When it comes to maintaining a pristine yard, having a reliable machine is essential. The effectiveness of any cutting tool heavily relies on the intricate assembly of its various components. Understanding how these elements work together not only enhances performance but also aids in troubleshooting issues that may arise during use.

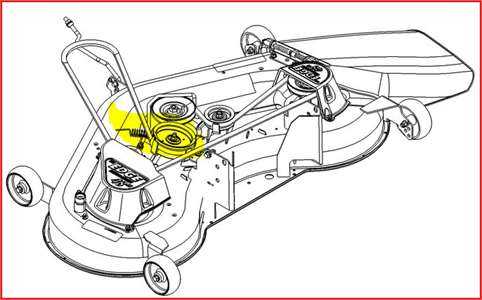

In this section, we will explore the key components that make up your lawn care equipment. From the cutting mechanism to the support structures, each part plays a critical role in ensuring efficient operation. A thorough knowledge of these elements can empower users to make informed decisions regarding maintenance and repairs.

Furthermore, recognizing the layout and functions of the essential components can significantly improve the user experience. This insight allows for better understanding of how to adjust settings, perform routine checks, and replace worn-out elements. Armed with this information, operators can extend the life of their equipment and enhance its overall performance.

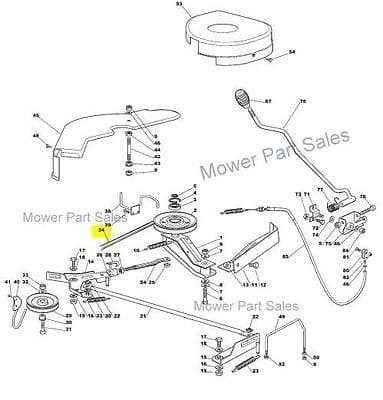

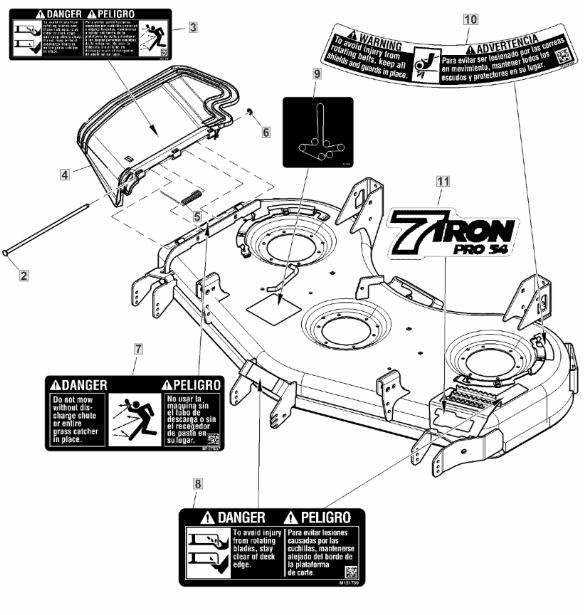

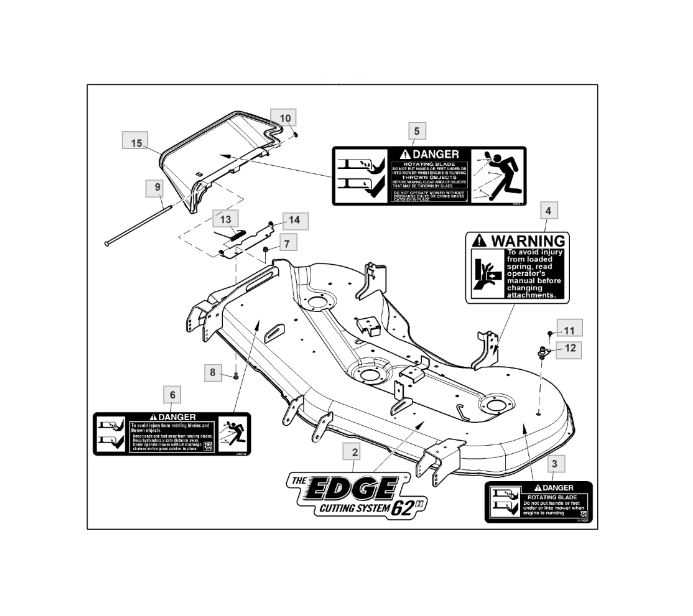

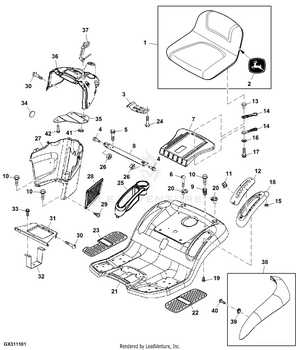

Understanding the arrangement of components is crucial for effective maintenance and troubleshooting of the equipment. Familiarity with each element allows for better handling and ensures that operations run smoothly. This section will guide you in recognizing the layout and function of various components, promoting an efficient approach to managing your machinery.

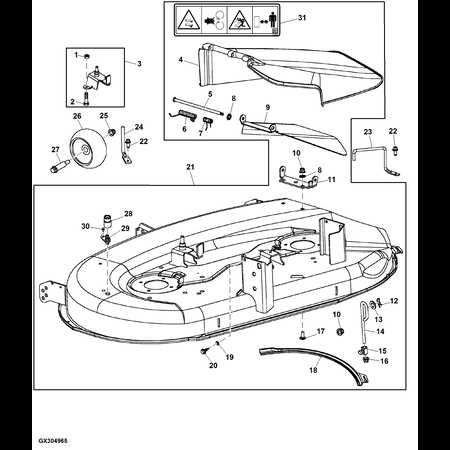

Key Components Overview

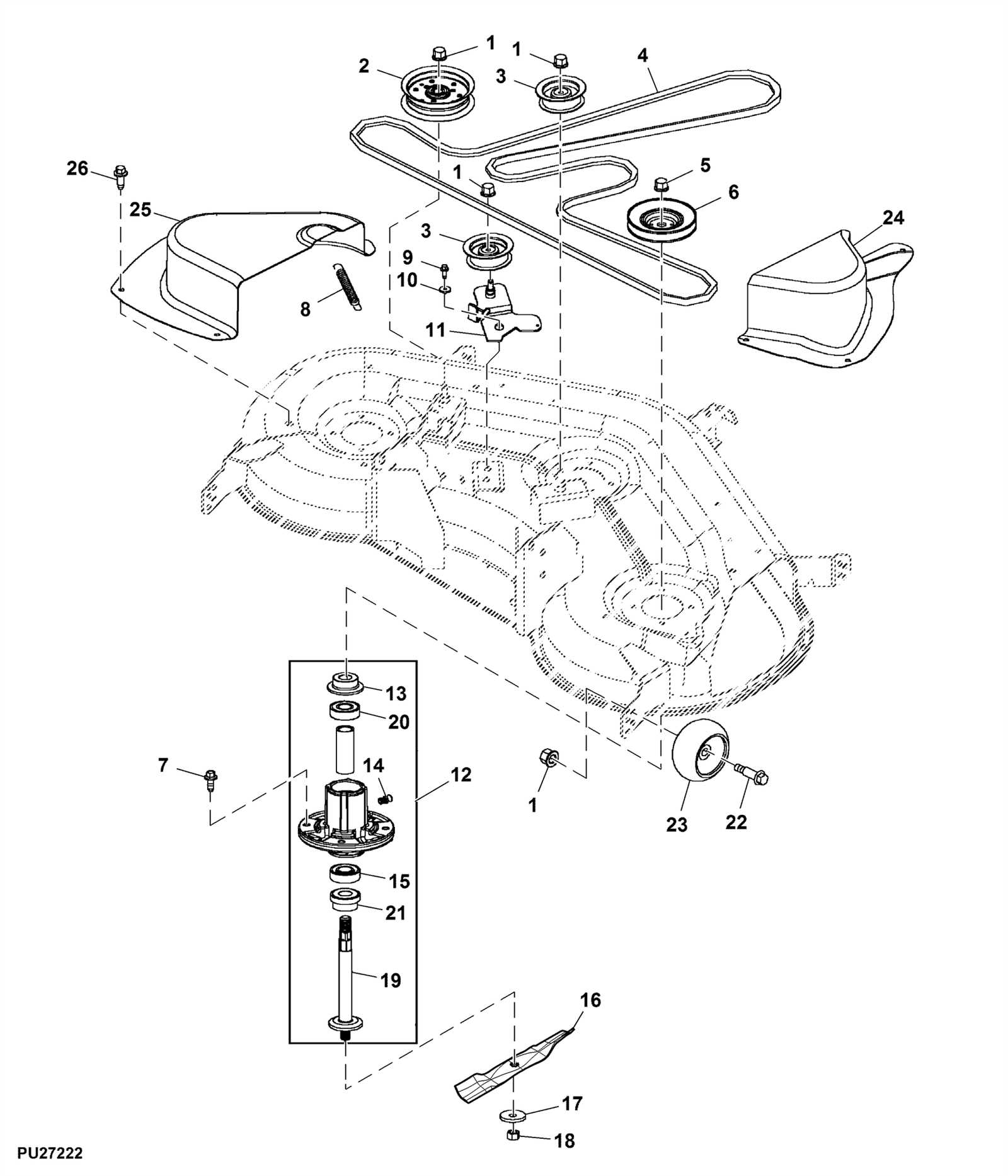

The structure comprises several essential elements, each playing a significant role in overall functionality. Here are the primary components you should be aware of:

- Housing: The main shell that protects internal mechanisms.

- Blades: Sharp elements responsible for cutting grass effectively.

- Spindles: Support the blades and allow them to rotate.

- Wheels: Provide mobility and stability during operation.

- Supports: Reinforcements that maintain structural integrity.

Understanding Each Element

Gaining insight into how each component interacts with others can enhance your operational knowledge. Here’s a brief explanation of the functions:

- Housing: Protects internal mechanisms from debris and damage.

- Blades: Cut through grass with precision and efficiency.

- Spindles: Facilitate blade rotation, allowing for smooth cutting actions.

- Wheels: Ensure easy movement across different terrains.

- Supports: Prevent bending or breaking under stress, ensuring durability.

By recognizing and understanding these components, you can optimize the use and maintenance of your machinery, ensuring longevity and performance.

Common Issues with Mower Decks

Maintaining the cutting mechanism of a lawn care machine is crucial for optimal performance. Various challenges can arise during operation, affecting the efficiency and quality of cutting. Identifying these issues promptly can prevent further damage and ensure a well-manicured lawn.

One frequent concern is uneven cutting, which may result from dull blades or improper height adjustments. Regularly sharpening the blades and setting the correct cutting height can significantly enhance the performance of the equipment. Additionally, foreign objects caught in the mechanism can obstruct movement, leading to subpar results.

Another issue is the buildup of grass clippings and debris. Over time, this accumulation can hinder the machine’s efficiency and lead to rusting. Routine cleaning after use is essential to maintain functionality and prolong the lifespan of the components.

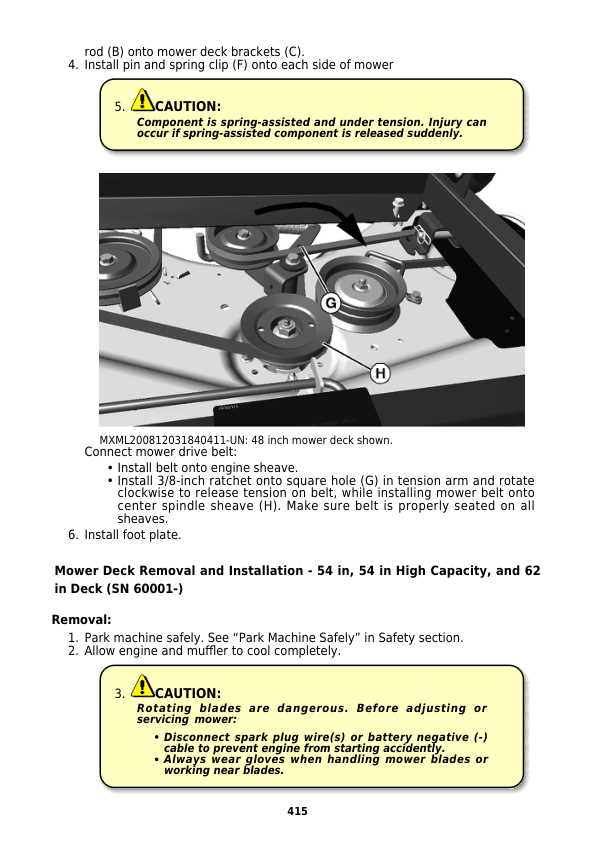

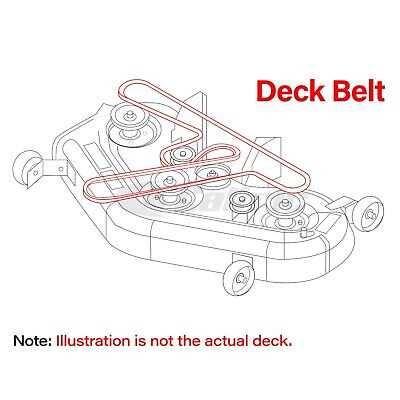

Furthermore, wear and tear on belts and pulleys can cause operational delays. Inspecting these parts regularly and replacing them when necessary will help maintain smooth operation. Being proactive about these common challenges can ensure that the equipment operates at its best.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular attention not only enhances functionality but also extends the lifespan of the components involved. Here are some valuable strategies to help maintain your machine effectively.

- Regular Cleaning: Remove any debris, grass clippings, or dirt from the exterior and underneath the unit. This prevents rust and ensures smooth operation.

- Inspect Components: Routinely check all elements for wear and tear. Look for signs of damage or excessive wear that may require replacement.

- Lubrication: Keep moving parts well-lubricated to reduce friction and prevent wear. Follow the manufacturer’s guidelines for the appropriate lubricants to use.

- Sharpen Blades: Ensure cutting tools are sharp to achieve clean cuts. Dull blades can strain the engine and lead to uneven trimming.

- Check Fluid Levels: Regularly monitor oil and coolant levels, topping up as necessary to avoid overheating or mechanical failure.

- Battery Maintenance: For battery-operated systems, ensure terminals are clean and connections are secure. Replace batteries as needed to maintain performance.

By following these maintenance tips, you can significantly improve the efficiency and durability of your machinery, ensuring it serves you well for years to come.

Replacing Worn or Damaged Parts

Ensuring optimal performance of your lawn maintenance equipment is essential for achieving a well-manicured yard. Over time, components may become worn or damaged, which can negatively impact functionality and efficiency. Regular inspection and timely replacement of these elements are crucial for maintaining the overall health of your equipment.

Identifying Worn Components

Recognizing when to replace specific elements can save you time and effort. Here are some common signs of wear:

- Unusual noises during operation

- Uneven cutting results

- Excessive vibrations

- Visible damage or cracks

Steps for Replacement

Once you have identified the components that require replacement, follow these steps:

- Gather the necessary tools and replacement components.

- Ensure the equipment is turned off and disconnected from any power source.

- Carefully remove the damaged components according to the manufacturer’s guidelines.

- Install the new components, ensuring a secure fit.

- Test the equipment to verify proper functionality before returning it to regular use.

By staying proactive about maintenance and replacements, you can extend the lifespan of your equipment and enhance its performance.

Tools Needed for Deck Repairs

When performing maintenance or repairs on the cutting mechanism of your equipment, having the right tools is essential for a smooth and efficient process. Proper tools not only facilitate quick fixes but also ensure that repairs are executed safely and effectively, minimizing the risk of future issues.

Essential Tools: The following tools are crucial for handling various tasks involved in the repair process:

- Wrenches: A set of adjustable and socket wrenches will help you loosen or tighten nuts and bolts securely.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and installing screws of different types.

- Socket Set: A comprehensive socket set allows you to work with various fasteners, providing versatility in your repair efforts.

- Pliers: Needle-nose and regular pliers are useful for gripping and manipulating components as needed.

- Jack Stands: These provide stability and safety when lifting the equipment for easier access to its underside.

Additional Supplies: In addition to tools, consider having some supplies on hand to facilitate repairs:

- Lubricants: Grease and oil are important for maintaining moving parts and preventing wear.

- Cleaning Agents: Keep the work area and components clean to ensure optimal performance.

- Replacement Fasteners: Having spare bolts and nuts can save time during the repair process.

Equipping yourself with the right tools and supplies will enhance your ability to carry out repairs effectively, ensuring your equipment remains in excellent working condition.

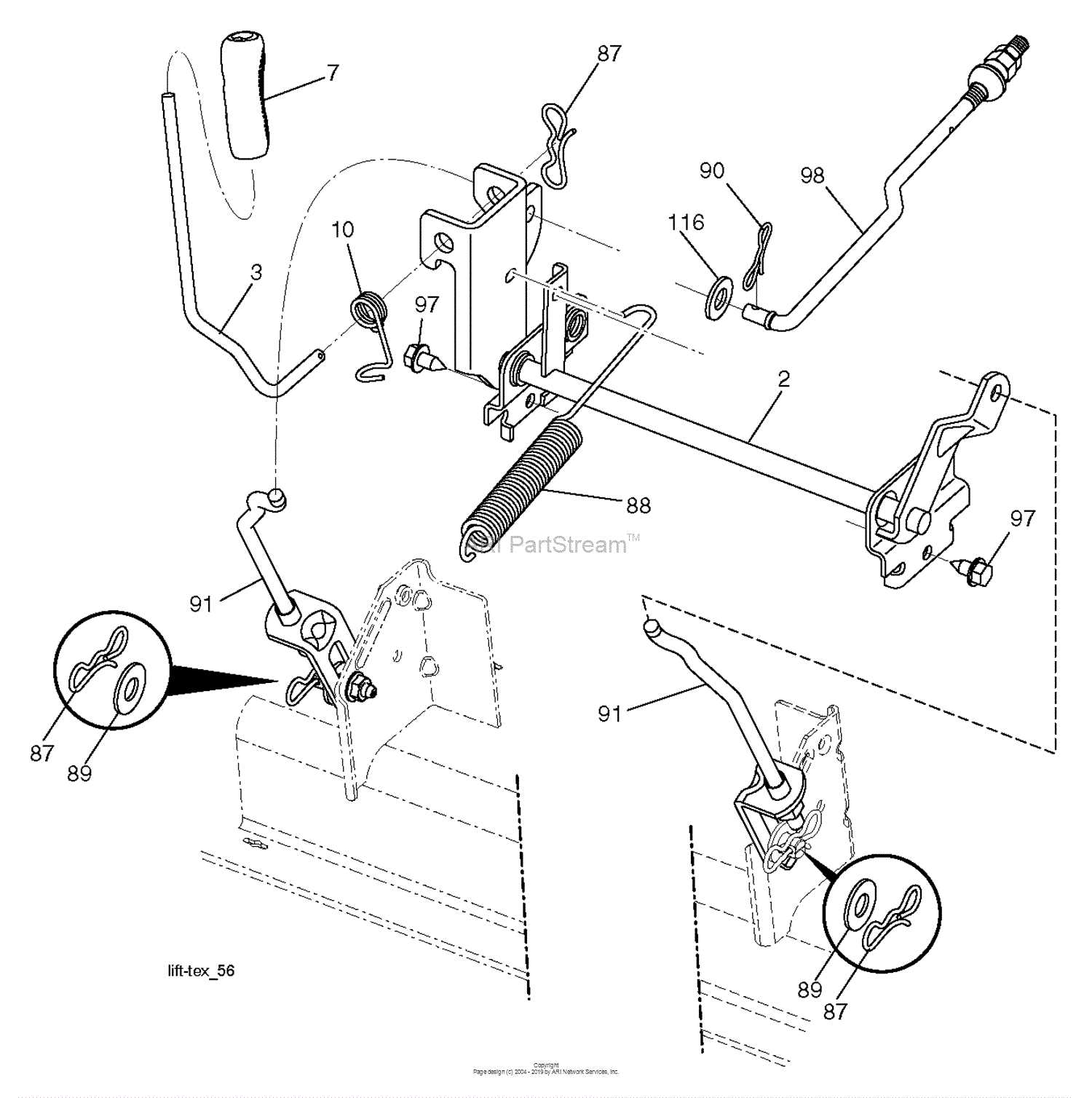

How to Properly Adjust the Deck

Ensuring that the cutting mechanism of your lawn equipment is correctly aligned is essential for achieving an even and professional-looking finish. Proper adjustment can enhance performance, improve cut quality, and extend the life of your machine. This guide will walk you through the steps needed to effectively calibrate your unit for optimal results.

First, park the machine on a level surface and engage the parking brake. Make sure the engine is off and cool to prevent any accidents. Check the current height settings using a ruler or gauge to assess if adjustments are necessary. The ideal height will vary based on the type of grass and specific conditions of your yard.

Next, locate the adjustment mechanisms. These are typically situated near the cutting assembly and may involve either a lever or a series of bolts. Loosen the fasteners slightly to allow for movement, but do not remove them completely. Adjust the height by raising or lowering the cutting assembly as needed.

After making the adjustments, tighten the fasteners securely to lock the settings in place. It is advisable to double-check the height again to ensure accuracy. Finally, take the machine for a test run to evaluate the performance and make further adjustments if necessary.

Regular maintenance and proper calibration will help you achieve the best results while prolonging the life of your lawn equipment. Following these steps will ensure a well-kept lawn that enhances the overall appearance of your outdoor space.

Safety Precautions During Maintenance

Ensuring safety while performing maintenance tasks is essential to prevent accidents and injuries. Proper preparation and awareness of the tools and equipment being used can significantly reduce risks. Adhering to safety protocols is crucial for both novice and experienced individuals, as even small oversights can lead to severe consequences.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is vital when working on machinery. This includes safety goggles to protect the eyes from debris, gloves to shield the hands from sharp edges, and sturdy footwear to prevent slips or injuries from falling objects. Additionally, consider using hearing protection if working near loud equipment.

Work Area Organization

Keeping the work area clean and organized is another key aspect of safety. Ensure that tools and equipment are stored properly and within reach to minimize the risk of tripping hazards. Clearing away any unnecessary materials will also help maintain focus on the task at hand and prevent distractions that could lead to accidents.

Where to Find Replacement Parts

Finding suitable components for your equipment can enhance its performance and longevity. Whether you are dealing with a minor repair or a major overhaul, knowing where to source these items is crucial. There are several reliable avenues to explore, ensuring you get the right replacements for your machine.

Authorized Dealers

One of the best options is to visit authorized dealers. These retailers specialize in original components and offer expert advice. They can help you identify the exact items you need based on your specific model. Furthermore, purchasing from these sources guarantees that you receive high-quality, reliable items that meet the manufacturer’s standards.

Online Marketplaces

Another convenient choice is to explore online marketplaces. Websites dedicated to equipment parts often feature extensive catalogs, allowing you to compare prices and availability. Many platforms provide user reviews, helping you gauge the quality of the items before making a purchase. Just ensure to verify the seller’s reputation to avoid potential issues with your orders.