In the world of outdoor power equipment, the efficiency and performance of a cutting tool heavily depend on its internal structure. A thorough comprehension of the various elements that constitute a particular model is crucial for effective maintenance and optimal functionality. Each component plays a significant role, contributing to the overall operation and durability of the machinery.

Exploring the intricacies of this specific cutting device can provide valuable insights into how each part interacts within the system. Understanding the placement and function of these individual elements allows users to make informed decisions regarding repairs and replacements. Such knowledge not only enhances the longevity of the equipment but also ensures safety during operation.

Moreover, familiarizing oneself with the arrangement of components facilitates smoother troubleshooting processes. By recognizing the essential roles that each part plays, operators can swiftly identify issues and address them efficiently. Thus, a detailed overview of the assembly will empower users to maintain their equipment effectively.

Key Components of the 201tc Model

This section explores the essential elements that contribute to the functionality and performance of a specific type of equipment. Understanding these crucial components can enhance user experience and ensure optimal operation.

The engine serves as the powerhouse, driving the entire mechanism and providing the necessary power for various tasks. The cutting head, designed for efficiency, is engineered to deliver precision and effectiveness during operation. Additionally, the fuel system plays a vital role, ensuring that the engine receives the appropriate mixture for combustion.

Moreover, the safety features incorporated into the design enhance user protection, minimizing risks associated with high-performance machinery. Each component is meticulously crafted to work in harmony, contributing to the overall efficiency and reliability of the equipment.

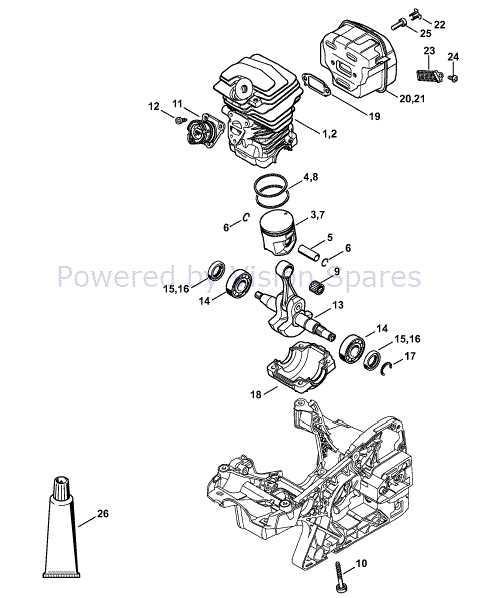

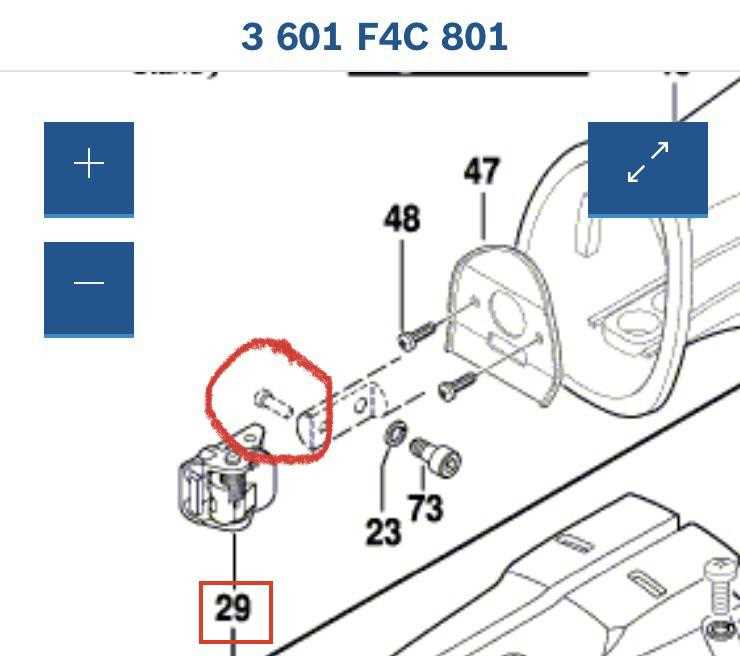

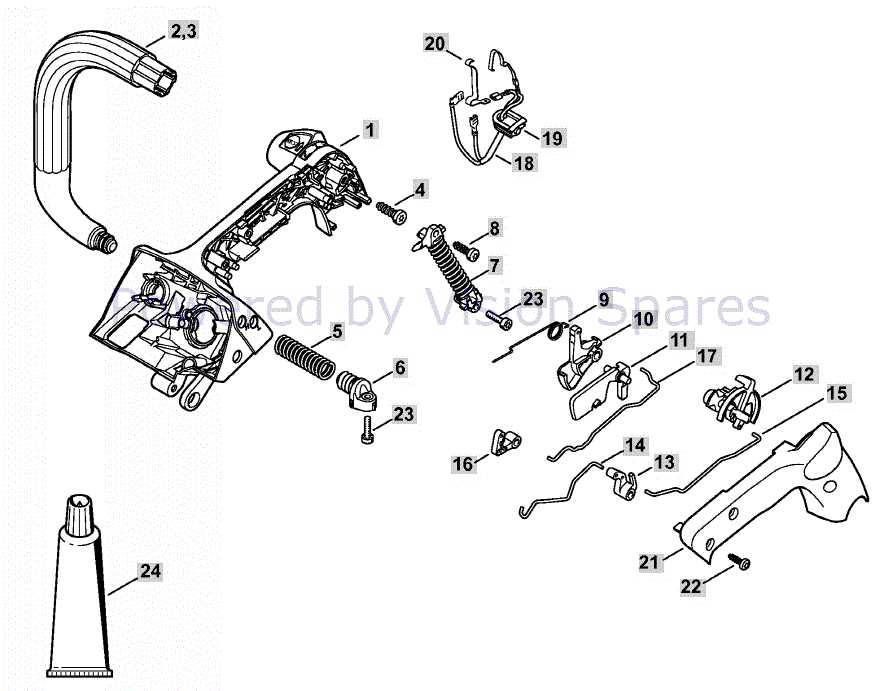

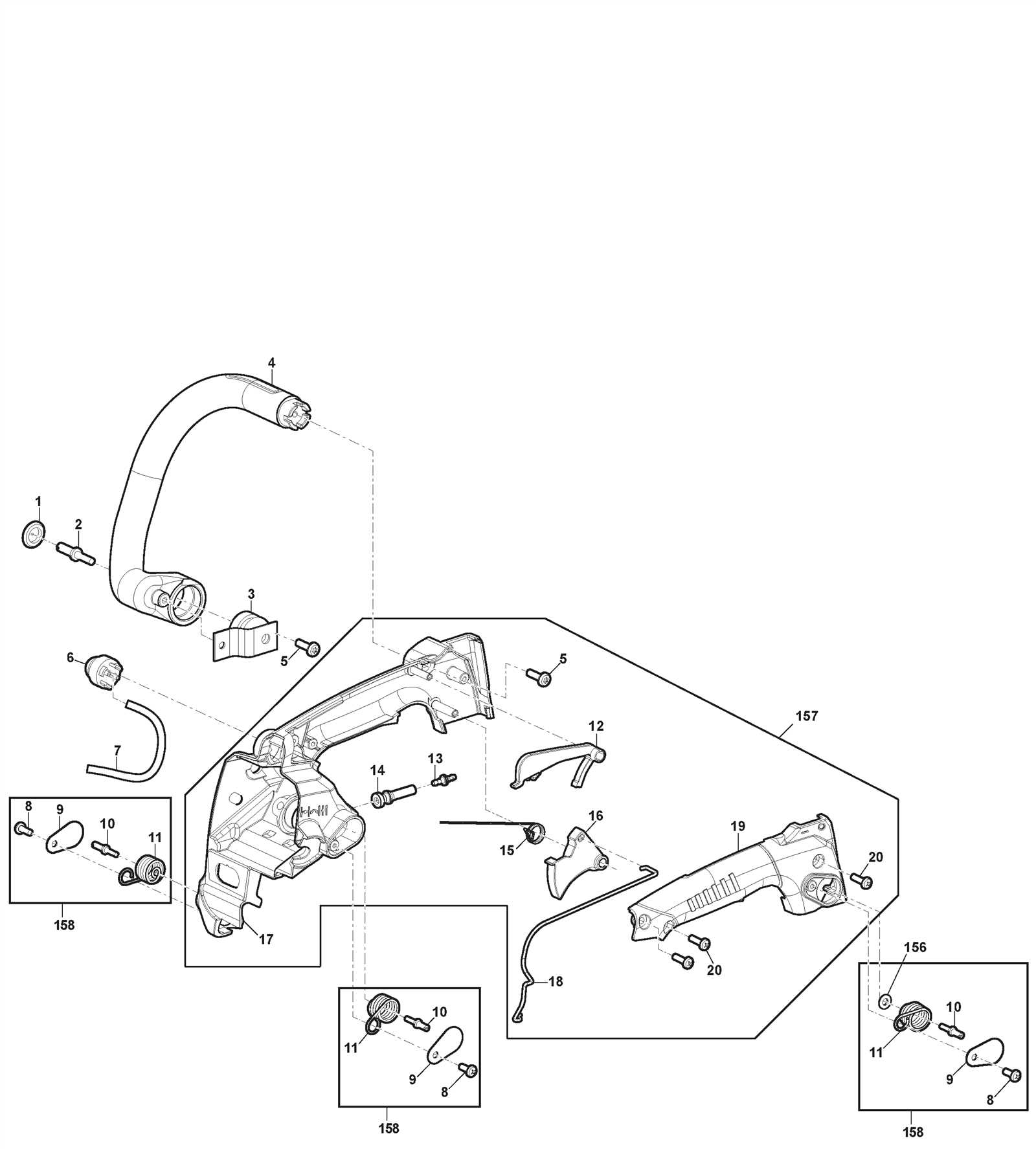

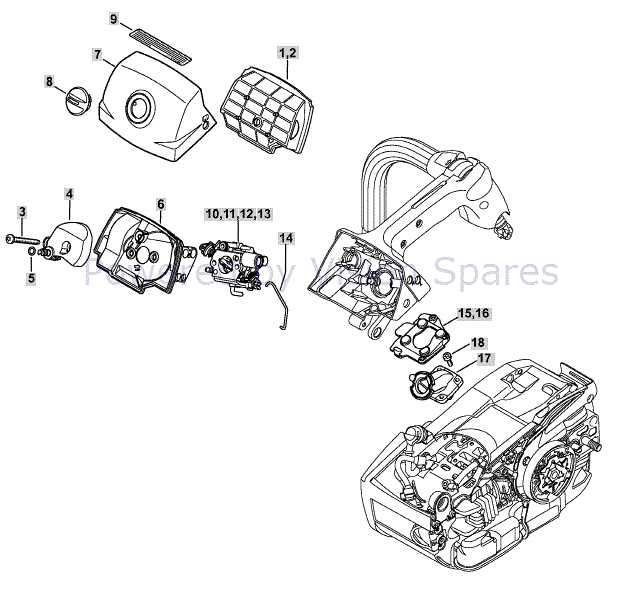

Understanding the Parts Diagram

Comprehending the assembly layout of a machine is essential for effective maintenance and repair. This visual representation illustrates the various components and their interconnections, providing valuable insights into the functionality and structure of the equipment. By analyzing this layout, users can identify specific elements, facilitating troubleshooting and enhancing the overall understanding of the device’s operation.

Importance of Familiarity with Component Layout

Being well-acquainted with the component arrangement aids in recognizing parts that may require attention or replacement. Knowledge of each element’s location and role contributes to more efficient servicing, reducing the likelihood of errors during repairs. This awareness ensures that users can confidently address issues as they arise.

Utilizing the Layout for Maintenance

Employing this visual reference during routine inspections enables users to systematically assess the condition of individual components. Regular checks can help prevent potential failures by addressing wear and tear early. Ultimately, understanding the assembly layout empowers users to maintain their equipment in optimal working condition.

Identifying Common Replacement Parts

Understanding the essential components of your equipment is crucial for effective maintenance and longevity. Various elements may wear out over time and require replacement to ensure optimal performance. Familiarity with these commonly used elements can help streamline repairs and improve functionality.

Key Components to Consider

When examining your tool, several crucial parts are typically subject to wear. Recognizing these components can aid in timely replacements and prevent potential issues during operation. Regular inspection and replacement of these items can enhance the efficiency of your equipment.

| Component | Description | Signs of Wear |

|---|---|---|

| Chain | The cutting element that performs the actual sawing. | Stretched or damaged links. |

| Bar | The metal rod that guides the chain. | Wear on the edges or bending. |

| Sprocket | The gear that drives the chain. | Worn teeth or slipping. |

| Filter | Prevents debris from entering the engine. | Clogging or reduced airflow. |

| Fuel Line | Transports fuel to the engine. | Cracking or leaks. |

Maintenance Tips

Regular maintenance and timely replacements of these key elements can significantly prolong the life of your tool. Always refer to your manufacturer’s recommendations for specific guidelines on care and replacement intervals to ensure optimal performance.

Importance of Genuine Stihl Parts

Using authentic components for your machinery is crucial for optimal performance and longevity. High-quality replacements ensure that the equipment operates efficiently, reducing the risk of malfunctions and costly repairs. Moreover, original items are designed to fit perfectly, promoting seamless functionality and safety during use.

Benefits of Authentic Components

- Quality Assurance: Genuine items are manufactured to meet strict quality standards, ensuring durability and reliability.

- Performance Optimization: Authentic components are engineered specifically for your model, providing enhanced efficiency and effectiveness.

- Safety Features: Original parts include essential safety mechanisms that may be absent in counterfeit alternatives.

Risks of Using Imitation Components

- Increased likelihood of breakdowns due to inferior materials.

- Potential damage to the machinery, leading to expensive repairs.

- Loss of warranty coverage when non-genuine components are utilized.

How to Use the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair tasks. Such illustrations serve as invaluable tools that simplify the identification and organization of various elements within machinery.

Identifying Key Components

To begin, focus on locating the main sections of the illustration. Each segment typically corresponds to a specific area of the equipment. Familiarizing yourself with these divisions will enhance your ability to navigate the representation efficiently.

- Examine the labels for clarity.

- Note any color codes or symbols that indicate different functions.

- Pay attention to the arrangement, as it often reflects assembly order.

Utilizing the Visual for Repairs

Once you have grasped the layout, you can effectively use the representation during repair processes. It is advisable to cross-reference the illustration with your repair manual for precise instructions.

- Gather necessary tools based on the identified components.

- Follow the sequence depicted for disassembly or reassembly.

- Ensure each piece is replaced or adjusted correctly according to the visual cues.

Maintenance Tips for 201tc Components

Regular upkeep of equipment is essential to ensure optimal performance and longevity. Proper care of various elements contributes to overall efficiency and reliability, minimizing the risk of unexpected failures. Adopting systematic maintenance practices can enhance functionality and prolong the lifespan of these vital components.

Here are some essential maintenance tips to consider:

| Component | Maintenance Tip |

|---|---|

| Air Filter | Clean or replace regularly to prevent dust and debris buildup, ensuring proper airflow. |

| Spark Plug | Check for wear and replace if necessary; a clean spark plug promotes efficient combustion. |

| Fuel System | Use fresh fuel and clean the fuel filter periodically to avoid clogging and ensure optimal fuel flow. |

| Chain | Regularly lubricate and inspect for damage; replace if excessively worn to maintain cutting performance. |

| Bar | Clean the guide bar and check for burrs; proper maintenance helps in achieving uniform cuts. |

Implementing these practices can significantly enhance the reliability of your equipment, reducing downtime and maintenance costs.

Where to Purchase Parts Online

Finding high-quality components for your machinery can be challenging, especially when you need reliable sources for online shopping. Fortunately, numerous websites offer a wide variety of options, ensuring you can locate the exact items you need to keep your equipment running smoothly. These platforms cater to different preferences, from OEM to aftermarket selections.

Reputable Retailers

When searching for components, it is essential to choose trustworthy online retailers. Websites such as Amazon and eBay provide extensive inventories and customer reviews, helping you make informed decisions. Additionally, specialized retailers often focus on specific machinery and offer competitive prices, ensuring you receive genuine products.

Manufacturer Websites

Another excellent option is to visit the official websites of manufacturers. Many offer online ordering systems and comprehensive catalogs of their available products. This approach ensures you receive authentic components and access to expert support, making it a valuable resource for maintaining your equipment effectively.

Common Issues and Solutions

In any machinery, operational difficulties may arise, impacting performance and efficiency. Identifying common challenges and their corresponding remedies is essential for maintaining optimal functionality and longevity. This section outlines prevalent problems encountered in similar devices and suggests effective solutions to address them.

Frequent Problems

- Engine Failure to Start

- Inconsistent Power Output

- Excessive Vibration

- Fuel Leaks

Possible Solutions

- Engine Failure to Start: Check the fuel levels and ensure that the spark plug is in good condition. If necessary, replace the spark plug and clean the fuel system.

- Inconsistent Power Output: Inspect the air filter and clean or replace it if it’s dirty. Additionally, verify that the fuel mixture is appropriate for optimal combustion.

- Excessive Vibration: Examine the mounting bolts and ensure they are tight. Consider checking the blade for damage or imbalance.

- Fuel Leaks: Inspect the fuel lines for cracks or damage and replace any faulty components to prevent leaks.

Comparison with Other Stihl Models

This section aims to explore the distinctions and similarities between various models in the same category. By analyzing different specifications, features, and functionalities, we can better understand how they cater to the needs of users with diverse requirements.

When assessing the range of devices available, it becomes clear that some versions offer enhanced power and efficiency, while others prioritize lightweight design and ease of handling. Each model serves specific applications, whether for professional landscaping or occasional use in home gardens.

Another point of comparison lies in the availability of replacement components and accessories. Some models may have a broader selection of compatible parts, making maintenance and upgrades more convenient for users.

In terms of pricing, there are notable variations across the models, reflecting their respective capabilities and intended use cases. This aspect is crucial for consumers looking to balance budget constraints with performance expectations.

Resources for Troubleshooting

When facing issues with outdoor equipment, it is essential to have access to reliable resources that can guide you through the troubleshooting process. Proper information can significantly reduce downtime and enhance the performance of your tools.

Online Guides and Manuals

Utilizing online resources can provide valuable insights into resolving common problems. Here are some helpful options:

- Official manufacturer websites often have downloadable manuals and troubleshooting tips.

- Forums and user communities can offer personal experiences and solutions for specific issues.

- Video tutorials on platforms like YouTube can visually demonstrate repair processes.

Local Repair Shops

Consulting with local experts can also be beneficial. Consider the following:

- Visit repair shops that specialize in outdoor equipment for professional advice and service.

- Ask for recommendations from friends or family who have dealt with similar issues.

- Participate in local workshops or classes to gain hands-on experience and knowledge.

Expert Advice on Parts Selection

Choosing the right components for any mechanical tool requires careful consideration of various factors. It’s essential to understand how different elements work together to ensure optimal performance and longevity. Selecting the right items can make a significant difference in functionality and maintenance.

Key Factors to Consider

Before making a choice, it’s important to evaluate the specific needs of your equipment. Compatibility with the overall system is crucial, as even minor mismatches can lead to inefficiencies or potential damage. Additionally, consider the quality and durability of the materials, as this directly impacts the reliability and lifespan of the equipment.

Ensuring Longevity

For long-term use, opt for c