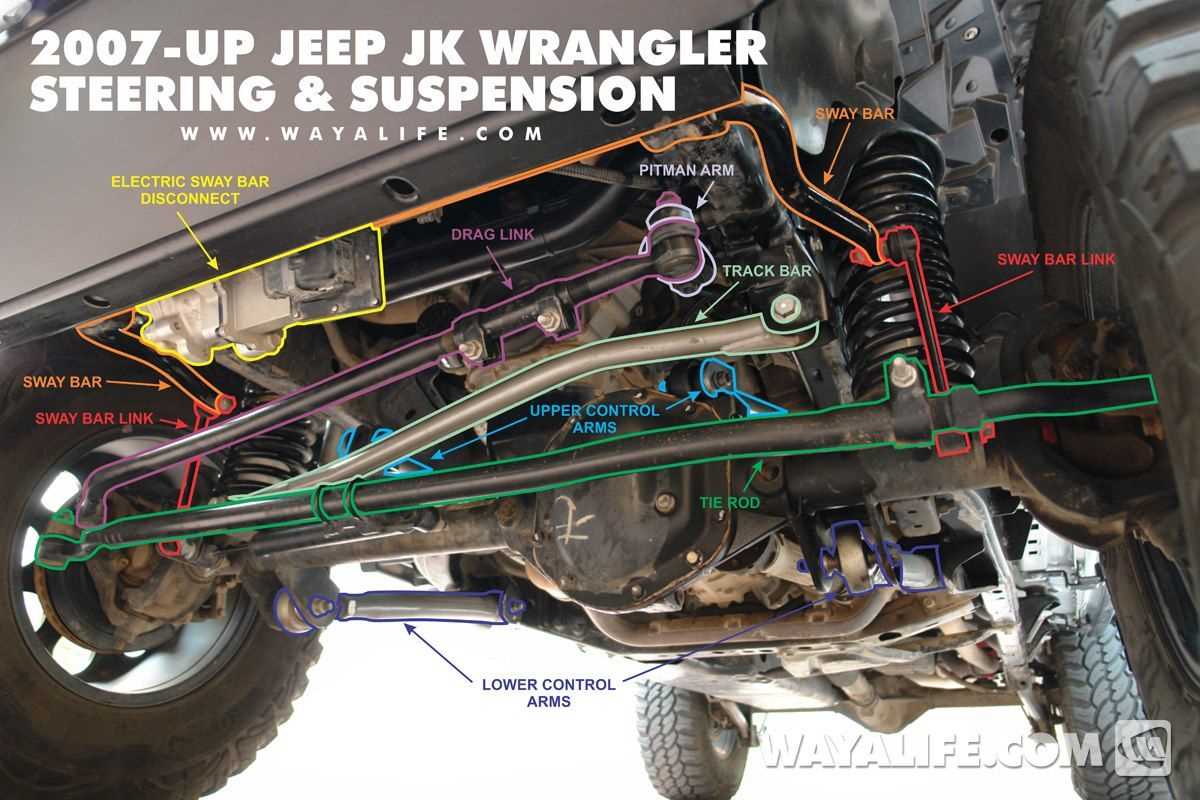

When exploring the intricacies of a vehicle’s directional control system, it is essential to grasp the various elements that contribute to its functionality. This section delves into the essential mechanisms that ensure precise maneuverability and stability on the road, providing a clearer picture of how these components interact to deliver optimal performance.

The assembly responsible for guiding a vehicle through turns and adjustments plays a crucial role in overall driving experience. By examining the interconnected elements, one can appreciate how each component contributes to the seamless operation of the system. A thorough understanding of these crucial components is vital for anyone involved in maintenance or enhancement of vehicle functionality.

In this discussion, we will highlight the significant aspects of the control mechanism, emphasizing their importance in both everyday driving and specialized applications. Recognizing how these components work together can empower owners and enthusiasts alike to make informed decisions regarding repairs and upgrades, ultimately enhancing their vehicle’s responsiveness and safety.

tags: Understanding Jeep JK Steering Components”>

tags: Understanding Jeep JK Steering Components”>

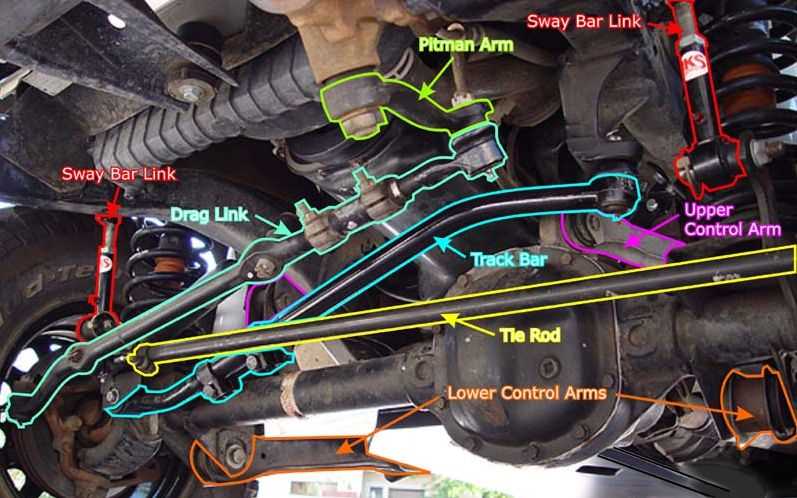

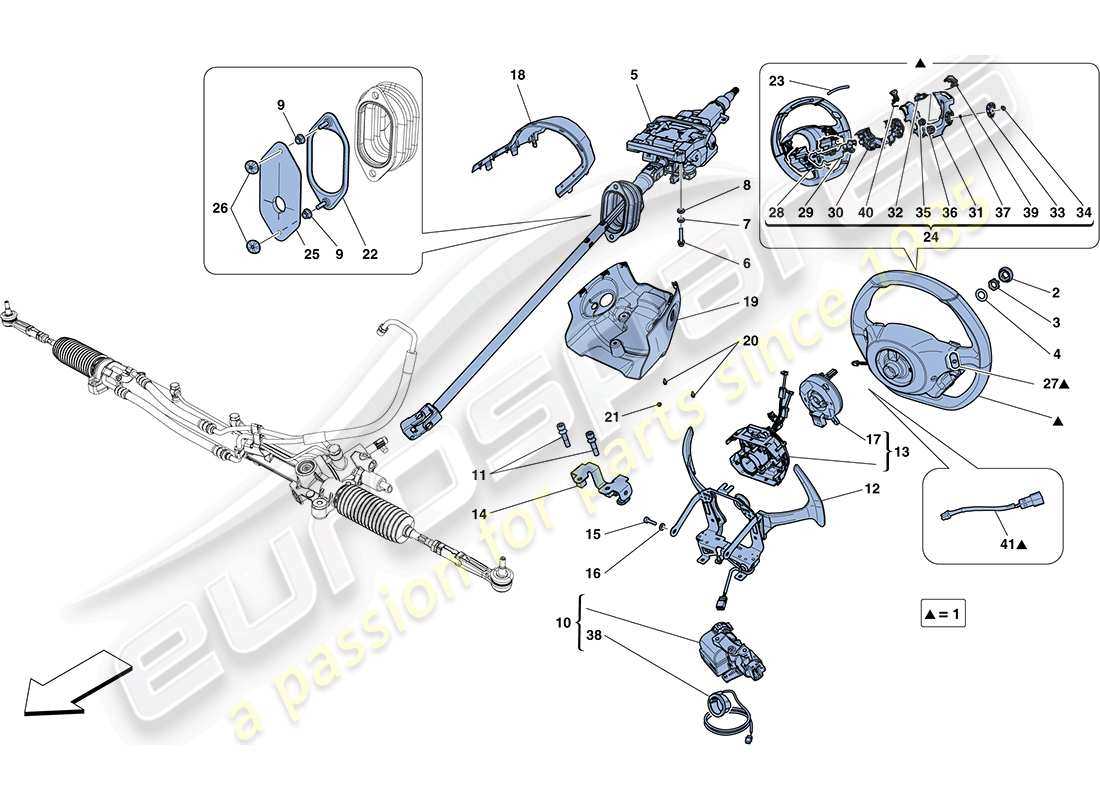

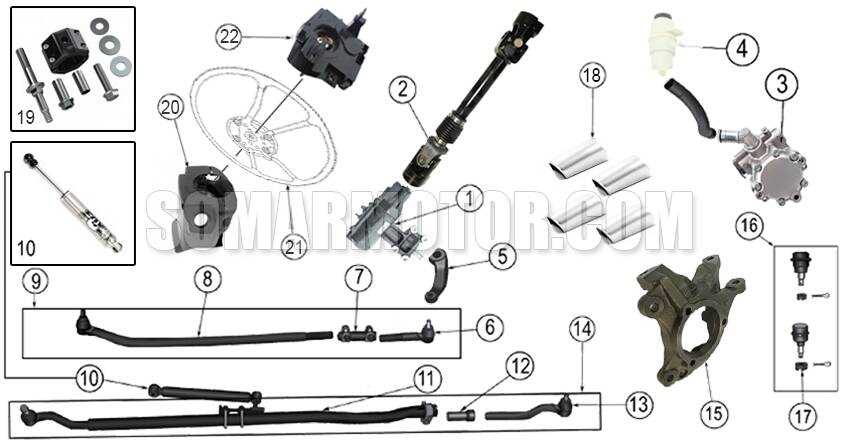

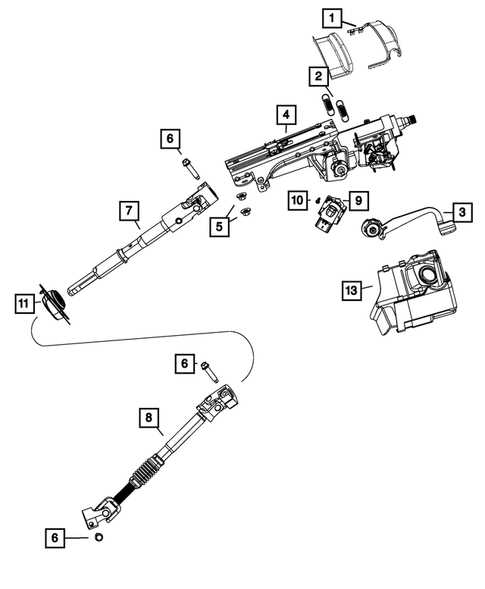

This section provides a comprehensive overview of the various components involved in the directional control system of the vehicle. It highlights the significance of each element in ensuring optimal handling and maneuverability, contributing to a smooth driving experience. The information presented here serves as a foundation for understanding how these components work together to achieve effective navigation.

| Component Name | Function |

|---|---|

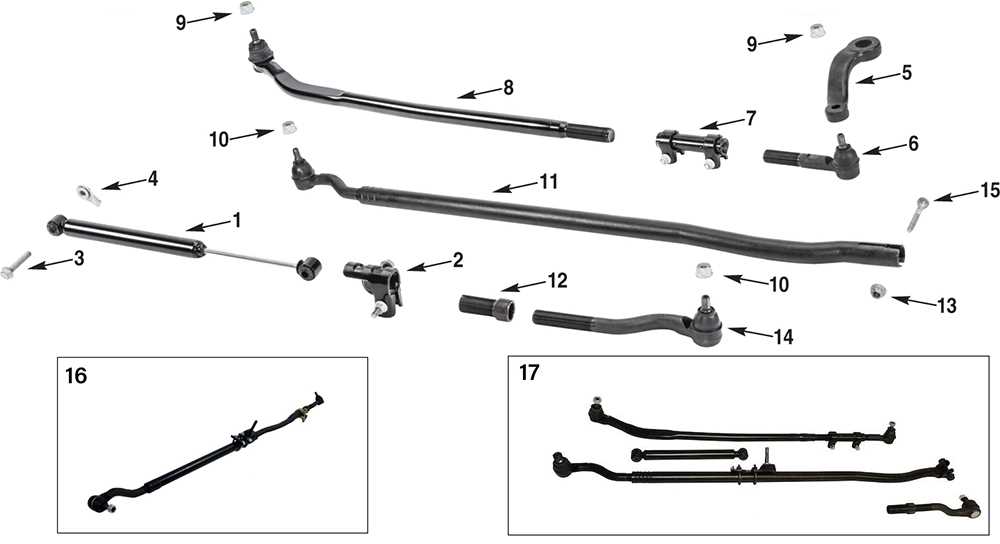

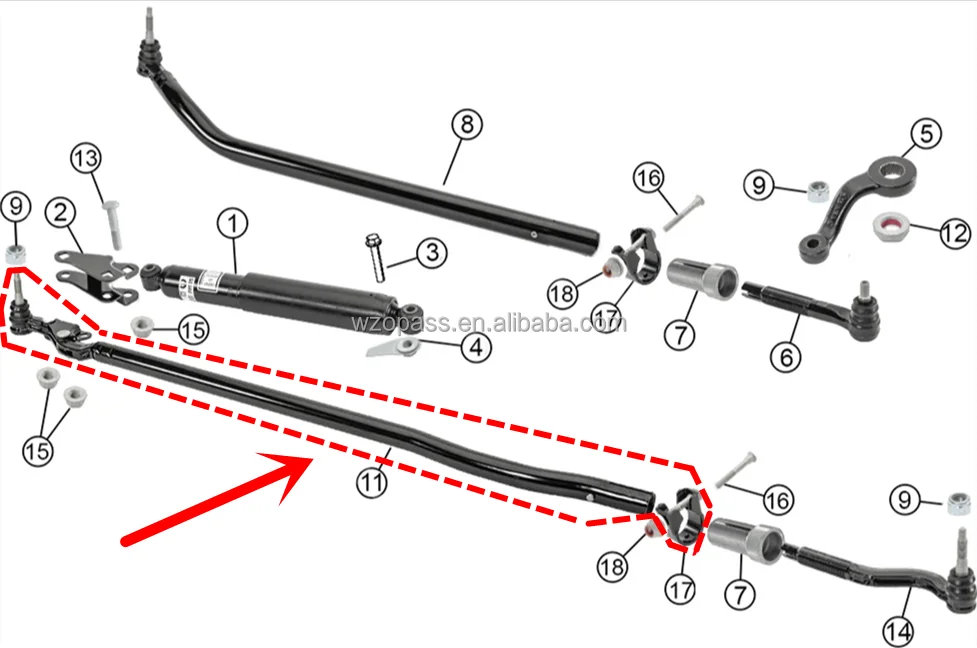

| Linkage Assembly | Connects the steering wheel to the turning mechanism, allowing for directional adjustments. |

| Pivot Points | Facilitate rotation and movement of the turning mechanism, enhancing responsiveness. |

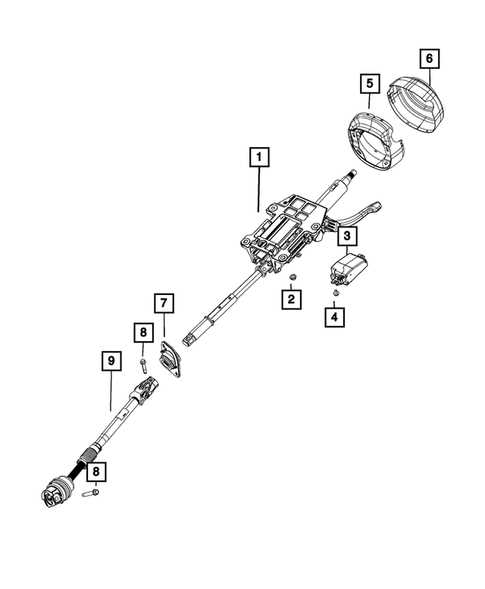

| Control Column | Houses the steering wheel and integrates controls for additional functions. |

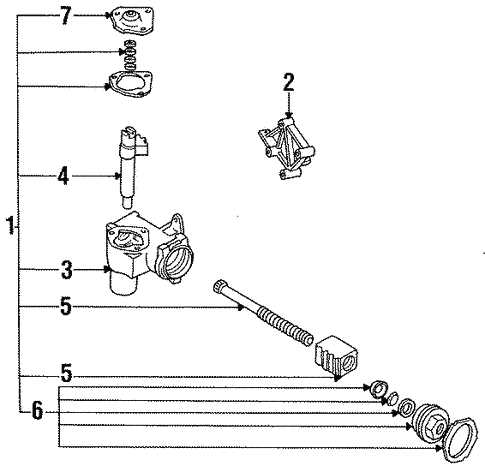

| Racks and Pinions | Converts the circular motion of the wheel into lateral movement for effective navigation. |

| Ball Joints | Allow for flexible movement and stability during directional changes. |

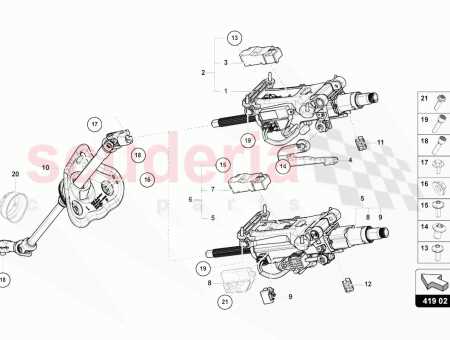

Overview of Steering System Parts

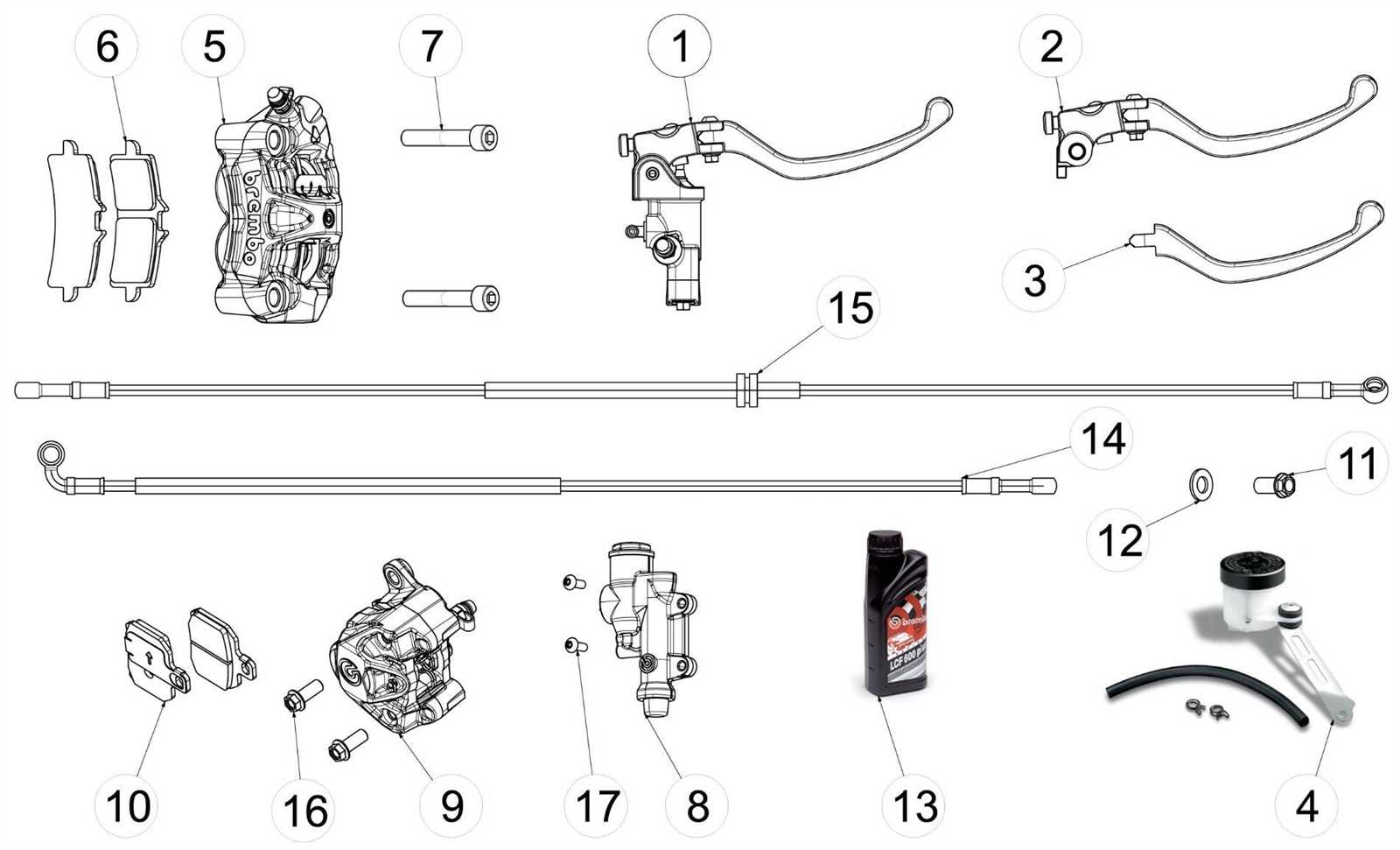

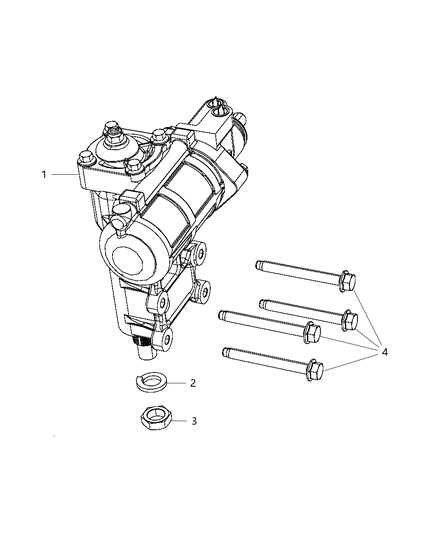

This section provides a comprehensive look at the components involved in the directional control mechanism of vehicles, focusing on their roles and functions within the assembly. Understanding these elements is crucial for ensuring optimal performance and safety while navigating various terrains.

- Control Wheel: The primary interface for the operator, allowing for adjustments in vehicle direction.

- Linkage System: A series of connections that transfer movements from the control wheel to the other components.

- Pivot Mechanism: Enables the connection to rotate, facilitating changes in direction.

- Position Sensors: Provide feedback to electronic systems for enhanced maneuverability.

- Fluid Reservoir: Stores hydraulic fluid, essential for systems that rely on hydraulic assistance.

Each component plays a vital role in the overall functionality, contributing to a smooth and responsive driving experience. Proper maintenance and awareness of these elements can prevent potential issues and enhance vehicle reliability.

Functions of Each Steering Element

This section explores the various components involved in the control and maneuverability of a vehicle, highlighting their essential roles in maintaining stability and responsiveness during operation.

The elements that contribute to the overall performance can be categorized based on their specific functions:

- Linkages: These connections ensure that movements are transmitted accurately, allowing for precise control over direction.

- Pivot Points: These are crucial for enabling rotation, facilitating smooth turns while minimizing wear and tear.

- Shock Absorbers: They play a vital role in reducing vibrations and impacts, contributing to a more comfortable ride.

- Mountings: These secure the components in place, ensuring stability and alignment during operation.

- Couplings: They connect various elements, allowing for flexibility and adaptability in movement.

Understanding the individual roles of these components helps in diagnosing issues and improving performance.

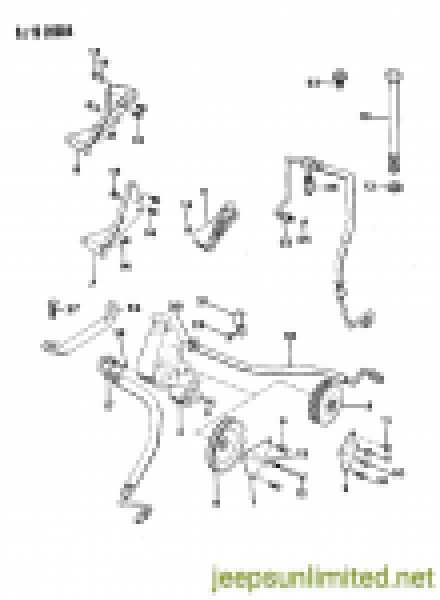

Common Issues in Steering Mechanics

Maintaining proper control over a vehicle is essential for safety and performance. Various challenges can arise in the system responsible for directing the front wheels, often leading to diminished responsiveness and stability. Understanding these common concerns helps in identifying and rectifying problems promptly.

1. Worn Components

Over time, certain elements within the directional control assembly can experience wear and tear, leading to noticeable performance issues. Regular inspection of these components can help in early detection and prevention of further damage.

- Ball joints

- Tie rods

- Linkages

2. Fluid Leaks

Leaks in hydraulic systems can severely impact the efficiency of the control mechanism. Identifying and addressing fluid loss is critical to maintain optimal functionality.

- Hydraulic fluid leaks from hoses

- Seals and gaskets deterioration

- Reservoir issues

How to Identify Steering Problems

Recognizing issues with the directional control system is crucial for maintaining vehicle safety and performance. Several signs can indicate that something is amiss, and being attentive to these can help prevent further complications.

Firstly, pay attention to any unusual sounds, such as grinding or whining noises, which may suggest wear or damage to the components involved in guiding the vehicle. Additionally, if you notice any difficulty in maneuvering the vehicle, such as excessive resistance when turning the wheel, it may indicate a malfunction.

Another key indicator is irregular vibrations felt through the wheel, which can signal an imbalance or misalignment in the system. It’s also essential to observe whether the vehicle tends to pull to one side while driving, as this can be a sign of uneven wear or improper adjustment.

Finally, regular checks of the fluid levels related to the directional control system can help detect leaks or contamination, further assisting in identifying potential issues before they escalate.

Maintaining Jeep JK Steering Systems

Ensuring the optimal performance of your vehicle’s directional control components is essential for a smooth driving experience. Regular upkeep not only enhances safety but also extends the lifespan of these crucial elements. By implementing a proactive maintenance routine, you can prevent potential issues and ensure reliable functionality on various terrains.

Regular Inspections: Conducting periodic checks on your vehicle’s directional control assembly is vital. Look for signs of wear or damage, such as unusual noises, loose connections, or fluid leaks. Addressing these concerns promptly can prevent more significant problems down the road.

Lubrication: Keeping moving parts well-lubricated is essential for smooth operation. Apply suitable grease to joints and pivot points, ensuring that everything operates without friction. Regular lubrication not only minimizes wear but also enhances overall responsiveness.

Alignment Checks: Proper alignment is crucial for maintaining control and stability. If you notice uneven tire wear or your vehicle pulling to one side, it may indicate an alignment issue. Regular alignment checks can prevent premature tire wear and ensure a safe driving experience.

Fluid Maintenance: Check fluid levels and quality in hydraulic systems if applicable. Replace fluids as recommended by the manufacturer to maintain optimal performance. Contaminated fluids can lead to inefficiency and potential damage.

Replacement of Worn Components: Components that show signs of significant wear should be replaced to maintain the integrity of the system. Investing in high-quality replacements ensures durability and performance, allowing for a better driving experience.

Aftermarket Parts vs. OEM Components

The decision between alternative components and original manufacturer items is crucial for vehicle enthusiasts. Each option carries distinct advantages and considerations, impacting performance, reliability, and budget. Understanding these differences helps in making informed choices tailored to specific needs.

Advantages of Aftermarket Options

Alternative components often present several benefits that attract buyers:

- Cost-effectiveness: Generally, aftermarket items are more affordable than their original counterparts, allowing for significant savings.

- Variety: The aftermarket sector offers a diverse range of products, catering to various preferences and performance requirements.

- Customization: Enthusiasts can find unique designs and features that enhance their vehicle’s aesthetics and capabilities.

Benefits of OEM Items

On the other hand, original manufacturer components also have compelling advantages:

- Quality Assurance: These items are designed and tested by the vehicle’s manufacturer, ensuring compatibility and reliability.

- Warranty Support: OEM components typically come with warranties, providing peace of mind regarding performance and longevity.

- Easy Installation: Original items often fit seamlessly, reducing the complexity of installation processes.

Upgrading Your Steering Setup

Enhancing the control system of your vehicle can significantly improve handling and responsiveness, providing a more enjoyable driving experience. By considering various upgrades, you can tailor your setup to meet your specific needs and driving conditions.

Benefits of Upgrading

- Improved maneuverability

- Increased stability on rough terrain

- Enhanced feedback for better driver awareness

Key Components to Consider

- High-performance linkages for better durability

- Adjustable alignments to fine-tune handling

- Quality bushings to reduce play and enhance feel

When selecting new components, ensure compatibility with your vehicle’s existing setup. Research various options and consult with professionals to make informed decisions that enhance overall performance.

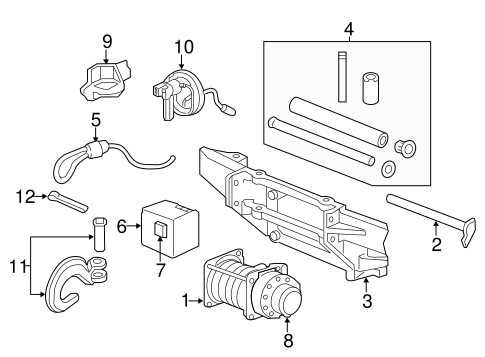

Tools Needed for Steering Repairs

When addressing issues related to vehicle handling, it is crucial to have the right equipment on hand. Proper instruments ensure that the process is efficient and prevents potential damage during disassembly or reassembly. For those planning to tackle mechanical tasks, being well-prepared is key to success.

Basic Essentials

Before starting, gather basic wrenches, sockets, and ratchets. These common tools are necessary for loosening or tightening various bolts and components. A torque wrench is also vital for ensuring correct tension during reassembly.

Specialized Equipment

In some cases, more specific devices like pullers or alignment tools may be needed. These items assist in safely removing components or ensuring precise adjustments, making the repair smoother and more accurate.

Step-by-Step Steering Replacement Guide

Replacing key components in your vehicle’s control system is a crucial task that demands precision and proper technique. This guide provides clear instructions on how to safely and efficiently complete the task, ensuring smooth handling and improved performance.

Preparation and Tools

Before starting the process, make sure you have all the necessary tools and materials. A well-organized workspace will help streamline the replacement process and prevent any interruptions.

- Socket wrench set

- Torque wrench

- Safety gloves and glasses

- Replacement hardware

Component Removal Process

Start by lifting the vehicle and securing it with jack stands. Carefully remove the old assemb

Preventative Measures for Steering Longevity

Ensuring the durability of your vehicle’s maneuvering system involves consistent care and attention. By implementing regular check-ups and adopting good driving habits, you can extend the life of critical components and avoid costly repairs. Proper maintenance will help reduce wear over time and improve overall performance.

Key Maintenance Practices

- Regularly inspect connections and fasteners

Expert Tips for DIY Repairs

Taking on repair projects at home can be a rewarding experience, offering both the satisfaction of hands-on work and the chance to maintain your vehicle without relying on professional help. Whether you’re fixing small issues or diving into more complex tasks, there are key strategies that can make the process smoother and more efficient.

Preparation is Key

Before starting, it’s essential to ensure you have all the necessary tools and equipment at hand. Proper preparation reduces downtime and helps you avoid mistakes. Here’s a quick checklist of actions to consider:

- Gather tools and safety gear in advance

- Familiarize yourself with the repair process

- Double-check that the environment is safe and well-lit

Step-by-Step Approach

Tackling the task in smaller, manageable steps

Resources for Jeep JK Enthusiasts

Finding the right tools and knowledge can greatly enhance the experience of owning and modifying a 4×4 vehicle. Whether you’re a seasoned off-road driver or just starting out, there are numerous ways to stay informed and prepared for any situation. Accessing reliable information and guides can make a big difference in ensuring your vehicle runs smoothly and performs optimally on any terrain.

Source Description Online Communities Join forums and social media groups where enthusiasts share their experiences, tips, and advice. Instructional Videos Watch step-by-step guides on various vehicle upgrades and maintenance tasks.