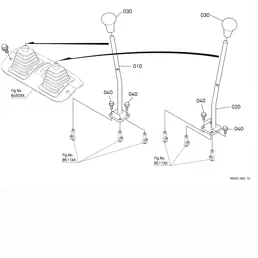

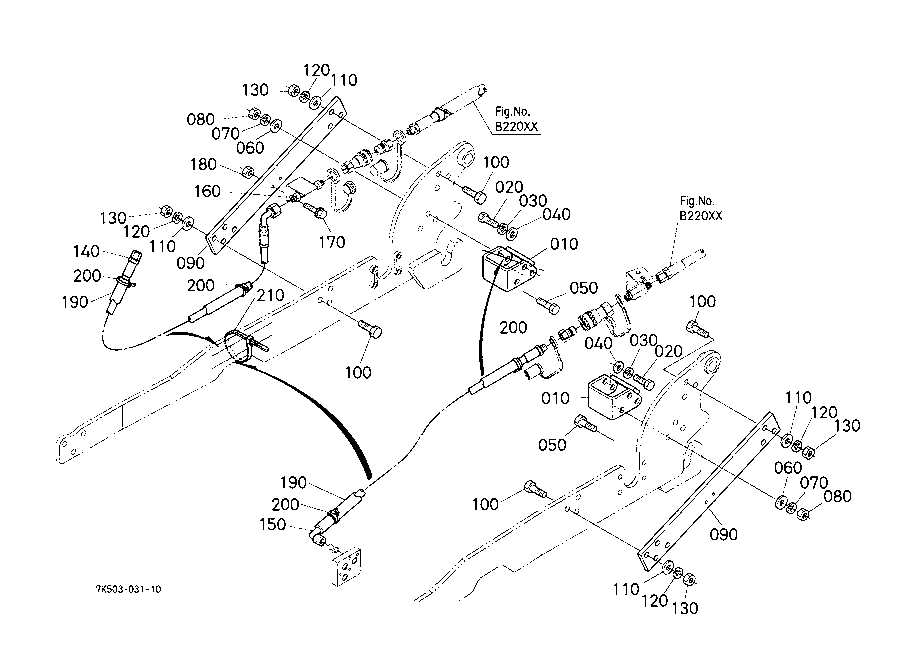

In any machinery, comprehending the arrangement of essential elements is crucial for effective maintenance and repairs. A clear representation of these components helps users identify parts and understand their functions within the overall system.

Having access to a visual guide that outlines the configuration of various sections allows for easier troubleshooting and enhances operational efficiency. Whether for novice users or seasoned professionals, a well-structured overview simplifies the process of locating specific items.

Moreover, such insights foster informed decision-making regarding replacements or upgrades. By familiarizing oneself with the layout, users can ensure their equipment remains in optimal condition, leading to improved performance and longevity.

Overview of the Excavator Attachment

This section provides an insight into the functionality and design of a popular excavator attachment. Understanding its components is essential for maintenance and optimal performance, ensuring that users can effectively utilize this tool in various applications.

The attachment is designed to enhance the capabilities of compact machinery, making it versatile for different tasks such as digging, lifting, and transporting materials. Each element within the assembly plays a crucial role in its overall operation.

| Component | Description |

|---|---|

| Frame | The main structure that supports other parts and provides stability. |

| Cylinder | Responsible for the lifting and lowering actions of the attachment. |

| Bucket | The part used for scooping and transporting materials. |

| Hydraulic Hoses | Transmits hydraulic fluid to power the movement of the attachment. |

Essential Components Explained

Understanding the vital elements of machinery is crucial for efficient operation and maintenance. This section delves into the core components that play significant roles in the functionality of construction equipment. Familiarity with these elements can enhance performance and prolong the lifespan of the machinery.

Main Functional Units

The primary functional units of equipment are designed to work in harmony, ensuring smooth operations. Each unit contributes uniquely, facilitating various tasks from movement to power generation. Recognizing the role of these units aids in troubleshooting and repair processes.

Supporting Structures

Supporting structures are essential for stability and durability. They provide the necessary framework that allows other components to operate effectively under various conditions. Maintenance of these structures is vital to prevent structural failure and ensure safety.

| Component | Description |

|---|---|

| Hydraulic System | Enables powerful lifting and movement through fluid pressure. |

| Transmission Unit | Transfers power from the engine to the wheels for movement. |

| Chassis | Framework that supports the overall structure and components. |

| Engine | Converts fuel into mechanical energy to drive the machine. |

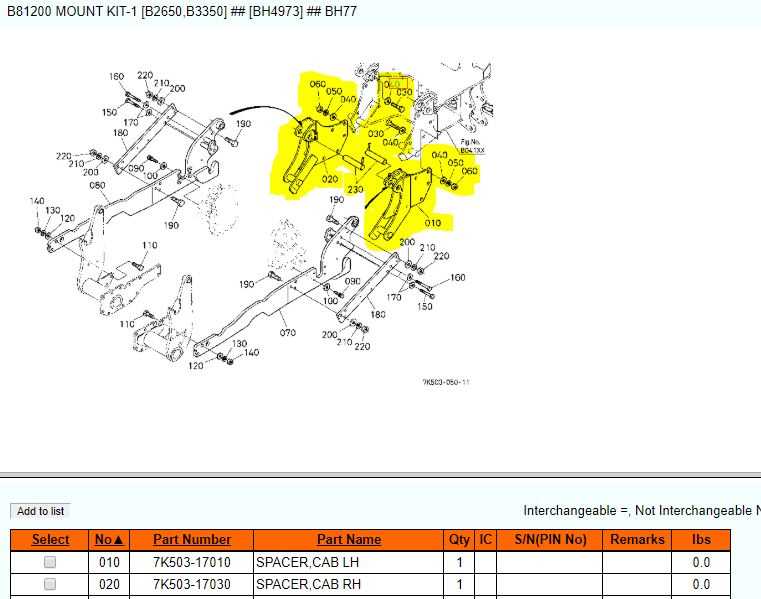

Parts Identification Guide

This section provides an essential overview for recognizing and understanding the various components of your machinery. Familiarity with these elements enhances maintenance efficiency and ensures optimal performance, enabling operators to easily identify any necessary replacements or repairs.

Common Components Overview

Understanding the main elements of your equipment involves recognizing their functions and locations. Each component plays a crucial role in the overall operation, and being aware of these can aid in troubleshooting potential issues.

Identification Tips

To effectively identify components, it is advisable to refer to manufacturer documentation or visual references. Labeling and organized storage can also streamline the identification process, ensuring that operators can quickly find what they need when performing maintenance tasks.

Common Issues and Solutions

In any machinery, occasional problems can arise due to wear and tear or improper maintenance. Understanding these common issues and their respective solutions can significantly enhance the longevity and efficiency of the equipment.

Frequent Problems

- Engine performance issues

- Hydraulic system failures

- Electrical malfunctions

- Leakage from various components

Solutions to Consider

- Regularly check and replace air and fuel filters to improve engine efficiency.

- Inspect hydraulic fluid levels and check for leaks to maintain system integrity.

- Examine electrical connections and replace faulty wiring to ensure proper functionality.

- Conduct routine maintenance to identify potential issues before they escalate.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By following a few essential practices, you can significantly extend its operational life and enhance performance. Regular maintenance not only prevents unexpected breakdowns but also optimizes efficiency during usage.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Monthly | Inspect and replace oils and fluids as necessary to maintain optimal function. |

| Filter Replacements | Every 100 hours | Change air and fuel filters to ensure clean operation and prevent clogging. |

| Visual Inspections | Weekly | Look for signs of wear or damage to components to address issues early. |

| Greasing | Every 50 hours | Apply lubricant to moving parts to reduce friction and wear. |

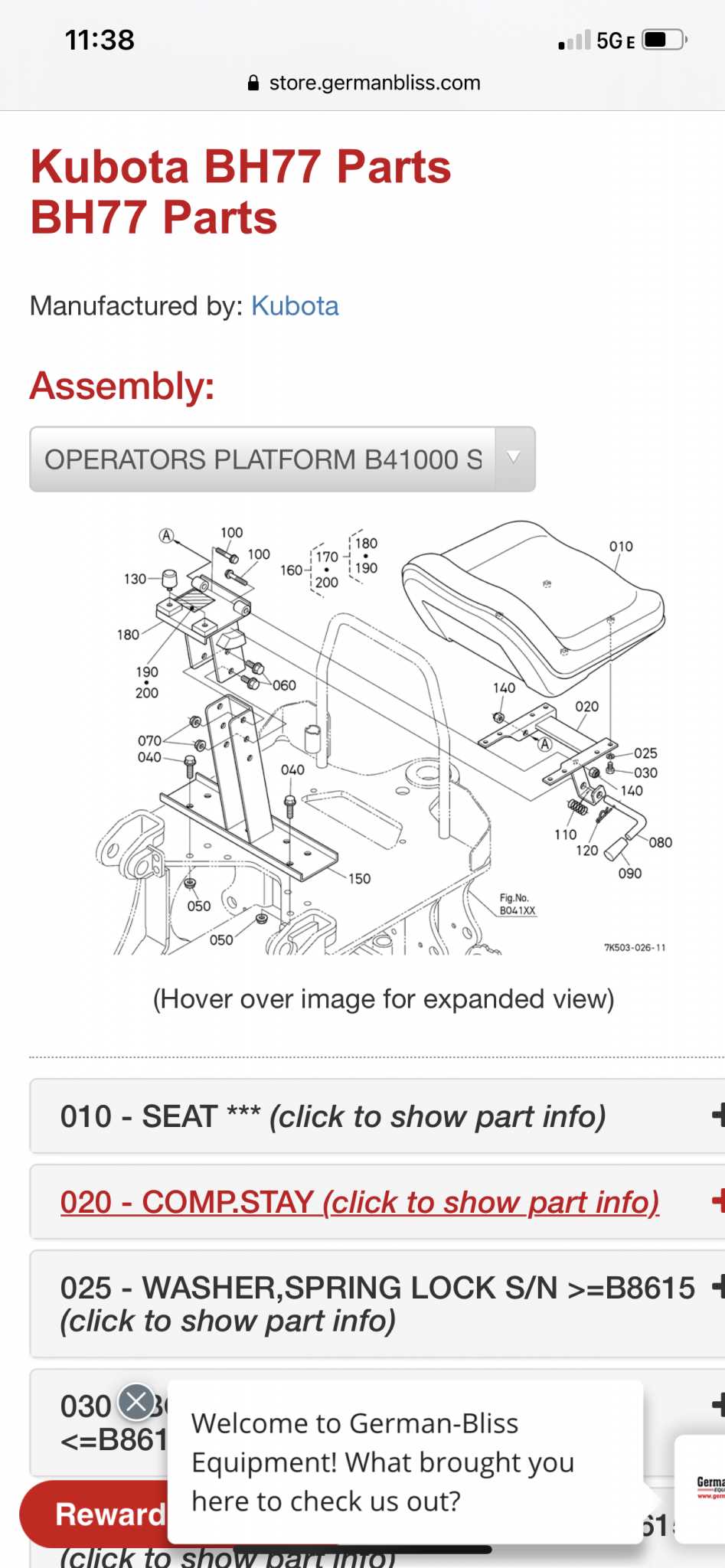

Where to Find Replacement Parts

Locating suitable components for machinery maintenance can be a straightforward process if you know where to look. There are several reliable sources that offer a wide range of options for acquiring the necessary items to keep your equipment running smoothly.

Authorized Dealers and Distributors

One of the most dependable places to find high-quality components is through authorized dealers. These retailers typically offer original equipment manufacturer (OEM) items, ensuring compatibility and reliability. You can often find a directory of authorized sellers on the manufacturer’s website, which can guide you to the nearest locations.

Online Marketplaces and Retailers

Another convenient option is to explore online marketplaces. Websites dedicated to equipment and machinery often have extensive catalogs that allow you to compare prices and availability. Be sure to read customer reviews and check seller ratings to ensure you are purchasing from a reputable source. Additionally, online forums and communities can provide valuable recommendations on where to find specific items.

Installation Instructions for Key Parts

This section provides essential guidance for the proper installation of vital components, ensuring optimal functionality and longevity of the machinery. Following these instructions carefully will help maintain efficiency and reduce the risk of malfunctions.

Preparation Steps

Before beginning the installation process, gather all necessary tools and materials. Ensure the work area is clean and organized to facilitate a smooth installation. It is advisable to consult the equipment manual for any specific requirements related to the components.

Installation Process

Carefully follow these steps to install the key components:

| Step | Description |

|---|---|

| 1 | Disconnect power supply to ensure safety during installation. |

| 2 | Remove any existing components that may obstruct the installation. |

| 3 | Align the new component with the designated area, ensuring proper fit. |

| 4 | Secure the component using appropriate fasteners as specified. |

| 5 | Reconnect the power supply and test the installation for proper functionality. |

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a safe working environment is paramount. Proper precautions not only protect the individual performing the work but also prevent damage to the equipment being serviced. This section outlines essential safety measures to adhere to during repair activities.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the work area is well-lit and free from clutter to minimize risks of accidents.

- Disconnect power sources and ensure the machinery is secure before starting any repairs.

- Use the right tools for the job to avoid injuries and ensure efficient operation.

- Follow manufacturer guidelines and specifications to avoid any potential hazards.

Emergency Preparedness

- Keep a first aid kit readily accessible in case of accidents.

- Be familiar with emergency procedures, including how to shut down machinery quickly.

- Ensure all personnel know the location of fire extinguishers and emergency exits.

- Report any unsafe conditions or hazards to the supervisor immediately.

Upgrading Your Equipment Efficiently

Enhancing your machinery is essential for maintaining productivity and ensuring optimal performance. By focusing on improvements and updates, operators can achieve greater efficiency and reliability in their tasks. This process involves assessing current capabilities and identifying areas where advancements can be made.

One effective approach to upgrading involves researching available enhancements that align with your operational needs. This may include integrating modern components that offer improved functionality or adopting innovative technologies that streamline processes. Investing in high-quality upgrades not only extends the lifespan of your equipment but also enhances overall output.

Additionally, staying informed about the latest advancements in machinery can significantly impact your decision-making. Regularly consulting with experts and attending industry events can provide valuable insights into which improvements are most beneficial. Ultimately, a strategic approach to upgrading will lead to increased efficiency and a more productive work environment.

Understanding the Wiring Diagram

A comprehensive understanding of the electrical layout is essential for efficient troubleshooting and maintenance. This section explores the significance of these schematics, illustrating how each component interconnects to form a functional unit.

Components and Their Functions

The wiring layout typically includes various elements such as switches, connectors, and sensors. Familiarizing oneself with these parts helps in identifying issues and making informed repairs.

Interconnections Explained

Each connection in the schematic serves a specific purpose, enabling power flow and communication between components. Recognizing these links aids in better understanding the system’s operation.

| Component | Function |

|---|---|

| Switch | Controls the flow of electricity |

| Connector | Links two or more wires |

| Sensor | Detects and measures changes |