The internal structure of heating equipment can often seem complex, with numerous elements working together to generate warmth for your home. Each individual component plays a crucial role in maintaining efficiency and ensuring reliable performance throughout the colder months. A deeper understanding of these interconnected elements can help in identifying issues, planning maintenance, and even making informed decisions when repairs are needed.

Key elements within heating systems are engineered to deliver heat consistently and effectively. From heat exchangers to safety controls, each part is designed with specific functionality in mind, ensuring both comfort and security. By familiarizing yourself with the layout and roles of these components, you can enhance the overall longevity and reliability of your heating solution.

In this section, we will explore the essential mechanisms of a typical home heating unit, offering insight into how these elements interact to provide warmth. Whether you’re troubleshooting a problem or simply curious about the inner workings of your system, a clear overview of the main components will give you valuable knowledge to approach any situation with confidence.

Understanding Key Components of Home Heating

Home heating systems are complex networks of various components that work together to efficiently warm a living space. Each element plays a crucial role in ensuring that heat is properly generated, distributed, and regulated within the household. Understanding these essential parts can help homeowners maintain their heating systems and ensure efficient performance, especially during colder months.

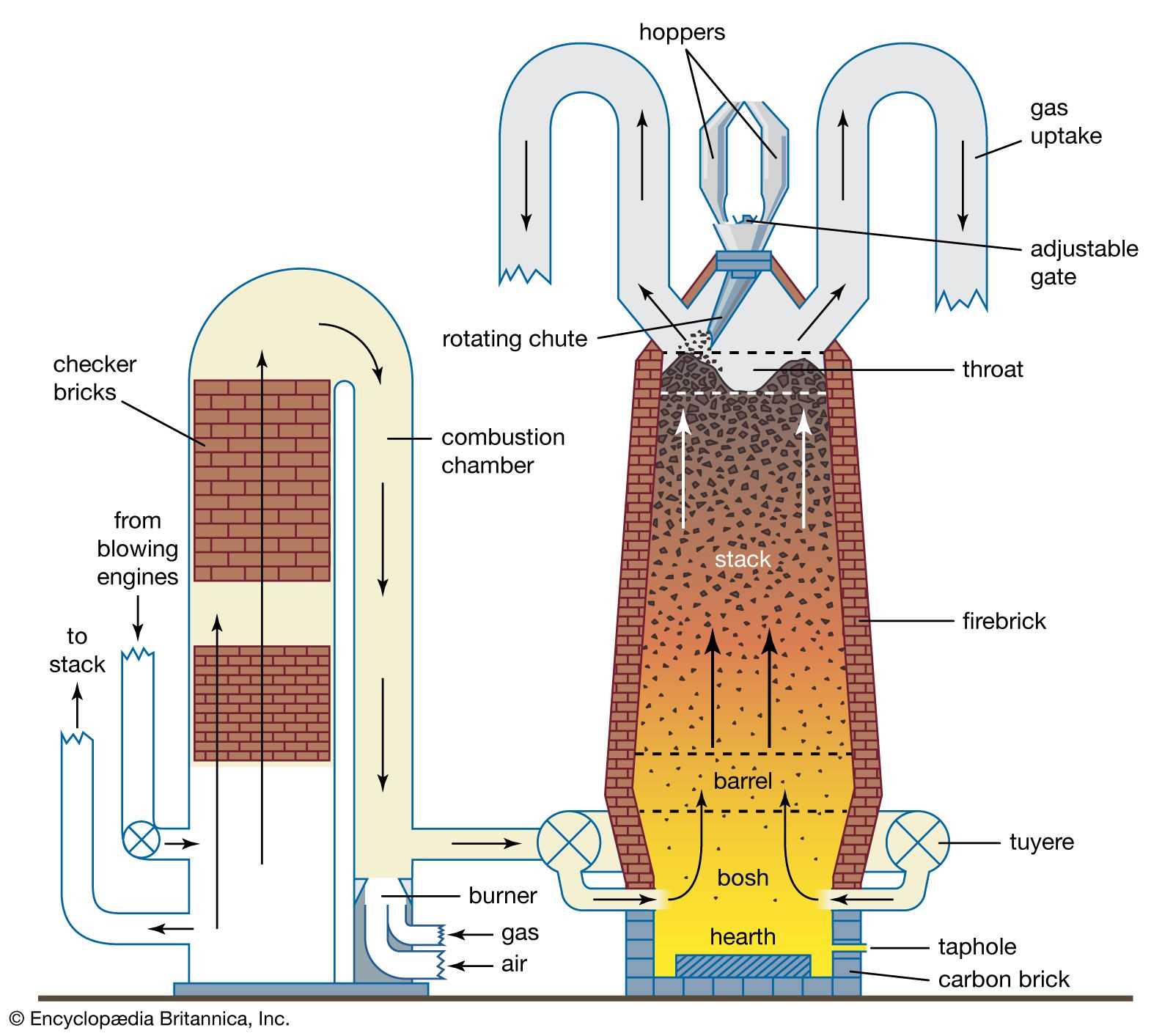

- Heat Exchanger: This is the core of the system where heat is transferred from burning fuel to the air, ensuring the warm air circulates through the home. It’s vital for both

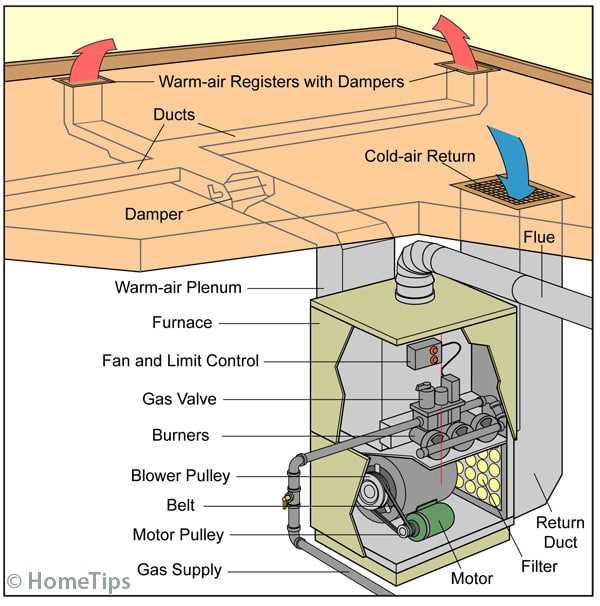

How Furnaces Function in Cold Seasons

In colder months, heating systems play a crucial role in maintaining a comfortable indoor environment. These systems are designed to ensure the efficient distribution of warmth throughout the home, addressing the increased demand for heat when temperatures drop.

The process begins with air intake and follows through a sequence of steps where the air is heated and circulated. As temperatures drop outside, the system’s sensors and controls adjust to provide the necessary warmth, ensuring an even and consistent indoor climate. Proper maintenance and timely checks are key to ensuring uninterrupted performance.

Internal Elements Vital for Efficient Heating

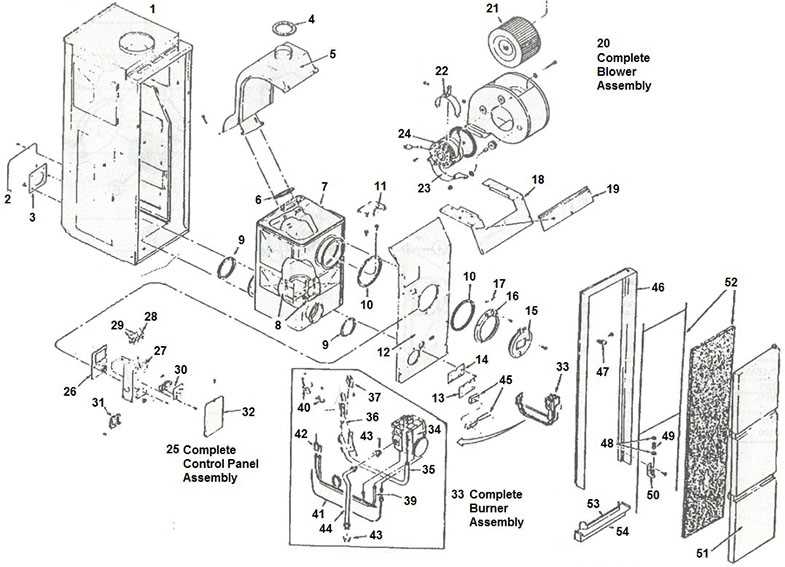

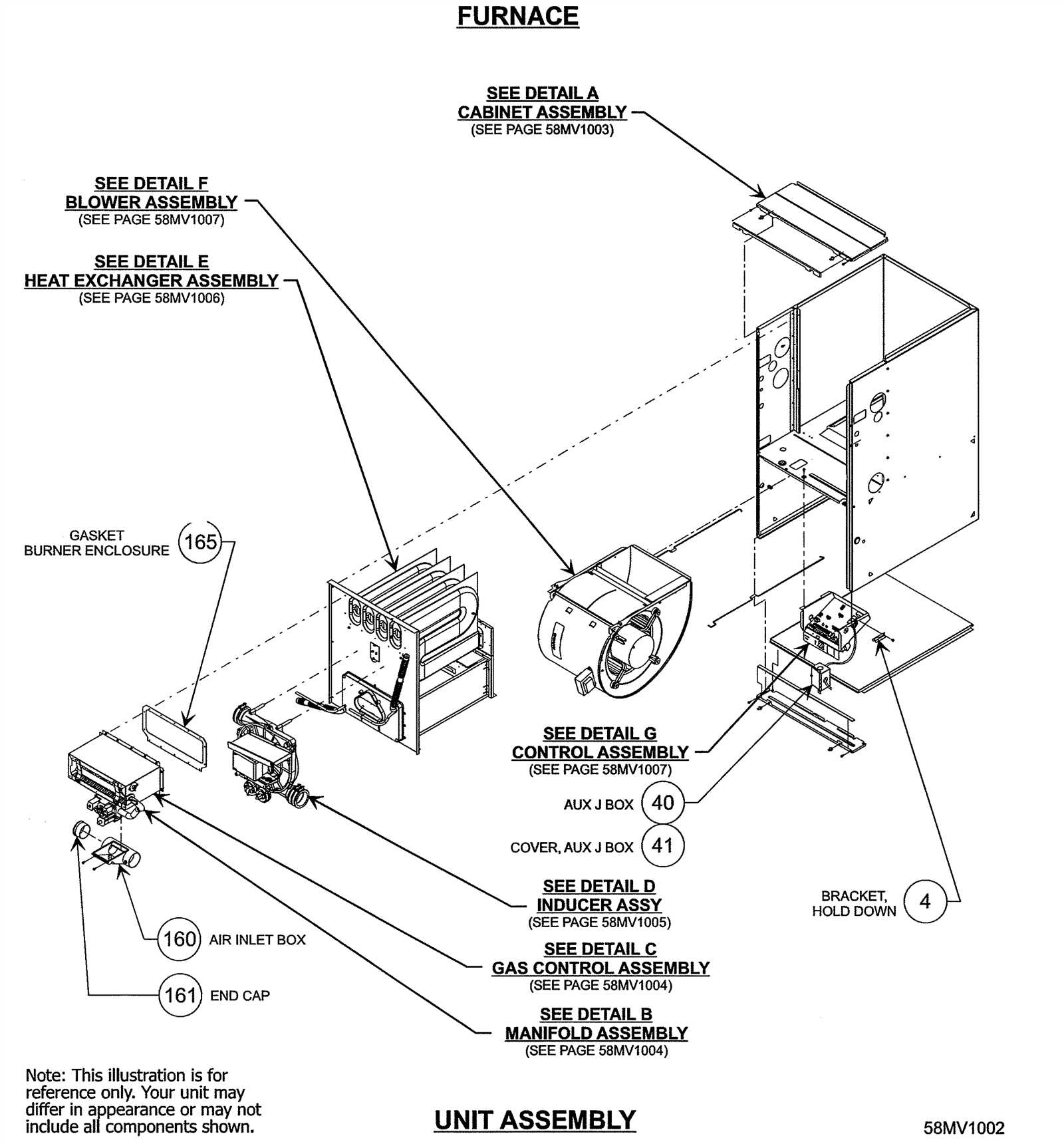

For a heating system to operate at peak performance, a variety of crucial internal components work in harmony. Each element plays a specific role in generating warmth and distributing it efficiently throughout the space, ensuring optimal comfort during cold seasons. Understanding these key elements helps in both maintaining and troubleshooting the system.

Key Components for Heat Generation

- Heat Exchanger: This critical component transfers warmth from the fuel to the air, ensuring that the heated air is safe for distribution.

- Blower Motor: Responsible for moving the warmed air through ducts and vents, the blower motor ensures consistent airflow.

- Burner Assembly: The burner is where the fuel is ignited to create the warmth needed for heat exchange.

Systems

Fan Systems for Air Circulation

Effective airflow is a key component in optimizing indoor temperature regulation. A well-designed air distribution setup ensures that heated or cooled air is circulated throughout the space efficiently. This continuous movement of air helps maintain consistent comfort levels, while also preventing energy waste and prolonging the lifespan of heating and cooling systems.

Blower Motor Functions

At the heart of air distribution is the blower motor. This essential element drives the airflow through the ductwork, ensuring that conditioned air reaches all rooms evenly. It works in tandem with the system’s other components to control the flow and pressure of air, providing a steady climate across the entire space. Regular maintenance of this component helps avoid airflow disruptions and ensures peak performance.

Heat Exchanger’s Role in Warm Air The heat exchanger is a critical element in delivering warm air throughout a heating system. Its primary function is to transfer warmth generated by combustion or another energy source to the air that circulates through the vents. This process ensures the home stays comfortable while maintaining efficient energy use.

As the heat exchanger warms up, it absorbs thermal energy, which is then passed on to the air circulating over its surface. This heated air is distributed through ducts to various rooms, providing a stable and consistent temperature. The exchanger also plays a key role in separating harmful gases from the airflow, ensuring safe operation of the heating system.

Thermostat Connections and Furnace Control

Understanding the interplay between the temperature-regulating device and heating mechanisms is essential for optimal climate management within residential or commercial spaces. The connections made by this device are crucial for ensuring efficient operation and accurate temperature readings.

In a typical configuration, the temperature-regulating device interfaces with various components to maintain the desired ambient conditions. Here are the primary connections involved:

- Power Supply: This connection provides the necessary electricity to the temperature-regulating device, allowing it to function correctly.

- Heating Element Activation: Through this connection, the device signals the heating element to activate when temperatures drop below the set point.

- Fan Control: This connection allows the device to control the operation of the circulating fan, ensuring even distribution of heated air.

- Safety Features: Connections related to safety mechanisms monitor for any irregularities, shutting down the system if necessary to prevent hazards.

Proper installation and maintenance of these connections are vital for the effective performance of the heating system. Regular checks can help identify potential issues early, ensuring a comfortable and safe environment.

Electrical Wiring and Furnace Safety

Ensuring safe and efficient operation of heating systems relies heavily on proper electrical connections and safety measures. Understanding the intricacies of electrical systems is essential for maintaining reliability and preventing potential hazards in heating equipment.

Correct Wiring Practices are vital for the optimal functioning of heating units. It is crucial to follow manufacturer specifications and local electrical codes when installing or repairing wiring. This adherence not only promotes efficiency but also reduces the risk of electrical fires or malfunctions.

Importance of Safety Precautions cannot be overstated. Regular inspections of electrical components, such as connections and insulation, are necessary to identify wear or damage. Implementing safety protocols, including the use of circuit breakers and grounding techniques, further safeguards against electrical faults.

In conclusion, a thorough understanding of electrical systems, combined with diligent safety practices, plays a pivotal role in ensuring the safe operation of heating devices. By prioritizing these elements, homeowners can protect their living spaces from electrical hazards while enhancing the performance of their heating solutions.

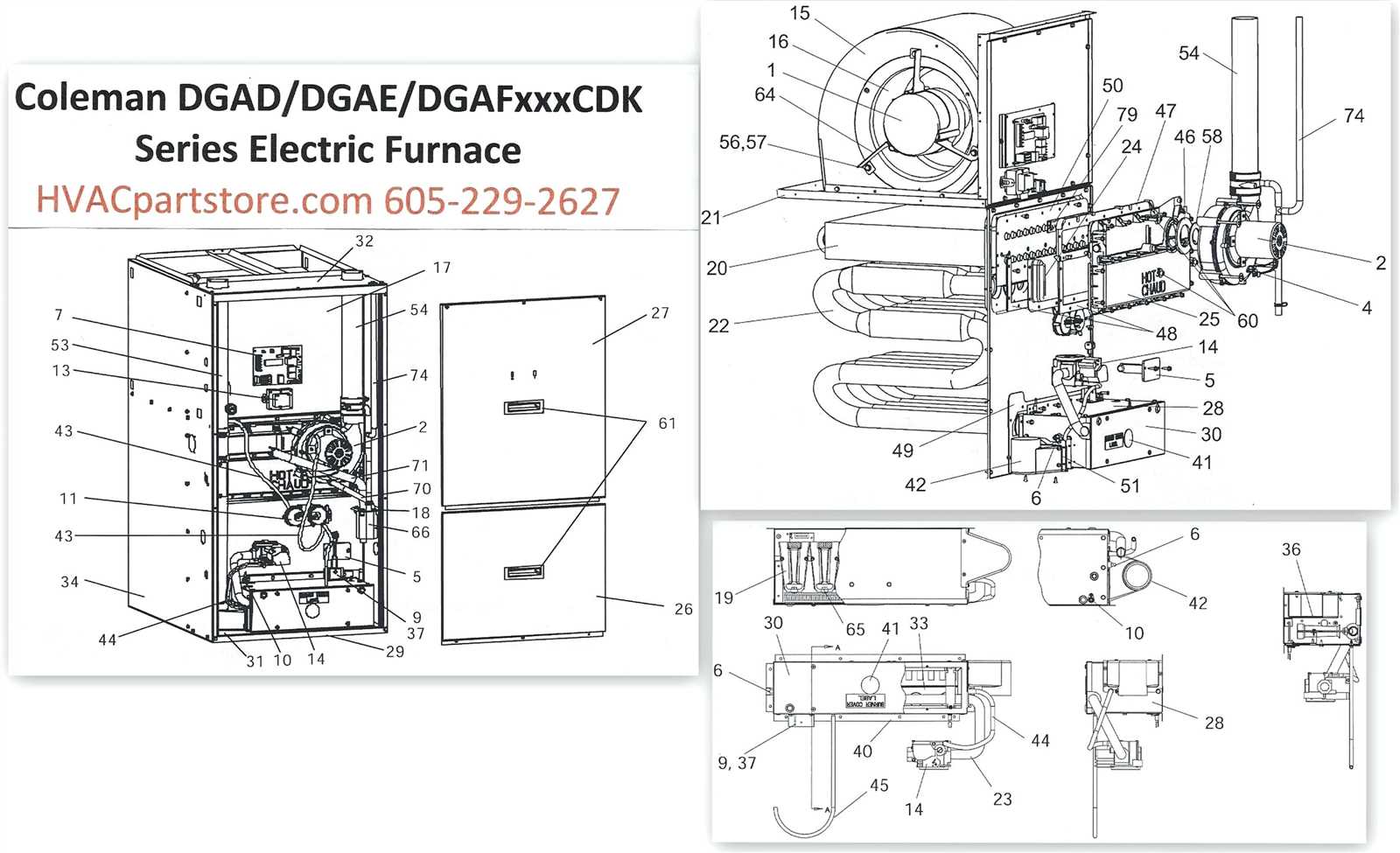

Blower Motors and Airflow Management

Efficient circulation of heated or cooled air is essential for maintaining a comfortable indoor environment. The mechanisms that drive this airflow play a critical role in ensuring that air reaches every corner of a space, contributing to overall climate control. Understanding the components involved in airflow dynamics, particularly the driving elements, is crucial for optimal performance and energy efficiency.

Importance of Blower Mechanisms

The driving components are responsible for propelling air through the distribution system, impacting how well the atmosphere is regulated. A well-functioning motor ensures a consistent flow, allowing for even temperature distribution and improved comfort levels. Furthermore, selecting the appropriate motor type is vital for energy savings and enhancing the system’s overall longevity.

Airflow Efficiency Strategies

To maximize airflow efficiency, regular maintenance and strategic system design are essential. This includes checking filters for blockages, ensuring proper duct sizing, and maintaining the cleanliness of the components. These practices not only improve airflow but also contribute to the longevity of the entire system, reducing the risk of premature failures.

Gas Valves and Burners for Heat Generation

The components responsible for converting fuel into thermal energy play a crucial role in ensuring efficient operation. These elements work in tandem to regulate the flow of gas and facilitate combustion, ultimately providing the heat necessary for various applications. Understanding their functionality is essential for maintaining optimal performance.

Gas valves serve as the control mechanisms that govern the supply of fuel to the combustion chamber. They ensure a steady flow while preventing leaks and ensuring safety. Burners, on the other hand, are designed to mix the gas with air and ignite it, allowing for a controlled and effective heating process.

Component Function Key Features Gas Valve Controls gas flow to the burner Safety shut-off, pressure regulation Burner Mixes gas with air for combustion Varied designs for efficiency, adjustable flame Ignition System Initiates combustion process Electrical or pilot ignition, reliable spark generation Ignition Systems and Furnace Startup

The ignition mechanism plays a crucial role in the effective initiation of heating systems. This process ensures that the burner ignites properly, allowing for the efficient transfer of heat throughout the space. Understanding how these systems function is vital for troubleshooting and maintaining optimal performance.

Types of Ignition Mechanisms

There are primarily two types of ignition systems commonly employed: standing pilot and electronic ignition. The standing pilot system utilizes a small flame to ignite the burner, providing a constant source of heat. In contrast, electronic ignition systems operate using a spark or hot surface igniter, which activates only when heat is required. This distinction affects both energy efficiency and operational reliability.

Startup Procedures

During the startup phase, various steps must be followed to ensure a safe and effective ignition process. Initially, the system checks for gas flow and verifies the safety mechanisms are functioning correctly. Once these parameters are met, the ignition system activates, lighting the burner and commencing the heating cycle. Regular maintenance is essential to ensure these components remain in optimal condition, preventing failures that could lead to safety hazards.

Filter Placement and Air Quality Impact

Effective positioning of air filtration elements is crucial for maintaining optimal indoor air quality. The location of these components can significantly influence the efficiency of airflow and the overall cleanliness of the environment. Properly installed filters trap pollutants and allergens, ensuring that the air circulated within a space remains fresh and healthy.

Impact on Airflow Efficiency

When filters are strategically placed, they facilitate smoother airflow, reducing strain on ventilation systems. This not only enhances performance but also prolongs the lifespan of associated equipment. Conversely, improper placement can lead to blockages, diminishing the efficiency of air circulation and resulting in potential health hazards.

Influence on Indoor Air Quality

Air quality is closely linked to the effectiveness of filtration systems. Filters positioned in optimal locations capture dust, pollen, and other airborne contaminants effectively. By minimizing the presence of these pollutants, the overall comfort and health of occupants are improved. Regular maintenance and timely replacement of these elements further contribute to a healthier living environment.

Maintenance Tips for Furnace Longevity

Ensuring the durability and efficient operation of heating systems involves regular care and attention. Implementing a few key practices can significantly extend the lifespan of your equipment while enhancing performance. Here are some essential maintenance strategies to consider.

Regular Inspections

Conducting routine assessments of the heating unit is crucial. Check for any visible signs of wear or damage, such as loose connections or leaks. Early detection of issues can prevent more severe problems and costly repairs down the line.

Clean Filters and Vents

Keeping filters and ventilation pathways clean is vital for optimal airflow. Dirty filters can restrict airflow, leading to decreased efficiency and increased energy consumption. Replace or clean filters regularly to maintain a steady and efficient operation.