In the world of outdoor equipment, understanding the intricate arrangement of a trimmer’s elements is crucial for both maintenance and optimal performance. Each component plays a vital role in ensuring that the device operates smoothly and efficiently. A detailed exploration of these individual sections can provide valuable insights into the overall functionality and reliability of the equipment.

Comprehending the various sections involved can greatly assist users in troubleshooting issues and performing necessary repairs. Whether it’s the engine assembly or the cutting mechanism, familiarity with each part’s placement and connection will enhance the user experience. This knowledge empowers users to take charge of their equipment, facilitating proper care and longevity.

Additionally, having access to a comprehensive representation of the component layout allows for easier identification of potential wear or damage. As enthusiasts and professionals alike seek to maximize their trimmer’s capabilities, understanding how these pieces fit together becomes essential. This examination opens the door to a more profound appreciation for the craftsmanship behind these machines.

Overview of Echo SRM 280T Components

This section provides a comprehensive look at the various elements that constitute a particular model of handheld power equipment. Understanding these components is essential for effective operation, maintenance, and potential upgrades. Each part plays a crucial role in the overall functionality and efficiency of the device.

Key Components

- Engine: The heart of the equipment, responsible for generating the necessary power.

- Fuel System: Includes the tank and lines, ensuring the engine receives the proper fuel mixture.

- Cutting Mechanism: This includes blades or string, critical for executing the intended tasks.

- Handle: Provides control and stability during operation, ensuring user comfort.

- Guard: A protective element that ensures safety while operating the equipment.

Supporting Elements

- Air Filter: Maintains engine performance by filtering out debris.

- Starter Mechanism: Facilitates the ignition of the engine.

- Drive Shaft: Transmits power from the engine to the cutting mechanism.

- Vibration Dampening System: Reduces operator fatigue by minimizing vibrations during use.

Each of these components works synergistically to ensure the equipment performs optimally. Regular maintenance and understanding of each part’s function can significantly enhance the longevity and efficiency of the tool.

Understanding the Parts Layout

Familiarizing yourself with the arrangement of components in a tool can significantly enhance your maintenance and repair efforts. A well-organized layout allows users to identify and access necessary elements efficiently, facilitating a better understanding of how the machine operates. This knowledge is crucial for anyone looking to perform routine checks or replacements.

The configuration of a device typically includes several key elements, each playing a vital role in overall functionality. Recognizing these components and their positions aids in troubleshooting issues and ensures optimal performance. Below is an overview of common components found in similar machines.

| Component Name | Description | Function |

|---|---|---|

| Engine | The power source for the tool. | Drives the cutting mechanism. |

| Fuel Tank | Holds the necessary fuel. | Supplies energy to the engine. |

| Cutting Head | The assembly that houses the cutting line. | Enables trimming and cutting tasks. |

| Handle | The grip for operator control. | Allows for maneuvering the tool effectively. |

| Starter Mechanism | System for igniting the engine. | Initiates operation of the machine. |

Understanding the arrangement and function of these elements will empower users to navigate maintenance tasks more effectively. Being well-informed about the layout contributes to longer equipment lifespan and improved efficiency during use.

Essential Tools for Maintenance

Regular upkeep of outdoor equipment ensures optimal performance and longevity. Having the right instruments at hand simplifies the maintenance process and prevents potential issues. This section outlines the fundamental tools necessary for effective care of your machinery.

Basic Tools for Upkeep

- Wrenches: Useful for tightening and loosening bolts and nuts.

- Screwdrivers: Essential for adjusting various components and securing covers.

- Pliers: Handy for gripping and manipulating small parts.

- Grease Gun: Vital for applying lubricant to moving parts, reducing wear and tear.

- Fuel Container: Needed for safely transporting and storing fuel.

Safety Gear

- Protective Gloves: Shield your hands from sharp edges and harmful substances.

- Safety Goggles: Protect your eyes from debris and chemicals during maintenance tasks.

- Ear Protection: Necessary when operating loud machinery to prevent hearing damage.

Equipping yourself with these essential tools not only streamlines the maintenance process but also enhances safety, ensuring a more enjoyable and productive experience.

Common Issues and Solutions

Maintenance and operation of outdoor power equipment can present various challenges that users may encounter. Understanding these common problems and their respective solutions can enhance the performance and longevity of the equipment. Below are some typical issues along with effective remedies.

Engine Start Failure

One frequent issue is the failure of the engine to start. This can often be attributed to a lack of fuel or a clogged air filter. Ensure that the fuel tank is filled with the correct fuel mixture and check the air filter for any blockages. Cleaning or replacing the air filter can improve airflow and facilitate easier starting.

Loss of Power During Operation

Another common problem is experiencing a decrease in power while the equipment is in use. This may result from a dull cutting tool or an improperly adjusted throttle. To address this, inspect the cutting tool and sharpen or replace it as necessary. Additionally, adjusting the throttle settings can help restore optimal performance. Regular maintenance checks can prevent this issue from arising.

Step-by-Step Assembly Instructions

This section provides a detailed guide to assembling the components of a particular outdoor power tool. Each step is designed to ensure that the assembly process is straightforward and efficient, allowing users to successfully put together their equipment with confidence.

Required Tools and Materials

Before beginning the assembly, gather the necessary tools and materials. This will streamline the process and help avoid interruptions.

| Tool/Material | Description |

|---|---|

| Screwdriver | A basic tool required for fastening screws securely. |

| Wrench | Used for tightening bolts and nuts to ensure stability. |

| Assembly Manual | A guide that includes diagrams and detailed instructions for each step. |

Assembly Steps

Follow these steps to assemble your outdoor equipment effectively:

- Start by laying out all components on a flat surface. Ensure everything is accessible and organized.

- Begin with the main frame. Attach the base to the frame using the screws provided in the kit.

- Secure the handle by aligning it with the designated slots on the frame. Use the wrench to tighten the bolts.

- Install the motor assembly by carefully fitting it into place, ensuring all connectors are properly aligned.

- Finally, double-check all connections and fastenings to confirm that everything is secure and properly assembled.

Safety Precautions During Repairs

When undertaking maintenance or restoration tasks on outdoor power equipment, adhering to safety guidelines is crucial. These measures help prevent accidents and ensure a safe working environment. By following established protocols, individuals can minimize risks associated with equipment malfunctions and ensure their personal safety during repairs.

Personal Protective Equipment (PPE)

Using the right personal protective gear is essential when engaging in repair activities. This equipment can shield against potential hazards such as flying debris and sharp edges. Key items to consider include:

| Protective Gear | Purpose |

|---|---|

| Safety Goggles | To protect eyes from debris and chemical splashes. |

| Gloves | To safeguard hands from sharp objects and hot surfaces. |

| Ear Protection | To prevent hearing damage from loud machinery. |

| Steel-Toed Boots | To protect feet from heavy falling objects. |

Work Environment Considerations

Creating a safe workspace is as important as using personal protective gear. Ensure that the area is well-ventilated and free from clutter. Proper organization can significantly reduce the risk of accidents. Additionally, it is advisable to have a first aid kit readily available in case of emergencies.

Where to Find Replacement Parts

When it comes to maintaining outdoor power equipment, sourcing the right components is essential for optimal performance. Whether you’re repairing a trimmer or another type of machinery, knowing where to look for quality replacements can save time and ensure your device operates effectively.

Authorized Dealers

One of the most reliable sources for obtaining new components is through authorized retailers. These dealers typically stock genuine items that are specifically designed for your equipment model. By purchasing from authorized locations, you can be confident that you are getting parts that meet the manufacturer’s specifications.

Online Marketplaces

The internet provides a vast array of options for finding components. E-commerce platforms often have a wide selection of aftermarket and original items. When shopping online, it’s crucial to check customer reviews and ratings to ensure the quality and compatibility of the components you intend to purchase.

Comparing OEM and Aftermarket Options

When it comes to maintaining outdoor power equipment, users often face a crucial decision: whether to choose original manufacturer components or explore alternative options. Each choice has its unique advantages and potential drawbacks that can significantly affect performance, durability, and cost-effectiveness. Understanding the distinctions between these two types of offerings is essential for making informed decisions that align with individual needs and preferences.

| Aspect | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Manufactured to original specifications, ensuring optimal performance. | Varies widely; some may match or exceed OEM quality, while others might not. |

| Price | Generally higher due to brand reputation and quality assurance. | Often more affordable, making them attractive for budget-conscious users. |

| Availability | Readily available through authorized dealers and specific retailers. | Widely accessible through various online platforms and local shops. |

| Warranty | Typically includes a manufacturer’s warranty, providing peace of mind. | May offer warranties, but they are less common and can vary by brand. |

| Compatibility | Guaranteed to fit and function with the specific equipment. | Compatibility can be hit or miss; some may require modifications. |

Ultimately, the choice between original and alternative components will depend on individual circumstances, including budget, performance expectations, and personal preferences. Evaluating the options carefully can lead to satisfactory results and optimal equipment functionality.

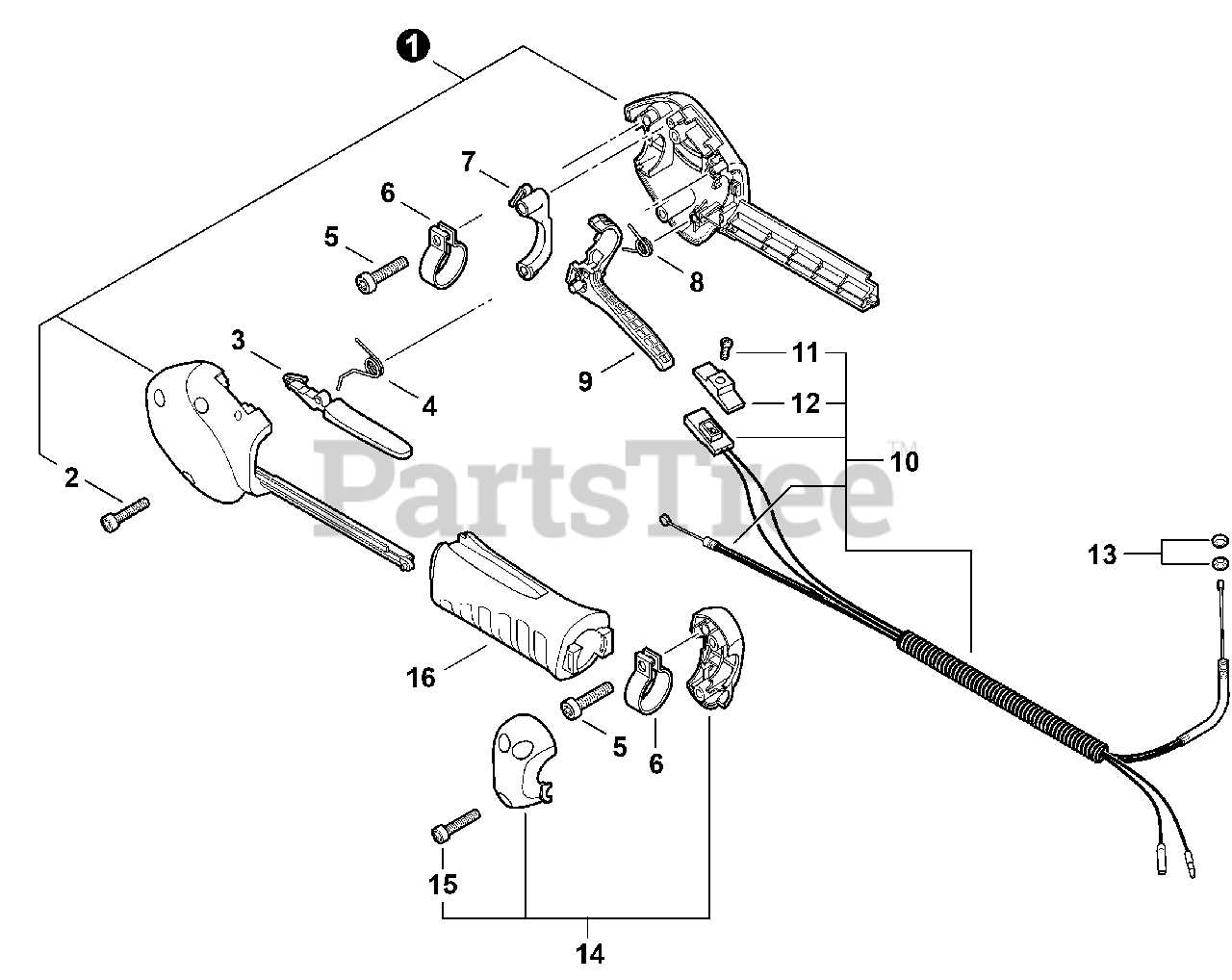

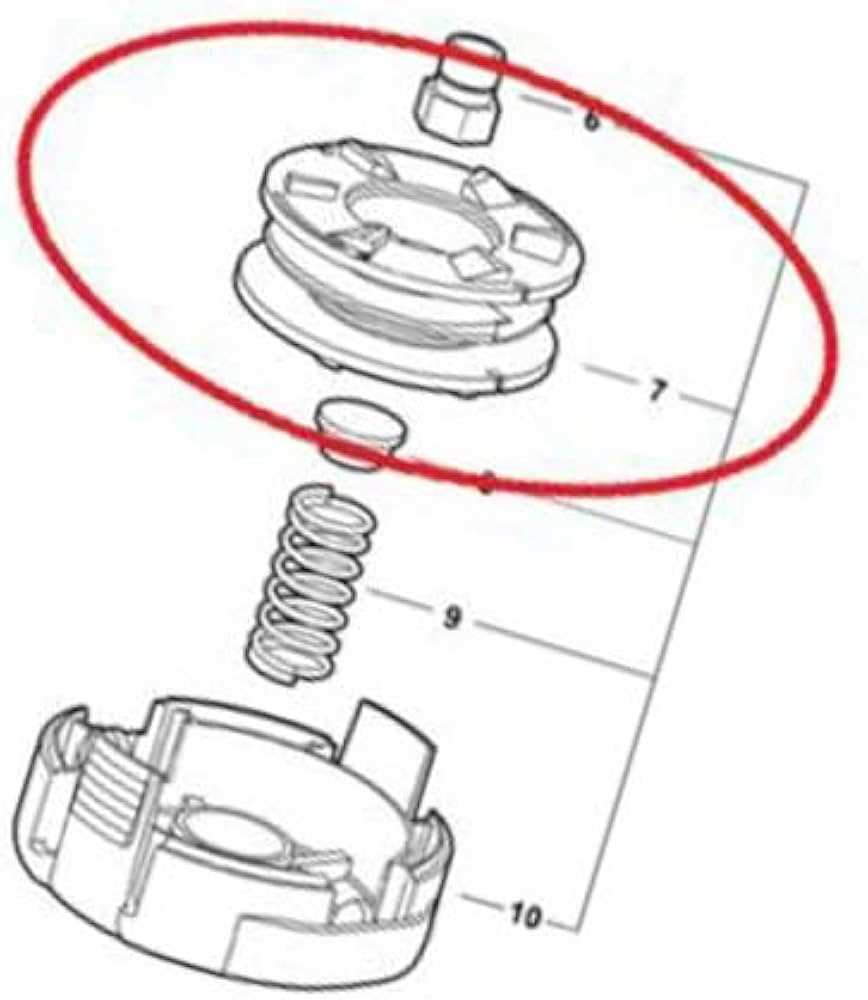

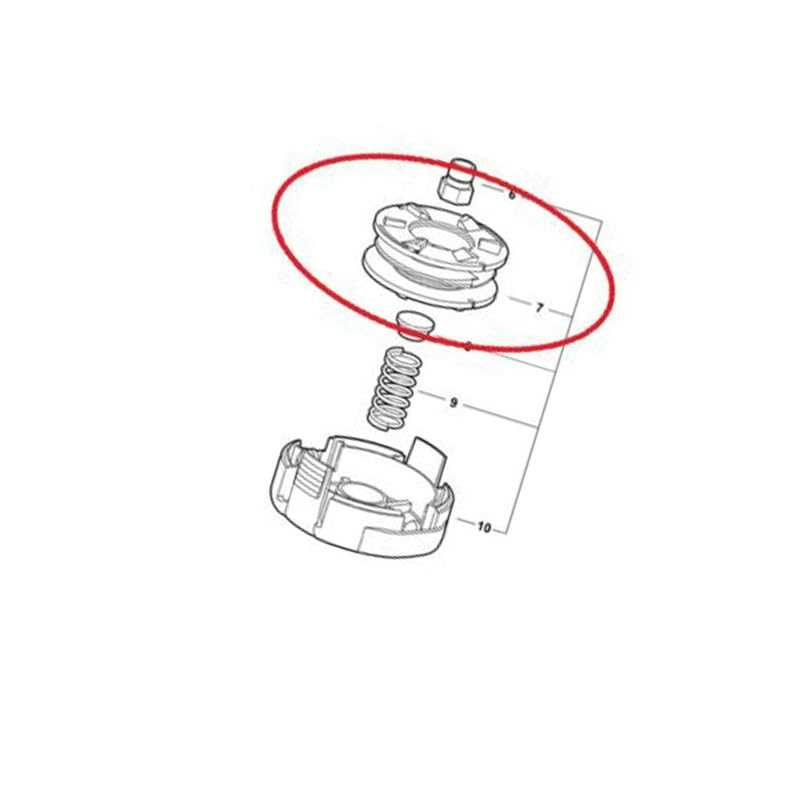

Diagrams for Easy Reference

Visual aids play a crucial role in understanding the components and assembly of various machines. Utilizing clear illustrations allows users to quickly identify individual elements, making maintenance and repairs more straightforward. This section aims to provide accessible visuals that enhance comprehension and facilitate effective troubleshooting.

Reference visuals simplify the process of locating specific components within a machine. They serve as a guide to ensure that users can easily navigate through complex structures without confusion. By having these illustrations readily available, individuals can efficiently address any issues that may arise during operation or servicing.

Incorporating visuals into repair processes not only saves time but also minimizes the risk of errors. With detailed representations, users can follow the assembly or disassembly processes with confidence. This approach promotes a smoother experience and fosters a better understanding of the overall functionality.

Tips for Troubleshooting Performance Problems

When dealing with performance issues in outdoor power equipment, it’s crucial to approach the situation methodically. Identifying the root cause can lead to more effective solutions and enhance the longevity of the machine. Here are some practical suggestions to help diagnose and resolve common performance-related concerns.

- Check Fuel Quality: Ensure that the fuel used is fresh and of good quality. Stale or contaminated fuel can lead to engine inefficiencies.

- Inspect the Air Filter: A clogged air filter restricts airflow, leading to poor combustion. Regularly clean or replace the air filter as needed.

- Examine the Spark Plug: A worn or fouled spark plug can cause starting issues and erratic performance. Inspect it for wear and replace if necessary.

- Review the Carburetor: Ensure the carburetor is clean and properly adjusted. Blockages or incorrect settings can affect fuel delivery and engine power.

- Monitor the Throttle Linkage: Ensure that the throttle linkage is functioning smoothly. Any sticking or binding can hinder performance.

- Inspect the Cutting Head: If the equipment includes a cutting head, check for damage or wear. A dull or damaged cutting element can result in decreased efficiency.

By systematically evaluating these areas, you can often pinpoint the source of performance issues and restore your equipment to optimal functioning.