This section provides a comprehensive look at the essential components of a specific cutting unit used for maintaining outdoor areas. Understanding the various elements that make up this system is crucial for effective operation and maintenance. Each part plays a significant role in the overall functionality, ensuring a smooth and efficient performance.

In the subsequent details, you will find valuable insights into the arrangement and specific roles of individual components. By familiarizing yourself with these elements, you can enhance your knowledge and skills in managing the equipment effectively. Proper awareness of the system not only aids in troubleshooting but also ensures longevity and optimal operation.

Whether you are a seasoned user or a novice, grasping the intricacies of these elements will empower you to make informed decisions regarding maintenance and repairs. This understanding contributes to achieving the best results during usage, allowing for a well-kept landscape.

Maintaining optimal functionality of your equipment is essential for efficient performance. Access to high-quality components is crucial for ensuring longevity and reliability. Understanding where to find these replacements can significantly impact the upkeep of your machinery.

Several options exist for acquiring necessary components. Local dealerships often carry a range of items suitable for various models, while online retailers provide extensive selections that may include hard-to-find components. It’s advisable to compare prices and check for warranties to ensure quality.

| Component Type | Availability | Recommended Sources |

|---|---|---|

| Blades | Widely available | Local dealerships, online retailers |

| Belt | Commonly found | Specialty stores, online marketplaces |

| Spindle Assembly | Moderately available | Authorized distributors, online sources |

| Mounting Hardware | Readily accessible | Local hardware stores, online retailers |

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. By following a few essential practices, you can enhance performance and minimize potential issues, allowing for a smooth and productive operation.

Routine Inspections

Conducting frequent assessments is crucial for identifying wear and tear before it becomes a significant problem. Focus on the following areas:

- Check for loose or damaged components.

- Inspect belts and cables for fraying or breaks.

- Look for any signs of rust or corrosion.

Proper Cleaning

Keeping your equipment clean is essential for maintaining optimal functionality. Regular cleaning helps to prevent the buildup of debris and grime, which can lead to performance issues:

- Clear away grass clippings and dirt after each use.

- Use a soft brush or cloth to wipe down surfaces.

- Ensure that air filters are free from obstructions.

Tools Required for Parts Replacement

When undertaking the task of replacing components on your equipment, having the appropriate tools is essential for ensuring efficiency and effectiveness. The right implements not only facilitate the process but also help prevent damage to the machinery and new components.

Essential Tools

- Socket set: A variety of socket sizes will be necessary to accommodate different fasteners.

- Wrench set: Both standard and adjustable wrenches will provide the versatility needed for various bolts and nuts.

- Screwdrivers: A selection of flathead and Phillips screwdrivers is crucial for accessing certain components.

- Pliers: Needle-nose and standard pliers are helpful for gripping and manipulating small parts.

- Torque wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications.

- Safety gear: Gloves and goggles should be worn to protect yourself during the process.

Additional Recommendations

In addition to the basic tools, consider the following items to enhance your replacement experience:

- Magnetic tray: Keeps small screws and washers organized and prevents loss.

- Cleaning materials: Having cloths and degreaser handy will help maintain cleanliness during the procedure.

- Work light: Adequate lighting is vital for visibility in tight spaces.

Understanding Deck Assembly and Disassembly

Grasping the fundamentals of assembling and disassembling the cutting apparatus is crucial for optimal maintenance and operation. This process involves a systematic approach to ensure that each component is securely attached and can be easily removed when necessary. By understanding the structure and function of each element, users can enhance performance and extend the lifespan of their equipment.

Key Components

- Spindle assemblies

- Blades

- Mounting brackets

- Belts

- Support structures

Assembly Steps

- Gather all necessary tools and components.

- Align the spindle assemblies with the mounting brackets.

- Secure each component using appropriate fasteners.

- Attach the cutting blades to the spindles.

- Double-check all connections for tightness and stability.

Following these steps will ensure that the entire assembly is correctly configured for effective operation. Regular inspection and maintenance will further promote reliability and performance.

Safety Precautions During Maintenance

Ensuring safety while performing maintenance tasks is essential for preventing accidents and injuries. Proper precautions should always be taken to protect both the individual and the equipment. Adhering to safety guidelines not only promotes a secure working environment but also enhances the overall efficiency of the maintenance process.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the equipment is turned off and disconnected from any power source before beginning maintenance.

- Keep the work area clean and free from hazards to avoid slips, trips, and falls.

Handling Tools and Equipment

- Use the right tools for the job to minimize the risk of injury.

- Inspect tools for damage or wear before use, replacing any faulty equipment immediately.

- Store tools safely after use to prevent accidents.

Upgrades for Enhanced Mowing Efficiency

Improving the performance of your grass cutting equipment can significantly enhance its functionality and user experience. Various modifications can optimize efficiency, ensuring a cleaner cut and reducing maintenance time. By investing in certain enhancements, operators can achieve superior results and extend the lifespan of their tools.

Improved Blade Technology

Upgrading to high-quality cutting blades is one of the most effective ways to boost performance. Blades made from durable materials and featuring advanced designs provide sharper edges and better cutting precision. Regularly replacing worn-out blades ensures consistent results and reduces the strain on the machine.

Advanced Engine Options

Considering an engine upgrade can also lead to improved power and efficiency. Higher horsepower options offer better performance, allowing for quicker mowing sessions and the ability to tackle tougher terrains. Additionally, ensuring proper maintenance of the engine enhances its efficiency, providing reliable operation over time.

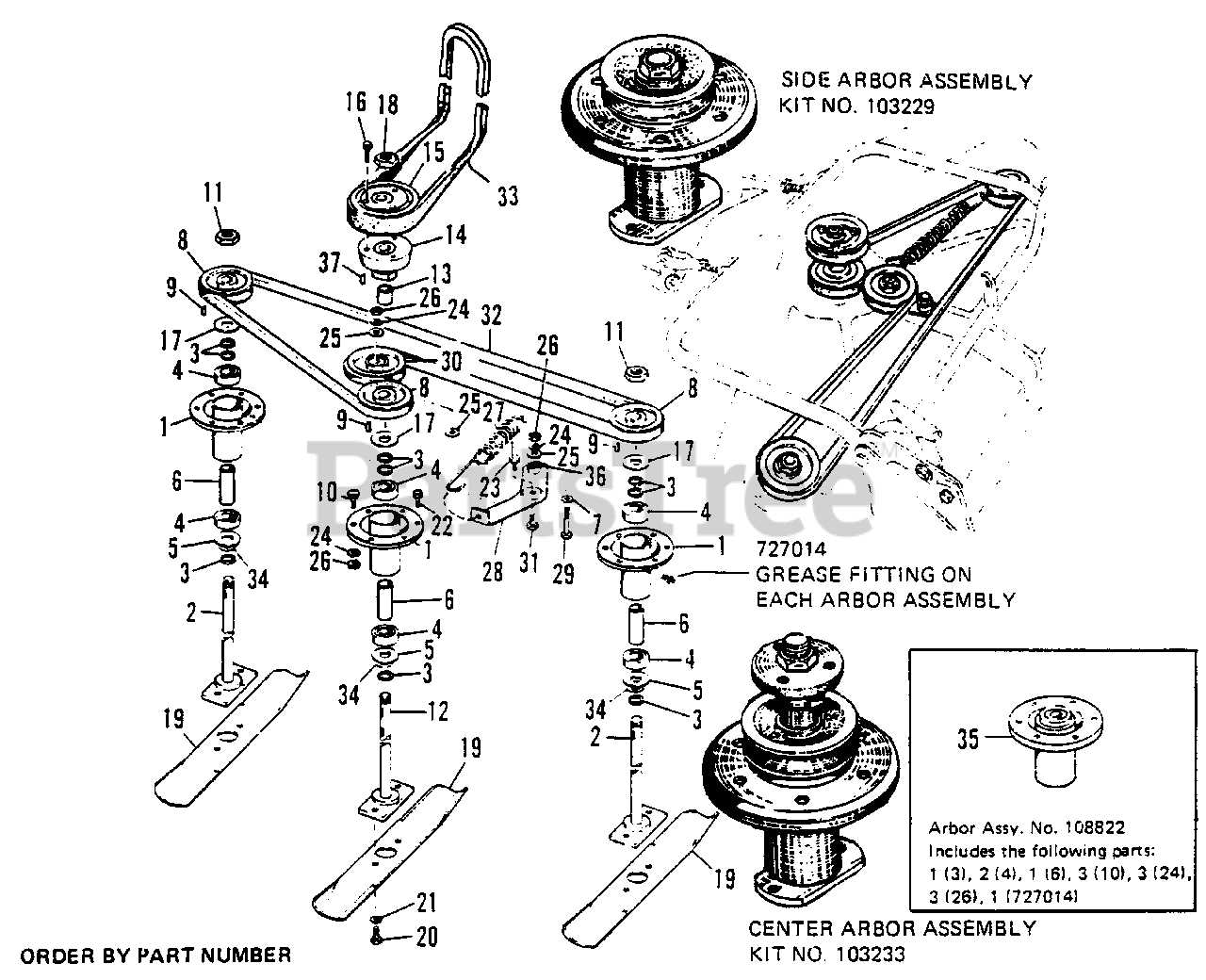

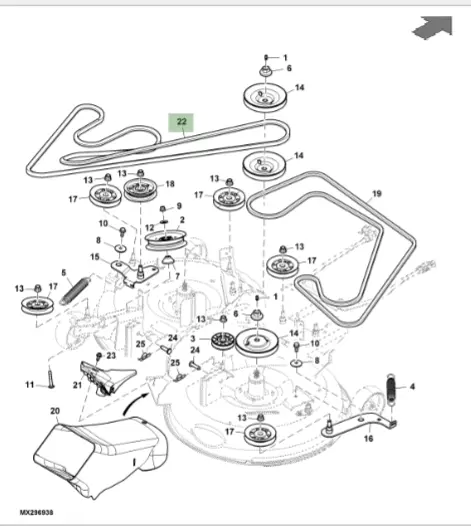

Visual Guide to Parts Diagram

This section aims to provide a comprehensive overview of the components that make up the equipment assembly. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance of the machinery.

Below are the key components commonly found in the assembly:

- Blade assembly

- Housing structure

- Mounting brackets

- Drive belt

- Spindle units

Each part plays a vital role in the functionality of the equipment. Here’s a detailed breakdown:

- Blade Assembly: Responsible for cutting grass and maintaining an even lawn surface.

- Housing Structure: Encloses and protects the internal components, providing stability.

- Mounting Brackets: Securely attach the assembly to the frame, ensuring proper alignment.

- Drive Belt: Transfers power from the engine to the blades, enabling movement.

- Spindle Units: House the blades, allowing for smooth rotation during operation.

Familiarizing oneself with these components will enhance the overall understanding of how the equipment operates and assist in identifying any potential issues.

Frequently Asked Questions About Mower Decks

This section aims to address common inquiries related to the essential components involved in the operation of lawn care equipment. Understanding these elements can help users maintain their machines effectively and troubleshoot any issues that may arise.

What should I do if my equipment isn’t cutting evenly? This issue can often be resolved by checking the alignment of the blades and ensuring they are sharpened properly. Uneven cutting may also indicate that the height settings need adjustment.

How can I tell if the blades need replacement? Signs that it’s time for a blade replacement include visible damage, such as chips or cracks, as well as a noticeable decline in cutting performance. Regular inspection is key to maintaining optimal functionality.

What maintenance is required for the components? Regular cleaning is essential to prevent grass buildup, which can hinder performance. Additionally, lubricating moving parts and checking for any signs of wear can prolong the lifespan of the equipment.

Can I use my equipment on uneven terrain? While many machines are designed for varied landscapes, operating on excessively rough ground can lead to damage. It’s advisable to assess the terrain and use appropriate settings to ensure safe operation.