchasing decisions.

Manufacturer Websites

Visiting the official websites of manufacturers is another reliable approach. They typically offer detailed catalogs, specifications, and sometimes even a direct purchasing option, ensuring that you acquire the correct items tailored for your specific engine model.

| Resource Type | Examples |

|---|---|

| Online Marketplaces | eBay, Amazon |

| Manufacturer Sites | Official Brand Websites |

| Specialized Retailers | Marine Supply Stores |

Comparison of OEM vs Aftermarket Parts

The choice between original components and those from alternative manufacturers often leads to significant considerations for users. Each category offers distinct advantages and potential drawbacks, influencing performance, reliability, and cost. Understanding these differences can aid in making an informed decision that aligns with individual needs.

Advantages of OEM Components

Original components are designed specifically for a particular model, ensuring perfect compatibility and performance. Their quality often meets stringent manufacturer standards, providing peace of mind for users who prioritize reliability.

Benefits of Aftermarket Components

Alternative options can be more budget-friendly and readily available. They may offer enhanced features or improved performance, appealing to those seeking customization or cost savings without sacrificing quality.

| Criteria | OEM Components | Aftermarket Components |

|---|---|---|

| Compatibility | Perfect fit | Varies |

| Cost | Generally higher | Typically lower |

| Quality Assurance | Manufacturer certified | Variable |

| Availability | Limited | Widely accessible |

Step-by-Step Repair Process

This section provides a comprehensive guide to efficiently tackling repairs on your marine engine. Following a structured approach ensures that each step is performed methodically, reducing the risk of errors and enhancing the overall maintenance experience.

-

Preparation

- Gather necessary tools and safety equipment.

- Read the user manual to understand the specific components.

- Ensure a clean and organized workspace to avoid losing small parts.

-

Initial Inspection

- Visually check for any signs of damage or wear.

- Test the engine to identify any unusual sounds or performance issues.

-

Disassembly

- Carefully remove the exterior casing, taking note of each step.

- Label screws and small components to ensure correct reassembly.

-

Replacement of Components

- Identify parts that require replacement based on wear and tear.

- Install new components, ensuring a snug fit and proper alignment.

-

Reassembly

- Follow your initial disassembly notes to reattach all components.

- Double-check that all fasteners are secured appropriately.

-

Final Checks

- Perform a thorough inspection to ensure everything is in order.

- Run the engine to confirm that repairs have resolved previous issues.

By adhering to this systematic process, you can enhance the longevity and reliability of your marine equipment, ensuring it performs optimally for years to come.

Upgrading Your Outboard Engine

Enhancing the performance of your marine propulsion system can significantly improve your boating experience. Whether you seek greater speed, fuel efficiency, or reliability, investing in upgrades can yield impressive results. This section will explore various options and considerations for elevating your engine’s capabilities.

Assess Your Current Setup

Before making any upgrades, it’s essential to evaluate your existing configuration. Identify the strengths and weaknesses of your current engine, taking note of its performance metrics and any areas that may require improvement. This assessment will help you determine the most effective enhancements.

Explore Engine Modifications

Consider tuning your power unit for optimized performance. Modifications such as upgrading the fuel delivery system, enhancing the exhaust, or adjusting ignition timing can lead to notable improvements. Each change should be carefully planned to ensure compatibility and efficiency.

Upgrade Components

Investing in high-quality components can have a substantial impact. Look into replacing the propeller for better thrust or upgrading the cooling system to prevent overheating. These enhancements not only boost performance but can also extend the lifespan of your machinery.

Seek Professional Guidance

Consulting with experts can provide valuable insights into the best options for your specific engine model. Professionals can recommend the most suitable upgrades and help with installation, ensuring that everything functions harmoniously.

Regular Maintenance

In addition to upgrades, maintaining your engine is crucial for optimal performance. Regular checks and servicing can prevent issues and keep your system running smoothly. Create a maintenance schedule to address potential problems before they escalate.

By thoughtfully considering upgrades and maintaining your system, you can enhance your boating adventures and enjoy a more efficient and powerful experience on the water.

Safety Tips for DIY Repairs

When tackling repairs on mechanical equipment, prioritizing safety is essential. Proper precautions not only protect you from injury but also ensure effective and efficient work. Whether you’re a seasoned handyman or a novice, understanding the risks involved and how to mitigate them is crucial for a successful outcome.

Always wear appropriate protective gear, including gloves and safety goggles, to shield yourself from debris and hazardous materials. Ensure your workspace is well-lit and free from clutter, reducing the chances of accidents. Familiarize yourself with the tools you plan to use, and maintain them in good condition to prevent malfunctions.

Before starting any repair, disconnect power sources to avoid electrical shocks and other dangers. Take time to read manuals or guides related to the task, and don’t hesitate to seek help if you encounter challenges. By adopting these practices, you can delve into your projects with confidence, making the experience both enjoyable and safe.

Resources for Further Learning

Expanding your knowledge in the field of marine engines can significantly enhance your skills and understanding. Whether you are a novice or an experienced enthusiast, utilizing a variety of educational materials can help you gain deeper insights into maintenance, troubleshooting, and repair techniques.

- Books and Manuals:

- Technical manuals specific to engine models

- Comprehensive guides on marine mechanics

- Books on general engine theory and practices

- Online Courses:

- Platforms offering courses on marine technology

- Webinars hosted by industry experts

- Video tutorials on repair and maintenance

- Forums and Communities:

- Online forums for enthusiasts and professionals

- Social media groups focused on marine engineering

- Local clubs and meetups for hands-on experience

- Manufacturer Resources:

- Official websites with technical documents

- Customer support for specific inquiries

- Parts catalogs and service bulletins

Engaging with these resources can lead to improved skills and a greater appreciation for the intricacies of marine machinery.