For those who operate outdoor machinery, a comprehensive understanding of the different components and their arrangement is essential. This knowledge enhances maintenance practices and promotes efficient operation, ensuring that every piece of equipment functions optimally. An organized visualization of the machinery’s structure can greatly aid in identifying parts and understanding their interconnections.

In this section, we delve into the intricate layouts of various machinery, focusing on the elements that make up these robust systems. By examining the arrangement and relationships of different components, operators can gain valuable insights into how to effectively manage and troubleshoot their equipment. Such familiarity is not only beneficial for routine checks but also crucial for addressing any operational challenges that may arise.

Equipped with this knowledge, users will be better prepared to maintain their machinery in peak condition. Understanding how each element fits into the overall framework empowers individuals to take proactive steps in their maintenance routines, ultimately prolonging the life of their equipment.

Toro Workman Overview

This section provides an overview of a versatile utility vehicle designed for various outdoor tasks. Known for its rugged construction and efficiency, this machine serves a broad range of applications, from landscaping to maintenance in diverse environments. Its robust performance and reliability make it a preferred choice among professionals in the field.

The vehicle boasts an ergonomic design, ensuring comfort during prolonged use. With an array of attachments available, it can be customized to meet specific operational needs. Additionally, its powerful engine and exceptional maneuverability enable users to tackle challenging terrain with ease, enhancing productivity on the job site.

Maintenance of this equipment is straightforward, thanks to its accessible components. Regular servicing not only prolongs its lifespan but also ensures optimal performance throughout its usage. By prioritizing user experience and operational effectiveness, this vehicle stands out as a dependable solution for various outdoor projects.

Importance of Parts Diagrams

Understanding the layout of components within a machine is essential for effective maintenance and repair. Visual representations of these elements serve as valuable resources, providing clarity on how various parts interact and function together. This knowledge not only aids technicians in performing tasks efficiently but also enhances the overall reliability and longevity of the equipment.

Facilitating Efficient Repairs

When issues arise, having a clear visual guide can significantly speed up the troubleshooting process. Here are some advantages of utilizing such resources:

- Quick identification of malfunctioning elements

- Streamlined disassembly and reassembly processes

- Reduced downtime during repairs

Enhancing Knowledge and Skills

Visual aids play a crucial role in educating operators and technicians about machinery. Key benefits include:

- Improved understanding of machine mechanics

- Support for training new personnel

- Encouragement of proactive maintenance practices

Key Components of Toro Workman

This section provides an overview of essential elements that contribute to the functionality and efficiency of a versatile utility vehicle. Understanding these fundamental components is crucial for anyone seeking to optimize the performance of this remarkable equipment.

| Component | Description |

|---|---|

| Engine | Power source responsible for driving the vehicle and enabling various operations. |

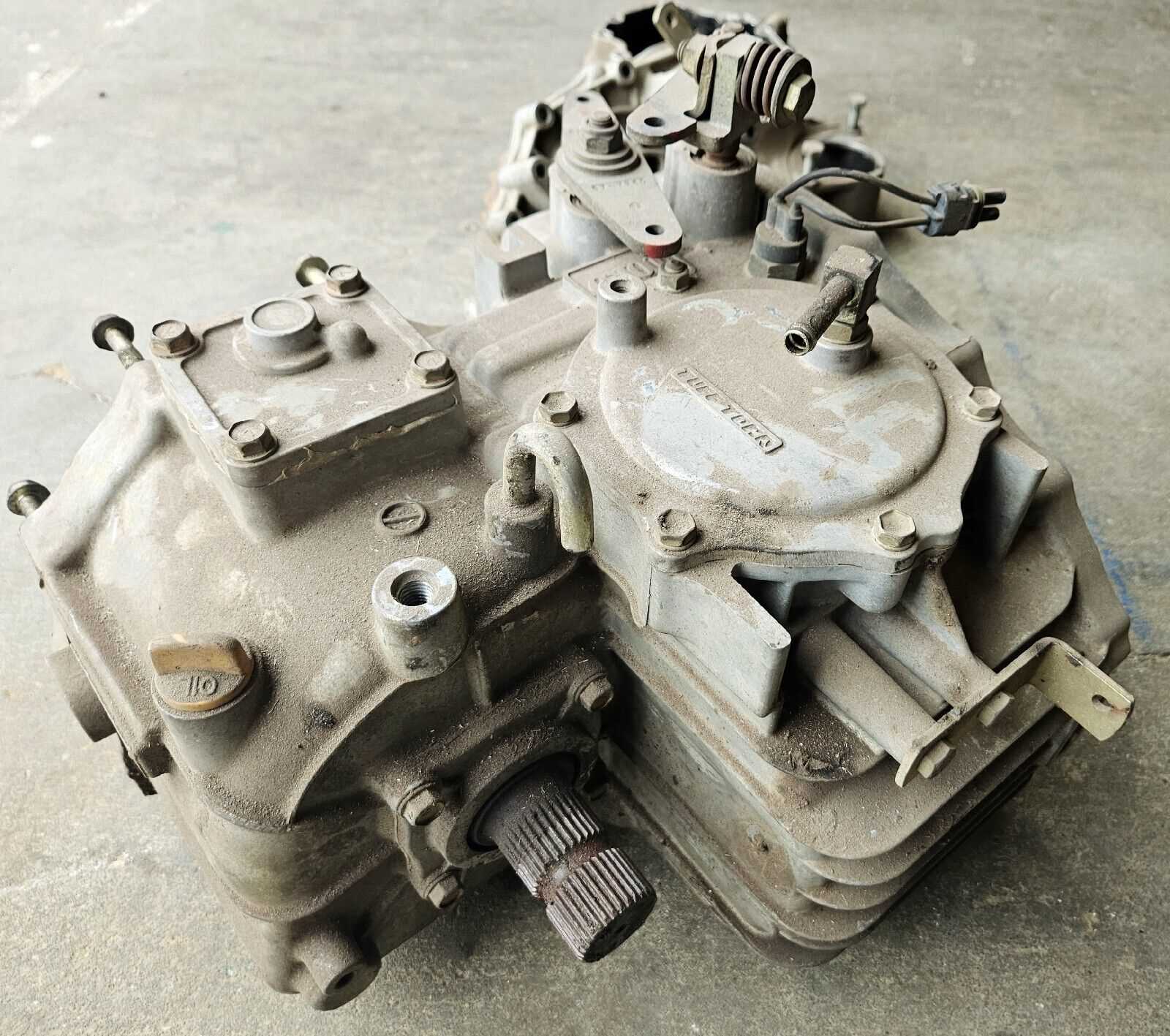

| Transmission | Mechanism that transfers power from the engine to the wheels, allowing for smooth movement. |

| Chassis | The framework that supports all other components and provides structural integrity. |

| Steering System | Controls the direction of the vehicle, ensuring precise maneuverability. |

| Hydraulic System | Facilitates the operation of various attachments and implements, enhancing versatility. |

| Braking System | Enables the vehicle to slow down or stop safely, ensuring operator control. |

| Suspension | Absorbs shocks and provides stability, improving ride quality on uneven surfaces. |

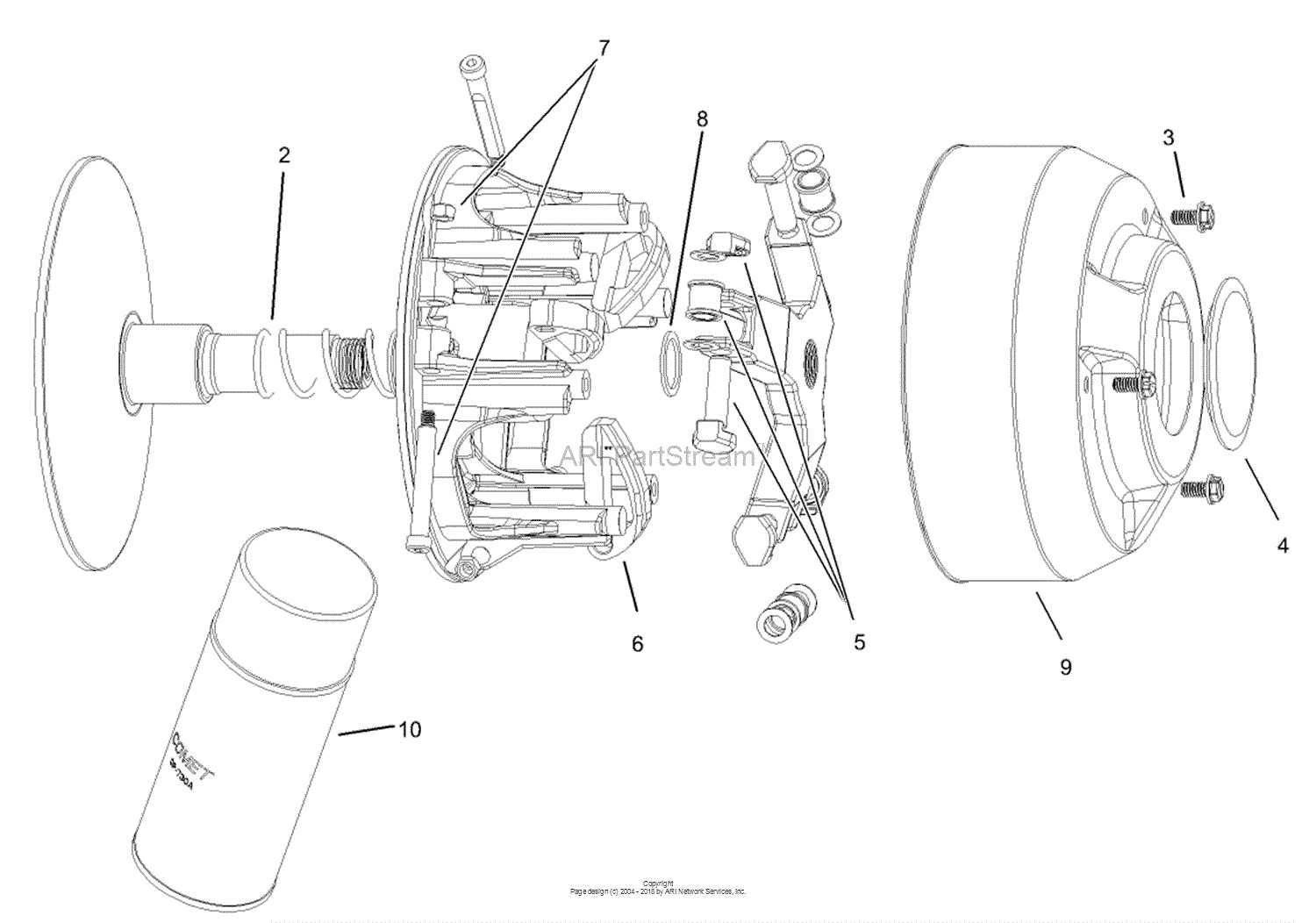

Understanding the Parts Diagram

The components of a machine can be complex, yet comprehending their layout is essential for effective maintenance and repair. A visual representation often provides clarity, showcasing how each element fits into the overall structure. This knowledge is crucial for anyone involved in the upkeep or enhancement of equipment.

Recognizing individual elements allows operators to identify specific areas requiring attention. When you familiarize yourself with these illustrations, it becomes easier to locate potential issues and understand the relationship between different parts. This understanding not only aids in troubleshooting but also enhances overall operational efficiency.

Furthermore, knowing the layout of various components can significantly reduce downtime during repairs. With a clear reference at hand, technicians can quickly pinpoint the necessary tools and replacement items. This preparation streamlines the maintenance process, ultimately leading to more effective and timely solutions.

Common Issues in Toro Workman

When operating utility vehicles, users often encounter various challenges that can affect performance and efficiency. Understanding these common issues can help in maintaining optimal functionality and prolonging the lifespan of the equipment. Addressing these concerns promptly ensures that the vehicle remains reliable for various tasks.

Engine Performance Problems

One frequent issue involves engine performance, which may manifest as poor starting or uneven running. These problems can stem from several factors, including fuel quality, air filter obstructions, or spark plug wear. Regular maintenance, such as replacing filters and checking fuel systems, is essential for preventing these complications and ensuring smooth operation.

Electrical System Failures

Another area of concern is the electrical system, where users might experience malfunctioning lights or difficulty starting the vehicle. These issues are often linked to battery health, wiring connections, or faulty ignition components. Routine inspections and timely replacements of worn-out parts can mitigate these electrical challenges and enhance the vehicle’s reliability.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a daunting task, especially when the right resources are not readily available. Understanding the options and where to find them can streamline the process, making it more efficient and less stressful.

To simplify your search for necessary components, consider the following strategies:

- Utilize online marketplaces that specialize in equipment supplies.

- Refer to manufacturer websites for catalogs and listings of compatible items.

- Join forums or groups related to equipment maintenance for recommendations.

- Consult local dealers who might offer valuable insights and availability.

- Check for manuals or guides that outline compatible components and their specifications.

By employing these methods, you can enhance your chances of quickly finding the right items needed for effective repairs and maintenance.

Maintenance Tips for Toro Workman

Ensuring the longevity and efficiency of your outdoor utility vehicle requires regular upkeep and attention. Proper maintenance not only enhances performance but also reduces the likelihood of unexpected breakdowns. Following systematic procedures can help extend the lifespan of various components, keeping the machinery in optimal condition for daily tasks.

Regular Inspection

Conducting frequent inspections is crucial for identifying potential issues before they escalate. Check for signs of wear and tear, particularly on belts, tires, and brakes. Regularly examining fluid levels, including oil and coolant, ensures that the engine operates smoothly. Addressing minor concerns promptly can prevent more significant repairs down the line.

Cleaning and Lubrication

Maintaining a clean work environment for your machinery is essential. Remove dirt, debris, and any obstructions that may hinder performance. Additionally, ensure that moving parts are adequately lubricated to minimize friction and wear. Utilizing appropriate cleaning agents and lubricants will help maintain efficiency and prolong the life of your equipment.

Benefits of Using Genuine Parts

Choosing authentic components for machinery is crucial for maintaining optimal performance and longevity. These specialized items are designed to fit seamlessly and function effectively within the system, ensuring that the equipment operates at its best. By opting for high-quality replacements, users can avoid the pitfalls often associated with inferior alternatives.

Enhanced Durability

Genuine components are crafted from superior materials, resulting in increased resilience against wear and tear. This durability not only extends the lifespan of the equipment but also reduces the frequency of replacements, leading to significant cost savings in the long run.

Improved Efficiency

Using authentic replacements guarantees compatibility with existing machinery. This synergy between parts leads to improved efficiency, allowing the equipment to perform tasks more effectively. Enhanced performance translates to better results and higher productivity, making the investment in genuine components worthwhile.

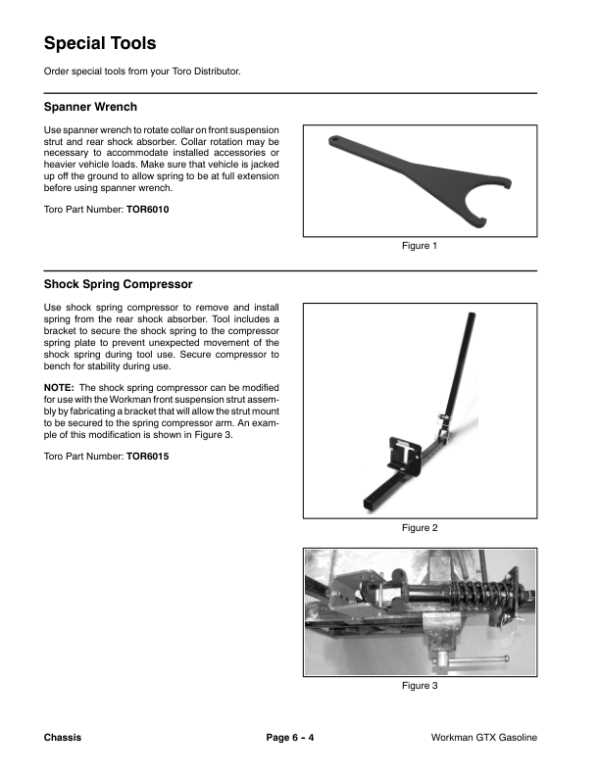

How to Read a Parts Diagram

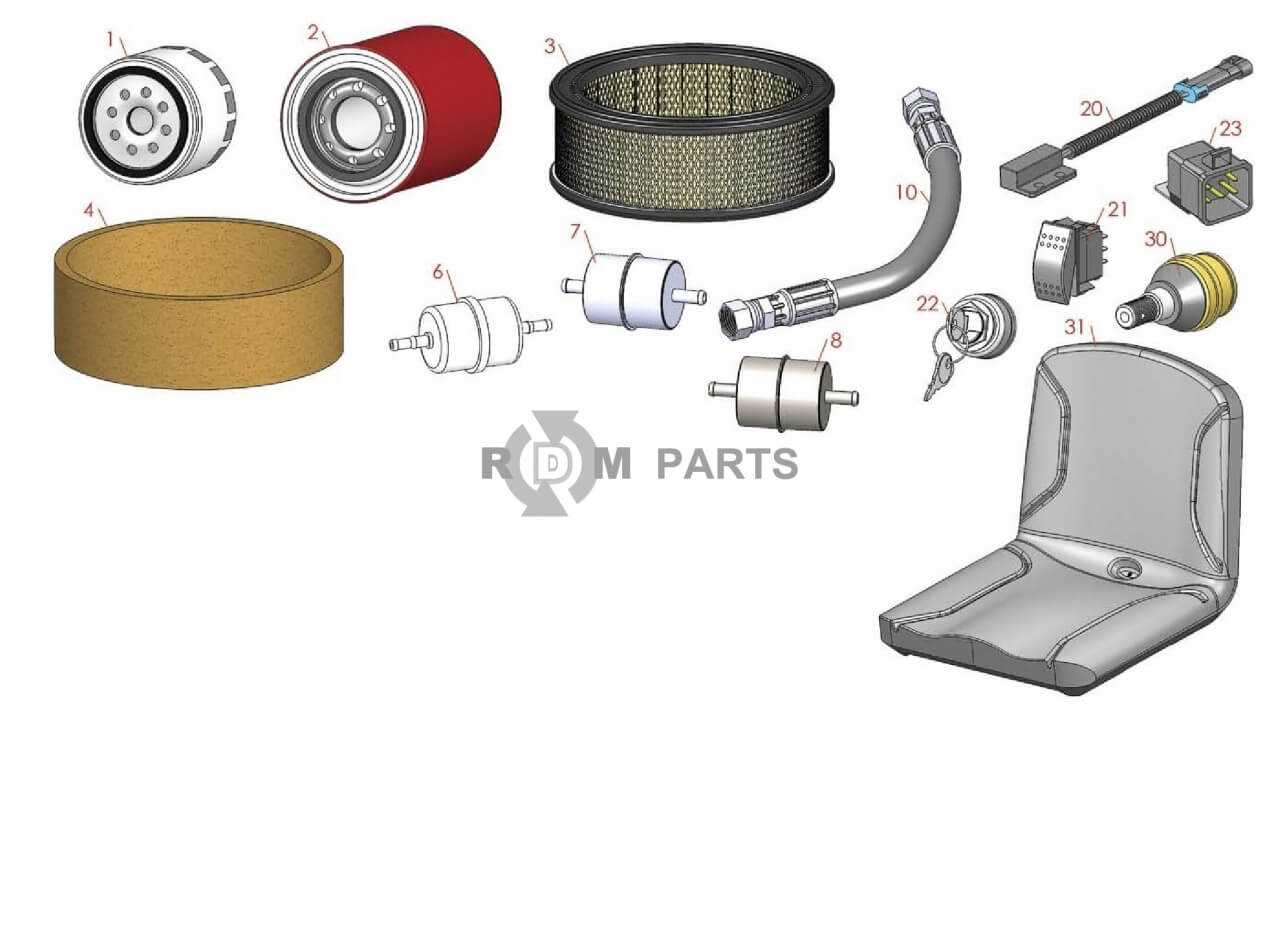

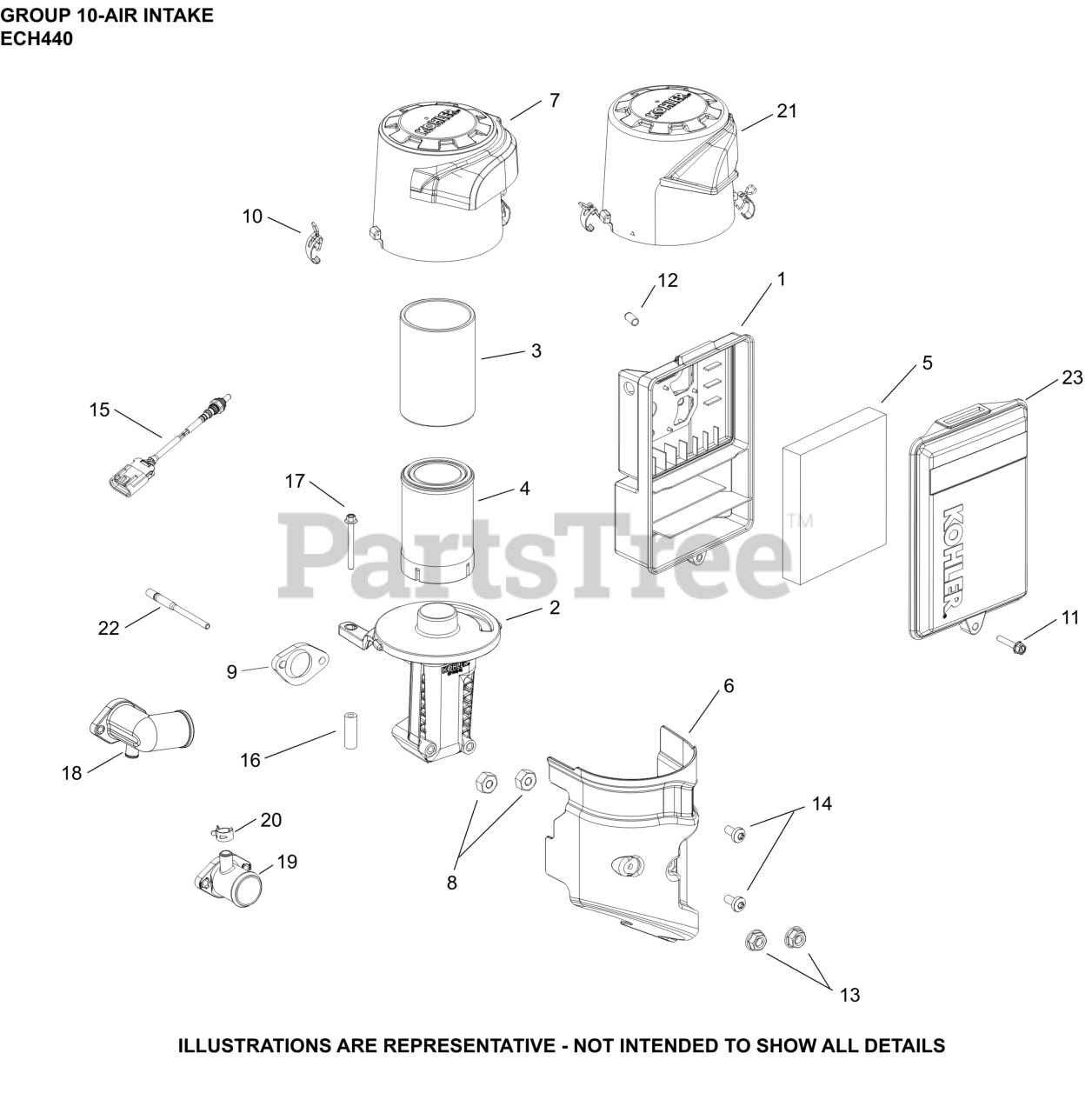

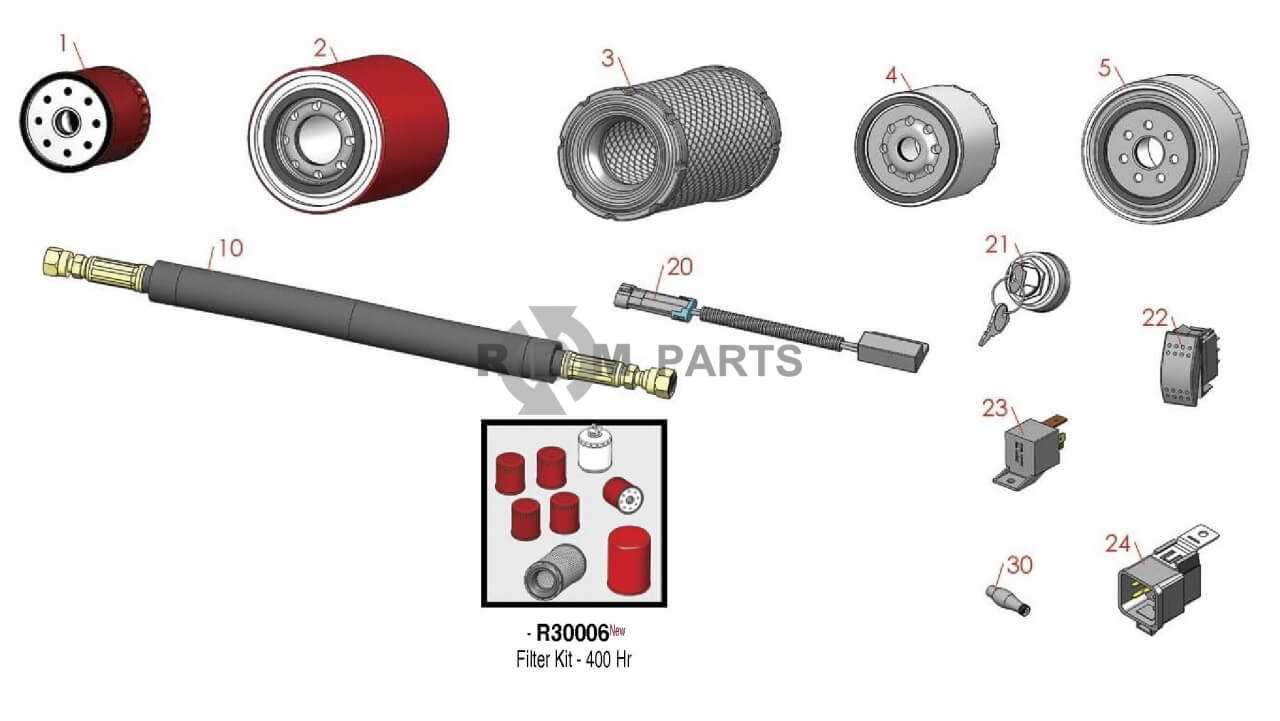

Understanding a visual representation of components is essential for efficient maintenance and repairs. This type of illustration provides a detailed overview of various elements, helping users identify their locations and functions within a machine.

Begin by familiarizing yourself with the key features of the illustration. Look for reference numbers or labels next to each component, which typically correspond to a list or catalog. This information aids in recognizing specific items needed for replacements or repairs.

Next, pay attention to the arrangement of parts within the image. Components are often grouped based on their functionality or proximity to one another, which can simplify the identification process. Take note of the connections and pathways between elements, as this insight can assist in troubleshooting and assembly.

Finally, practice using the representation by comparing it with the actual machine. Regularly referring to the visual guide while working can enhance your familiarity with the layout, ultimately improving your efficiency and confidence in handling repairs.

Frequently Replaced Components

Regular maintenance often involves the replacement of specific elements that experience wear over time. These components are crucial for the optimal functioning of equipment, ensuring both performance and safety. Identifying which parts commonly need replacement can help streamline maintenance efforts and prolong the lifespan of the machinery.

Among the frequently changed items are filters, which play a vital role in maintaining clean fluid circulation. Belts are also essential; they may wear out due to constant tension and motion, requiring periodic checks and replacements. Additionally, batteries are often replaced, especially in equipment used for prolonged periods, as their efficiency diminishes with time.

Other notable components include spark plugs and hoses, both of which can significantly impact performance if not properly maintained. Keeping a close eye on these elements and replacing them as necessary can lead to smoother operation and reduced downtime.

Resources for Toro Workman Owners

Owning a specialized utility vehicle comes with the need for reliable information and support. This section aims to provide essential resources that assist users in maximizing their vehicle’s performance and longevity. From maintenance guides to community forums, there are numerous avenues available to enhance the ownership experience.

Maintenance and Repair Guides

Accessing comprehensive maintenance and repair manuals is crucial for keeping the vehicle in optimal condition. These guides typically cover a range of topics, including routine inspections, troubleshooting common issues, and detailed procedures for repairs. Online resources often provide downloadable PDFs or access to interactive platforms where users can find specific information tailored to their vehicle’s model and year.

Community and Support Forums

Joining dedicated forums and community groups can be invaluable for owners seeking advice or sharing experiences. These platforms allow users to connect with fellow enthusiasts, ask questions, and gain insights from seasoned operators. Many forums also feature sections for buying and selling parts, providing a space to find quality components and share recommendations for trusted suppliers.