When it comes to heavy machinery, a thorough grasp of the various elements that constitute these powerful tools is essential for optimal performance and maintenance. Each component plays a vital role in the overall functionality, and understanding their arrangement can significantly enhance operational efficiency. This knowledge is particularly beneficial for technicians and operators alike.

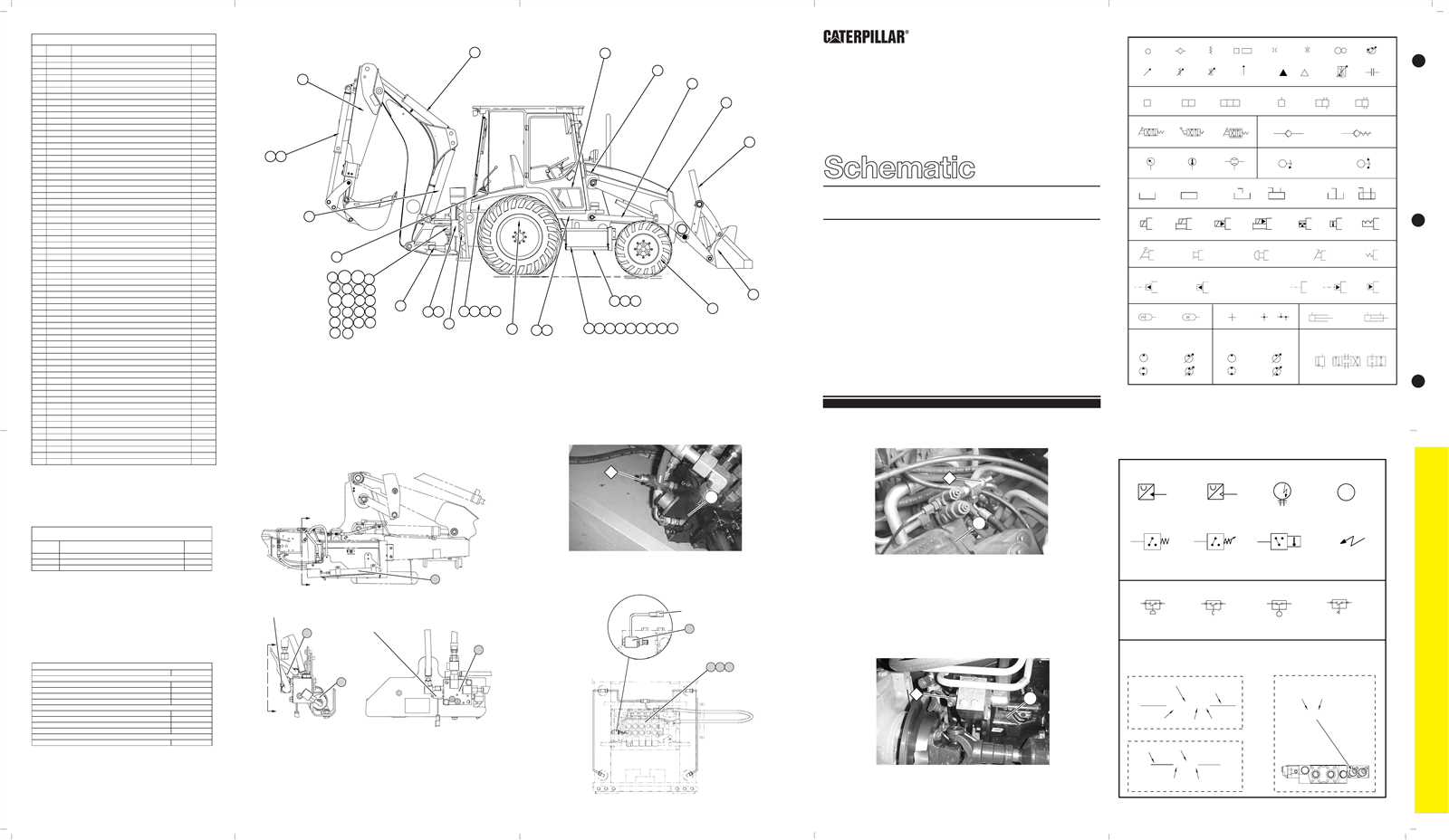

Visual aids serve as invaluable resources in this context. By examining the arrangement and interrelation of parts, one can pinpoint issues more swiftly and execute repairs or replacements with confidence. A well-structured illustration can simplify complex systems, making it easier to comprehend how each segment contributes to the machine’s functionality.

Additionally, the importance of accurate identification cannot be overstated. In a field where precision is key, having a clear reference for each element allows for better decision-making and fewer errors during maintenance tasks. This insight ultimately leads to enhanced performance and longevity of the equipment, ensuring it remains reliable in demanding environments.

Understanding the Cat 420D Backhoe

This section aims to provide an insightful overview of a versatile piece of construction machinery widely utilized in various projects. Known for its efficiency and functionality, this equipment plays a crucial role in tasks ranging from excavation to material handling. Its design incorporates multiple components that work in harmony to achieve optimal performance in challenging environments.

Key Features

The machinery is equipped with several noteworthy characteristics that enhance its usability and effectiveness. These features contribute to its reputation as a reliable choice for operators and contractors alike.

| Feature | Description |

|---|---|

| Powerful Engine | Provides ample horsepower to tackle heavy-duty tasks efficiently. |

| Robust Design | Built to withstand harsh working conditions and ensure longevity. |

| Versatile Attachments | Compatible with various tools to perform different operations seamlessly. |

| Operator Comfort | Designed with ergonomic controls and a spacious cabin for enhanced usability. |

Maintenance Considerations

Key Features of the Cat 420D

This section explores the distinctive attributes that make this versatile construction machine a valuable asset on any job site. From its robust design to its exceptional performance, the equipment is engineered to tackle a variety of tasks with efficiency and reliability.

Exceptional Performance

Powered by a high-efficiency engine, this machinery delivers impressive horsepower while maintaining fuel economy. The advanced hydraulic system ensures rapid response times, enhancing the operator’s ability to execute tasks swiftly. Enhanced digging and lifting capabilities allow for seamless transitions between different operations, making it a multifaceted tool for any project.

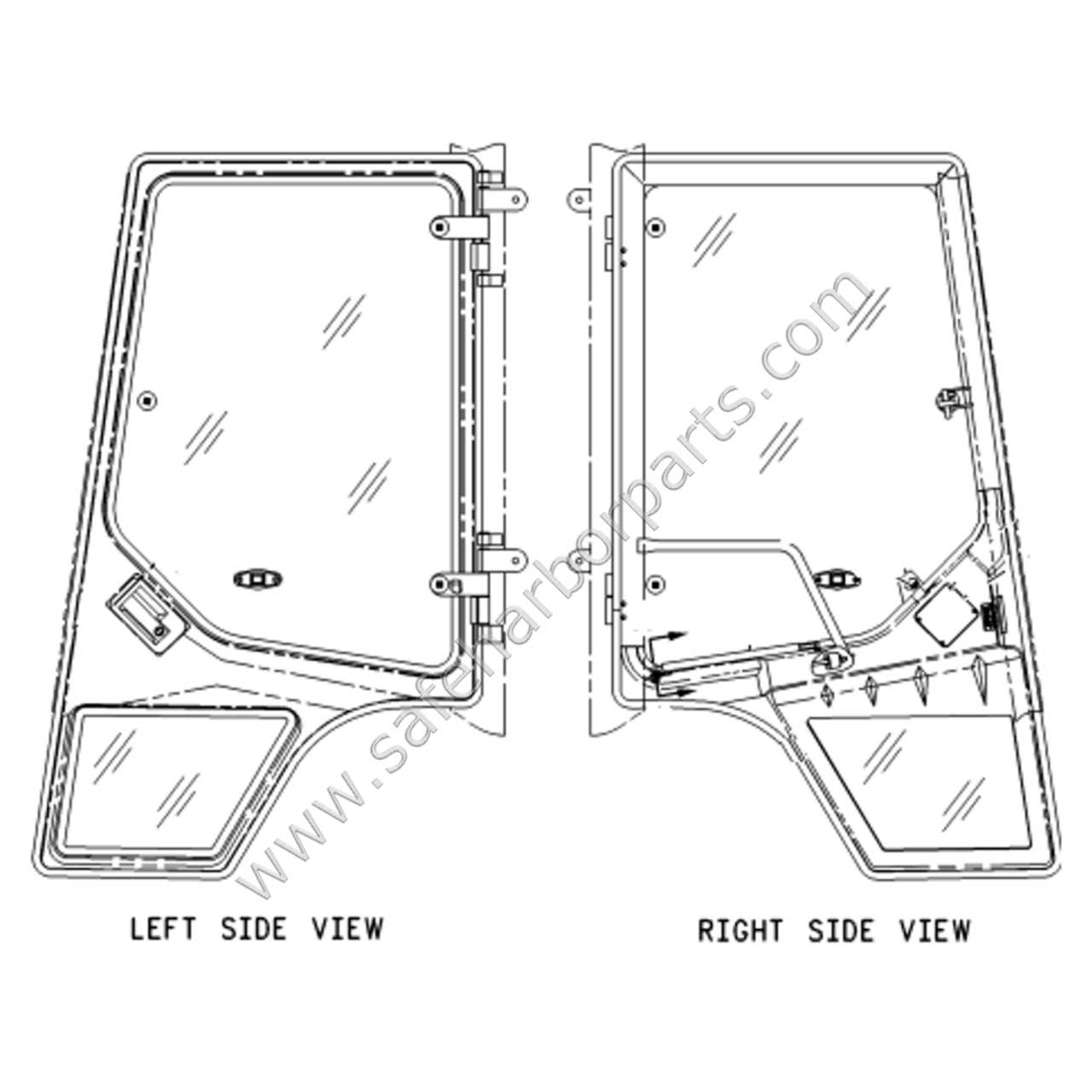

User-Friendly Design

The ergonomic operator’s station is designed for maximum comfort and visibility, reducing fatigue during long hours of operation. Intuitive controls and advanced monitoring systems provide the operator with essential information at a glance, facilitating better decision-making on the job. Additionally, the machine’s compact dimensions allow for easy maneuverability in tight spaces.

Importance of Accurate Parts Diagrams

Precise schematics are crucial for maintaining the efficiency and longevity of machinery. They serve as essential references that aid technicians and operators in identifying components, ensuring that maintenance and repairs are conducted accurately. When every element is represented clearly, the likelihood of errors diminishes significantly, leading to more effective troubleshooting and replacement strategies.

Enhancing Maintenance Efficiency

Utilizing detailed illustrations streamlines the maintenance process. Technicians can quickly locate specific items and understand their interactions within the assembly. This not only saves time but also reduces the potential for damage during disassembly and reassembly. Furthermore, accurate visuals help in planning and executing repairs without unnecessary delays.

Facilitating Training and Knowledge Transfer

Well-structured visuals play a vital role in the training of new personnel. They provide an intuitive understanding of how different components fit together and function. By using these resources, trainers can effectively convey complex concepts, enabling trainees to gain confidence and competence in their roles more rapidly.

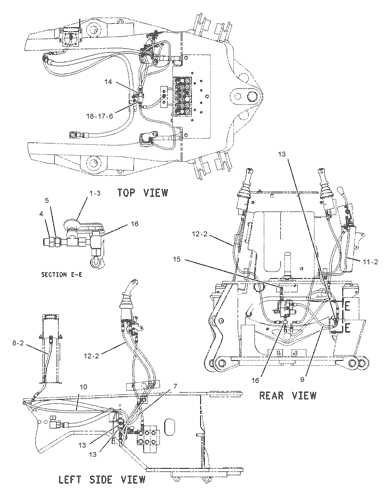

Common Components of Backhoe Loaders

Understanding the essential elements of excavation machinery is crucial for effective operation and maintenance. These versatile machines are equipped with a range of components that work together to perform various tasks, from digging to lifting and transporting materials. Familiarity with these key elements not only aids in troubleshooting but also enhances overall efficiency on the job site.

1. Loader Bucket: This front-mounted attachment is primarily used for scooping and lifting materials. Its design can vary, featuring different sizes and shapes depending on the specific application.

2. Excavator Arm: The arm extends from the rear of the machine, allowing for deep digging and precise maneuvering. Its hydraulic system provides the necessary power to execute a range of tasks with ease.

3. Hydraulic System: This vital mechanism powers various components of the machine. It utilizes fluid to transmit force, enabling the movement of the arm, bucket, and other attachments effectively.

4. Chassis: The robust frame serves as the foundation of the equipment, supporting all other components while ensuring stability during operation. Its design contributes to the machine’s overall durability and performance.

5. Tires or Tracks: Depending on the model, the machine may be fitted with either tires for increased mobility on paved surfaces or tracks for enhanced traction on uneven terrain. This choice affects the machine’s operational capabilities in diverse environments.

6. Operator Cabin: This enclosed area provides the operator with comfort and control, housing various controls and instruments necessary for efficient operation. A well-designed cabin enhances visibility and accessibility to essential functions.

By becoming acquainted with these fundamental components, operators can better manage maintenance and ensure their machinery remains in peak condition for any task at hand.

Maintenance Tips for Cat 420D Parts

Regular upkeep is essential for the longevity and efficiency of heavy machinery. By following a systematic maintenance approach, operators can ensure optimal performance and reduce the likelihood of unexpected breakdowns. This section outlines key practices to maintain the integrity of your equipment.

Routine Inspections

- Check fluid levels weekly, including hydraulic and engine oil.

- Inspect belts and hoses for wear and tear.

- Examine the undercarriage for any signs of damage or corrosion.

Cleaning and Lubrication

- Clean components regularly to prevent dirt accumulation.

- Apply appropriate lubricants to moving parts to reduce friction.

- Ensure air filters are clean to promote efficient engine performance.

Identifying Components in the Diagram

Understanding the layout of machinery components is essential for effective maintenance and repair. By familiarizing oneself with the arrangement and function of each element, operators can enhance performance and prolong the lifespan of their equipment.

When examining the schematic representation, consider the following categories of components:

- Structural Elements: These are the main frameworks that support the overall structure and integrity of the machine.

- Hydraulic Components: Essential for controlling movement and power transmission, these parts include cylinders, pumps, and valves.

- Electrical Systems: Wiring, switches, and sensors fall under this category, crucial for operational functionality and safety.

- Drive Train Parts: These elements transmit power from the engine to the various operational mechanisms.

- Attachment Mechanisms: These parts facilitate the connection of various tools and implements necessary for different tasks.

To successfully navigate the schematic, it’s beneficial to:

- Study the legend or key that often accompanies the illustration, which provides symbols and their meanings.

- Familiarize yourself with each section by referencing user manuals and technical specifications.

- Utilize visual aids or exploded views for a clearer understanding of how components interact.

By methodically identifying these parts, operators can better troubleshoot issues and streamline repair processes, ensuring their machinery operates at peak efficiency.

Common Issues with Cat 420D Parts

When working with heavy machinery, certain components may encounter problems that affect overall performance. Identifying these issues early can save time and reduce maintenance costs. Here, we explore frequent challenges faced by operators and maintenance teams regarding various elements of the machine.

Frequent Component Failures

One of the primary concerns with machinery is the wear and tear on essential components. Regular inspections can help identify parts that require replacement or repair. Below is a table highlighting some of the most commonly reported failures.

| Component | Common Issue | Symptoms |

|---|---|---|

| Hydraulic Cylinder | Leakage | Loss of pressure, visible fluid |

| Transmission | Slipping Gears | Delayed engagement, unusual noises |

| Engine | Overheating | Warning lights, steam |

| Electrical System | Faulty Wiring | Inconsistent power, blown fuses |

Maintenance Tips

Preventative maintenance plays a crucial role in mitigating these issues. Regularly scheduled checks and timely replacements of worn parts can enhance longevity and reliability. Always consult the manufacturer’s guidelines for specific maintenance intervals and recommendations to ensure optimal functionality.

How to Source Replacement Parts

Finding suitable components for your machinery is essential for maintaining its efficiency and longevity. The process involves several key steps that can help ensure you acquire the right items without unnecessary delays or expenses. Understanding where to look and how to verify the authenticity of the products can make all the difference.

Start by researching reputable suppliers, both online and local. Websites specializing in heavy equipment often have a wide selection of components, along with detailed specifications. Local dealers can also be valuable, offering insights and immediate availability. Always compare prices and terms to find the most favorable options.

Another important aspect is verifying the compatibility of the components with your machine. Consult your user manual or manufacturer’s resources to ensure you are sourcing the correct items. If in doubt, reach out to experts or forums dedicated to heavy equipment; the community can provide valuable recommendations.

Consider the option of purchasing from salvage yards or auctions for cost-effective solutions. However, always inspect the condition of used items thoroughly to avoid potential issues down the line. Ultimately, a careful and informed approach to sourcing replacements will help you maintain your equipment in optimal working condition.

Tools Needed for Backhoe Repairs

When maintaining heavy machinery, having the right equipment is crucial for ensuring efficient and effective repairs. Various tools facilitate the disassembly and assembly processes, allowing for a thorough inspection and replacement of essential components.

Essential Hand Tools

Wrenches and screwdrivers are fundamental for loosening and tightening bolts. Socket sets enhance versatility, while pliers assist with gripping and bending tasks.

Power Tools and Diagnostic Equipment

For more extensive repairs, impact wrenches can save significant time. Additionally, multimeters and diagnostic scanners are vital for troubleshooting electrical issues and ensuring optimal functionality.

Benefits of Using Genuine Parts

Utilizing authentic components in machinery enhances overall performance and longevity. Genuine items are designed to meet specific standards, ensuring optimal functionality and reliability in every application.

| Advantage | Description |

|---|---|

| Quality Assurance | Original components undergo rigorous testing to ensure they meet manufacturer specifications. |

| Durability | These parts are built to last, reducing the frequency of replacements and repairs. |

| Performance | Genuine components work seamlessly with the machine, enhancing overall efficiency. |

| Warranty Protection | Using authentic items helps maintain the warranty on your equipment, safeguarding your investment. |

DIY Repair vs. Professional Services

When faced with equipment malfunctions, individuals often grapple with the decision of whether to tackle repairs themselves or to enlist the help of experts. Both approaches have their own merits and drawbacks, which can significantly influence the outcome and efficiency of the restoration process.

Opting for a do-it-yourself approach can offer several advantages:

- Cost Savings: By handling repairs personally, one can save on labor costs associated with hiring professionals.

- Skill Development: DIY efforts can enhance technical skills and knowledge about the machinery, leading to greater confidence in future tasks.

- Flexibility: Working on repairs at one’s own pace allows for a more convenient schedule, free from the constraints of appointment times.

However, this method also comes with potential pitfalls:

- Time Consumption: Repairing complex machinery can be time-intensive, often taking longer than anticipated.

- Risk of Errors: Lack of experience may lead to mistakes, which could exacerbate the problem or cause additional damage.

- Limited Tools: Professionals often have access to specialized equipment that an average individual may lack.

On the other hand, hiring professionals offers distinct benefits:

- Expertise: Professionals bring extensive knowledge and experience, often leading to quicker and more effective repairs.

- Warranty Protection: Many services provide guarantees for their work, ensuring peace of mind in case of future issues.

- Comprehensive Services: Experts can identify and address underlying problems that may not be apparent to a novice.

Yet, this option isn’t without its challenges:

- Higher Costs: Professional services can be significantly more expensive than handling repairs independently.

- Scheduling Issues: Appointments may not align with one’s availability, potentially delaying the repair process.

- Dependence on Others: Relying on external help can lead to uncertainty regarding the quality and timeliness of the service.

Ultimately, the choice between DIY repairs and professional assistance depends on various factors, including budget, urgency, and individual skill level. Assessing these elements can guide one toward the most suitable option for effective machinery restoration.

Upgrades for Improved Performance

Enhancing machinery efficiency can significantly impact productivity and operational costs. By implementing targeted upgrades, operators can achieve greater power, improved fuel efficiency, and extended service life. This section explores various enhancements that can optimize performance and reliability.

Key Enhancements

Consider integrating advanced components that offer superior durability and functionality. Upgrading hydraulic systems, utilizing high-performance filters, and enhancing engine efficiency are among the most effective strategies. Each improvement not only boosts productivity but also minimizes downtime.

Upgrade Options

| Upgrade | Benefits |

|---|---|

| Hydraulic System Upgrade | Increased lifting capacity and responsiveness. |

| Engine Tuning | Improved fuel efficiency and power output. |

| High-Performance Filters | Enhanced filtration leads to longer engine life. |

Understanding Warranty Options for Parts

When it comes to maintaining and repairing heavy machinery, comprehending the various warranty options available for components is essential. Warranties serve as a safeguard, ensuring that your investment is protected against potential defects or failures. This section delves into the different types of warranties and what you should consider when selecting replacement components for your equipment.

Types of Warranties

Warranties generally fall into two main categories: limited and full. A limited warranty typically covers specific parts or issues for a designated period. In contrast, a full warranty offers broader coverage, often including both parts and labor for repairs. Understanding these distinctions can help you make informed decisions regarding the longevity and reliability of your machinery.

What to Look For

When evaluating warranty options, consider the duration, coverage, and any conditions that may apply. It’s crucial to read the fine print and be aware of what is excluded, such as wear and tear or improper usage. Additionally, inquire about the process for filing claims, as a straightforward process can save you time and frustration down the line. By being diligent about these factors, you can enhance the protection of your equipment and ensure peace of mind during operations.