The effectiveness of winter maintenance equipment heavily relies on the intricate design and functionality of its individual elements. Understanding how these components interact can significantly enhance operational efficiency and maintenance practices.

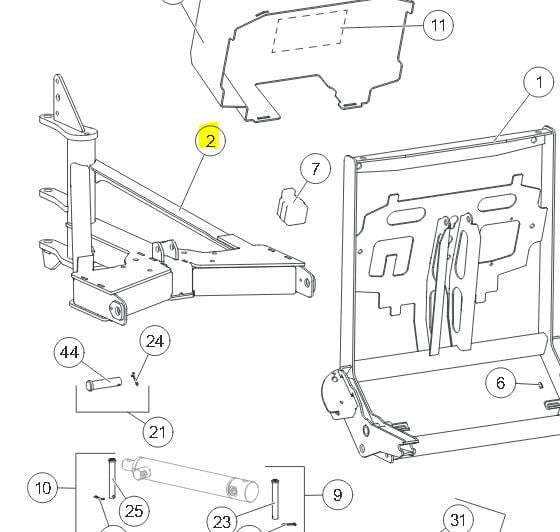

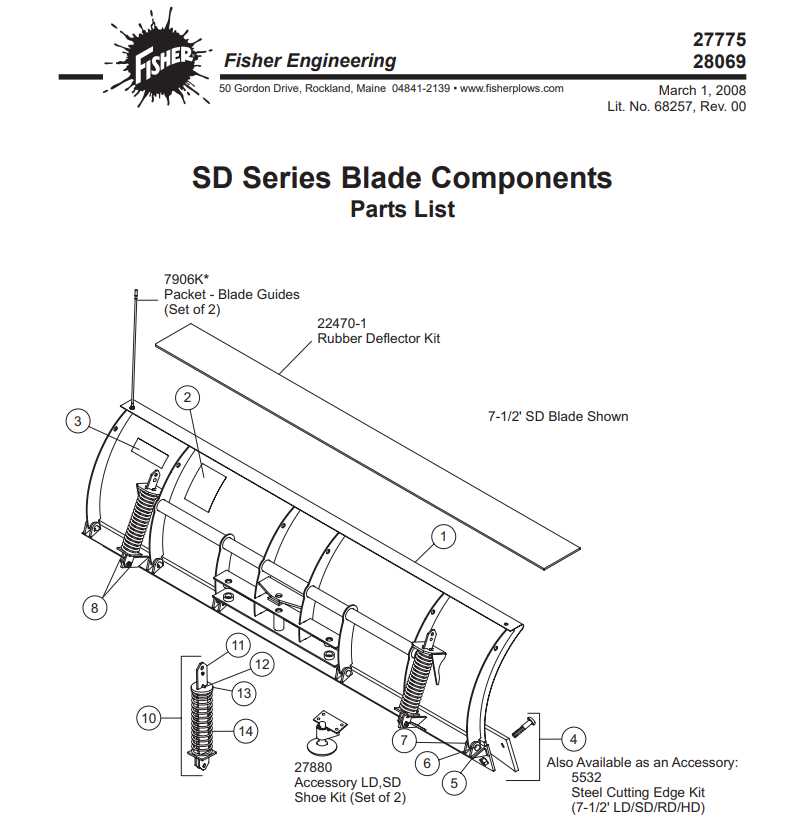

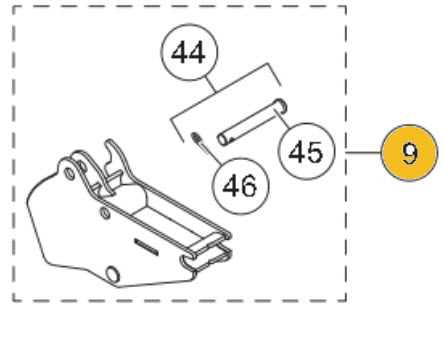

In this section, we delve into the detailed representation of the various components of snow-clearing machinery. This visual guide serves as a valuable resource for technicians and enthusiasts alike, facilitating easier identification and understanding of each element’s role within the system.

By exploring the layout and connection of these components, users can gain insights into troubleshooting and optimizing performance. Comprehensive knowledge of these details empowers operators to ensure their equipment remains in top working condition throughout the demanding winter months.

This section provides an insight into the essential components that contribute to the effective functioning of a snow removal system. Understanding these elements is crucial for maintaining efficiency and ensuring optimal performance during winter operations.

The key components include:

- Frame: The foundational structure that supports the entire assembly.

- Mounting System: A mechanism that facilitates attachment to the vehicle.

- Blade: The main element responsible for clearing snow from surfaces.

- Control System: The interface used to operate the system, allowing for adjustments and directional control.

- Hydraulic System: A critical feature that powers the movement and positioning of the blade.

Each of these components plays a vital role in enhancing the effectiveness of snow clearing operations, ensuring that the vehicle can efficiently navigate and remove snow from various surfaces.

Familiarity with these features can assist users in troubleshooting issues and performing necessary maintenance to prolong the lifespan of the equipment.

Essential Components of the Plow

The efficiency of any snow-clearing device relies on its fundamental elements. Understanding these crucial components is vital for optimal performance and maintenance. Each piece plays a significant role in ensuring the machinery operates smoothly, allowing for effective snow removal in various conditions.

| Component | Description |

|---|---|

| Blade | The main surface that pushes and directs snow, available in various shapes and materials for different tasks. |

| Frame | The structural backbone that supports the entire system, ensuring stability and strength during operation. |

| Mounting System | The mechanism that connects the device to the vehicle, allowing for easy attachment and detachment. |

| Hydraulic System | A critical component that enables movement and adjustment of the blade angle, enhancing control during use. |

| Control Mechanism | The interface that allows the operator to manage the equipment’s functions, ensuring ease of use. |

Understanding the Hydraulic System

The hydraulic mechanism plays a crucial role in the operation of various machinery, enabling efficient movement and control. This system utilizes fluid under pressure to transmit force, allowing for precise adjustments and movements essential for effective performance.

Key Components of the Hydraulic Mechanism

At the heart of the hydraulic system are several key elements, including the pump, reservoir, valves, and cylinders. The pump generates pressure, which is then directed through valves to control the flow of hydraulic fluid. The cylinders convert this hydraulic energy into mechanical movement, facilitating various functions of the equipment.

Importance of Maintenance

Regular maintenance of the hydraulic system is vital to ensure its longevity and reliability. This includes checking fluid levels, inspecting hoses for leaks, and testing the functionality of the valves. Proper upkeep not only enhances performance but also prevents costly breakdowns and repairs.

Power Connections and Wiring Guide

This section provides essential information for setting up electrical connections and wiring for your equipment. Proper configuration is crucial to ensure optimal functionality and safety during operation. Understanding the wiring layout and connection points will facilitate a smooth installation process.

Electrical Setup Overview

Before beginning the installation, familiarize yourself with the wiring components and their respective functions. Properly identifying each element will help prevent errors and ensure a secure connection. It is advisable to refer to a schematic to visualize the layout.

Connection Table

| Component | Connection Type | Description |

|---|---|---|

| Battery | Positive and Negative | Connect the battery terminals to the main power supply using appropriate gauge wiring. |

| Control Switch | Toggle Switch | Link the control switch to the wiring harness for operational control. |

| Motor | Direct Connection | Establish a direct connection from the control switch to the motor for efficient power transfer. |

| Fuse | Inline Fuse Holder | Install an inline fuse to protect the circuit from overload. |

Common Replacement Parts to Consider

When maintaining any snow management equipment, certain components frequently require attention due to wear and tear. Identifying and replacing these essential elements can enhance performance and prolong the lifespan of the machine. Below are some key components often in need of replacement.

Essential Components

Regular inspections can help detect which elements may need replacing. Here are a few commonly replaced components:

| Component | Description | Frequency of Replacement |

|---|---|---|

| Cutting Edge | The front edge that makes contact with the ground, subject to wear from constant friction. | Every season or as needed |

| Hydraulic Hoses | Used for transferring fluid, these can degrade over time due to pressure and environmental factors. | Every few years or when leaks are detected |

| Mounting Brackets | These secure the assembly to the vehicle and may become damaged from impacts or stress. | As needed, based on inspection |

| Wear Shoes | Attached to the edges, these help control the height and protect the cutting edge from excessive wear. | Seasonally or when worn down |

Conclusion

By keeping an eye on these critical components, operators can ensure their equipment operates efficiently and effectively throughout the winter season. Regular maintenance and timely replacements are vital for optimal performance.

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan of your equipment. By adhering to a structured maintenance routine, you can ensure optimal performance and minimize the risk of unexpected failures. This section provides valuable insights into effective practices that contribute to the durability of your machinery.

Routine Inspection

Conducting regular inspections allows you to identify potential issues before they escalate. Look for signs of wear and tear, and ensure that all components are functioning correctly. Address any minor concerns promptly to prevent major breakdowns.

Proper Cleaning

Keeping your equipment clean is crucial for its longevity. Debris, dirt, and corrosive materials can accumulate and cause damage over time. After each use, thoroughly clean all surfaces and components to maintain optimal functionality.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for signs of wear and damage. |

| Lubrication | Monthly | Use appropriate lubricants for moving parts. |

| Deep Cleaning | Seasonally | Remove all debris and dirt buildup. |

Identifying Wear and Tear Issues

Understanding the signs of deterioration in equipment is crucial for maintaining optimal performance and ensuring longevity. Regular inspections help to detect problems early, allowing for timely interventions that can prevent further damage. This section outlines key indicators that suggest components may require attention.

Visual Inspections: Regularly examine all elements for visible signs of damage, such as cracks, dents, or excessive rust. Pay close attention to areas subjected to heavy stress, as they are more prone to wear.

Functional Performance: Monitor the operational efficiency of your equipment. Any unusual noises, decreased effectiveness, or sluggish responses can indicate underlying issues that may need addressing.

Surface Condition: Check the surfaces of the equipment for signs of wear. Smooth or polished areas may suggest excessive friction or lack of lubrication, while rough or uneven surfaces could indicate more serious damage.

Component Integrity: Assess the structural soundness of critical components. Look for signs of bending or deformation that may compromise functionality.

By being proactive and attentive to these indicators, one can effectively manage and mitigate wear, ensuring reliable performance for years to come.

Importance of Regular Inspections

Routine evaluations are essential for maintaining the functionality and safety of equipment. By conducting these assessments, one can identify potential issues before they escalate into significant problems, ensuring that all components operate smoothly and efficiently.

Early Detection of Issues

Regular inspections allow for the early identification of wear and tear, which can lead to unexpected breakdowns if left unaddressed. By monitoring the condition of various elements, operators can make timely repairs, thus extending the lifespan of the machinery and avoiding costly downtime.

Enhanced Performance

Systematic evaluations contribute to optimal performance by ensuring all components are functioning correctly. When equipment is in peak condition, it not only improves efficiency but also enhances the overall user experience. Investing time in these inspections ultimately leads to better productivity and reliable operation.

Upgrades and Enhancements Available

When it comes to improving the functionality and efficiency of your snow removal equipment, there are various upgrades and enhancements that can be implemented. These modifications can significantly enhance performance, durability, and user experience, ensuring that the equipment operates at its best during the harsh winter months.

One popular option for enhancement is the addition of a high-efficiency motor. This upgrade can provide greater power output while consuming less energy, resulting in improved overall performance. Another viable option is incorporating advanced control systems, which allow for more precise operation and better responsiveness to changing conditions.

Additionally, users may consider upgrading to high-strength materials for various components, increasing the lifespan of the equipment and reducing the need for frequent replacements. Customizable attachments can also be introduced to suit specific needs, providing versatility in different snow conditions and terrains.

Implementing these upgrades not only enhances performance but also contributes to safer and more effective operation, making the entire snow management process more efficient.

Using the Parts Diagram Effectively

Understanding a visual representation of components is essential for efficient maintenance and repairs. This tool enables individuals to identify various elements and their specific roles within a larger system. By leveraging this information, one can streamline the troubleshooting process and enhance overall performance.

Familiarization with Symbols is the first step in utilizing this visual aid. Each symbol or illustration corresponds to a particular component, allowing users to quickly locate the necessary parts. Taking the time to understand these representations can significantly reduce the time spent on maintenance tasks.

Cross-Referencing with Manuals can further enhance the effectiveness of the visual guide. Consulting instructional literature alongside the visual representation ensures that all aspects of the system are thoroughly understood. This approach minimizes errors and fosters a more comprehensive understanding of the equipment’s functionality.

Planning Repairs Strategically is another crucial aspect of effective use. By analyzing the visual aid, users can prioritize which components need immediate attention and which can be addressed later. This methodical approach not only saves time but also helps in budgeting resources more effectively.

Incorporating these strategies will lead to improved operational efficiency and a better grasp of the overall system dynamics, ultimately resulting in enhanced reliability and performance.