When it comes to maintaining and repairing outdoor equipment, having a clear understanding of its structure is essential. This knowledge not only enhances the efficiency of repairs but also prolongs the lifespan of the machinery. Familiarizing oneself with the various elements involved can lead to more informed decisions when it comes to troubleshooting or replacement.

The intricate arrangement of individual components plays a crucial role in the overall functionality of any device. Each part serves a specific purpose, and comprehending how they interconnect can significantly streamline maintenance processes. Whether it’s for regular upkeep or unexpected repairs, a detailed overview of the assembly is invaluable.

By exploring a visual representation of these elements, users can gain insight into how each piece interacts with others. This understanding is particularly beneficial when it comes to identifying issues or sourcing appropriate replacements. Ultimately, mastering the layout of these essential parts can enhance both user confidence and operational effectiveness.

Overview of the Equipment

This section provides a comprehensive examination of a specific model designed for outdoor tasks. Engineered for efficiency and user-friendliness, the unit stands out due to its robust construction and reliable performance. It is ideal for both residential and commercial applications, making it a versatile choice for various users.

Key Features

The device is equipped with several innovative characteristics that enhance its functionality. Its powerful engine ensures effective operation across different terrains, while its ergonomic design facilitates ease of use. Additionally, the inclusion of safety features promotes secure handling, which is essential during operation.

Applications

Whether for maintaining residential lawns or managing larger green spaces, this equipment proves to be a valuable asset. Its adaptability allows users to tackle a range of tasks efficiently, from cutting grass to clearing debris. With the right maintenance, the unit promises longevity and consistent performance, making it a worthy investment for anyone involved in outdoor management.

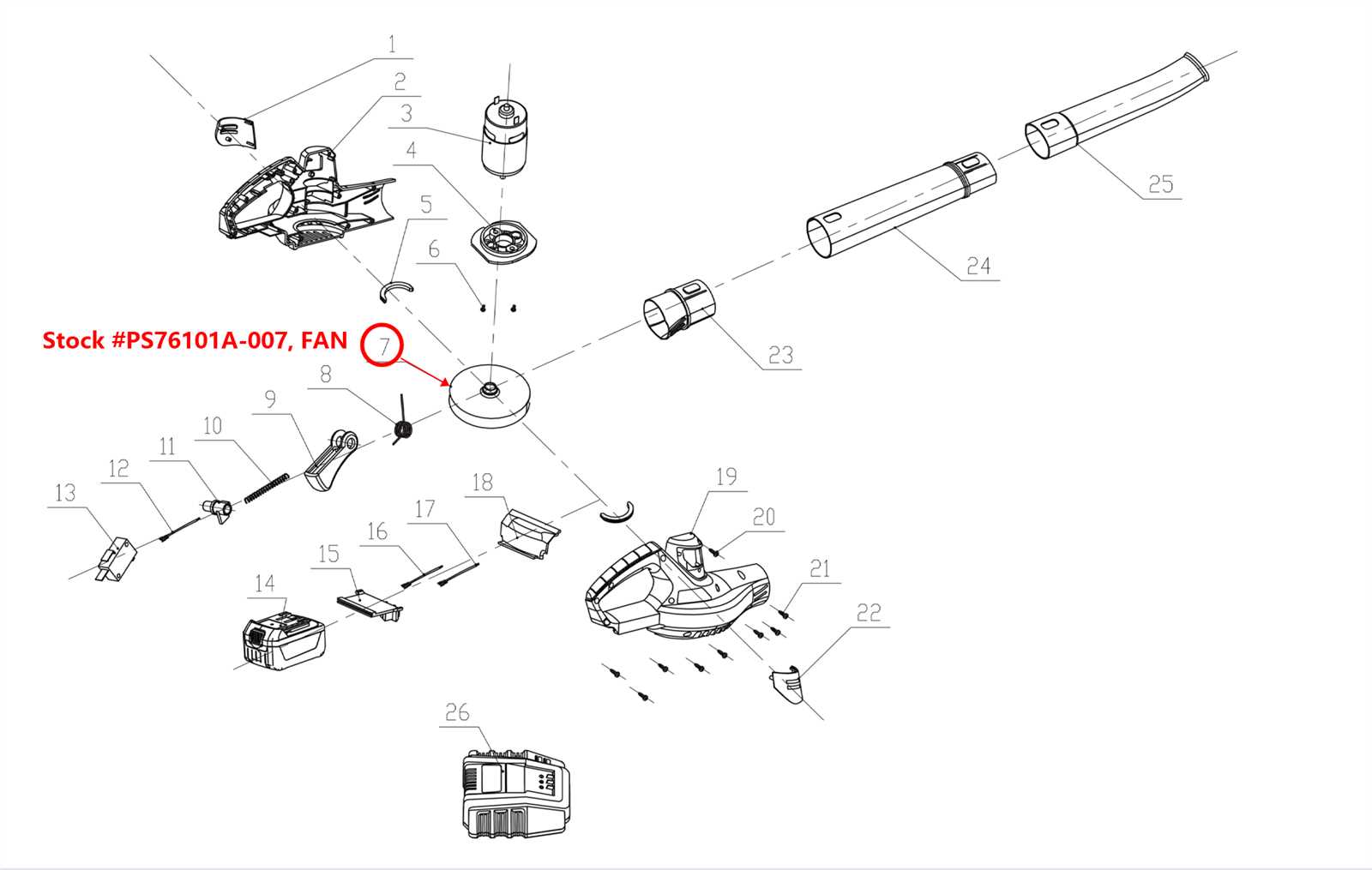

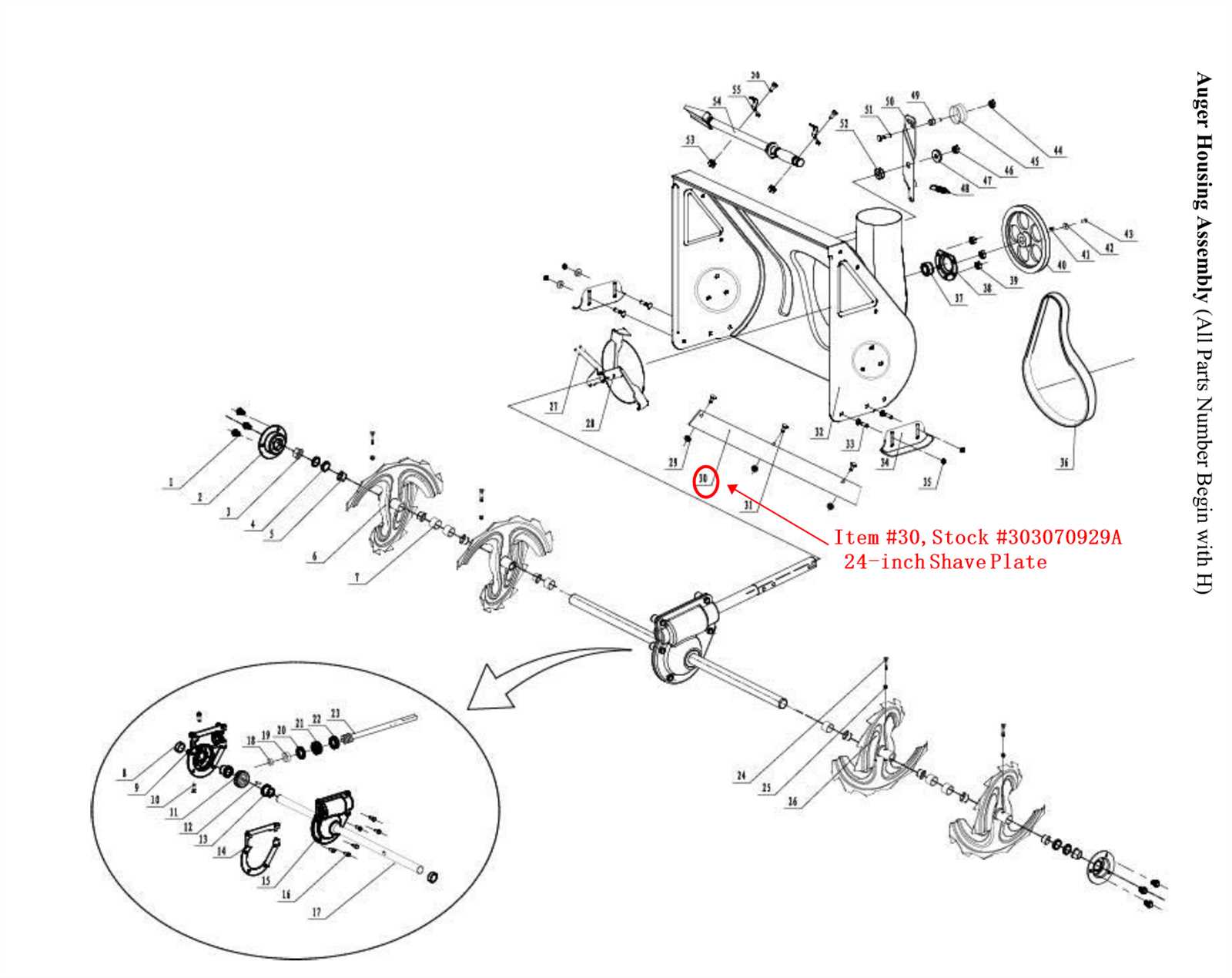

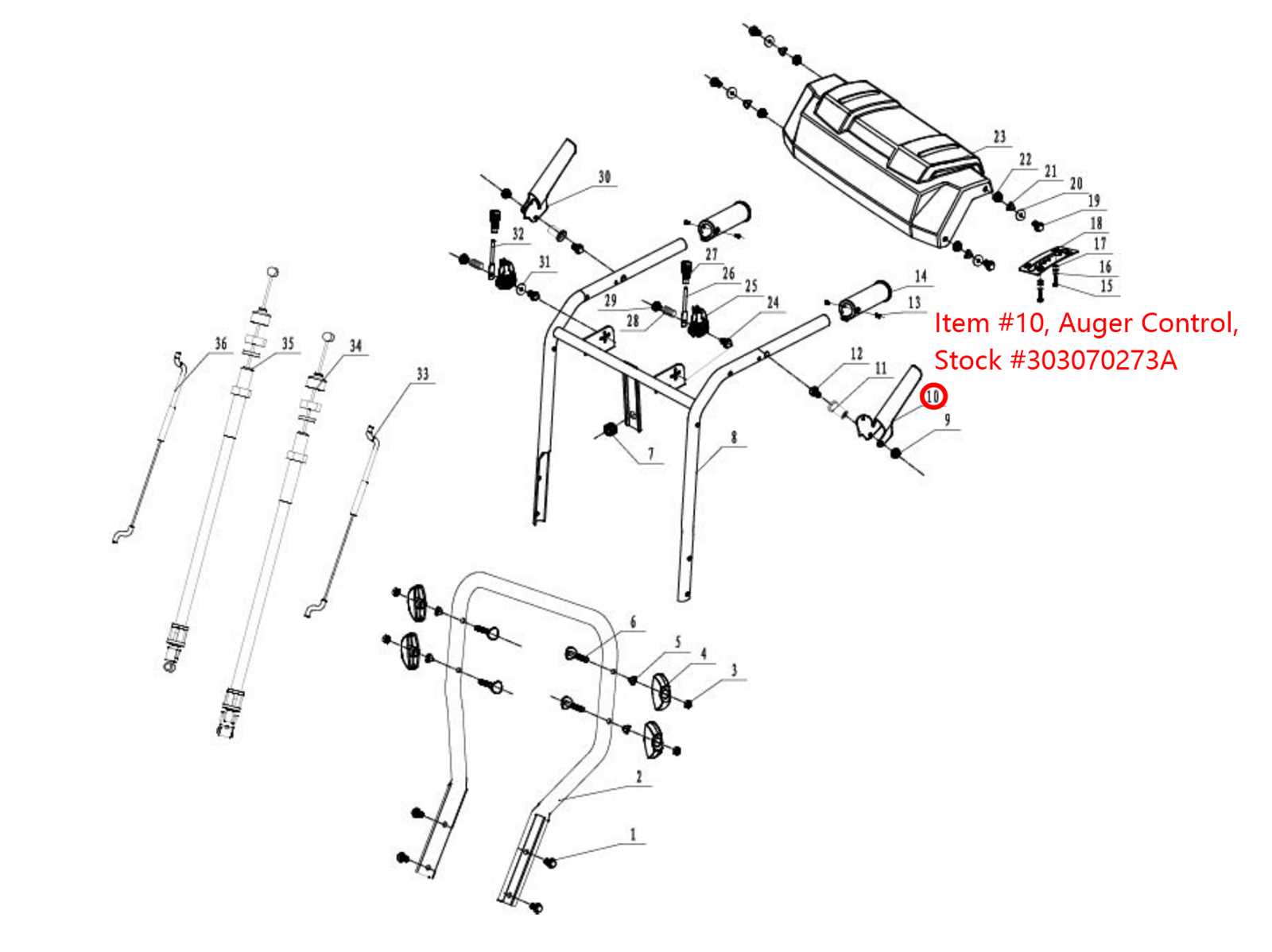

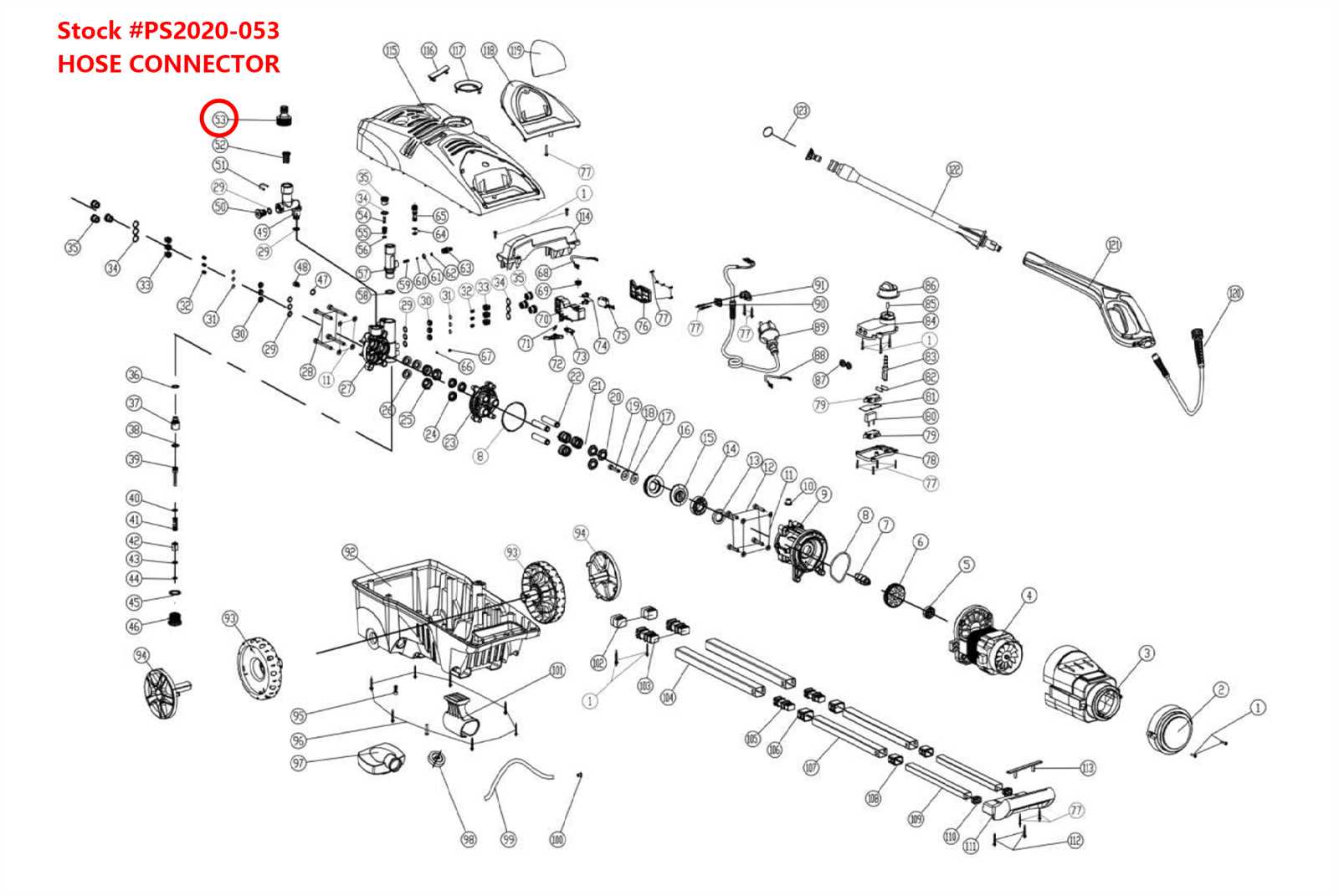

Understanding the Parts Diagram

Grasping the visual representation of components is essential for anyone looking to maintain or repair machinery. Such illustrations serve as a crucial guide, providing clarity on how various elements fit together and function cohesively. By interpreting these visuals, users can effectively identify individual parts, making troubleshooting and replacement tasks more manageable.

The Importance of Component Identification

Accurate identification of each element enhances the efficiency of repair and maintenance tasks. Here are some key benefits:

- Facilitates quick location of specific items.

- Aids in understanding the assembly process.

- Helps avoid errors in ordering replacements.

- Streamlines maintenance routines.

How to Read the Visual Representation

When approaching these illustrations, consider the following steps:

- Start by familiarizing yourself with the layout.

- Identify major sections and their functions.

- Locate individual components and note their labels.

- Refer to accompanying notes or legends for additional information.

By following these guidelines, users can effectively navigate the visual guide, ensuring a smoother experience in their repair and maintenance endeavors.

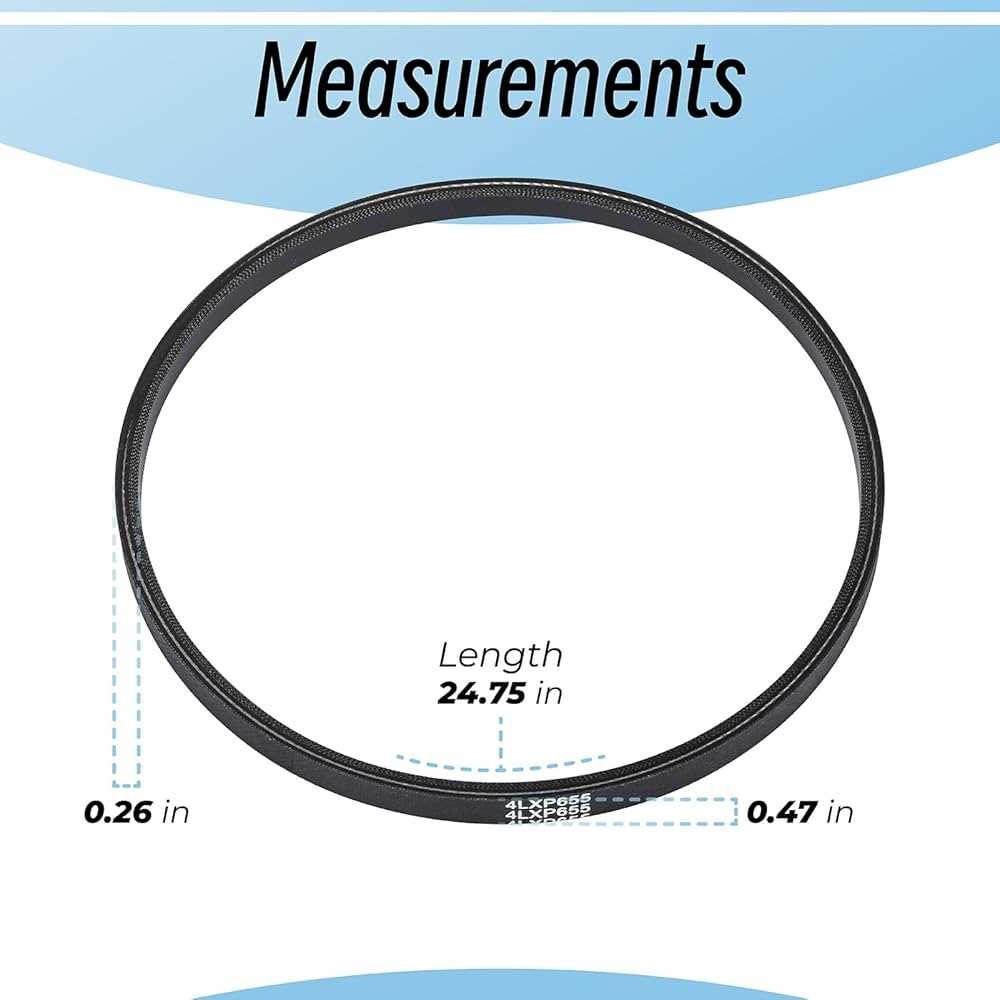

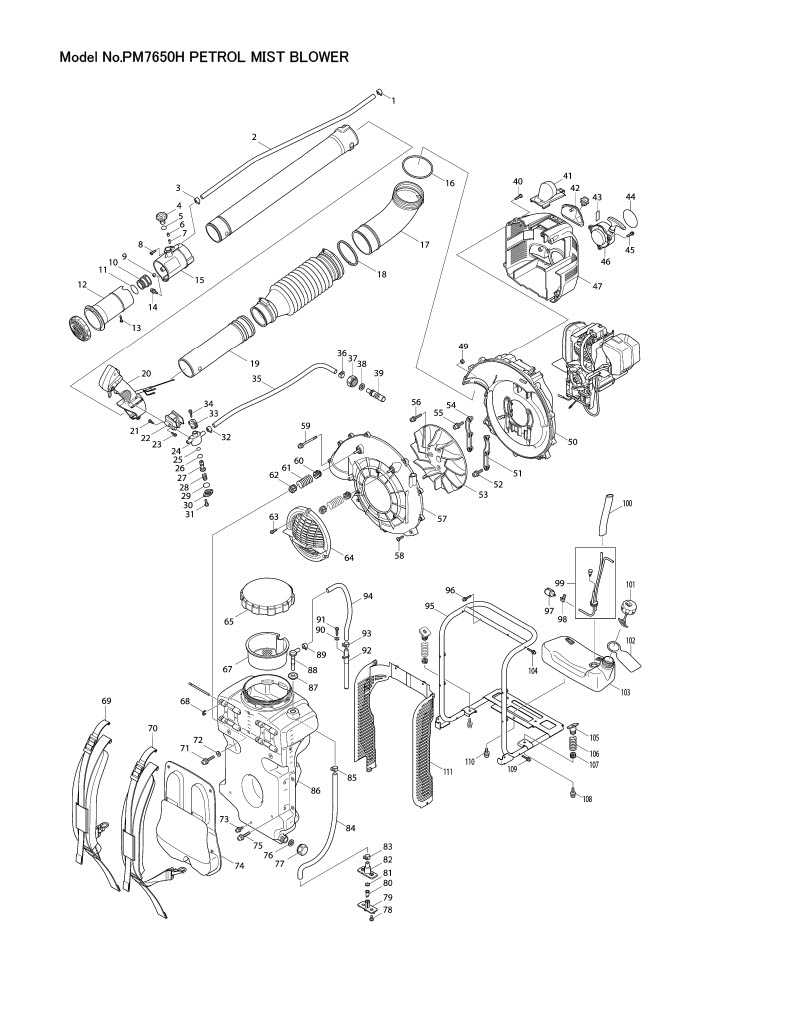

Key Components of DB7651-24

Understanding the essential elements of any equipment is crucial for maintenance and optimal performance. This section highlights the vital parts that contribute to the effective functioning of the model, ensuring longevity and reliability in various applications.

Core Features

The primary components play a significant role in the overall operation. Each part is designed to fulfill specific functions, enabling the machine to perform tasks efficiently. Recognizing these features helps users troubleshoot issues and ensure proper care.

Component Specifications

| Component Name | Function | Material |

|---|---|---|

| Engine | Drives the system | Aluminum |

| Handle | Provides control | Plastic |

| Blade | Cuts through materials | Steel |

| Fuel Tank | Holds fuel | Polyethylene |

| Air Filter | Filters air intake | Foam |

Identifying and understanding these components enhances user experience, ensuring that the machinery operates smoothly and effectively for various tasks.

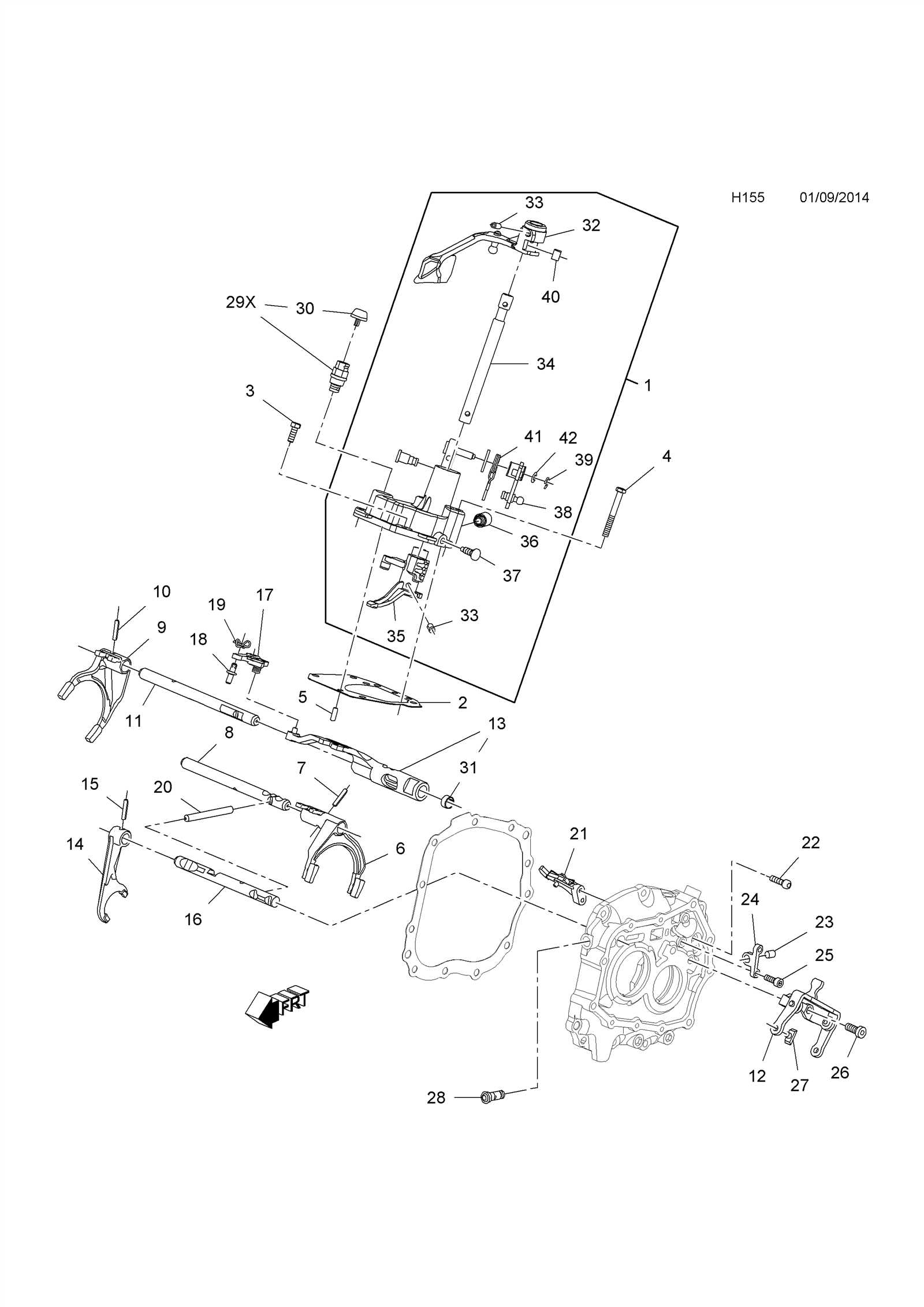

How to Interpret the Diagram

Understanding a technical illustration can be essential for effective maintenance and repair tasks. Such visual representations provide critical information about the components and their relationships within a system. Familiarity with the symbols and layout will enhance your ability to navigate the material efficiently.

First, take note of the legend or key, which usually explains the various symbols and lines used throughout the illustration. This section is crucial, as it clarifies what each symbol represents, helping you identify parts and their functions.

Next, observe the arrangement of elements. Components may be organized in a specific order, often reflecting their operational sequence or physical proximity. Understanding this layout can provide insight into how parts interact and assist in troubleshooting.

Additionally, pay attention to any annotations or notes included in the illustration. These often highlight important details such as torque specifications, part numbers, or assembly instructions that can be invaluable during repair or assembly processes.

Finally, consider cross-referencing the illustration with the accompanying manual or guide. This can further clarify complex areas and ensure you have a comprehensive understanding of the system’s structure. By mastering these aspects, you’ll be better equipped to undertake maintenance tasks with confidence.

Common Issues with DB7651-24 Parts

When dealing with specific equipment components, users often encounter a range of recurring problems that can hinder performance. Understanding these challenges is crucial for ensuring efficient operation and longevity of the device. Identifying potential issues early can save time and reduce repair costs.

One frequent concern is the wear and tear of mechanical elements, which can lead to diminished efficiency or complete failure. Regular maintenance and timely replacement of worn-out components can prevent more significant malfunctions. Users may also experience difficulties related to electrical connections, such as corrosion or loose wiring, which can disrupt functionality.

Another common issue arises from overheating, often due to inadequate airflow or blocked ventilation. It is essential to monitor temperature levels and ensure that the equipment is kept in a well-ventilated area. Additionally, compatibility problems between various components can lead to operational inefficiencies, making it important to verify that all parts are suitable for use with the specific model.

Lastly, inadequate user manuals or guides can lead to improper installation or operation, resulting in frustration and potential damage. Having clear and detailed instructions is vital for successful assembly and maintenance. By addressing these typical challenges, users can enhance the performance and durability of their equipment.

Replacement Parts Availability

When maintaining or restoring equipment, access to essential components is crucial for ensuring optimal functionality. Finding suitable alternatives can enhance the longevity and performance of your machinery. Understanding where to source these items is vital for any repair or upgrade project.

Here are several reliable sources to consider when searching for these crucial components:

- Authorized Dealers: These vendors typically offer genuine items that guarantee compatibility and reliability.

- Online Marketplaces: Websites such as Amazon, eBay, and specialized retailers provide a wide selection of options, often at competitive prices.

- Local Repair Shops: Many local establishments may carry inventory or be able to order specific components for your needs.

- Manufacturer’s Website: Often, the official site provides direct access to authentic replacements and can offer guidance on the appropriate selections.

Before making a purchase, it’s advisable to verify compatibility and read reviews to ensure quality. Proper research can help avoid delays and additional costs during repairs.

Step-by-Step Assembly Instructions

Putting together your new equipment can be a straightforward task when following a clear set of guidelines. This section provides a comprehensive outline to ensure each component is correctly assembled, resulting in optimal performance.

-

Gather Your Tools

- Screwdriver (appropriate type)

- Wrench or pliers

- Measuring tape

- Safety gloves

-

Prepare the Workspace

- Choose a clean, flat surface.

- Ensure adequate lighting.

- Have all parts and tools within reach.

-

Assemble the Base

- Attach the legs to the main platform using screws.

- Ensure all screws are tightened securely.

-

Install the Motor Unit

- Position the motor onto the designated spot on the base.

- Secure with bolts and check for tightness.

-

Connect the Control Panel

- Attach the control panel to the designated area.

- Connect wiring according to the reference guide.

-

Final Checks

- Inspect all connections for security.

- Ensure there are no loose parts or tools left behind.

- Perform a safety check before powering on.

By following these detailed steps, you can ensure that your assembly process goes smoothly and efficiently. Always refer to the provided guidelines for any specific adjustments or additional tips.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your outdoor equipment involves regular upkeep and attention to detail. By adopting a proactive approach to maintenance, you can enhance performance, prevent issues, and ultimately save on repair costs. Here are some essential practices to keep in mind.

Routine Inspection

- Check for any signs of wear and tear, such as frayed belts or loose components.

- Inspect all moving parts to ensure they are functioning smoothly without obstruction.

- Look for leaks in fuel or oil systems, addressing any concerns immediately.

Proper Cleaning

- Remove debris and dirt from the equipment after each use to prevent buildup.

- Clean filters regularly to maintain optimal airflow and efficiency.

- Wash the exterior with mild soap and water to prevent corrosion and keep it looking new.

By following these tips, you can significantly enhance the durability of your equipment and ensure it operates efficiently for years to come.

Safety Precautions to Consider

Ensuring a safe working environment is crucial when handling equipment. Understanding potential hazards and implementing protective measures can significantly reduce the risk of accidents. This section outlines essential guidelines to maintain safety during operation and maintenance activities.

General Safety Guidelines

Before engaging with any machinery, familiarize yourself with the user manual and safety instructions provided by the manufacturer. Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and hearing protection, to safeguard against potential injuries. Additionally, ensure that the workspace is clean and well-organized to prevent trips and falls.

Operational Safety Measures

When operating the device, remain attentive and avoid distractions. Always inspect the equipment for any signs of damage or wear before use. If any irregularities are detected, cease operation immediately and consult a qualified technician. In case of emergency, know the location of the nearest emergency shut-off and first aid kit, and be prepared to act swiftly if an incident occurs.

Frequently Asked Questions

This section addresses common inquiries related to the assembly and components of a particular model. Whether you’re seeking information on troubleshooting, maintenance, or replacement elements, these questions aim to provide clarity and guidance for users.

What should I do if I can’t identify a specific component?

If you’re having trouble pinpointing a particular element, consult the user manual or reference materials that accompany the device. Additionally, online forums and support communities can be excellent resources for identifying components and their functions.

How can I ensure the longevity of my device?

To extend the lifespan of your equipment, follow the manufacturer’s maintenance recommendations. Regular cleaning, timely replacement of worn-out parts, and proper storage are essential practices that contribute to optimal performance and durability.