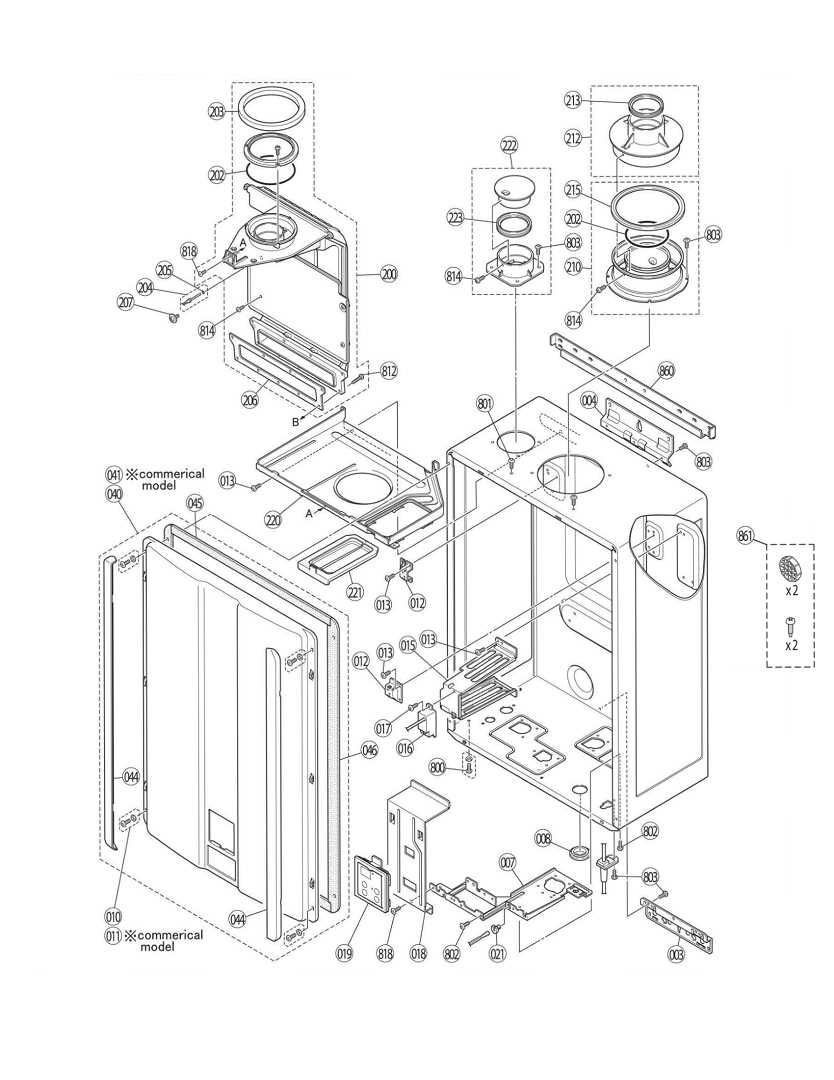

The functionality of complex systems relies heavily on the seamless interaction between various elements. By examining the internal structure, users can gain a clear understanding of how each component fits into the larger system, ensuring proper operation and maintenance. Knowing where each element is located and its specific role can greatly improve efficiency when troubleshooting or making adjustments.

Each element within the system serves a distinct purpose, contributing to the overall functionality. Identifying these individual components, along with their placement, is crucial for anyone seeking to maintain or repair the setup. A clear and accurate overview helps simplify what might otherwise seem like a complicated structure.

Whether performing routine maintenance or handling unexpected malfunctions, having a clear understanding of the layout ensures that everything operates smoothly. A well-organized system layout enhances not only the usability but also extends the overall longevity of the equipment, minimizing the risk of errors or breakdowns.

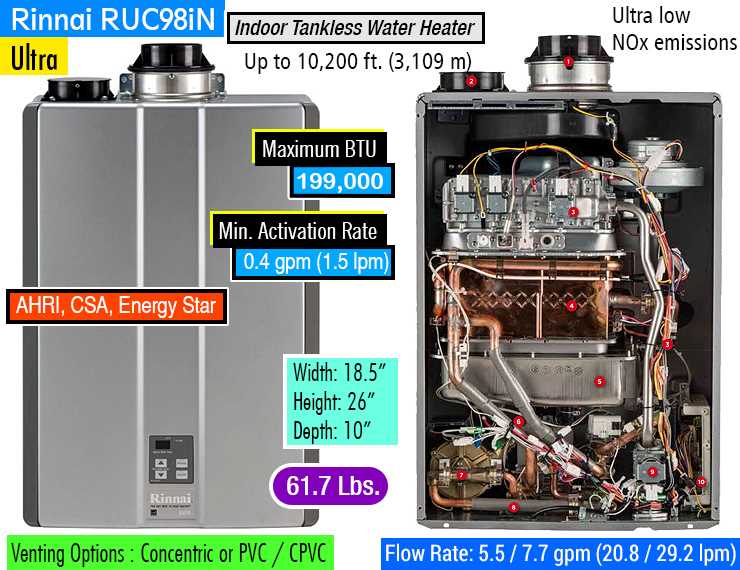

Overview of Rinnai System Components

Understanding the different elements of a heating and hot water system can help with effective maintenance and optimal performance. Each unit is designed to work in harmony with other elements, ensuring seamless operation and energy efficiency. Recognizing the core components and their roles is crucial for troubleshooting and upkeep.

Heat Generation Unit: The central device responsible for producing warmth and heated water. This unit regulates temperature and works based on the system’s demand, adjusting output for optimal efficiency.

Control Mechanism: A user interface allowing adjustments to the system. It helps manage the temperature, set schedules, and monitor operation modes, making the system responsive to specific preferences.

Safety Features: Integrated safeguards prevent overheating and ensure safe functioning. These features activate when irregularities are detected

Key Elements of Rinnai Heating Units

Heating systems are designed with a combination of vital components that work together to ensure efficient operation. These elements serve different functions, from heat generation to distribution, and play a crucial role in maintaining a comfortable indoor environment. Understanding the core mechanisms helps in better managing, troubleshooting, and maintaining these systems.

Primary Heating Component

The core element responsible for producing heat is the burner, which converts fuel into thermal energy. This component is typically housed within the system and ignites to begin the heating process. Its proper functioning is essential for the overall performance of the system.

Heat Exchange Mechanism

A critical part of the unit’s operation is the heat exchanger, which transfers the warmth generated by the burner to the air or water that circ

Understanding the Inner Structure of Rinnai Devices

The internal design of modern heating systems follows a well-coordinated structure aimed at ensuring efficiency and reliability. These devices are composed of several key components working in harmony to regulate temperature and provide consistent performance. Knowing how these elements interact helps in understanding the overall functionality and potential troubleshooting areas.

- Heat Exchanger: This critical element transfers energy from the burner to the water, playing a central role in the heating process.

- Burner Assembly: Responsible for igniting the fuel and creating the heat necessary for operation. Its efficiency directly affects the overall system output.

- Control Board: This part manages all electrical functions, from adjusting temperature settings to ensuring safety protocols are followed.

- Valves and Sensors: These components regulate fuel flow and monitor vari

Essential Parts for Rinnai Water Heaters

Efficient performance and long-lasting durability depend on the proper functioning of several crucial components in modern water heating systems. Understanding these key elements allows for better maintenance and more efficient operation, ensuring hot water availability when needed.

Heat Exchanger: This is the core of the system, responsible for transferring energy to the water. Its efficiency directly impacts the overall performance, making it one of the most important elements to keep in optimal condition.

Control Valve: A vital regulator that manages the flow of gas and water within the system. Proper functionality ensures consistent water temperature and flow, contributing to user comfort and safety.

Burner Assembly: Designed to ignite the gas and produce th

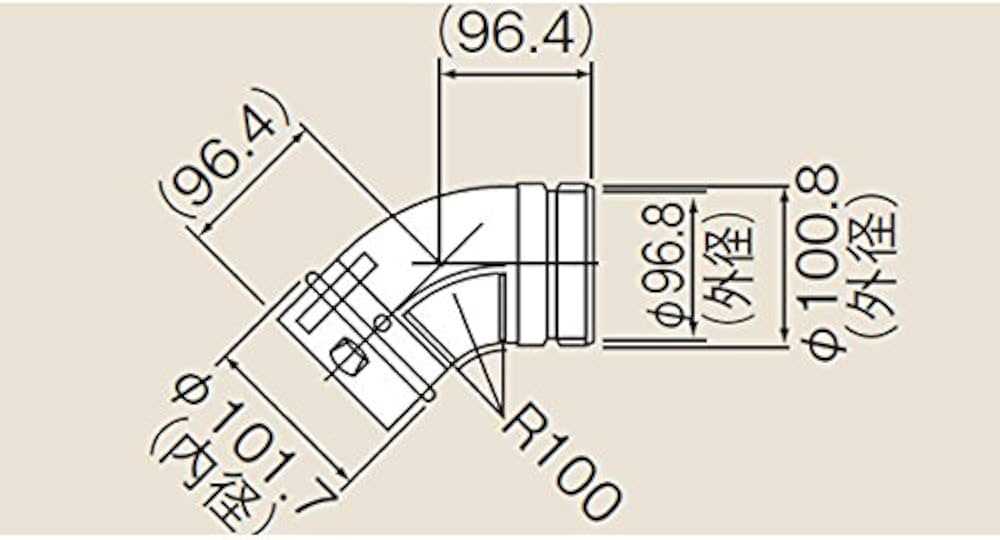

How Rinnai Ventilation Systems Are Built

The construction of modern ventilation systems is designed to ensure efficient airflow and optimal temperature control within a home or building. These systems are engineered with specific components that work together to regulate the intake and exhaust of air. By facilitating proper circulation, they enhance both comfort and safety in various environments, while reducing the buildup of unwanted particles and maintaining air quality.

Core Components of the Ventilation Structure

At the heart of these systems are key elements that include intake and exhaust mechanisms, filters, and ducts. Each of these plays a critical role in controlling the flow of air. The intake allows fresh air to enter, while exhaust components remove stale air. Filters ensure that airborne contaminants are minimized, contributing to healthier living conditions. Properly installed ducts transport the air throughout the space, making sure it reaches

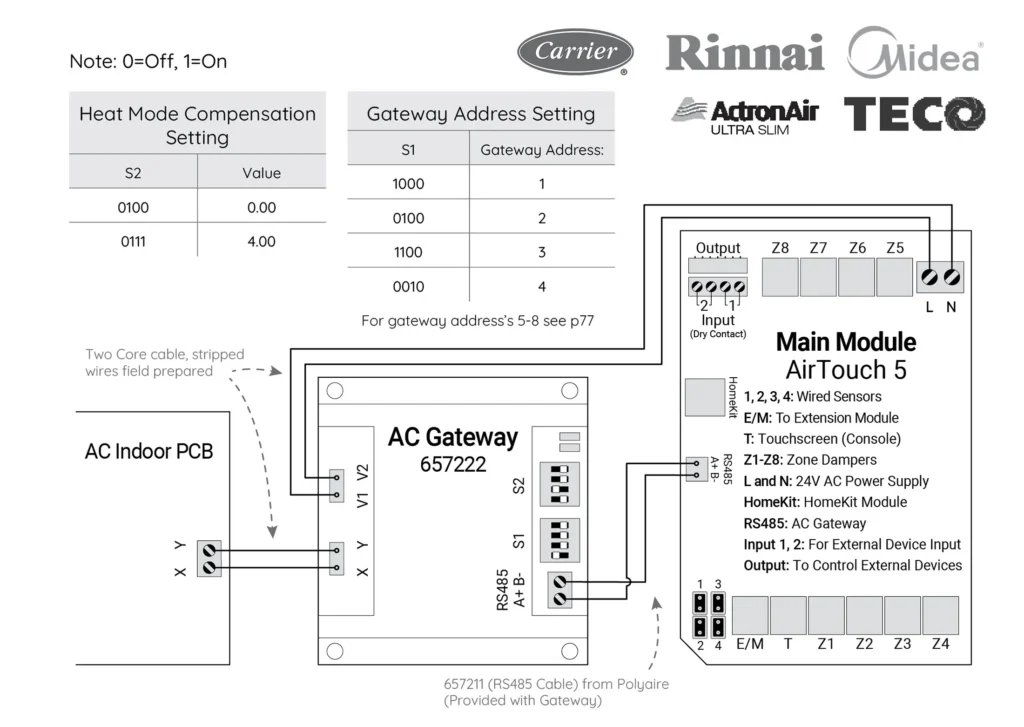

Analyzing the Design of Rinnai Control Panels

The design of control interfaces plays a crucial role in user experience and operational efficiency. Understanding the layout and functionality of these interfaces can enhance maintenance and troubleshooting processes. By examining the various components, users can gain insights into the operational mechanisms that govern these systems.

Control panels are typically structured to facilitate easy interaction. The arrangement of buttons, displays, and indicators is designed to provide clear feedback and streamline user actions. Here is a simplified overview of the common features found in such panels:

Component Function Buttons Allow users to adjust settings and control functions. Display Screen Provides visual information about system status and settings. Indicator Lights Signal operational states or alerts for user attention. Control Knobs Enable fine adjustments for temperature and other parameters. Analyzing these components reveals how thoughtful design can lead to improved functionality and user satisfaction. Recognizing the interplay between various elements helps in understanding how to effectively operate and maintain these systems.

Heat Exchanger Functions in Rinnai Units

The heat exchanger is a crucial component within these heating systems, serving the essential role of transferring thermal energy from one medium to another. This process enhances efficiency and ensures optimal performance, allowing the unit to operate effectively under varying conditions.

Thermal Efficiency and Energy Conservation

One of the primary functions of the heat exchanger is to maximize thermal efficiency. By transferring heat from combustion gases to the water, it minimizes energy loss, ensuring that most of the energy produced is utilized. This not only conserves fuel but also reduces operational costs for the user.

Temperature Regulation and Safety

Another important aspect is temperature regulation. The heat exchanger helps maintain stable temperatures throughout the system, preventing overheating and ensuring safe operation. This contributes to the longevity of the unit and enhances the safety of the overall heating process.

Flow Sensors and Their Importance

Flow sensors play a crucial role in monitoring and controlling the movement of liquids and gases within various systems. By accurately measuring the flow rate, these devices ensure optimal performance, safety, and efficiency. Their integration in heating and hot water systems exemplifies their significance in modern technology.

Understanding the Functionality

These sensors operate by detecting changes in flow velocity and translating these variations into measurable data. This information is vital for maintaining consistent performance, as it allows for real-time adjustments to be made within the system. The data collected can also be used for troubleshooting, ensuring that any issues are addressed promptly.

Benefits of Using Flow Sensors

Implementing flow sensors in a system provides numerous advantages. They enhance energy efficiency by allowing for precise control over flow rates, reducing waste and operational costs. Additionally, they contribute to safety by identifying potential leaks or blockages, thereby preventing damage and ensuring the reliability of the system. Overall, these devices are essential for maintaining the integrity and functionality of various applications.

Examining Rinnai Ignition System Components

Understanding the key elements of an ignition mechanism is essential for maintaining optimal functionality in heating appliances. This section delves into the various components that work together to ensure a reliable start and smooth operation of the ignition process, enhancing overall performance and efficiency.

Essential Elements of the Ignition Mechanism

The ignition mechanism typically comprises several crucial components. These include a spark generator that produces the initial spark necessary for ignition, and sensors that monitor the operational status. Additionally, the control module plays a vital role by coordinating the entire process, ensuring that each part operates in harmony for effective ignition.

Maintenance and Troubleshooting Tips

Regular inspection and maintenance of the ignition components are vital to prevent failures. Checking the spark generator for wear, ensuring connections are secure, and testing sensors for accurate readings can help identify issues early. Proper care not only prolongs the life of these components but also ensures efficient performance during operation.

Role of Gas Valves in Rinnai Devices

Gas valves play a crucial part in the operation of heating systems that rely on gaseous fuels. These components are designed to regulate the flow of gas, ensuring efficient and safe performance of the equipment. By controlling the gas supply, they contribute to the overall efficiency and functionality of the heating appliances, enhancing user comfort and safety.

Functionality and Importance

These valves are responsible for managing the gas pressure and flow rate, which are essential for optimal performance. A well-functioning valve ensures that the correct amount of gas reaches the burner, allowing for effective combustion and heat generation. Inadequate regulation can lead to issues such as incomplete combustion, increased emissions, and even potential hazards.

Maintenance and Troubleshooting

Regular inspection and maintenance of gas valves are essential to ensure their longevity and reliability. Users should be aware of signs of malfunction, such as irregular heating, unusual noises, or gas leaks. Addressing these issues promptly can prevent more serious complications and maintain the efficiency of the heating system.

Fan and Air Circulation Mechanism in Rinnai

The effectiveness of heating and cooling systems greatly relies on the efficiency of the airflow and circulation mechanisms. These elements work together to ensure that air is evenly distributed throughout the environment, maintaining a comfortable atmosphere while optimizing energy consumption.

The fan plays a crucial role in this system, drawing air into the unit and pushing it through various pathways. This movement helps to circulate warm or cool air, enhancing the overall performance of the appliance. The design of the fan blades and motor influences both the speed and volume of airflow, allowing for adjustments based on specific needs.

In addition to the fan, the circulation framework includes ducts and vents that direct the flow of air. These components are strategically positioned to maximize efficiency, ensuring that every corner of the space benefits from regulated temperatures. Proper maintenance of these elements is essential for sustained performance and longevity.

Understanding the interplay between the fan and air circulation components allows users to make informed decisions regarding maintenance and operation. This knowledge can lead to improved efficiency and comfort, creating an optimal environment for various applications.

Maintenance Tips for Rinnai Spare Parts

Regular upkeep of components is essential for ensuring optimal performance and longevity. Implementing effective maintenance practices can prevent issues and enhance the overall efficiency of your equipment.

- Routine Inspections: Conduct regular checks on all components to identify wear or damage. Look for signs of corrosion, leaks, or unusual noises.

- Cleanliness: Keep all components clean from dust and debris. Use appropriate cleaning solutions and methods to avoid damaging any surfaces.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and wear. Ensure you use the recommended type for optimal results.

- Replace Worn Components: Replace any worn or damaged items promptly to maintain performance and prevent further issues.

- Consult Manuals: Refer to the user manuals for specific maintenance guidelines and recommended service intervals to ensure compliance with best practices.

By following these guidelines, you can extend the life of your components and maintain the efficiency of your systems. Proper maintenance not only saves time and costs but also enhances safety.

Choosing the Right

When selecting components for your heating appliance, it is essential to ensure compatibility and quality. The right choice can enhance performance, improve efficiency, and extend the lifespan of your system. Understanding your requirements and available options is crucial for making informed decisions.

Factors to Consider

Several factors should guide your selection process. First, evaluate the specifications and functionalities of the options available. Look for products that match the operational demands of your heating system. Additionally, consider the manufacturer’s reputation and the reliability of the components. Reviews and recommendations can provide valuable insights into performance and durability.

Quality and Compatibility

Opt for components that adhere to industry standards and have been tested for safety and performance. Compatibility with your existing system is paramount; using mismatched items can lead to inefficiencies or even damage. Investing in high-quality materials can significantly reduce the need for frequent replacements and repairs, ultimately saving you time and money.