In the realm of aquatic maintenance, grasping the intricacies of various machinery is crucial for optimal performance and longevity. A comprehensive overview of essential elements can enhance efficiency and prevent costly repairs. Each unit comprises specific features that work in harmony to ensure smooth operation.

Exploring the intricacies of these components allows enthusiasts and professionals alike to troubleshoot issues effectively. Recognizing how each element functions and interacts with others provides valuable insights for both installation and upkeep. With this knowledge, users can delve deeper into the mechanics behind their equipment.

Ultimately, an informed approach to understanding these vital parts will empower users to make better decisions regarding maintenance and replacements. By mastering the layout and functionality, one can ensure their system operates at peak performance, prolonging its lifespan and enhancing overall enjoyment.

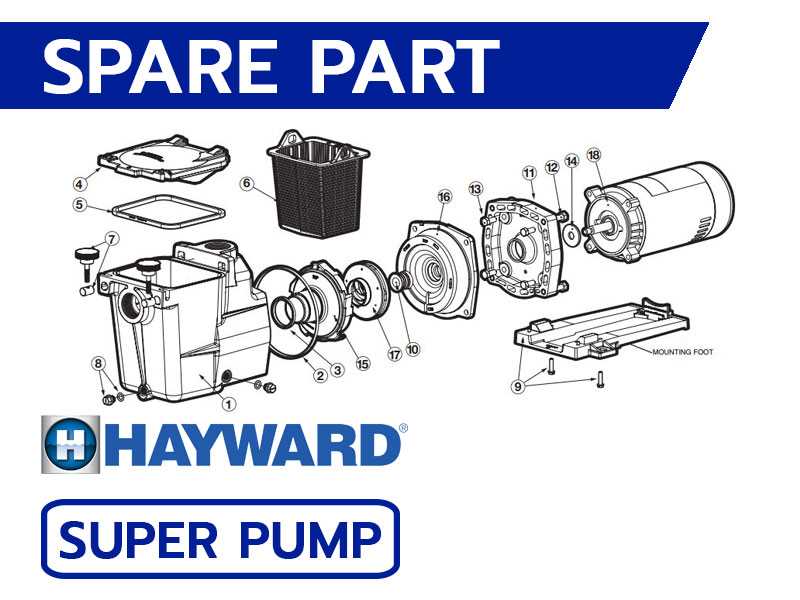

Understanding Hayward Super Pump Components

Grasping the essential elements of a filtration system is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficient water circulation and clarity. Familiarity with these individual parts helps users troubleshoot issues effectively.

- Housing: The outer shell that protects internal mechanisms.

- Impeller: Responsible for moving water through the system.

- Diffuser: Directs water flow from the impeller to the outlet.

- Seal: Prevents leaks and maintains pressure within the unit.

Each section works in harmony, contributing to the overall functionality and longevity of the entire setup.

Overview of Hayward Super Pump Design

This section provides a comprehensive look at the innovative engineering behind one of the leading solutions for water circulation. The design incorporates advanced technologies and high-quality materials to ensure efficiency and reliability. Each component works in harmony to deliver optimal performance, making it an essential choice for maintaining pristine water quality.

The system features a streamlined casing that minimizes resistance, promoting effective fluid movement. Inside, a robust assembly includes precision-engineered elements that enhance durability and reduce noise during operation. This meticulous design not only supports longevity but also contributes to energy savings, positioning it as a top contender in the market.

Additionally, user-friendly features are integrated to facilitate maintenance and accessibility, ensuring that upkeep remains straightforward for operators. Overall, this solution exemplifies a balance of functionality, efficiency, and ease of use, meeting the ultimate needs of users.

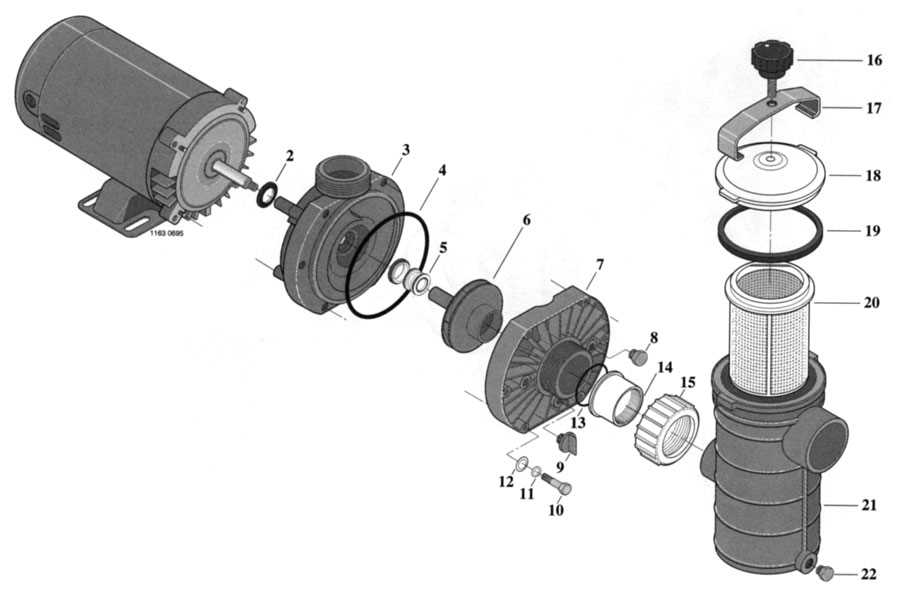

Key Functions of Motor Parts

The components of an electric drive system play crucial roles in ensuring efficient operation and longevity. Each element contributes uniquely to the overall functionality, facilitating seamless energy conversion and mechanical movement.

- Stator: This stationary part generates a magnetic field that interacts with the rotor, initiating motion.

- Rotor: A pivotal component that rotates within the magnetic field, converting electrical energy into mechanical energy.

- Bearings: Essential for reducing friction, these elements support rotating parts, ensuring smooth and reliable operation.

- Capacitor: This device stores electrical energy, helping to start the system and improve efficiency during operation.

- Windings: Coils of wire that create magnetic fields when electricity flows through them, crucial for the system’s functioning.

Understanding the individual roles of these components can aid in troubleshooting and maintenance, ultimately enhancing performance and durability.

Identifying Pump Assembly Elements

Understanding the components of a circulation system is crucial for effective maintenance and troubleshooting. Each element plays a specific role in ensuring efficient operation, contributing to the overall performance and longevity of the system. Familiarity with these parts allows users to diagnose issues quickly and implement appropriate solutions.

Key Components Overview

The main elements include the casing, impeller, and diffuser, each serving distinct functions. The casing houses the internal components, providing protection and structure. The impeller, a vital component, is responsible for moving fluid through the system, while the diffuser helps convert kinetic energy into pressure, ensuring optimal flow. Recognizing these parts is essential for any maintenance task.

Maintenance and Care

Regular inspection of these components can prevent common issues such as leaks and reduced efficiency. By understanding how to identify and access each part, users can perform necessary upkeep, ensuring reliable operation. This proactive approach not only enhances performance but also extends the lifespan of the entire system.

Importance of Electrical Connections

Electrical connections play a crucial role in the overall functionality and efficiency of any system relying on electricity. Properly established links ensure optimal performance and longevity of the equipment.

Key reasons to prioritize quality connections include:

- Safety: Reliable connections reduce the risk of electrical faults, preventing potential hazards.

- Efficiency: Well-maintained links minimize energy loss, enhancing overall performance.

- Durability: Quality connections prolong the lifespan of components, saving time and resources on repairs.

- Maintenance: Simplified inspections and troubleshooting processes lead to quicker resolutions of issues.

In summary, ensuring robust electrical connections is vital for maximizing performance and ensuring the safe operation of electrical systems.

Maintenance Tips for Motor Longevity

Ensuring the durability of your device’s engine is essential for optimal performance and efficiency. Regular upkeep can significantly extend its lifespan, minimizing the need for costly repairs or replacements. This section outlines effective strategies to maintain your unit in peak condition.

Regular Inspections

Conducting periodic assessments is crucial. Look for signs of wear and tear, loose connections, or unusual noises. Early detection of issues can prevent more significant problems down the line.

Proper Lubrication

Maintaining the right level of lubrication is vital. Insufficient oil can lead to overheating and increased friction, which may damage internal components. Ensure that you use the recommended lubricant and apply it at regular intervals.

| Tip | Frequency |

|---|---|

| Inspect for wear | Monthly |

| Lubricate components | Every 3 months |

| Check connections | Bi-monthly |

| Clean debris | Monthly |

By following these maintenance tips, you can enhance the reliability and efficiency of your engine, ensuring it serves you well for years to come.

Common Issues with Motor Components

Understanding frequent problems related to engine components is essential for maintaining optimal performance. These challenges can stem from various factors, impacting efficiency and longevity.

Overheating and Electrical Failures

One prevalent issue involves overheating, which may result from inadequate ventilation or blocked airflow. Electrical failures can also occur due to wear and tear, leading to poor functionality and unexpected shutdowns.

Noise and Vibration Problems

Unusual sounds or excessive vibrations often indicate misalignment or worn bearings. Addressing these symptoms early can prevent more severe damage and ensure smoother operation.

Replacement Procedures for Damaged Components

Addressing faulty elements in a mechanical system is crucial for maintaining optimal functionality. Understanding the proper methods for replacement can prevent further issues and enhance performance.

- Identify the damaged component through a thorough inspection.

- Gather the necessary tools and replacement items to ensure a smooth process.

- Carefully disconnect any electrical or fluid connections associated with the damaged part.

- Remove the faulty component, taking note of its positioning and connections for accurate reassembly.

- Install the new part, ensuring it aligns correctly with existing fixtures.

- Reconnect all electrical and fluid lines securely.

- Test the system to confirm that the replacement has restored functionality.

Regular maintenance and timely replacements contribute significantly to the longevity and efficiency of your equipment.

Tools Needed for Repair Work

When undertaking repair tasks, having the right instruments at hand is crucial for efficiency and effectiveness. Proper tools not only streamline the process but also ensure that repairs are conducted safely and correctly, minimizing the risk of further damage.

Essential Hand Tools

A variety of hand tools are indispensable for most maintenance jobs. Wrenches, screwdrivers, and pliers are fundamental for disassembling and reassembling components. Additionally, a reliable set of socket wrenches can facilitate the tightening and loosening of fasteners in tight spaces.

Power Tools and Equipment

In more extensive repair scenarios, power tools can significantly reduce manual labor. Drills, grinders, and saws enable precise adjustments and modifications. Investing in high-quality equipment will ultimately enhance the overall repair experience and outcomes.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a clear overview of various elements and their relationships, facilitating a more efficient troubleshooting process.

Key Elements to Focus On

- Labels: Pay attention to the names and numbers assigned to each component.

- Connections: Observe how different elements are linked or interact with one another.

- Legend: Refer to the key to understand symbols and color codes used in the illustration.

Steps to Interpret the Visuals

- Begin by identifying the main components outlined in the visual.

- Trace the connections to comprehend how each part functions within the system.

- Use the provided legend to decode any unfamiliar symbols or markings.

- Cross-reference with manufacturer manuals for additional context.

Where to Find Replacement Parts

Locating the necessary components for your equipment can often seem daunting, but several reliable avenues exist to simplify the process. Whether you’re dealing with maintenance or repairs, knowing where to look ensures that your system runs smoothly and efficiently.

Online Retailers

Many reputable online retailers specialize in offering a wide variety of components. Websites like Amazon, eBay, and specialized suppliers provide easy access to numerous options, often accompanied by user reviews to help inform your choice. Ensure you verify the compatibility with your specific model before making a purchase.

Local Supply Stores

Visiting local hardware or specialty supply stores can also yield great results. Many of these establishments maintain a selection of components and can provide personalized assistance. Engaging with knowledgeable staff can lead to discovering alternatives or obtaining expert advice for your needs.

Safety Precautions During Repairs

When engaging in maintenance tasks, adhering to safety measures is crucial to ensure both personal well-being and the integrity of the equipment. Proper precautions can prevent accidents and promote a secure working environment.

Understanding Electrical Hazards

Before starting any repair, it is essential to disconnect power sources to eliminate the risk of electric shock. Always verify that the system is fully de-energized using appropriate testing tools. Wearing insulated gloves can further enhance protection against potential electrical dangers.

Using Protective Gear

Utilizing personal protective equipment (PPE) is vital during any repair process. Safety goggles, gloves, and steel-toed boots can shield you from hazardous materials and sharp objects. Additionally, ensuring proper ventilation in the workspace can mitigate the risks associated with fumes and dust.