Understanding the structure of essential cutting machine components is crucial for efficient use and maintenance. A detailed layout provides clarity on the placement and connection of individual elements, ensuring smooth operation and prolonged equipment lifespan.

When delving into the mechanics of these systems, the arrangement of key parts plays a vital role in optimizing performance. Properly identifying and organizing these elements can prevent common operational issues and simplify troubleshooting.

Component layouts also aid in identifying wear and tear, facilitating timely replacements. This knowledge enhances both safety and productivity, contributing to better management of the machinery.

Overview of Hypertherm Powermax 30 Components

The equipment is composed of various essential elements that work together to ensure efficient cutting performance. Each component plays a vital role in ensuring smooth operation and reliability over time.

- Power source: Provides the necessary energy to generate a plasma arc, essential for cutting through different materials.

- Torch: This is the primary tool used for cutting, guiding the plasma arc precisely to the material.

- Consumables: These replaceable parts, including electrodes and nozzles, wear out with use and need regular replacement to maintain cutting quality.

- Cables and connectors: Responsible for safely transmitting power and signals between components, ensuring proper communication and energy flow.

- Cooling system: Helps in maintaining the temperature of the machine, preventing overheating and ensuring longer operation times.

Key Features of Powermax 30 Parts

The components of this cutting system are designed to deliver reliable and efficient performance, ensuring precision and durability during operation. Each element plays a crucial role in maintaining the functionality of the device, contributing to its overall efficiency.

Durability and Longevity: The materials used in these components are engineered to withstand high levels of stress and heat, making them suitable for long-term use even in demanding environments.

Efficiency and Precision: Advanced technology integrated into these parts ensures precise cuts with minimal waste, enhancing the overall productivity of the system.

Ease of Maintenance: Regular upkeep of the system is simplified due to the design of the individual elements, which allows for easy replacement and maintenance.

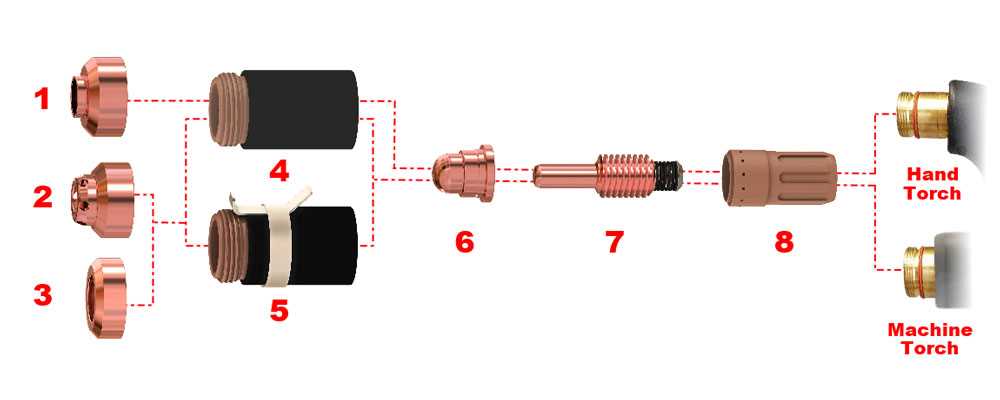

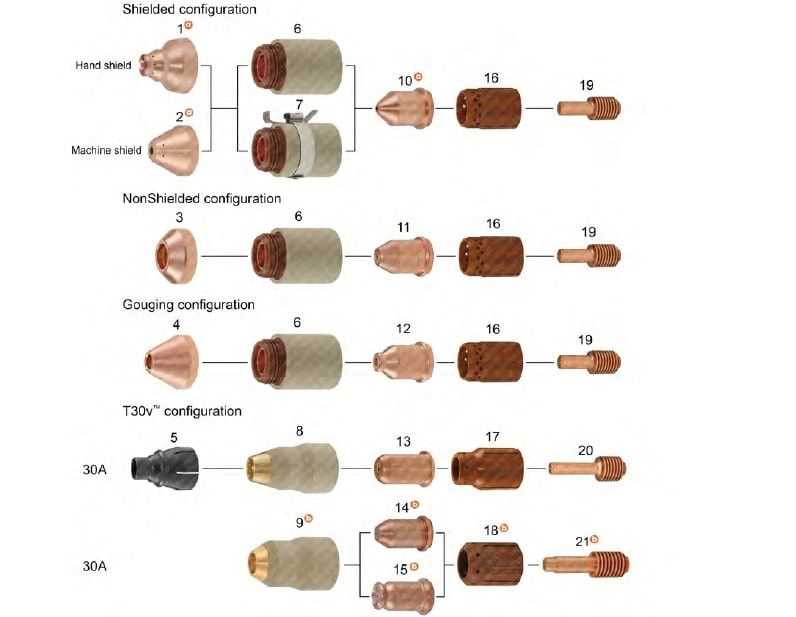

Understanding the Powermax 30 Torch Assembly

The torch assembly plays a crucial role in ensuring efficient and precise cutting. It consists of various components that work together to direct the flow of plasma and control the cutting process. Proper alignment and maintenance of these elements are essential for optimal performance.

Electrode: The electrode is responsible for conducting the electric current necessary to form the plasma arc. It is one of the key parts that need regular replacement to maintain cutting efficiency.

Nozzle: Positioned near the electrode, the nozzle focuses the plasma stream onto the material. Any damage or wear to the nozzle can impact cutting precision, so it’s important to monitor its condition frequently.

Shield: The shield serves as a protective layer for both the operator and the torch. It prevents excess material from interfering with the plasma arc and safeguards other torch components.

Swirl Ring: This part helps to control the flow of gas, which in turn stabilizes the plasma arc. It ensures the gas is evenly distributed, leading to cleaner cuts

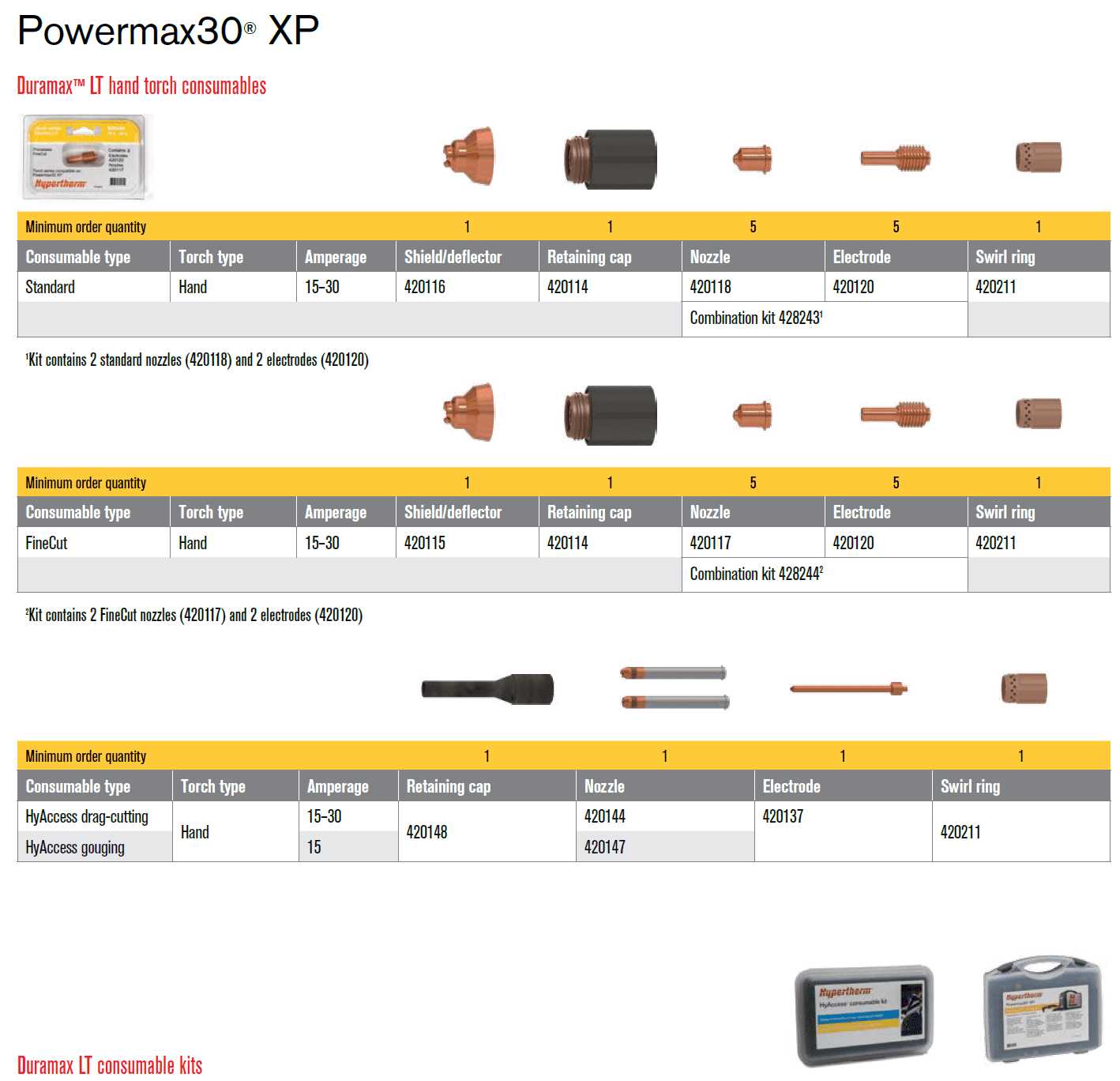

Guide to Powermax 30 Consumables

Consumables play a crucial role in maintaining the efficiency and lifespan of plasma cutting equipment. These components are essential for ensuring precise cuts, minimizing wear, and reducing operational costs. Understanding the different types of consumables and their specific functions can help improve the overall performance of your cutting system.

Main Types of Consumables

There are several key components to consider when discussing consumables. These include the nozzle, which directs the plasma arc, and the electrode, responsible for conducting electricity. Each part is critical for the smooth functioning of the machine, ensuring clean cuts and extending the life of the equipment.

Maintenance and Replacement

Regularly inspecting and replacing worn consumables is vital for keeping your equipment in top condition. Factors like

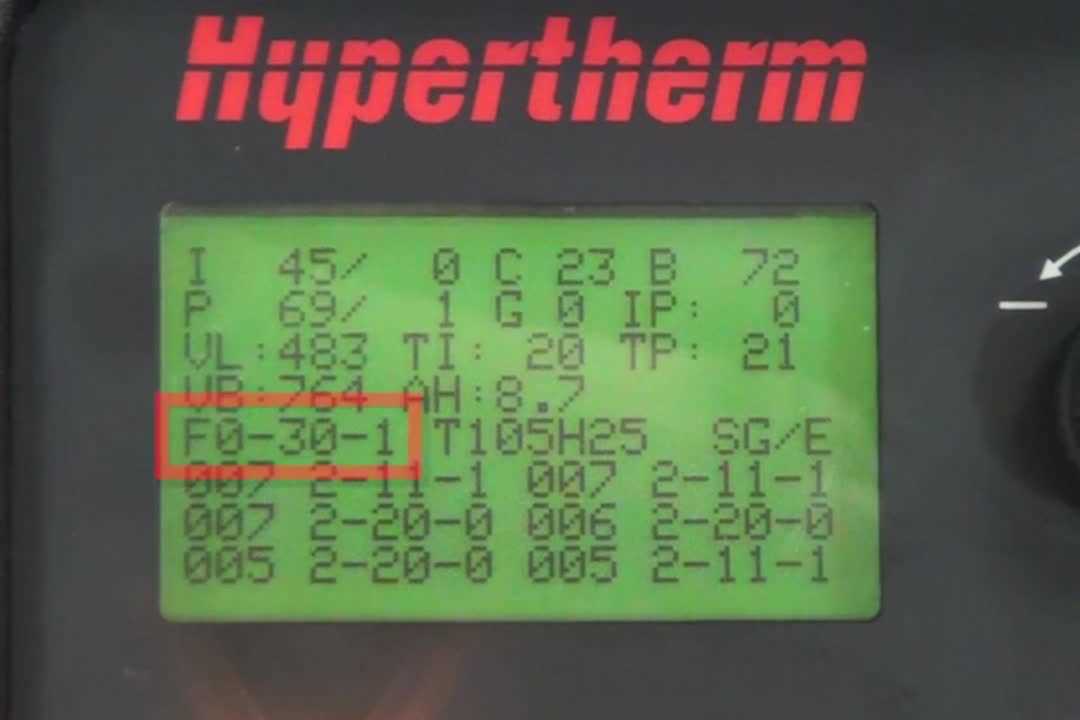

Internal Structure of Powermax 30 Machine

The internal components of this cutting device are designed to optimize performance and durability. Each element plays a specific role in ensuring efficient operation and safety. The arrangement of these components is essential for maintaining functionality and precision during use.

| Component | Function | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control Board | Manages all operational settings and adjustments. | ||||||||||||||||||||||

| Cooling System | Prevents overheating by maintaining optimal internal temperatures. | ||||||||||||||||||||||

| Electrode and Nozzle | Facilitates the cutting process by directing the electrical arc. | ||||||||||||||||||||||

| Air Filtration Unit | Ensures clean air is used during cutting, preventing contamination. | ||||||||||||||||||||||

| Component Type | Compatible Models | Notes |

|---|---|---|

| Electrode | Model A, Model B | Ensure correct fit for optimal cutting performance. |

| Nozzle | Model A, Model C | Different sizes available for various applications. |

| Retaining Cap | Model B, Model C | Check specifications for proper alignment. |

Maintenance Considerations

Regular maintenance of the components is essential to ensure compatibility and extend the lifespan of the cutting equipment. Users should always refer to the manufacturer’s guidelines for recommended practices and component specifications.

Replacing Worn-Out Powermax 30 Parts

When it comes to maintaining cutting equipment, addressing deteriorated components is essential for optimal performance and longevity. Timely replacement of these elements can significantly enhance functionality, ensuring precise operation and reducing downtime during tasks. Understanding which components may require attention is key to achieving efficient repairs and maintaining productivity.

Identifying Worn Components

Regular inspections play a vital role in identifying components that may have worn out. Common indicators include decreased efficiency, unusual noises, or inconsistent performance. It’s important to develop a routine to evaluate the condition of critical elements, as early detection can prevent further complications and costly repairs.

Replacement Process

Once you have identified the components that need to be replaced, follow a systematic approach for the replacement process. Ensure you have the correct replacement items on hand and adhere to safety protocols throughout the procedure.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Electrode | Reduced cutting speed | Use compatible electrodes for best results. |

| Nozzle | Inconsistent arc stability | Choose a nozzle designed for your specific model. |

| Shield | Visible damage or cracks | Ensure proper fit to prevent damage to internal components. |

Safety Features of Powermax 30 Components

The components of advanced cutting systems are designed with various safety mechanisms to ensure user protection and enhance operational reliability. Understanding these safety features is crucial for both effective use and maintenance.

Key safety features include:

- Thermal Overload Protection: This mechanism prevents overheating by automatically shutting down the unit when temperatures exceed safe levels.

- Pressure Relief Valves: These components help manage internal pressure, reducing the risk of bursts or leaks during operation.

- Safety Interlocks: Designed to prevent accidental activation, interlocks ensure that the system operates only when all conditions are met.

- Insulated Handles: These reduce the risk of electric shock, providing a safer grip while operating the equipment.

- Emergency Shutoff Switch: Easily accessible, this feature allows for quick termination of power in emergencies.

Incorporating these safety elements into the design of cutting systems not only enhances user security but also promotes efficient operation. Regular inspections and adherence to safety protocols are essential to maintain these protective features.

Troubleshooting Common Powermax 30 Issues

When working with cutting equipment, encountering problems is not uncommon. Understanding typical issues and their solutions can enhance efficiency and prolong the lifespan of your device. Here are some frequent challenges faced by users and ways to address them effectively.

Common Problems and Solutions

- No Arc or Poor Arc Quality:

- Check the connection of the torch and ensure it is secure.

- Inspect the electrodes and nozzles for wear or damage; replace if necessary.

- Verify the power supply settings and ensure they are configured correctly.

- Excessive Slag:

- Adjust the cutting speed; too slow can cause slag buildup.

- Ensure the correct type of consumables is being used for the material.

- Check for proper voltage settings as incorrect settings can affect performance.

- Inconsistent Cutting Performance:

- Inspect the workpiece for uneven surfaces, which can affect cuts.

- Ensure that the cutting path is free of obstructions.

- Regularly maintain and clean the machine to ensure optimal performance.

When to Seek Professional Help

If issues persist after troubleshooting, it may be necessary to consult a technician. Persistent problems can indicate underlying faults that require professional assessment and repair. Maintaining regular service checks can help prevent major breakdowns and extend the longevity of your cutting system.