The intricate design of modern vehicles involves numerous essential elements that work together to ensure optimal performance. Grasping the arrangement and functionality of these components can significantly enhance your driving experience and maintenance routine. Each section contributes to the overall efficiency and safety of your machine.

In this exploration, we aim to provide insights into the various units that constitute your vehicle’s system. By delving into the specifics, you will gain a clearer perspective on how these elements interact and their role in everyday operation. Understanding these connections is ultimately beneficial for both enthusiasts and casual users alike.

As you embark on this journey through the mechanical landscape, you’ll uncover the significance of each section. Equipped with this knowledge, you will be better prepared to address any concerns and ensure your vehicle runs smoothly for years to come.

Understanding the 03 Avalanche AC System

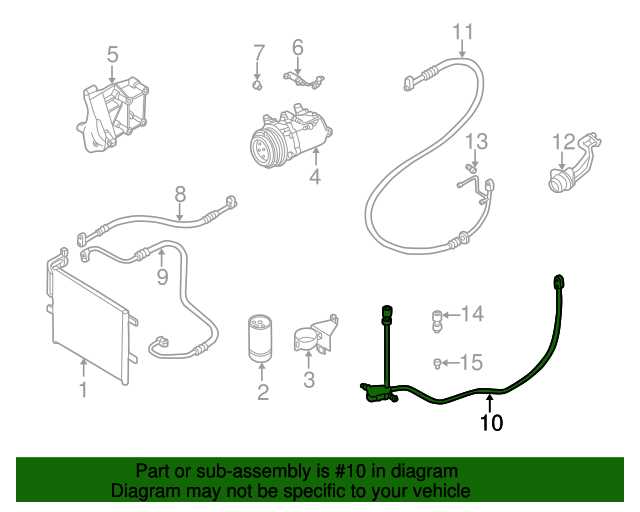

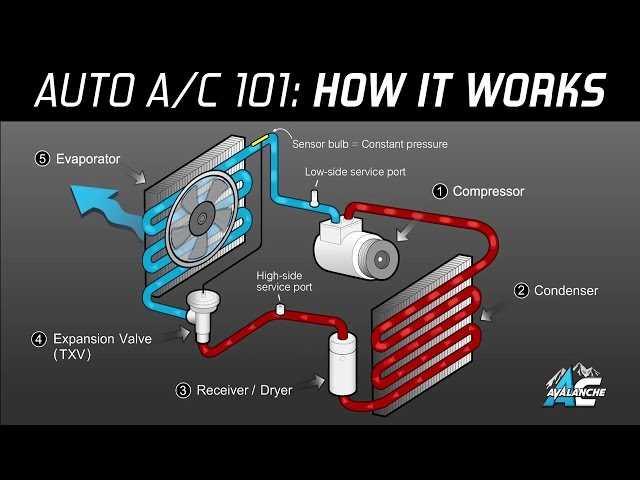

The air conditioning mechanism in the 2003 model is an intricate network designed to regulate temperature and enhance comfort within the cabin. Comprising several components, each plays a vital role in ensuring optimal performance and efficiency.

To comprehend how this system operates, it is essential to explore the various elements involved and their functions. From the compressor to the evaporator, each component works in harmony to maintain a pleasant environment for occupants.

| Component | Function |

|---|---|

| Compressor | Pressurizes refrigerant and circulates it through the system. |

| Condenser | Allows refrigerant to cool and condense from gas to liquid. |

| Expansion Valve | Regulates the flow of refrigerant into the evaporator. |

| Evaporator | Absorbs heat from the cabin air, providing cooling. |

| Receiver/Dryer | Filters and stores refrigerant, removing moisture and contaminants. |

By understanding these components and their interactions, drivers can better appreciate how the cooling system operates, troubleshoot potential issues, and maintain optimal functionality throughout the vehicle’s lifespan.

Key Components of the AC Unit

Understanding the essential elements of an air conditioning system is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and efficiency.

Major Elements

- Compressor

- Condenser Coil

- Evaporator Coil

- Expansion Valve

- Refrigerant

Supportive Parts

- Fan

- Filter

- Drain Pan

- Thermostat

Each of these components works in harmony to provide the ultimate cooling experience, highlighting the importance of regular checks and potential upgrades for improved efficiency.

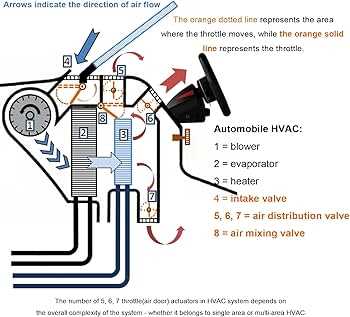

How AC Parts Work Together

The components of an air conditioning system function in harmony to create a comfortable environment. Each element plays a specific role, contributing to the overall efficiency and effectiveness of the cooling process. Understanding the interplay among these elements can illuminate how they collectively maintain desired temperatures and humidity levels.

This cooled liquid then travels to the expansion device, where it undergoes a pressure drop. This process transforms it into a low-pressure mixture of liquid and vapor, which enters the evaporator. Here, the refrigerant absorbs heat from the indoor air, resulting in a cooling effect that lowers the temperature of the surrounding space.

The cycle repeats as the refrigerant returns to the compressor, continuously providing a cooling effect. Each component must function optimally for the system to operate efficiently, illustrating the importance of their interdependence in achieving a stable and pleasant atmosphere.

Common Issues in the 03 Avalanche

The model from 2003 has been known to present several recurring challenges that owners often encounter. These problems can range from minor inconveniences to more serious concerns that require immediate attention.

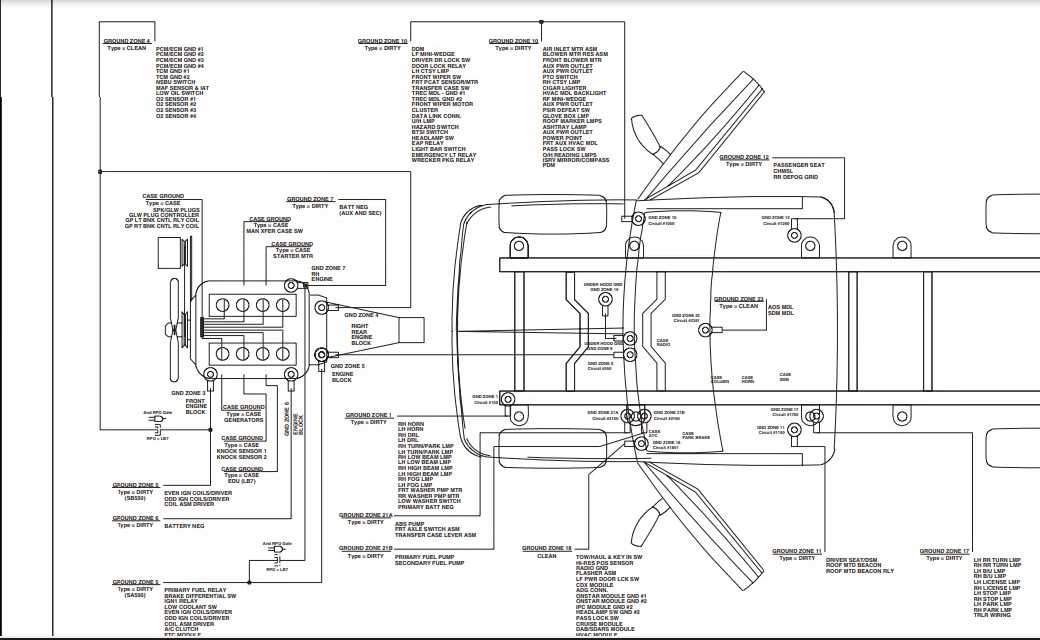

Electrical Problems: One of the most frequently reported issues is related to the electrical system. Many users experience irregularities such as flickering lights or malfunctioning gauges, which can stem from faulty wiring or weak connections.

Transmission Troubles: Shifting difficulties can arise, particularly during acceleration. Drivers may notice delays or harsh engagements, often pointing to fluid issues or worn components that necessitate inspection.

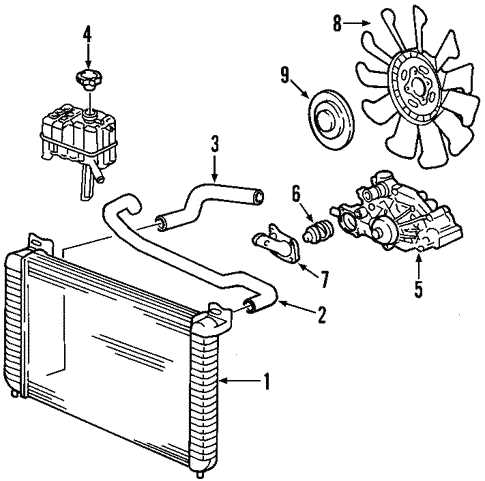

Cooling System Failures: Overheating is another common complaint, often attributed to a failing thermostat or leaking hoses. These factors can lead to serious engine damage if not addressed promptly.

Suspension Wear: Aged suspension parts can result in a rough ride or uneven tire wear. Regular maintenance checks are crucial to ensure optimal handling and comfort.

Addressing these issues proactively can enhance performance and longevity, making ownership a more enjoyable experience.

Symptoms of AC Failure

Recognizing the signs of a malfunctioning cooling system is crucial for timely repairs and maintaining comfort. Various indicators can suggest that your air conditioning unit is not functioning properly, impacting its efficiency and overall performance.

Unusual Noises: If you hear strange sounds such as grinding, squeaking, or hissing, this may indicate mechanical issues or refrigerant leaks.

Inconsistent Cooling: If some areas of your space remain warm while others are cool, the system might be struggling to circulate air effectively.

Increased Energy Bills: A sudden spike in your electricity bills could suggest that the unit is working harder than usual due to underlying problems.

Odors: Foul smells, particularly those reminiscent of mildew or burning, can signal mold growth or electrical issues.

Water Leaks: Puddles or moisture around the unit may indicate a clogged drain line or other drainage issues that require attention.

Understanding these symptoms can help you delve deeper into potential problems and ensure that your cooling system remains in optimal condition.

Step-by-Step Repair Process

Undertaking a repair task requires careful planning and methodical execution. This guide will outline a systematic approach to addressing issues effectively, ensuring each step is thoroughly followed for optimal results. Understanding the components involved and how they interact is crucial for a successful resolution.

Preparation and Inspection

Begin by gathering all necessary tools and materials. Conduct a thorough inspection of the unit to identify the specific problem areas. Document any visible damage or wear, as this will inform your subsequent steps. Make sure to work in a well-lit environment, and consider wearing protective gear if needed.

Disassembly and Replacement

Carefully disassemble the unit, taking note of the order and orientation of each component. This is essential for reassembly later. Replace any damaged elements with new or refurbished ones, ensuring compatibility with the original setup. Once replacements are made, reassemble the unit methodically, following your initial documentation to maintain accuracy.

Tools Needed for AC Maintenance

Proper upkeep of cooling systems requires specific instruments that ensure efficient performance and longevity. Having the right tools not only simplifies the maintenance process but also helps in identifying and resolving issues effectively. Below is a list of essential equipment for maintaining your cooling unit.

| Tool | Description |

|---|---|

| Multimeter | Used to measure electrical values, ensuring components are functioning correctly. |

| Refrigerant Gauge Set | Helps in checking refrigerant levels and diagnosing pressure issues. |

| Screwdrivers | Essential for tightening or loosening screws on various components. |

| Wrench Set | Useful for working on bolts and nuts that hold the system together. |

| Fin Comb | Restores bent fins on the condenser and evaporator coils for better airflow. |

| Vacuum Pump | Used to remove moisture and air from the system before charging it with refrigerant. |

| Thermometer | Measures temperature to ensure the system is operating within the correct range. |

Equipping yourself with these tools can make maintenance tasks more efficient and effective, ultimately extending the life of your cooling system.

Finding Replacement Parts Online

In today’s digital age, sourcing necessary components for your vehicle has become more accessible than ever. With just a few clicks, you can locate what you need from various suppliers, ensuring your automobile remains in top condition.

Here are some effective strategies to enhance your search:

- Utilize specific keywords related to the component you’re seeking.

- Check multiple online retailers for price comparisons and availability.

- Read customer reviews to gauge the reliability of sellers.

Consider these sources for your search:

- Official manufacturer websites for genuine replacements.

- Aftermarket suppliers that offer competitive pricing.

- Local classifieds or online marketplaces for second-hand options.

With these tips, you can streamline your quest for the right components effectively.

OEM vs. Aftermarket Parts Explained

When it comes to maintaining or upgrading your vehicle, the choice between original equipment and alternative components can significantly impact performance, reliability, and cost. Understanding the differences between these options is essential for making informed decisions that suit your needs and preferences.

Understanding OEM Components

Original equipment manufacturer components are produced by the same company that made the original items for your vehicle. They are typically designed to match the specifications and quality of the original installation, ensuring a seamless fit and optimal performance. Choosing these can provide peace of mind regarding longevity and reliability.

Exploring Alternative Options

Aftermarket alternatives are manufactured by third parties and can offer a variety of benefits, including potentially lower costs and unique features. However, quality can vary widely, so it’s important to research and select reputable brands to ensure that these components will meet your expectations in terms of durability and performance.

DIY vs. Professional Repairs

When it comes to fixing your vehicle, you often face a choice between handling the task yourself or hiring an expert. Each approach has its own merits and drawbacks, influencing both time investment and cost. Understanding these factors can help you make an informed decision that best suits your needs.

Taking the DIY route can offer significant savings and the satisfaction of completing a project on your own. However, it requires a solid understanding of the task and access to appropriate tools. On the other hand, relying on a professional guarantees expertise and potentially a quicker resolution, albeit at a higher price. Weighing your skills and available resources against the complexities of the repair is essential for determining the ultimate path forward.

Cost Estimates for AC Repairs

Understanding the potential expenses involved in air conditioning repairs is crucial for any vehicle owner. Knowing the typical costs can help you prepare financially and make informed decisions when faced with issues. Various factors contribute to these estimates, including the nature of the problem, the specific components affected, and labor costs in your area.

Factors Influencing Repair Costs

Several elements impact the overall price of fixing an air conditioning system. Diagnosis is often the first step, where a technician identifies the underlying issue, which can range from minor leaks to major component failures. Parts availability also plays a significant role; some components may be more expensive or harder to find, influencing the total repair bill.

Average Price Ranges

On average, repairs can vary widely. Simple tasks, such as recharging refrigerant, may cost around $100 to $200, while more complex fixes, like replacing a compressor, could range from $500 to $1,500. Always consider obtaining multiple quotes from professionals to ensure a fair assessment of your specific situation.

Seasonal Maintenance Tips for AC

Regular upkeep is essential for ensuring optimal performance and longevity of your cooling system. By following a few simple guidelines, you can keep your unit running efficiently and reduce the likelihood of unexpected breakdowns. Here are some key maintenance practices to consider throughout the year:

- Spring Preparation:

- Inspect and clean the outdoor unit to remove debris.

- Replace or clean the air filter to maintain airflow.

- Check refrigerant levels to ensure they are within the recommended range.

- Summer Checks:

- Monitor the thermostat settings for accurate temperature control.

- Keep vents clear of obstructions to maximize airflow.

- Inspect ductwork for leaks or damage that could affect efficiency.

- Fall Wrap-Up:

- Schedule a professional inspection to identify any potential issues.

- Cover the outdoor unit to protect it from harsh winter weather.

- Change the air filter again to prepare for the heating season.

- Winter Care:

- Keep the area around the unit clear of snow and ice.

- Avoid running the system in extreme cold to prevent damage.

By adhering to these seasonal maintenance tips, you can enhance the efficiency of your cooling system and extend its lifespan, ensuring a comfortable environment year-round.

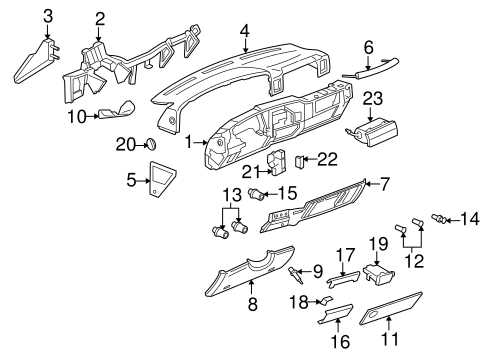

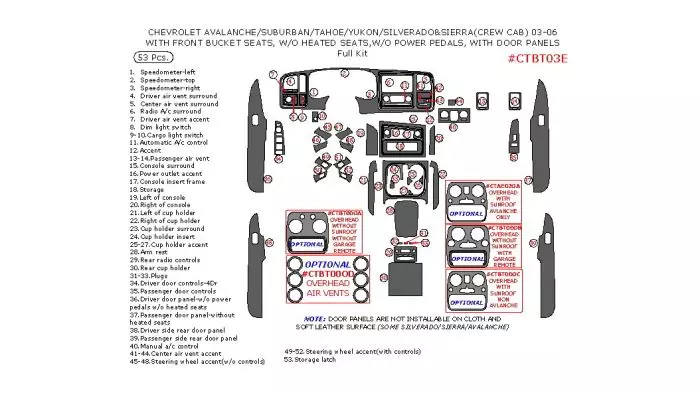

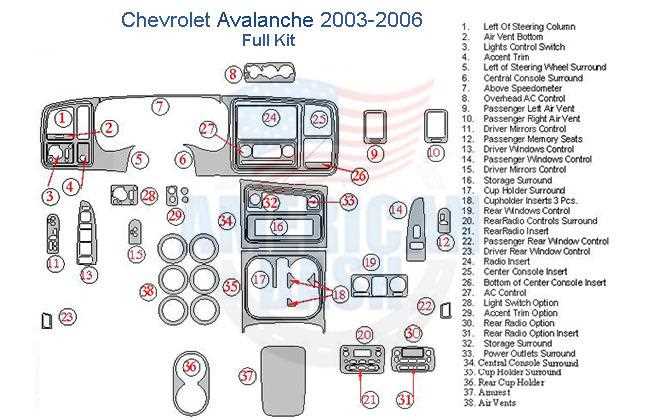

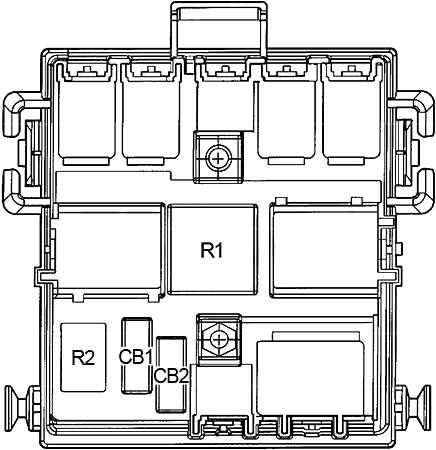

Understanding AC System Diagrams

Comprehending the layout of an air conditioning system is crucial for efficient maintenance and troubleshooting. These illustrations serve as a visual representation of components and their interconnections, providing insights into the system’s functionality.

Key elements to focus on include:

- Components: Identify major parts such as compressors, condensers, and evaporators.

- Connections: Understand how different units interact and communicate.

- Flow Direction: Recognize the movement of refrigerants through the system.

To effectively analyze these layouts, consider the following steps:

- Familiarize yourself with common terminology used in the field.

- Study the layout systematically, starting from the power source to the final output.

- Utilize visual aids and reference materials for clarification.

Ultimately, a firm grasp of these illustrations enhances your ability to diagnose issues and implement solutions efficiently.