In the realm of maintenance tools, certain machines stand out for their effectiveness in tackling tough cleaning tasks. These devices, often utilized for both residential and commercial purposes, require a thorough understanding of their individual elements to ensure optimal performance. Familiarity with the inner workings of such equipment is essential for users aiming to maintain and repair their devices efficiently.

Every model has its unique set of features, which can vary widely depending on the manufacturer and intended use. This makes it crucial to delve into the specific configuration and arrangement of components. A comprehensive examination of these elements not only aids in troubleshooting but also enhances the overall user experience.

By exploring the assembly of these machines, users can gain insights into how each piece contributes to functionality. Whether it involves replacing worn-out components or making adjustments for improved efficiency, understanding the layout serves as a foundation for successful operation. In the following sections, we will explore the various segments and their roles in maintaining the longevity of your cleaning device.

Understanding Husky Power Washer Basics

This section aims to explore the fundamental elements associated with a specific cleaning device designed for effective maintenance. By grasping the core components and their functions, users can enhance their familiarity and proficiency with the equipment.

Essential Features: Each model is equipped with various attributes that contribute to its efficiency, including motor specifications and water flow rates. Understanding these features helps in selecting the right model for different cleaning tasks.

Maintenance Tips: Regular upkeep is crucial for optimal performance. Simple practices, such as checking for wear and ensuring proper fluid levels, can prolong the lifespan of the device and enhance its reliability.

In summary, a thorough comprehension of these basic elements empowers users to utilize their equipment to its fullest potential, leading to effective and satisfying results.

Key Features of the 2000s Model

This section explores the notable characteristics that define the performance and reliability of this particular model from the early 2000s. Understanding these features can enhance user experience and facilitate maintenance.

Performance and Efficiency

The model is designed to deliver exceptional cleaning capabilities while optimizing energy usage. Its robust motor ensures consistent power, enabling users to tackle various tasks with ease.

Durability and Design

Constructed with high-quality materials, this version emphasizes longevity and resilience. The ergonomic design also enhances user comfort during operation, making it suitable for both casual and professional use.

| Feature | Description |

|---|---|

| Motor Power | High-efficiency motor for reliable performance. |

| Construction Material | Durable components that withstand wear and tear. |

| Ergonomics | Designed for comfortable handling and maneuverability. |

| Energy Efficiency | Optimized to reduce energy consumption during use. |

Common Problems with Power Washers

Every cleaning device can encounter issues over time, leading to inefficiencies or complete failures. Understanding these common challenges can help users maintain optimal performance and extend the lifespan of their equipment.

Loss of Pressure

A frequent complaint is the reduction in pressure, which can stem from several factors. Blockages in hoses or nozzles, leaks in connections, or worn-out seals may contribute to this problem. Regular maintenance and cleaning are essential to prevent these issues.

Engine Troubles

Another prevalent issue involves engine performance. Difficulty starting or irregular operation can be traced to fuel quality, clogged air filters, or faulty spark plugs. Identifying these factors early can save time and repair costs, ensuring smooth operation.

Importance of Maintenance and Care

Regular upkeep and attention are vital for ensuring optimal performance and longevity of any equipment. Neglecting these aspects can lead to diminished efficiency, costly repairs, and even complete failure. Proper maintenance not only enhances functionality but also promotes safety during use.

Benefits of Regular Maintenance

- Improved Efficiency: Well-maintained machinery operates more smoothly, requiring less energy and delivering better results.

- Extended Lifespan: Routine checks and servicing can significantly prolong the life of your equipment, delaying the need for replacement.

- Cost Savings: Investing time in maintenance reduces the likelihood of major repairs, leading to lower overall costs.

- Enhanced Safety: Regular inspections can identify potential hazards, reducing the risk of accidents during operation.

Essential Maintenance Practices

- Conduct routine inspections to identify wear and tear.

- Clean all components regularly to prevent buildup and corrosion.

- Replace worn parts promptly to maintain performance standards.

- Follow manufacturer guidelines for servicing intervals and procedures.

By committing to consistent maintenance, users can ensure their equipment remains in peak condition, ultimately enhancing productivity and reliability.

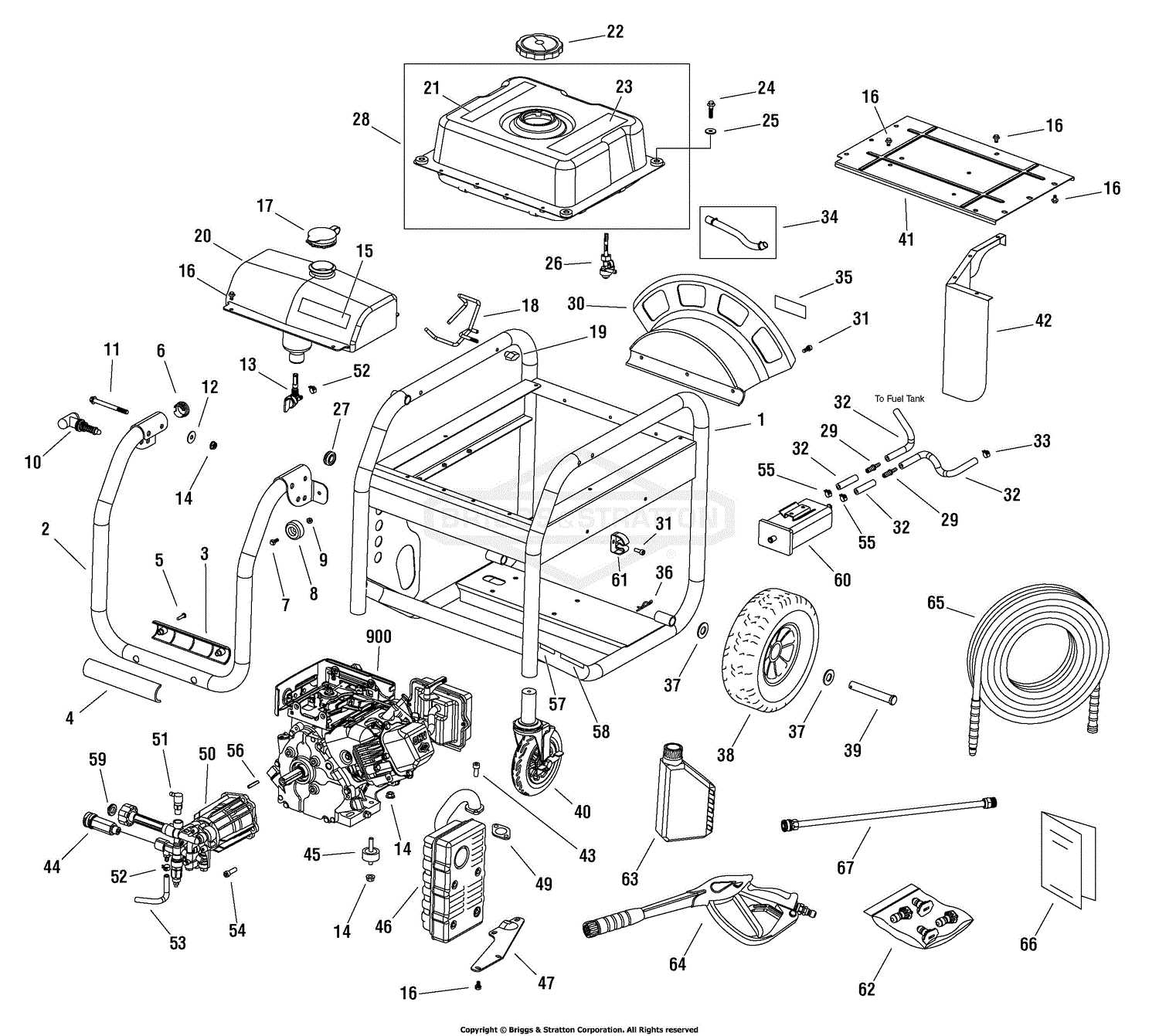

Parts Breakdown for Efficient Repair

Understanding the components of a cleaning device is essential for seamless maintenance and repair. By dissecting its structure, users can easily identify and address issues, ensuring optimal performance. This knowledge empowers owners to undertake repairs with confidence, minimizing downtime and enhancing longevity.

Essential Components Overview

Every cleaning unit consists of several critical elements that work in harmony. Recognizing these key sections allows for more targeted troubleshooting and effective repairs.

| Component | Description |

|---|---|

| Motor | Powers the device, driving all other functions. |

| Hose | Delivers the cleaning solution to the desired area. |

| Nozzle | Controls the spray pattern and intensity of the flow. |

| Pump | Maintains pressure and circulates the cleaning fluid. |

Troubleshooting Tips

Familiarity with the individual components can greatly simplify the repair process. Regular inspection of each element, along with prompt replacement of worn parts, can prevent more extensive issues and ensure the device remains in peak condition.

Tools Needed for Replacement Parts

When undertaking maintenance or repairs, having the right tools is essential for a smooth and efficient process. Proper equipment not only facilitates the task at hand but also ensures safety and precision in the execution of work. Below is a list of essential tools that will help in the successful replacement of components.

Essential Tools

- Screwdrivers: Both flat-head and Phillips varieties are necessary for removing and securing screws.

- Wrenches: Adjustable or socket wrenches will help in loosening and tightening nuts and bolts.

- Pliers: Needle-nose and regular pliers are useful for gripping and manipulating small parts.

- Safety Gear: Protective eyewear and gloves are crucial for personal safety during any maintenance work.

Additional Equipment

- Utility Knife: Handy for cutting materials or opening packaging.

- Flashlight: Provides visibility in low-light areas, ensuring thorough inspection and installation.

- Measuring Tape: Useful for ensuring accurate dimensions when fitting new components.

- Bucket or Container: For holding screws and small parts to prevent loss during the process.

Having these tools readily available can significantly streamline the replacement process, making it easier to complete the task effectively and efficiently.

Finding Genuine Husky Parts Online

When seeking reliable components for your equipment, it’s essential to ensure authenticity. This not only guarantees compatibility but also enhances performance and longevity. With the vast array of online resources available, locating legitimate items can be straightforward if approached with the right strategy.

Identifying Authorized Retailers

Start by searching for authorized vendors or official websites that specialize in these components. Such retailers often provide detailed information about the products they offer, including specifications and compatibility details. This reduces the risk of purchasing substandard or counterfeit items.

Utilizing Online Marketplaces Wisely

While popular online marketplaces can be convenient, it’s crucial to exercise caution. Look for sellers with positive reviews and high ratings. Always read customer feedback to gauge the quality of the items and the reliability of the seller. Additionally, consider asking questions to clarify any doubts about the products before making a purchase.

By following these steps, you can confidently source authentic components for your equipment, ensuring optimal functionality and performance.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to troubleshooting and restoring your cleaning device. By following a systematic process, you can effectively address common issues and ensure optimal performance.

Identifying the Problem

Begin by observing the symptoms your equipment exhibits. Is it failing to start, or are there unusual noises during operation? Carefully note these issues, as they will guide your subsequent steps.

Gathering Necessary Tools

Before diving into repairs, ensure you have all required tools at hand. Common items may include wrenches, screwdrivers, and replacement components. Being prepared will streamline the process and enhance efficiency.

How to Assemble Power Washer Parts

Assembling components for a cleaning machine involves understanding how each element interacts with others to create an efficient system. Proper assembly ensures optimal functionality and longevity, making it essential for anyone looking to maintain or enhance their equipment.

Gather Necessary Tools

Before starting the assembly, collect all required tools such as wrenches, screwdrivers, and pliers. Having everything at hand streamlines the process and minimizes interruptions.

Step-by-Step Assembly

Begin by laying out all the components clearly. Follow the manufacturer’s instructions closely, ensuring each piece fits securely and aligns correctly. Tighten connections without overdoing it to prevent damage. Double-check the assembly to confirm everything is in place before testing the machine.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent injuries and ensure a smooth process. Understanding and adhering to basic safety measures can significantly reduce risks while enhancing overall efficiency.

Essential Safety Gear

Always wear appropriate protective equipment, such as gloves, goggles, and sturdy footwear. This gear acts as a barrier against potential hazards, ensuring that you remain safe while working on machinery.

Proper Tool Handling

Ensure that all tools are in good condition and used according to their intended purpose. Misusing equipment can lead to accidents, so always follow the manufacturer’s guidelines and maintain a clean workspace to avoid tripping hazards.

Enhancing Performance with Upgrades

Improving efficiency and effectiveness in cleaning tasks can be achieved through various enhancements. By focusing on specific components, users can experience significant boosts in functionality and convenience. Here are several strategies to elevate performance:

- Upgraded Nozzles: Selecting high-quality nozzles can greatly affect the water flow and pressure, ensuring optimal cleaning results.

- Enhanced Motors: Investing in a more powerful motor can lead to increased performance and quicker task completion.

- Improved Hoses: High-pressure hoses that resist kinks and abrasion will allow for better maneuverability and longevity.

- Advanced Detergents: Utilizing specially formulated cleaning solutions can enhance the effectiveness of the equipment, making it easier to tackle tough stains.

- Regular Maintenance: Routine checks and servicing can prevent wear and tear, ensuring that all components function at their best.

Implementing these upgrades not only optimizes the device’s capabilities but also extends its lifespan, making it a worthwhile investment for any user. By focusing on the details, you can transform the cleaning experience into a more efficient and satisfying task.

FAQs About Husky Power Washer Parts

This section addresses common inquiries related to components and accessories associated with high-pressure cleaning machines. Understanding these elements can enhance maintenance and troubleshooting efforts, ensuring optimal performance.

Common Questions

- What should I do if I can’t find a specific component?

- How often should I replace the accessories?

- Are there universal parts that can be used with my model?

Maintenance Tips

- Regularly check seals and hoses for wear and tear.

- Clean filters to prevent blockages.

- Store components in a dry place to avoid corrosion.