This section provides a comprehensive overview of the structural arrangement and functionality of key components within a specific marine propulsion system. By exploring the intricate details of each element, readers can gain valuable insights into how these parts interact to ensure optimal performance and efficiency.

In the context of boating and marine engineering, understanding the configuration of various components is essential for both maintenance and repair. Proper knowledge of these elements can lead to enhanced operational capabilities and extended lifespan of the system.

Furthermore, familiarity with the layout aids in troubleshooting and identifying potential issues that may arise during use. By delving into this topic, users will be better equipped to manage their marine equipment effectively.

This section highlights the significant attributes of a specific marine propulsion system that is designed for enhanced performance and durability. Its innovative design and advanced technology ensure reliability and efficiency, making it an excellent choice for boating enthusiasts.

Performance and Efficiency

The propulsion system is engineered to deliver superior power while maintaining optimal fuel consumption. Key aspects include:

- Streamlined design for reduced drag.

- Advanced materials for weight reduction.

- Efficient transmission system for smoother acceleration.

Durability and Maintenance

Built to withstand harsh marine conditions, this model features components that promote longevity and ease of upkeep:

- Corrosion-resistant materials to enhance lifespan.

- Accessible maintenance points for quick service.

- Robust construction to endure heavy usage.

Commonly Used Components Explained

The functionality of marine propulsion systems relies heavily on a variety of essential elements. Understanding these components is crucial for maintaining optimal performance and ensuring safety during operation. Each part plays a specific role, contributing to the overall efficiency and reliability of the system.

Propellers are fundamental in generating thrust, allowing vessels to move through water. Their design and size directly impact the speed and maneuverability of the craft.

Stern Drives serve as the interface between the engine and the propeller, translating engine power into propulsion. These components are designed to provide smooth and efficient power transfer.

Transom Assemblies are integral to the installation of the propulsion system, providing structural support and housing various mechanical elements. A sturdy assembly ensures stability and performance during operation.

Cooling Systems are vital for maintaining optimal temperatures within the engine. They prevent overheating by circulating coolant, which is essential for extending the life of the engine and enhancing performance.

Regular inspection and maintenance of these components are key to avoiding potential failures and ensuring longevity. Understanding their functions helps in making informed decisions regarding repairs and upgrades.

Importance of Regular Maintenance

Consistent upkeep of your marine equipment is essential for ensuring optimal performance and longevity. Regular inspections and timely interventions can prevent minor issues from escalating into significant problems, ultimately saving time and costs associated with repairs.

Engaging in routine care not only enhances the reliability of your vessel but also contributes to safety on the water. Well-maintained machinery operates efficiently, reducing the likelihood of unexpected failures during critical moments. Moreover, adhering to a maintenance schedule can help identify wear and tear, allowing for proactive replacements.

Furthermore, regular servicing often improves fuel efficiency, resulting in better overall performance and lower operational costs. It also helps maintain the value of the equipment, ensuring it remains a worthwhile investment over time.

In summary, prioritizing maintenance is a key factor in maximizing the functionality and lifespan of your marine assets. By committing to a structured maintenance plan, you can enjoy a safer and more enjoyable boating experience.

Identifying Spare Parts

When maintaining marine engines, understanding how to recognize essential components is crucial for ensuring optimal performance. Having a clear approach to identifying these elements can simplify repairs and replacements, minimizing downtime during operations.

Understanding Component Functionality

Each item within the engine assembly plays a specific role, contributing to the overall efficiency of the vessel. Familiarizing yourself with the functionality of these components allows for more informed decisions when selecting replacements. Key elements include mechanisms that facilitate propulsion, cooling systems, and electrical connections, all of which should be regularly inspected.

Utilizing Reference Guides

Using reference materials can significantly aid in pinpointing necessary components. Diagrams and manuals can provide invaluable insights, highlighting where each part fits within the larger system. Make sure to keep these resources accessible for quick consultations, ensuring a smooth maintenance process.

Installation Guidelines for Components

Proper installation of various components is crucial for ensuring optimal performance and longevity of the system. Adhering to specific guidelines during the installation process can prevent potential issues and enhance overall efficiency.

- Preparation: Before beginning the installation, ensure that all necessary tools and components are on hand. This includes reviewing any relevant manuals and installation instructions.

- Safety Measures: Always prioritize safety. Wear appropriate protective gear and ensure the work area is well-ventilated and free of hazards.

- Component Inspection: Check all components for signs of damage or wear. Replace any defective parts before installation to avoid complications later.

- Installation Steps: Follow these general steps during the installation process:

- Begin by securing the main assembly in a stable position.

- Align the components according to the specified layout.

- Carefully fasten all connections, ensuring a tight fit without over-torquing.

- Double-check all connections and components for proper alignment and security.

- Test the installation by running the system briefly to ensure everything operates smoothly.

Following these guidelines will facilitate a successful installation process and contribute to the system’s reliable operation.

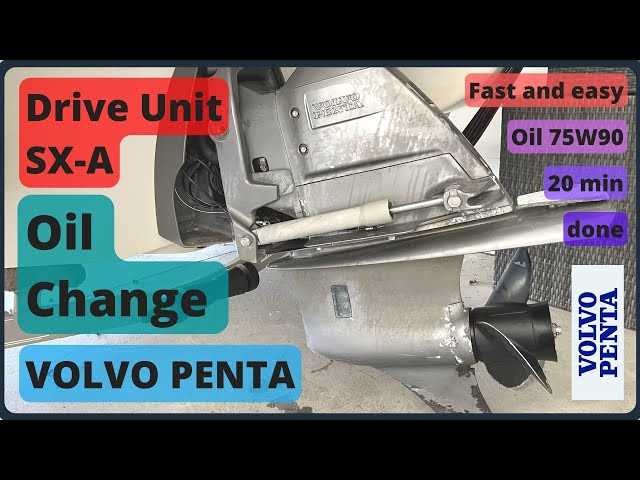

Common Issues with the SX-A Parts

When dealing with marine propulsion systems, users may encounter a range of challenges related to various components. Understanding these common issues can help ensure optimal performance and longevity of the equipment.

One prevalent problem involves wear and tear on critical elements due to prolonged exposure to water and environmental factors. This can lead to reduced efficiency and potential failures if not addressed promptly. Regular maintenance and inspections are essential to identify such deterioration early.

Another common concern is the accumulation of debris and contaminants, which can obstruct functionality. Regular cleaning and maintenance are vital to prevent blockages that may hinder performance. Users should be aware of the signs that indicate the need for servicing to maintain operational reliability.

Lastly, improper installation or adjustments can lead to misalignment issues, affecting the overall performance of the system. Ensuring that all components are correctly positioned and calibrated is crucial for smooth operation. Attention to detail during installation can mitigate these complications significantly.

Replacement Parts and Upgrades

Ensuring optimal performance and longevity of your marine engine often involves selecting suitable components and enhancements. Regular maintenance and timely replacements can significantly impact the overall efficiency and reliability of the system.

Essential Components for Maintenance

When considering component upgrades, it’s important to focus on essential elements that contribute to the engine’s functionality. High-quality replacements for filters, seals, and pumps can help maintain smooth operations. Using original or reputable aftermarket options guarantees better compatibility and durability.

Performance Enhancements

In addition to necessary replacements, various upgrades can enhance the performance of your engine. Consider options such as upgraded exhaust systems or fuel injectors that can improve power output and efficiency. These enhancements not only boost performance but also contribute to a more enjoyable experience on the water.

Safety Precautions During Repairs

When undertaking maintenance on marine propulsion systems, it is essential to prioritize safety to prevent accidents and ensure a smooth workflow. Proper precautions protect both the technician and the equipment, facilitating an effective repair process.

Before beginning any repair, always wear appropriate personal protective equipment, such as gloves and safety goggles. This minimizes the risk of injury from sharp objects or hazardous materials. Additionally, ensure that the workspace is well-ventilated, particularly when handling chemicals or fuels.

It is crucial to disconnect power sources and ensure that the engine is cool before initiating repairs. This reduces the likelihood of electrical shocks or burns. Furthermore, using the correct tools for the job can significantly reduce the chances of accidents.

Always follow manufacturer guidelines and service manuals for specific procedures and torque specifications. Keeping a tidy workspace and properly storing tools can help prevent tripping hazards and maintain an organized environment.

Finally, when working with heavy components, utilize hoisting equipment and ensure that the load is secure before lifting. This practice protects against injuries caused by falling objects and ensures a safer repair process.

Resources for Parts Acquisition

When seeking components for marine engines, it is essential to explore various avenues to ensure you obtain quality items. This section outlines several resources to assist in locating and purchasing necessary elements effectively and efficiently.

Online Marketplaces

Utilizing online platforms can significantly simplify the process of sourcing engine components. Websites specializing in marine supplies offer a wide range of options, enabling users to compare prices and find specific items. It is advisable to check customer reviews and seller ratings to ensure the reliability of the products.

Local Dealers and Distributors

Another valuable resource includes local dealerships and distributors. Establishing relationships with nearby suppliers can provide benefits such as personalized service and immediate availability of items. Additionally, local experts can offer guidance on the best options for your specific requirements.

FAQs About Volvo Penta SX-A Parts

This section aims to address common inquiries regarding components related to marine propulsion systems. Understanding these elements is crucial for maintaining optimal performance and ensuring longevity. Below are frequently asked questions that can help clarify any uncertainties.

What are the key components of a marine propulsion system?

The primary elements typically include the engine, transmission, propeller, and related accessories. Each plays a vital role in the overall functionality of the vessel.

How can I identify the right replacement components?

Identifying the appropriate replacements involves consulting the technical manual or parts list associated with your specific model. Additionally, cross-referencing with reliable suppliers can ensure compatibility.

What are common issues that may arise with these components?

Some typical problems include wear and tear, corrosion, and improper installation. Regular maintenance checks can help mitigate these issues and enhance the system’s reliability.

Where can I find quality replacements for these components?

Quality replacements can often be sourced from authorized dealers, reputable online retailers, or specialized marine supply stores. Always ensure that the products meet the required specifications.

How often should I perform maintenance on my system?

Regular maintenance is recommended at least once a season or more frequently if the system is used heavily. Adhering to a maintenance schedule can significantly prolong the lifespan of the components.