Properly maintaining heavy-duty machinery often requires a thorough understanding of how its various elements are organized and connected. Knowing the structure of essential components is key to ensuring smooth operation, allowing for quick identification of worn-out or damaged units. This detailed overview provides an organized layout of these critical mechanical elements, offering clarity on their placement and interaction within the system.

By reviewing the layout, operators and technicians can ensure that maintenance and repairs are carried out efficiently. Whether dealing with hydraulic mechanisms, electrical connections, or other key elements, a clear visual reference helps streamline the process of servicing equipment. Understanding the configuration can significantly reduce downtime and improve overall performance.

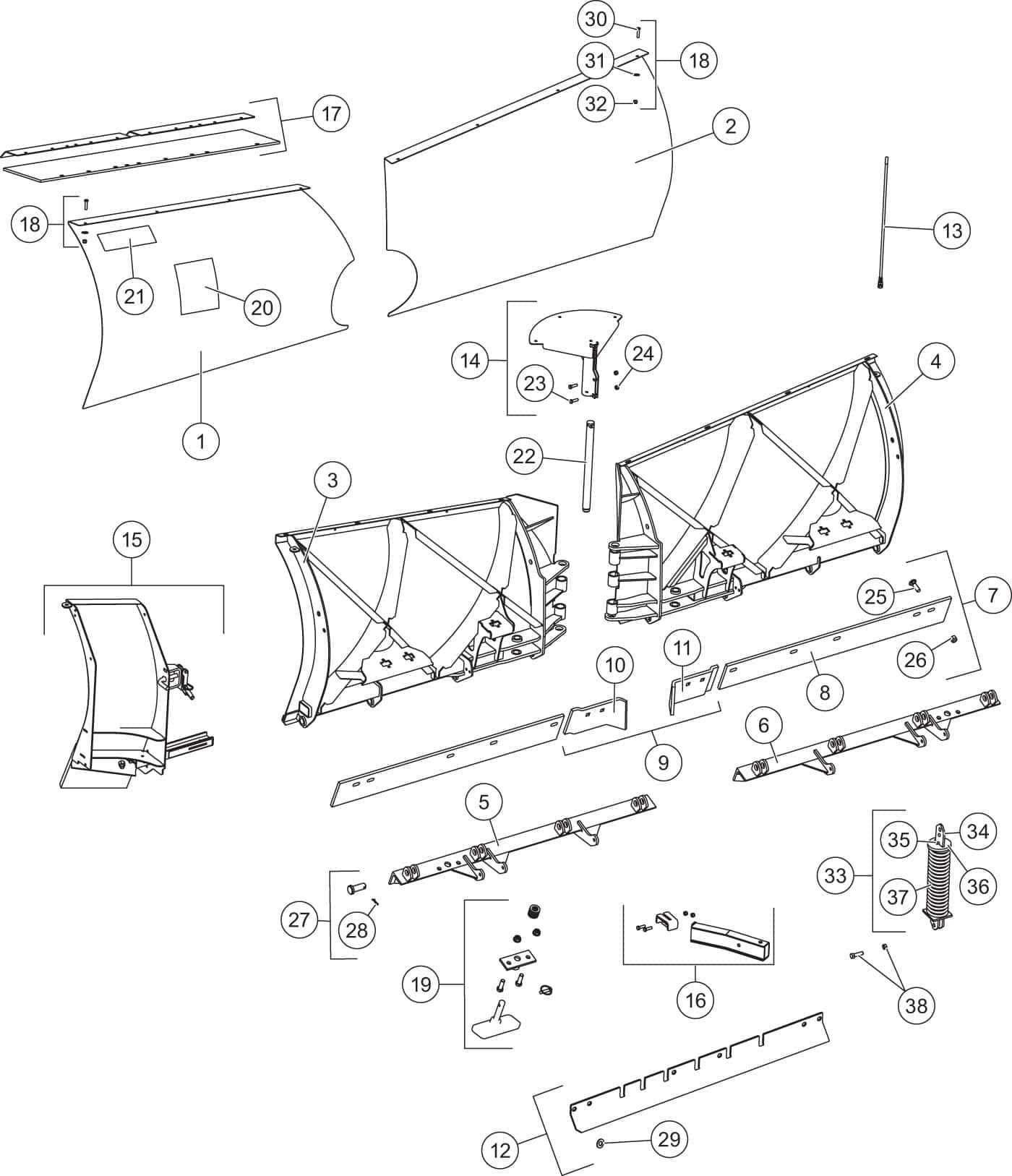

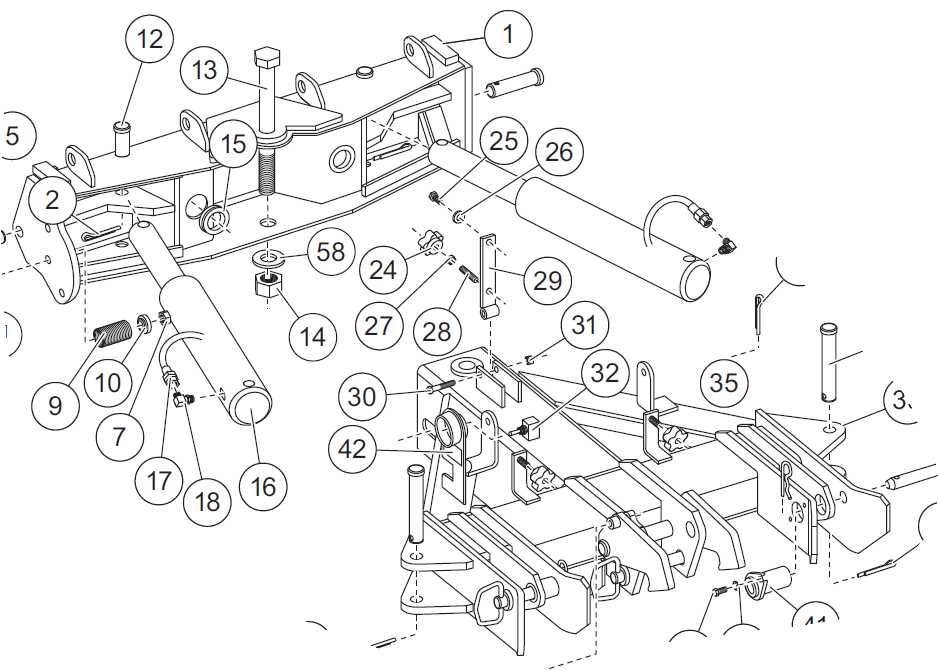

Blizzard Snow Plow Parts Diagram

Understanding the components of heavy-duty clearing equipment is essential for maintaining peak performance during harsh weather conditions. By familiarizing yourself with the various elements that make up this machinery, you can ensure smooth operation and address any potential malfunctions efficiently. Each section of the assembly plays a specific role, from control systems to moving mechanisms, working together to tackle demanding tasks.

Key components include structural supports, hydraulic controls, and interchangeable elements, all of which contribute to the overall functionality. Proper identification and regular maintenance of these mechanical parts can prevent costly repairs and downtime, making this understanding crucial for any operator.

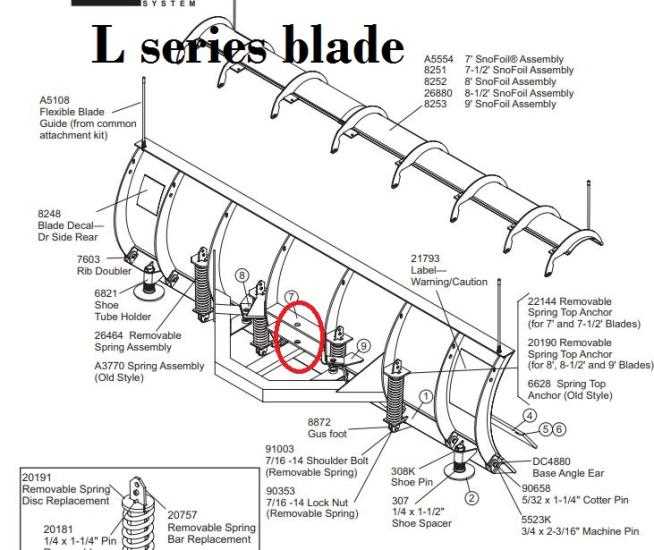

Identifying Key Components of Plow Systems

Effective clearing mechanisms rely on a combination of essential elements working together to ensure optimal performance in various conditions. Understanding how these elements interact allows for more efficient use and better maintenance of the system.

Cutting Edge: This component is responsible for making contact with the surface, ensuring debris or material is pushed aside. Regular inspection of this part is necessary to maintain efficiency and prevent damage to the surface.

Mounting Frame: The structural backbone, responsible for securely attaching the clearing system to a vehicle. Its durability is key to maintaining stability and handling in challenging environments.

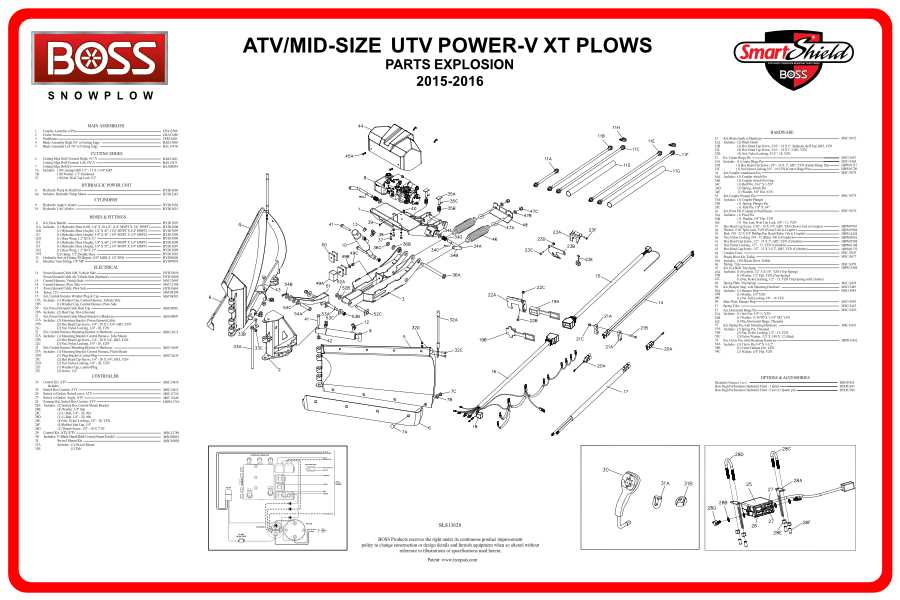

Guide to Understanding Hydraulic Mechanisms

Hydraulic systems play a crucial role in heavy-duty equipment, utilizing fluid pressure to generate force and movement. These systems are essential for controlling various mechanical functions, ensuring precise operation even under intense working conditions. Understanding how hydraulic mechanisms work is vital for maintaining and troubleshooting the equipment.

Core Principles of Hydraulic Operation

At the heart of any hydraulic system is the principle of fluid dynamics. Pressure is applied to a fluid, which then transfers this force to various components, allowing for controlled movement. The system typically consists of pumps, valves, cylinders, and hoses, all working together to manage force and direction.

Common Hydraulic Components

Exploring Electrical Wiring Layouts

Understanding the configuration of electrical connections is essential for ensuring optimal performance in mechanical systems. Proper wiring ensures that all components work together seamlessly, minimizing the risk of malfunction or failure.

Key Elements of Wiring Arrangements

Electrical wiring typically follows a well-structured layout that connects various mechanical parts, allowing for the flow of power and control signals. Cables and connectors must be properly aligned to meet the specific requirements of each system. Incorrectly arranged connections can result in inefficiencies or even damage.

Ensuring Safe Connections

For safety, it is critical to adhere to established guidelines when working with electrical layouts. Proper grounding, the use of insulated wires, and secure connections all play a role in maintaining a reliable and efficient system.

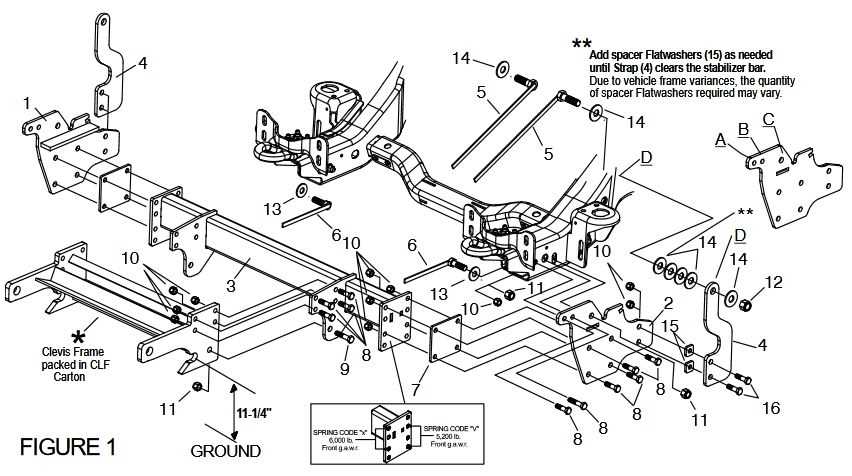

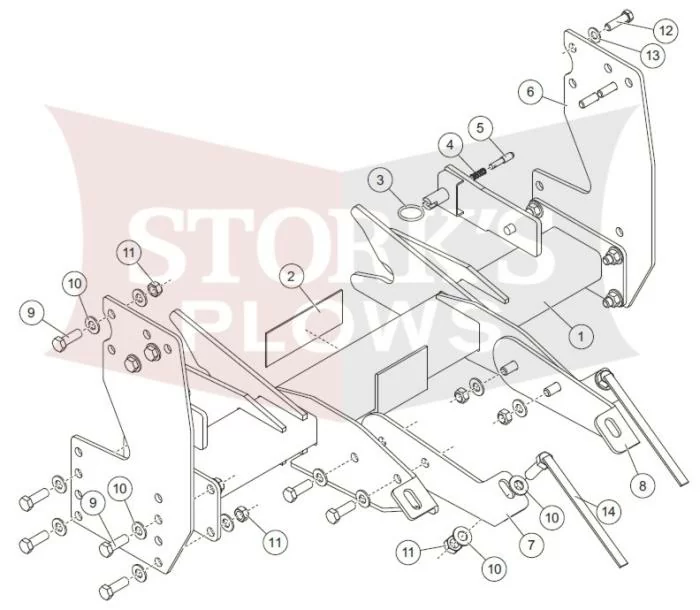

Overview of Snow Plow Mounting Structures

Mounting systems are essential components that ensure the attachment of heavy-duty equipment to vehicles. These structures are designed to provide stability and durability, enabling efficient operation in demanding conditions. They play a crucial role in distributing the weight evenly and preventing damage to the vehicle’s frame during usage.

Types of Mounting Systems

Mounting setups come in various designs, each optimized for specific vehicle models and operational needs. Some are permanent installations, while others are detachable, offering flexibility for different applications. Key elements include the frame brackets, hydraulic connections, and control mechanisms, all working together to ensure a secure fit

Blade Adjustment and Control Schematics

Proper alignment and control of the cutting edge are essential for optimal performance during operation. This section explores the mechanisms involved in adjusting the blade and the control systems that allow operators to manipulate its position effectively. Understanding these elements is crucial for ensuring efficiency and safety in challenging conditions.

Adjustment Mechanisms

The adjustment systems are designed to provide flexibility and precision when altering the angle and height of the cutting edge. Various components, such as hydraulic cylinders and linkage systems, facilitate smooth transitions and fine-tuning. Regular maintenance of these mechanisms is vital to prevent wear and ensure reliable operation over time.

Control Systems Overview

Control systems play a significant role in the operation of the cutting edge, allowing for real-time adjustments based on the operator’s preferences. Typically, these systems include joysticks or switches that communicate with hydraulic controls to modify the blade’s position. Familiarity with these controls enhances user experience and promotes effective management of the equipment during use.

Interpreting Pump Assembly Connections

The functionality of hydraulic mechanisms largely depends on the accurate interpretation of their component connections. Understanding how each element interacts is crucial for ensuring optimal performance and efficiency. This section provides insights into the assembly of fluid delivery systems, focusing on the essential connections that facilitate smooth operation.

In many cases, the assembly includes various fittings and connectors, each designed for specific roles within the system. Identifying these components and their purposes can significantly enhance maintenance practices and troubleshooting efforts.

| Component | Function |

|---|---|

| Inlet Connector | Allows fluid to enter the assembly from the reservoir. |

| Outlet Connector | Facilitates fluid discharge to the actuator. |

| Pressure Relief Valve | Prevents excessive pressure buildup by diverting excess fluid. |

| Return Line Connector | Directs fluid back to the reservoir after use. |

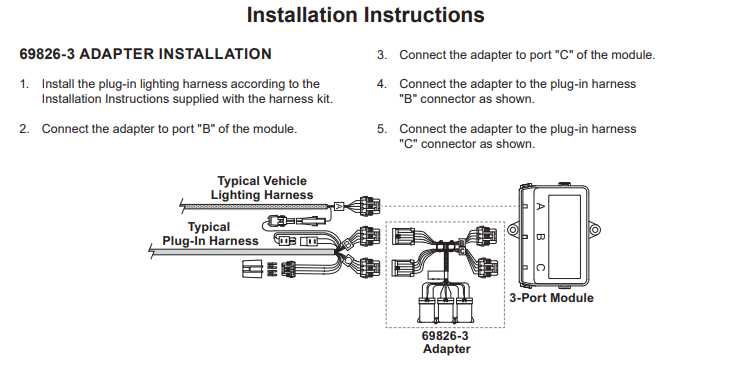

Understanding Lighting Circuit Configurations

This section provides an overview of how various components within lighting systems are interconnected to ensure proper functionality. Understanding these configurations is essential for diagnosing issues and performing effective repairs.

The lighting circuits can vary widely in their arrangement, depending on the specific requirements of the equipment and the intended application. Recognizing the basic layouts can help streamline troubleshooting and maintenance efforts.

| Configuration Type | Description |

|---|---|

| Series Circuit | Components are connected in a single path, allowing current to flow through each element sequentially. |

| Parallel Circuit | Components are connected across multiple paths, ensuring that each one receives the same voltage independently. |

| Complex Circuit | A combination of series and parallel connections, accommodating various operational requirements and enhancing flexibility. |

Decoding Hydraulic Valve Arrangements

The configuration of hydraulic control mechanisms plays a crucial role in the effective operation of heavy machinery. Understanding these arrangements is essential for optimal performance and maintenance. This section explores the fundamental aspects of hydraulic valve setups, shedding light on their functions and importance in various applications.

Hydraulic systems utilize valves to regulate fluid flow and pressure, which is vital for controlling movement and force in equipment. Below are key elements that define these configurations:

- Types of Valves: Different valves serve various purposes, including direction control, flow regulation, and pressure relief.

- Arrangement Patterns: The positioning of valves impacts the efficiency of fluid movement, affecting overall system performance.

- Connection Methods: Proper linkage between components is essential for seamless operation and maintenance.

Identifying and understanding these components is critical for anyone working with hydraulic machinery. Regular inspection and familiarity with valve arrangements can prevent potential issues and enhance operational longevity.

Tracking Fluid Reservoir and Hose Placement

Understanding the configuration of liquid storage and associated conduits is essential for maintaining the efficiency of hydraulic systems. Proper placement ensures optimal functionality and longevity of the equipment. This section will explore the positioning of the reservoir and hoses, emphasizing the significance of correct arrangement.

Importance of Proper Placement

Accurate positioning of the fluid reservoir and hoses minimizes the risk of leaks and enhances fluid flow. Ensuring that these components are strategically located helps in achieving effective operation and reduces the likelihood of system failure. Additionally, proper routing can simplify maintenance and troubleshooting processes.

Recommended Configuration

The following table outlines the ideal configurations for liquid reservoirs and hoses, detailing their recommended positions and connections:

| Component | Recommended Location | Connection Type |

|---|---|---|

| Fluid Reservoir | Near the hydraulic pump | Direct connection |

| Supply Hose | From reservoir to pump | High-pressure coupling |

| Return Hose | From pump back to reservoir | Standard coupling |

Electrical Component Troubleshooting Insights

Understanding the intricacies of electrical components is crucial for efficient operation and maintenance. This section delves into common issues faced during troubleshooting and offers practical solutions for resolving these challenges.

Identifying Common Electrical Issues

When diagnosing electrical problems, it is essential to recognize the symptoms that may indicate underlying faults. Typical issues include power failure, intermittent functionality, and unusual noises during operation. Observing these signs can help pinpoint the specific component requiring attention.

Troubleshooting Techniques

Implementing systematic troubleshooting techniques can significantly enhance the efficiency of repairs. Start by checking connections for corrosion or loose wires, then proceed to test voltage levels across various components. Documenting findings throughout the process ensures a structured approach.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| No power | Disconnected power supply | Check connections and ensure power source is active |

| Intermittent operation | Worn-out switch | Replace the switch with a new one |

| Unusual noise | Loose components | Tighten screws and secure all components |

Exploring Cutting Edge Replacement Parts

In the world of heavy machinery, the importance of advanced components cannot be overstated. These elements play a crucial role in enhancing efficiency, reliability, and overall performance. Understanding the latest innovations in replacement components allows operators to optimize their equipment, ensuring that they can tackle any challenge that arises with confidence.

Innovative Technologies

Recent advancements in materials and manufacturing processes have led to the development of more durable and efficient components. These innovations not only improve the lifespan of the equipment but also contribute to better performance in various conditions. Utilizing state-of-the-art technologies can make a significant difference in operational effectiveness.

Benefits of Upgrading Components

Upgrading to modern alternatives offers numerous advantages, including increased efficiency, reduced maintenance costs, and improved safety. Enhanced designs often lead to better compatibility with existing systems, ensuring a seamless integration. As a result, operators can expect a smoother experience and a higher return on investment.

Plow Frame and

The structure of the attachment is crucial for ensuring stability and functionality during operations. This framework serves as the backbone, connecting various components and facilitating the effective transfer of force. Understanding its configuration helps users appreciate the engineering behind effective snow clearing equipment.

Key Components of the Frame

Several essential elements comprise the overall structure, each playing a specific role in enhancing performance and durability. These components are designed to withstand the rigors of harsh environments while providing reliability in demanding conditions.

| Component | Description |

|---|---|

| Crossmember | Supports the weight and distributes stress across the frame. |

| Mounting Bracket | Connects the frame to the vehicle, ensuring secure attachment. |

| Support Arms | Provides additional stability and reinforcement to the frame structure. |

| Pivot Points | Allows for controlled movement and adjustment during use. |

Maintenance Considerations

Regular inspection and maintenance of the framework are essential to ensure longevity and optimal performance. Addressing wear and tear promptly can prevent more significant issues and enhance the overall efficiency of the equipment.