When maintaining outdoor machinery, having a clear reference for the components involved is essential. Familiarity with the intricate layout of various parts can significantly enhance the efficiency of repairs and upkeep. This understanding not only aids in identifying necessary replacements but also empowers users to optimize the performance of their equipment.

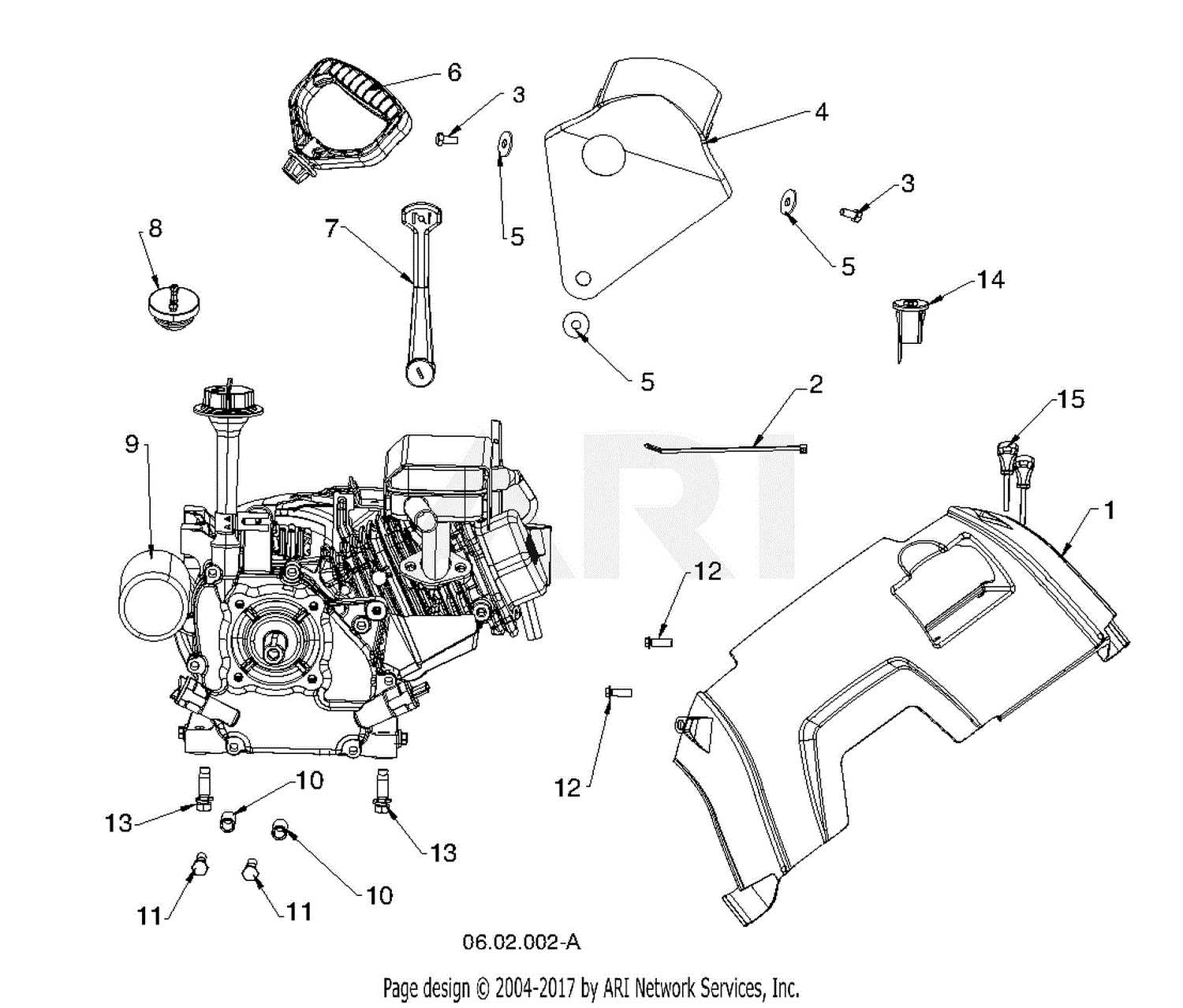

In this section, we will delve into the intricacies of a specific model’s configuration. By breaking down the assembly into its individual elements, we provide a visual guide that simplifies the maintenance process. This resource serves as an invaluable tool for both seasoned technicians and novice users alike, ensuring that everyone can navigate their tasks with confidence.

Whether you are tackling routine maintenance or troubleshooting unexpected issues, recognizing how each segment fits into the whole can save time and prevent errors. With detailed insights into the arrangement of these components, you will be better equipped to address any challenges that may arise during operation.

Poulan Pro PR5020 Overview

This section provides a comprehensive look at a popular outdoor power tool designed for efficiency and durability. Aimed at both professionals and enthusiasts, it combines robust features with user-friendly operation, making it an ideal choice for various landscaping tasks.

Key Features: This model is equipped with a powerful engine that delivers impressive performance, allowing for quick and effective cutting. Its lightweight design enhances maneuverability, reducing user fatigue during extended use.

Maintenance and Care: Regular maintenance is essential for longevity. Familiarizing oneself with the maintenance procedures can significantly improve performance and extend the tool’s lifespan.

Importance of Parts Diagrams

Understanding the layout and components of a machine is crucial for effective maintenance and repair. Visual representations that detail each element provide valuable insight into how a device operates and how its parts interact with one another. This knowledge is essential for anyone looking to ensure longevity and optimal performance of their equipment.

These visual aids serve multiple purposes, from simplifying the repair process to enhancing the overall understanding of the machinery. By clearly illustrating each component, they help users identify what needs to be replaced or repaired, reducing the time and effort required to complete maintenance tasks.

| Benefits | Description |

|---|---|

| Clarity | Visuals make it easier to comprehend complex assemblies. |

| Efficiency | Streamlined processes lead to quicker repairs and replacements. |

| Training | Helpful resources for educating new users on equipment operation. |

| Inventory Management | Facilitates tracking of components and necessary replacements. |

In conclusion, having a comprehensive visual reference not only aids in immediate repair efforts but also contributes to a deeper understanding of how machinery functions as a whole. This ultimately leads to more informed decisions regarding maintenance and care.

Common Issues with PR5020

Every mechanical device can experience challenges that hinder its performance. Understanding these common problems can enhance maintenance and prolong the lifespan of your equipment.

Typical Challenges

- Starting Difficulties

- Chain Tension Problems

- Fuel Leakage

- Overheating

Maintenance Tips

- Regularly check the spark plug for wear.

- Ensure the chain is correctly tensioned.

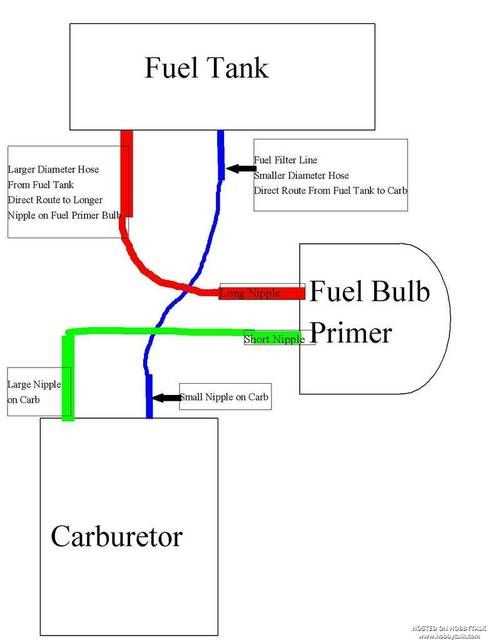

- Inspect fuel lines for cracks or damage.

- Keep the air filter clean to prevent overheating.

How to Read Parts Diagrams

Understanding schematics is essential for anyone looking to maintain or repair equipment effectively. These visual representations provide a clear overview of components, their relationships, and assembly instructions. Grasping how to interpret these illustrations can save time and prevent costly mistakes during maintenance or repairs.

Breaking Down the Illustration

The first step in interpreting these visuals is to familiarize yourself with the symbols and notations used. Each element is typically labeled, allowing you to identify specific components easily. Often, the layout follows a logical order, helping you trace connections and understand how parts interact.

Utilizing the Reference Table

Many schematics include a reference table that correlates numbers or letters on the illustration with detailed descriptions. This table serves as a guide to help you locate the necessary components efficiently. Below is an example of what such a table might look like:

| Label | Description | Part Number |

|---|---|---|

| A | Fuel Tank | 12345 |

| B | Air Filter | 67890 |

| C | Chain Brake | 54321 |

By combining insights from both the visual representation and the accompanying table, you can navigate the repair process with greater confidence and accuracy.

Essential Replacement Parts

Maintaining outdoor equipment often requires a selection of critical components to ensure optimal performance and longevity. Understanding which elements are essential can greatly enhance the efficiency of your machinery, allowing for seamless operation and reducing downtime.

Key Components to Consider

Engines play a vital role in the functionality of outdoor tools. Regular checks and timely replacements can prevent serious malfunctions. Additionally, fuel systems should be monitored closely; replacing filters and lines can significantly improve fuel efficiency and overall performance.

Maintenance Accessories

Beyond primary mechanisms, blades and chains are crucial for tasks requiring cutting precision. Keeping these sharp and in good condition is essential for safe operation. Also, consider spark plugs and batteries as they directly impact starting capabilities and operational reliability.

Maintaining Your Poulan Pro

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By implementing a consistent maintenance routine, you can prevent breakdowns and enhance efficiency. This section will cover key practices to keep your machine running smoothly.

Routine Checks

Frequent inspections of components such as the air filter, spark plug, and fuel system are vital. Cleaning or replacing these parts as needed will help maintain functionality and prevent potential issues.

Storage and Care

Proper storage techniques can significantly extend the lifespan of your equipment. Keep it in a dry, protected space, and ensure that all fluids are appropriately drained or stabilized before long-term storage.

Where to Find Parts Diagrams

Locating detailed schematics for equipment can significantly enhance your repair and maintenance efforts. Understanding how components fit together allows for efficient troubleshooting and replacement of damaged items. Here are several reliable sources to help you find these essential visual guides.

- Manufacturer Websites: The official sites often provide comprehensive resources, including schematics and manuals specific to your model.

- Online Retailers: Many e-commerce platforms specializing in equipment often feature parts breakdowns to assist customers in making informed purchasing decisions.

- Forums and Communities: Enthusiast communities and forums can be invaluable. Members frequently share diagrams and advice based on their experiences.

- Repair Manuals: Purchasing or downloading repair manuals can offer detailed visuals along with step-by-step instructions for assembly and disassembly.

- YouTube Tutorials: Video content often includes visual aids, helping to illustrate the layout and function of various components.

Using these resources can streamline your repair process and ensure that you have the right information at your fingertips.

Tips for Efficient Repairs

When tackling maintenance tasks, being organized and prepared can significantly enhance the process. A systematic approach not only saves time but also ensures that all necessary components and tools are readily available, minimizing disruptions during repairs.

Gather Your Tools

Before starting, collect all essential instruments and replacement items. Having everything at hand allows you to focus on the task rather than searching for tools mid-repair. Consider using a dedicated toolbox to keep everything organized.

Refer to Manuals

Utilize manuals and reference guides to gain insight into specific procedures and components. Understanding the assembly and disassembly process can prevent mistakes and enhance your overall efficiency, leading to a smoother experience.

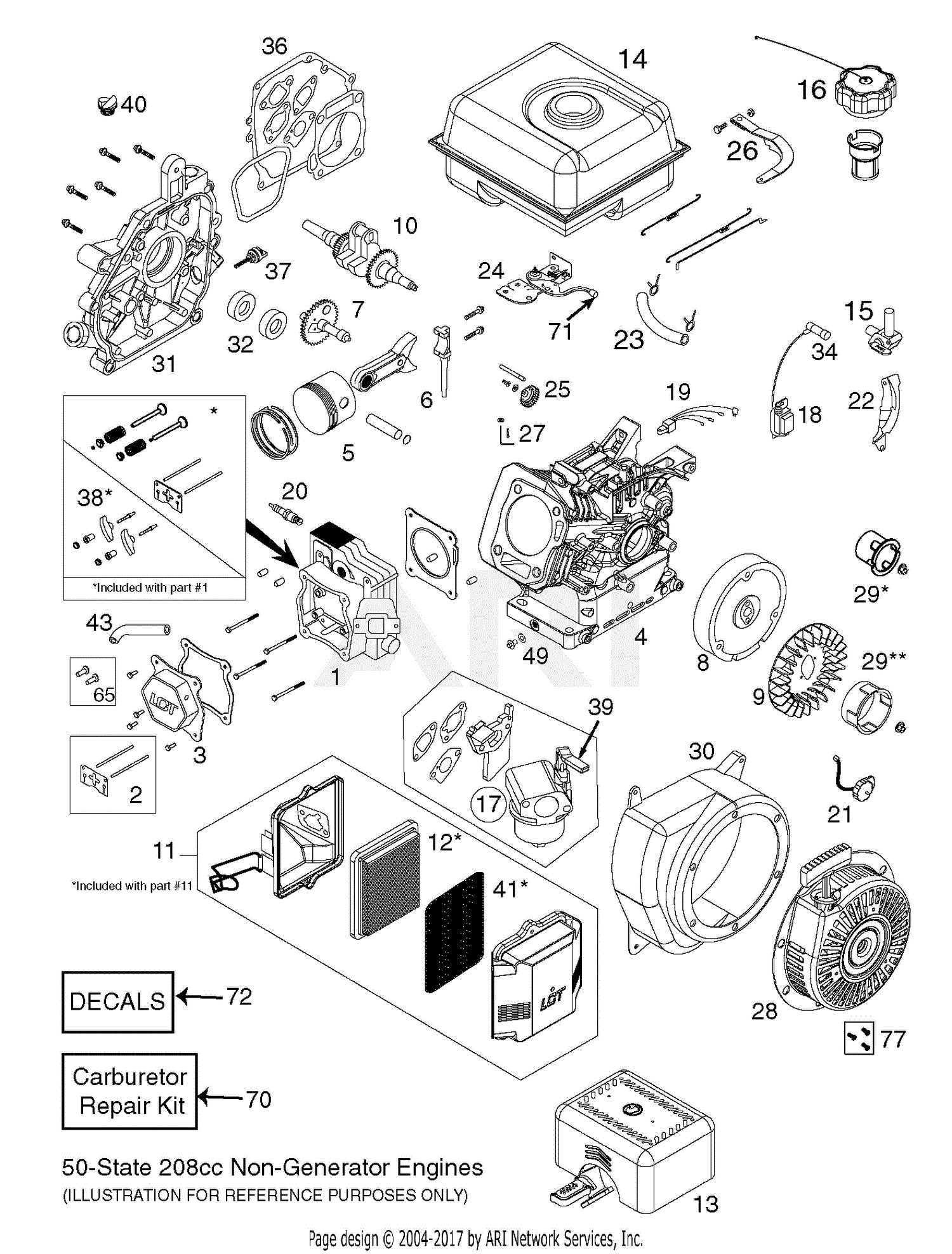

Understanding Engine Components

Engines are complex systems composed of various elements that work together to generate power. A thorough understanding of these components is essential for effective maintenance and repair, ensuring optimal performance and longevity. Each part plays a specific role in the overall operation, contributing to the efficiency and reliability of the engine.

Key components of an engine include:

- Cylinder: The chamber where fuel and air mix and ignite.

- Piston: A movable element within the cylinder that compresses the air-fuel mixture.

- Crankshaft: Converts the linear motion of the piston into rotational motion.

- Camshaft: Controls the opening and closing of the valves at the correct timing.

- Valves: Allow the intake of air and fuel while releasing exhaust gases.

- Ignition System: Responsible for igniting the air-fuel mixture for combustion.

Understanding how these components interact is crucial for diagnosing issues and making informed decisions regarding repairs. Regular inspection and maintenance of each part can prevent breakdowns and enhance performance.

Upgrading Your Poulan Pro Model

Enhancing your outdoor equipment can significantly improve its performance and longevity. By focusing on key components, you can ensure that your machine runs more efficiently, providing better results for your landscaping tasks. This section will explore various upgrades that can transform your device into a more powerful and reliable tool.

One effective approach to upgrading involves evaluating the engine and its accessories. Replacing old or worn-out parts with high-quality alternatives can boost efficiency. Additionally, considering modifications to the fuel system may lead to improved power output and fuel economy.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance air filter | Increased airflow and better combustion |

| Fuel System | Upgraded carburetor | Improved throttle response and efficiency |

| Ignition | Enhanced spark plug | More reliable starts and smoother operation |

| Chain | Advanced cutting chain | Faster cutting and reduced kickback |

Upgrading various components not only maximizes performance but also enhances the overall user experience. Consider these options carefully to make the most out of your outdoor equipment and achieve optimal results in your projects.