Modern transmission systems are complex mechanisms that require careful consideration of their structure and functioning. These systems are crucial for the smooth operation of a vehicle, ensuring seamless transitions between gears and overall driving performance. It’s essential to explore the individual elements that make up this intricate setup to fully grasp how the system operates efficiently.

The components within these systems work together in a synchronized manner, each playing a specific role in transferring power from the engine to the wheels. By examining these integral parts, we can better understand how to maintain and repair them when necessary. Knowing the function and location of each element is crucial for both maintenance professionals and enthusiasts.

In the following sections, we will break down the primary elements of the transmission system, discussing their roles and the common issues that might arise.

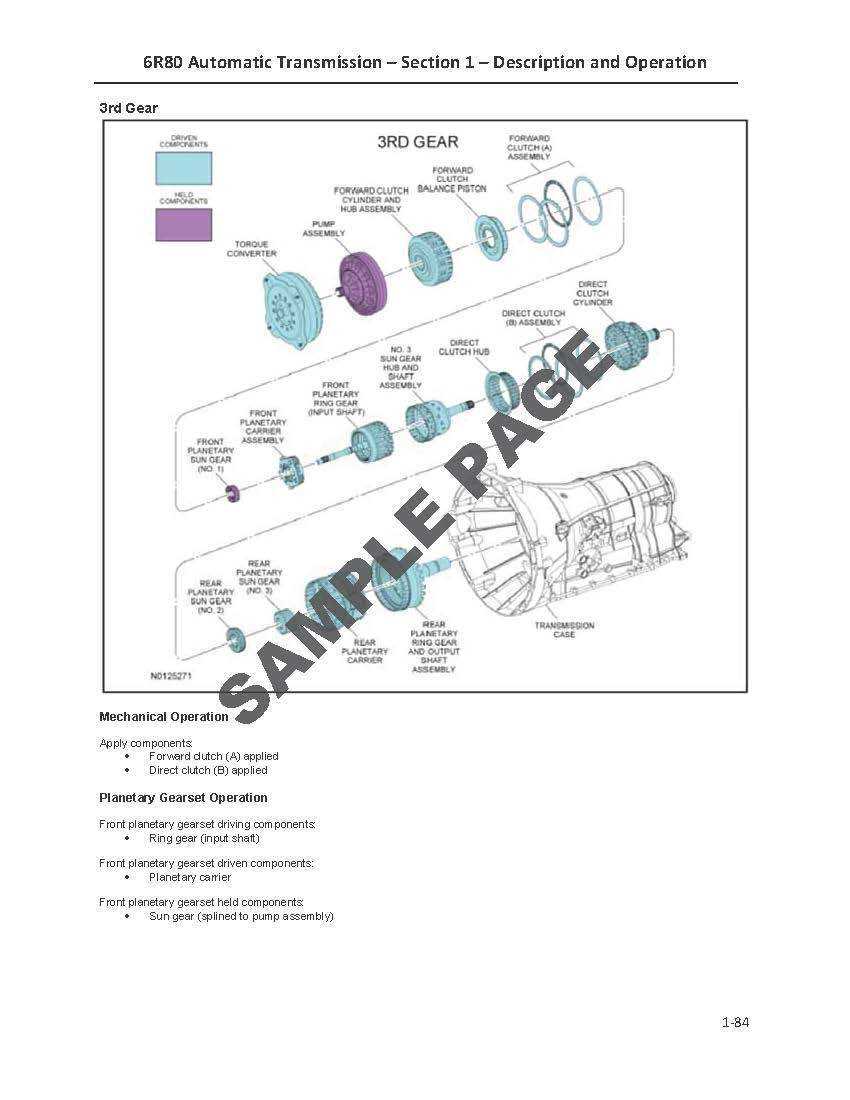

Understanding the 6R80 Transmission Components

The automatic transmission in modern vehicles consists of various elements working in unison to manage power delivery from the engine to the wheels. Each component plays a crucial role in ensuring smooth gear shifts, efficient torque conversion, and overall vehicle performance. Knowing the inner workings of this system is essential for both troubleshooting and maintenance.

Main Functional Elements

- Torque Converter: Transfers power from the engine to the transmission, enabling smooth acceleration.

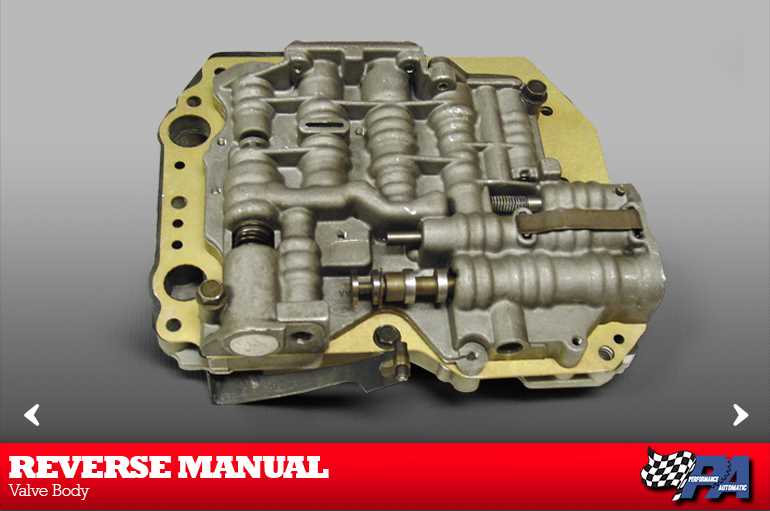

- Clutch Packs: Engage and disengage specific gears, ensuring seamless shifting between speeds.

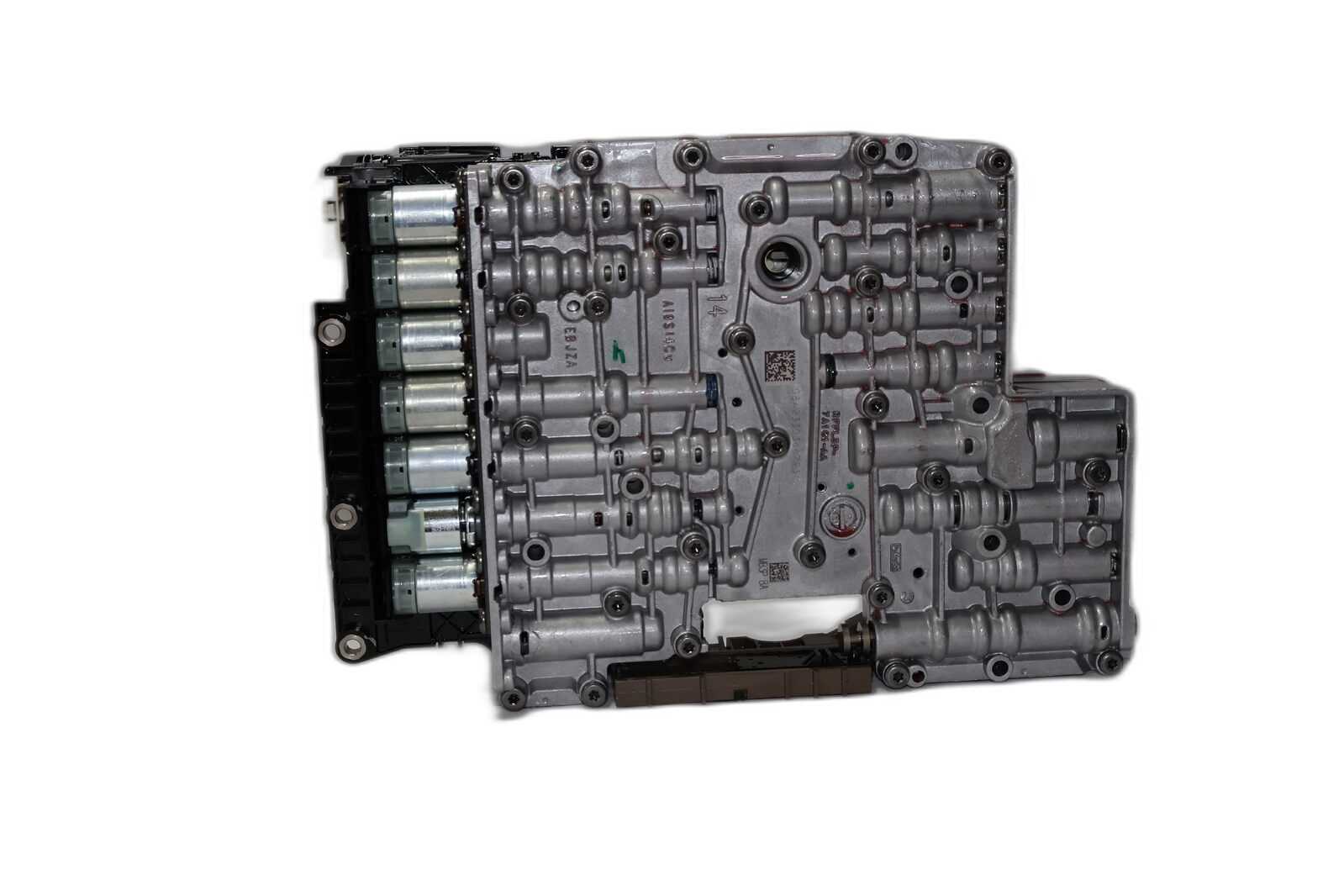

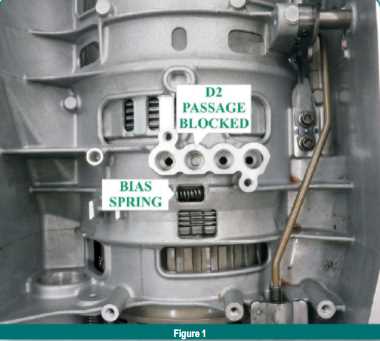

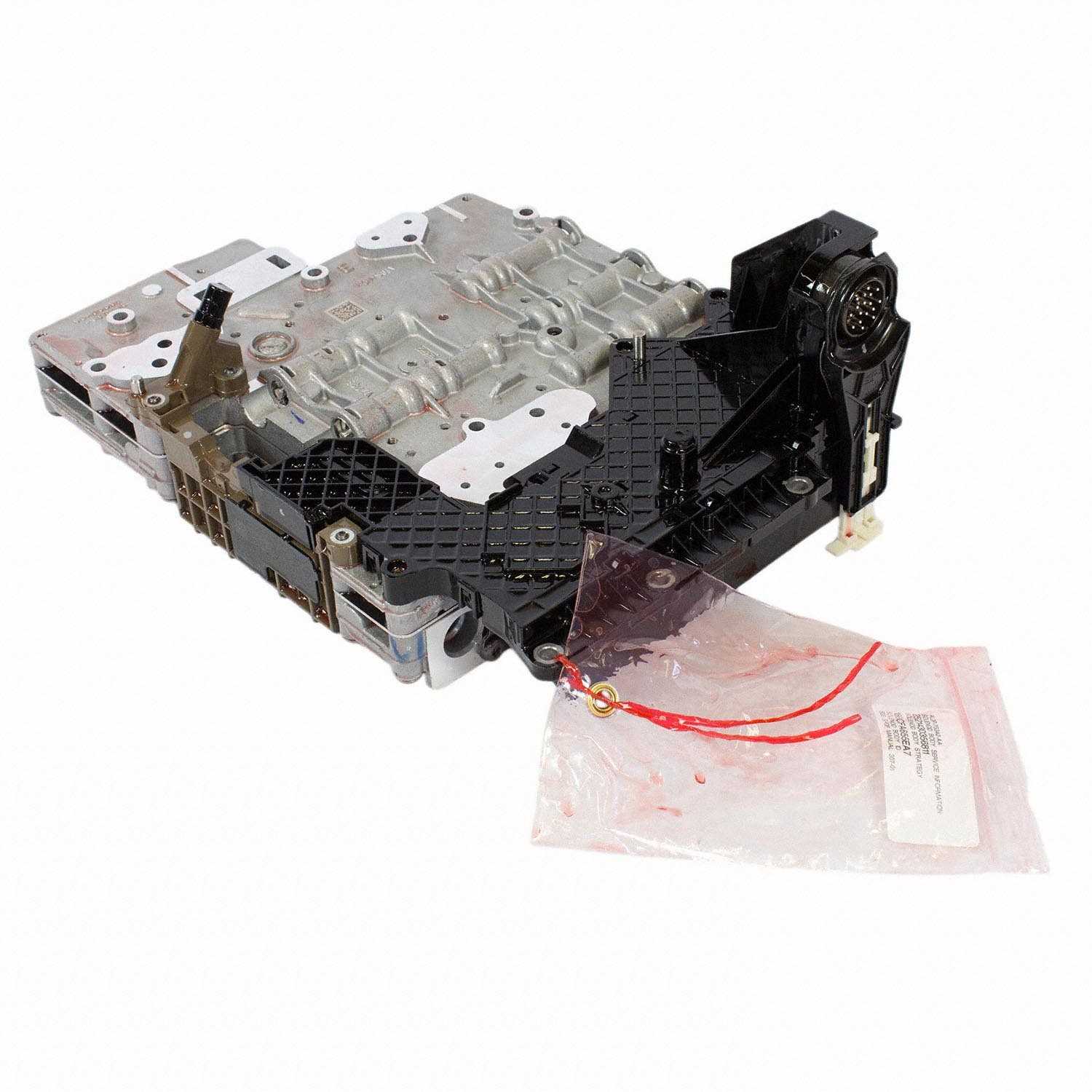

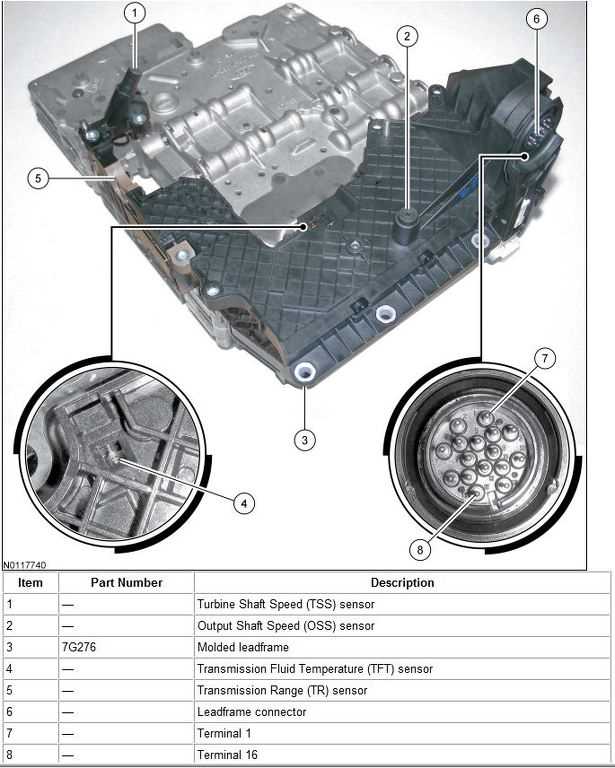

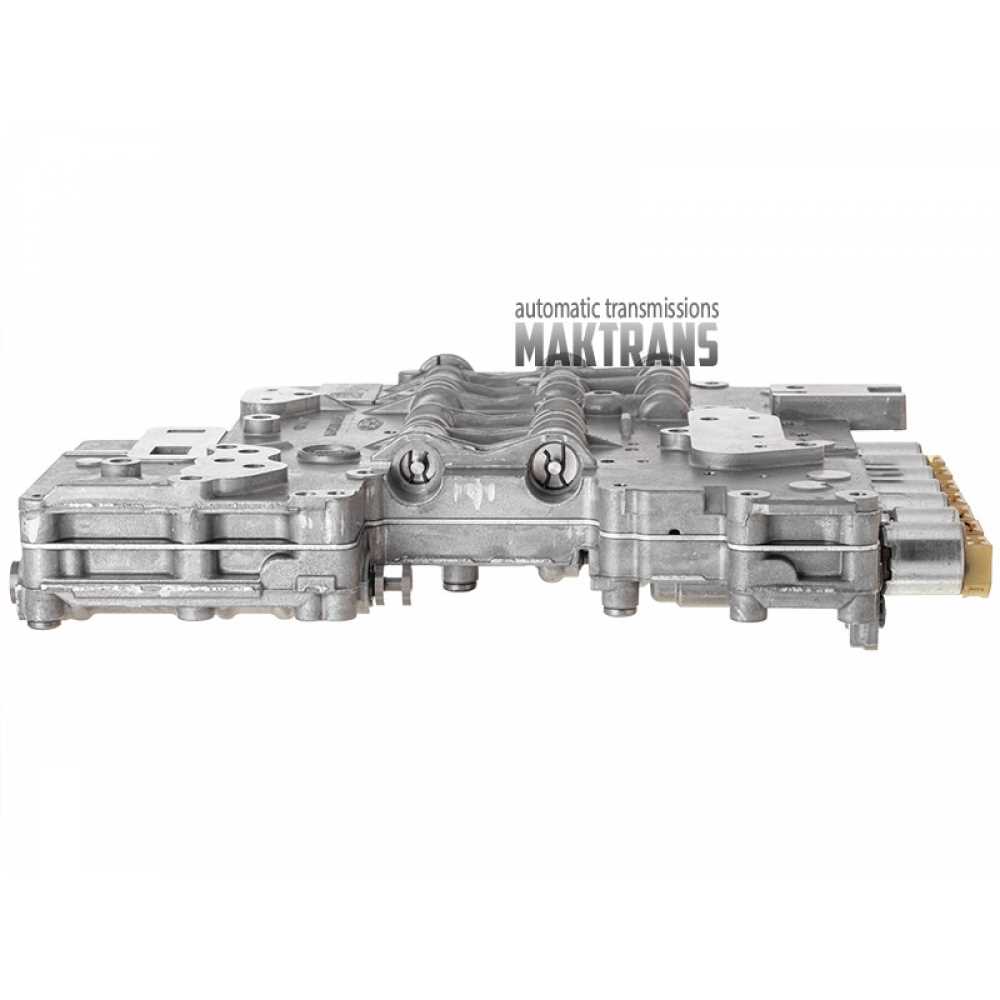

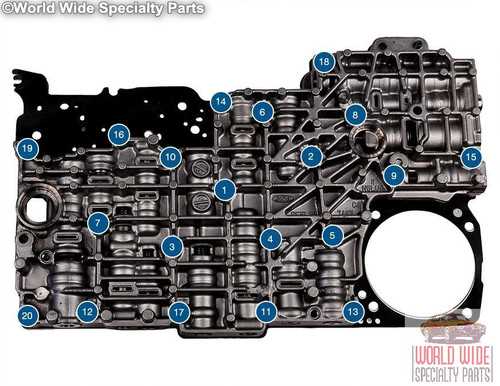

- Valve Body: Acts as the control center, directing hydraulic fluid to different parts for proper gear operation.

Additional Key Components

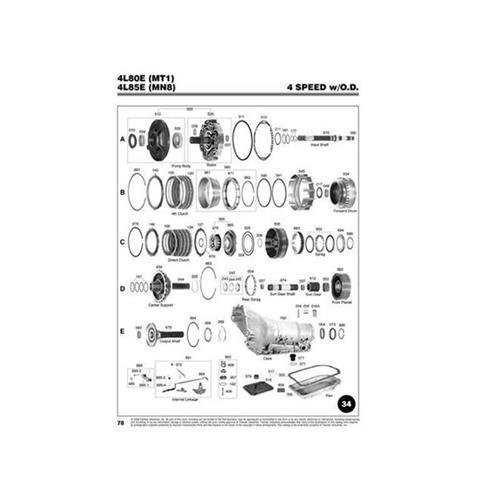

Main Internal Mechanisms of the 6-Speed Automatic Transmission

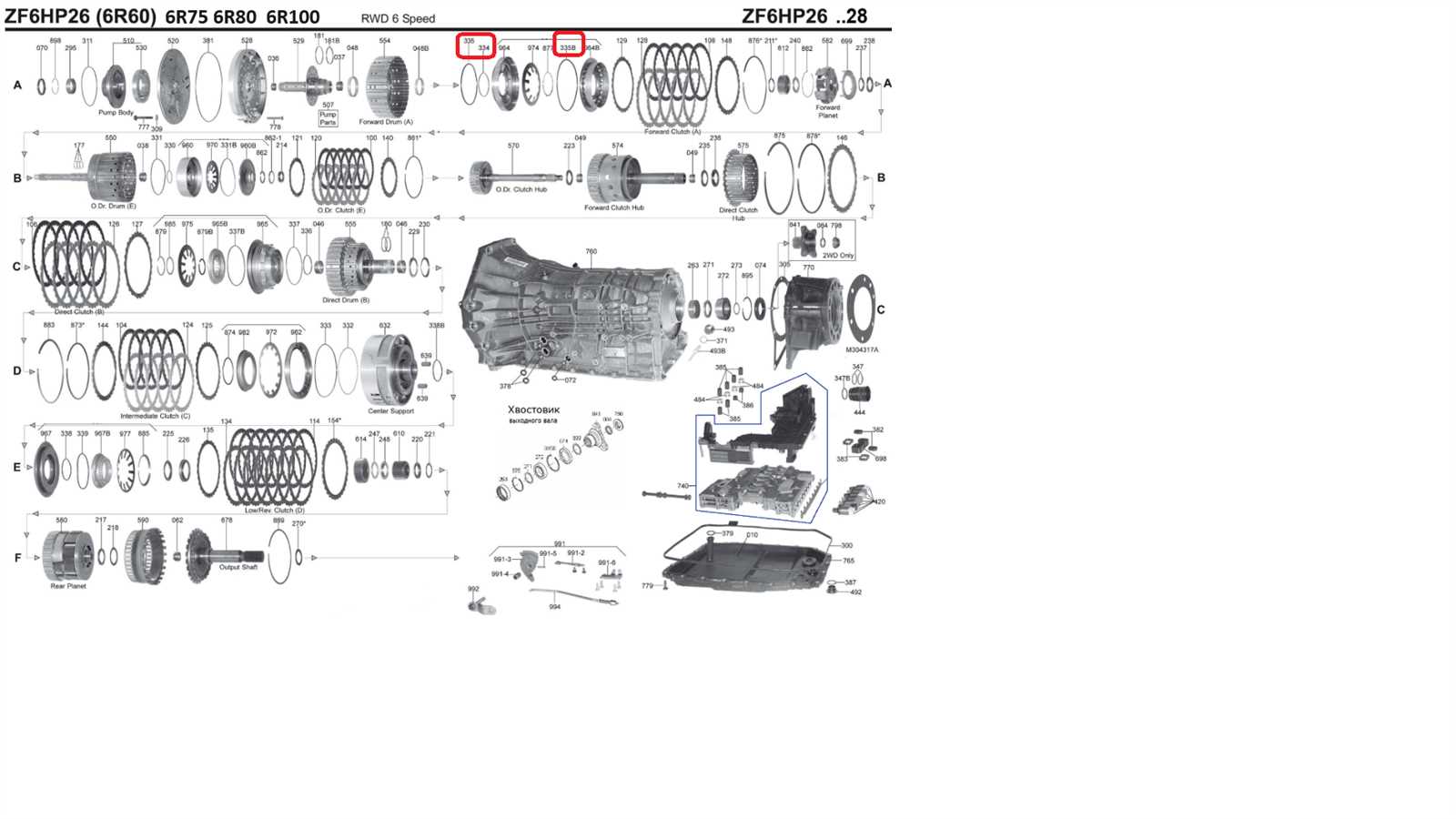

The inner workings of this advanced transmission rely on a combination of essential components that work together to ensure smooth and efficient gear shifting. Each element plays a vital role in managing the vehicle’s power and delivering it to the wheels with precision. Understanding these core mechanisms helps in grasping how the entire system functions in harmony, contributing to overall performance and durability.

Key Components

The structure consists of various parts that cooperate to optimize transmission efficiency. These include clutches, gears, and planetary sets, all of which are engineered to handle different torque levels and speed requirements.

| Component | Function | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clutches |

| Component | Description |

|---|---|

| Friction Plates | These plates create the necessary friction for power transfer when engaged. |

| Steel Plates | Provide structural support and enhance durability under high-stress conditions. |

| Spring Mechanism | Helps control the engagement pressure and ensures smooth operation. |

Examining the Oil Pump’s Importance

The oil pump plays a crucial role in maintaining the efficiency and longevity of a vehicle’s transmission system. Its primary function is to circulate lubricant throughout the components, ensuring smooth operation and preventing wear and tear. Without adequate lubrication, the risk of overheating and mechanical failure increases significantly.

Effective lubrication is essential for reducing friction between moving parts, which not only enhances performance but also contributes to the overall reliability of the transmission. When the oil pump operates effectively, it helps maintain optimal pressure, allowing for consistent shifting and improved fuel efficiency.

In summary, understanding the significance of the oil pump is vital for any vehicle owner or technician. Regular maintenance and timely inspections of this component can lead to better performance and a longer lifespan for the transmission system.

Role of the Planetary Gear System

The planetary gear system plays a crucial role in enhancing the efficiency and performance of modern transmission systems. This mechanism allows for multiple gear ratios within a compact design, enabling smooth power distribution and optimized torque management. By effectively distributing input power, the system contributes to improved vehicle dynamics and responsiveness.

Key Components

- Sun Gear: The central gear that drives the system, responsible for transferring power.

- Planet Gears: These gears orbit around the sun gear, allowing for torque multiplication and reduction.

- Ring Gear: This gear surrounds the planet gears and interacts with them to modify speed and torque.

- Carrier: It holds the planet gears in place and connects to the output shaft.

Advantages of Planetary Gear Systems

- Compact Design: Requires less space while providing various gear ratios.

- High Torque Capacity: Capable of handling significant torque loads efficiently.

- Smooth Operation: Facilitates seamless transitions between gears, enhancing driving comfort.

- Durability: Designed to withstand heavy usage and prolonged operation.

Understanding the 6R80 Solenoid Function

The solenoid plays a crucial role in the operation of modern automatic transmission systems. It serves as an essential component that controls the flow of hydraulic fluid within the transmission, influencing the engagement and disengagement of various gears. By managing pressure levels, the solenoid helps ensure smooth shifting and overall vehicle performance.

Functionality Overview: This device operates by receiving electrical signals from the transmission control module. When activated, it opens or closes specific hydraulic passages, enabling precise control of the transmission’s various functions. This functionality is vital for achieving optimal performance and efficiency.

Importance in Performance: The effectiveness of the solenoid directly impacts shifting quality and response times. A malfunctioning solenoid can lead to erratic shifting patterns, poor acceleration, and potential transmission damage. Regular maintenance and understanding the role of this component are essential for ensuring a well-functioning transmission system.

Cooling System and Its Impact on Longevity

The efficiency of a vehicle’s thermal management system plays a crucial role in ensuring optimal performance and durability. A well-functioning cooling mechanism not only regulates temperatures but also protects vital components from overheating. This section explores how effective cooling contributes to the overall lifespan of transmission systems.

Maintaining appropriate operating temperatures prevents excessive wear and tear on internal mechanisms. When the system is able to dissipate heat effectively, it minimizes the risk of fluid degradation and component failure. Regular maintenance of cooling elements is essential to preserve efficiency and prolong functionality.

Moreover, a properly calibrated cooling setup can enhance fuel efficiency and performance, allowing for smoother operation under various driving conditions. Investing in quality components and routine checks can lead to significant improvements in reliability and longevity, ensuring that the transmission remains in peak condition for an extended period.

Common Wear and Tear Parts in the 6R80

Automatic transmissions, like the one discussed here, often experience a range of components that can wear down over time due to constant use and the demands of various driving conditions. Understanding these common elements can help in proactive maintenance and timely replacements, ultimately extending the lifespan of the system.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Clutch Plates | Slipping or harsh shifting | Inspect and replace if necessary |

| Seals and Gaskets | Fluid leaks | Replace damaged seals |

| Torque Converter | Overheating or shuddering | Test and replace if faulty |

| Valve Body | Erratic shifting or delayed engagement | Check for clogs and consider servicing |