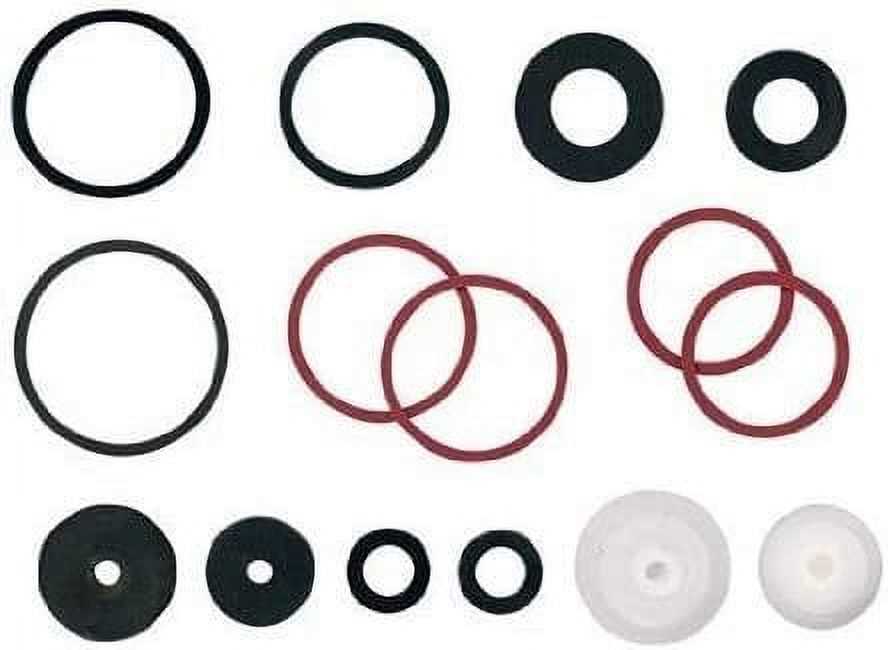

Seals and Barriers: These elements prevent unwanted leakage and help maintain a consistent flow within the system

Common Issues with Orbit Valves

Understanding typical problems associated with irrigation control mechanisms is essential for efficient maintenance and operation. Various factors can lead to malfunctions, affecting the system’s overall performance. Identifying these issues early can help ensure a reliable and effective watering experience.

Frequent Problems Encountered

- Water Leakage: A common issue where moisture escapes from connections, leading to inefficiency.

- Inconsistent Flow: Irregular water distribution may arise from clogs or internal damage.

- Electrical Failures: Wiring problems can disrupt the control signals, preventing proper operation.

- Debris Buildup: Accumulation of dirt and sediment can obstruct mechanisms and impede function.

Troubleshooting Steps

- Check for visible leaks at connection points and tighten fittings as needed.

- Inspect the interior for any blockages and clear out any debris.

- Examine electrical components for wear or loose connections.

- Test the system’s operation manually to ensure all parts are functioning correctly.

Addressing these common concerns promptly can prolong the life of the equipment and maintain optimal watering efficiency.

Replacing a Faulty Sprinkler Valve

Maintaining a functional irrigation system is essential for ensuring that your garden receives adequate water. When components fail, it can lead to inefficient watering or leaks. This section outlines the process for swapping out a malfunctioning mechanism, ensuring your system operates smoothly once again.

Before beginning the replacement, gather the necessary tools and materials. It is important to turn off the water supply and drain the system to prevent any accidents during the process. Identifying the specific component that requires replacement is crucial for a successful fix.

| Tools Needed |

Description |

| Wrench |

To loosen and tighten fittings |

| Replacement Mechanism |

Ensure compatibility with your existing system |

| Thread Seal Tape |

To prevent leaks at connections |

| Utility Knife |

For cutting any necessary tubing |

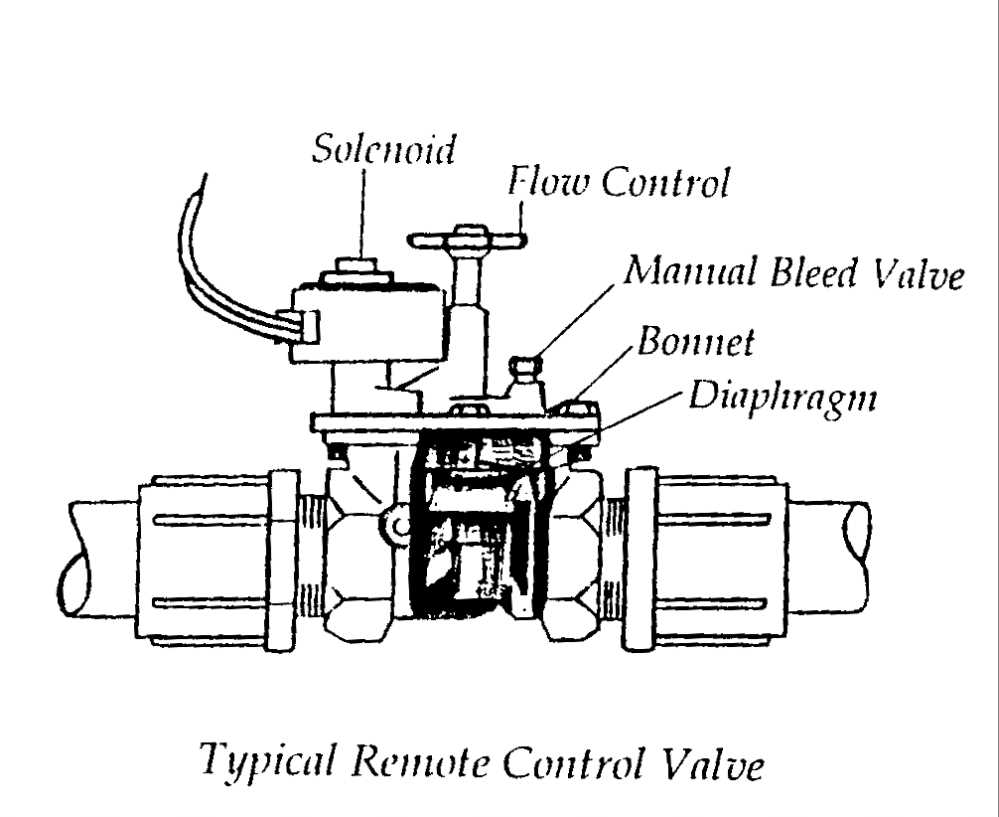

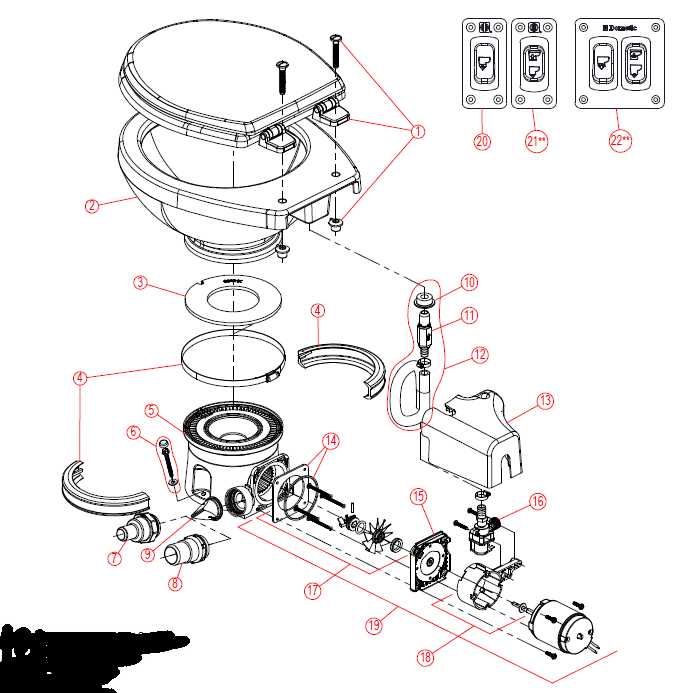

Once you have the tools ready, remove the faulty unit by unscrewing it from the connecting pipes. Carefully detach any wires if applicable, ensuring to note their original positions for reassembly. Next, position the new component in place, making sure it aligns with the existing piping. Secure it tightly and reattach any wiring.

After everything is connected, turn the water supply back on and check for any leaks. It may take a moment for the system to stabilize, but ensuring everything is working correctly will save time and resources in the long run.

Proper Maintenance for Longevity

Ensuring the durability of your irrigation system requires consistent upkeep and attention to detail. By implementing a regular maintenance routine, you can enhance the performance of your equipment, reduce the likelihood of malfunctions, and extend its overall lifespan. This section outlines essential practices for effective care, focusing on the various components that contribute to optimal functionality.

Routine Inspection

Conducting periodic evaluations is crucial for identifying potential issues before they escalate. Regularly check for any signs of wear, leaks, or blockages. Pay special attention to seals and connections, as these areas are often prone to deterioration. Timely repairs can prevent minor problems from developing into significant failures, ultimately saving time and resources.

Cleaning and Lubrication

Keeping the system clean is vital for maintaining efficient operation. Remove debris and buildup that can hinder performance. Additionally, lubricating moving parts will facilitate smoother operation and decrease the risk of friction-related damage. Proper cleaning and lubrication not only enhance functionality but also contribute to the longevity of the components, ensuring your irrigation system operates effectively for years to come.

Installing Orbit Sprinkler Valves Correctly

Proper installation of irrigation components is crucial for optimal performance and longevity of your watering system. Ensuring that each element is fitted accurately helps in maintaining efficiency, preventing leaks, and promoting even distribution of water. This section will guide you through the essential steps to effectively set up these crucial components in your landscape.

Preparation Before Installation

Before starting the installation process, it is vital to gather all necessary tools and materials. This preparation phase can significantly ease the process and minimize potential issues. Follow these steps to ensure a smooth installation:

| Tool/Material |

Purpose |

| Pipe Wrench |

To tighten connections securely |

| Pipe Cutter |

To cut piping to the required lengths |

| Teflon Tape |

To ensure a watertight seal |

| Shovel |

To dig trenches for pipe installation |

Step-by-Step Installation Process

Once you have everything ready, you can begin the installation process. Follow these steps to achieve an effective setup:

- Begin by digging a trench to accommodate the pipes, ensuring it is deep enough to prevent damage from surface activities.

- Cut the pipes to the appropriate lengths and connect them using the necessary fittings.

- Apply Teflon tape to the threads of the connections to prevent leaks.

- Carefully insert the components into the trench, ensuring they are positioned correctly for optimal operation.

- Finally, test the system to verify that everything is functioning as intended, checking for any leaks or irregularities.

How to Troubleshoot Sprinkler Valve Problems

Tackling issues with your irrigation system can be a daunting task, but understanding common challenges can significantly simplify the process. This section offers insights into identifying and resolving frequent complications that may arise in your watering setup, ensuring your landscape receives the necessary hydration efficiently.

Identifying Common Issues

Begin by observing the behavior of your system. If you notice uneven water distribution or complete shut-off, these are indicators of underlying problems. Examine the connections and components for signs of damage or blockage. It’s crucial to check for leaks, as they can lead to wasted resources and reduced effectiveness.

Steps to Resolve Malfunctions

Once you identify potential issues, take systematic steps to rectify them. Start by ensuring that all connections are tight and free of debris. If you suspect a blockage, disassemble the affected areas and clean them thoroughly. In cases where components are damaged, consider replacing them with new ones to restore optimal function.

Regular maintenance is key to preventing future difficulties. Schedule periodic checks and cleaning to keep your watering system in excellent condition. By staying proactive, you can enjoy a lush and thriving garden with minimal interruptions.

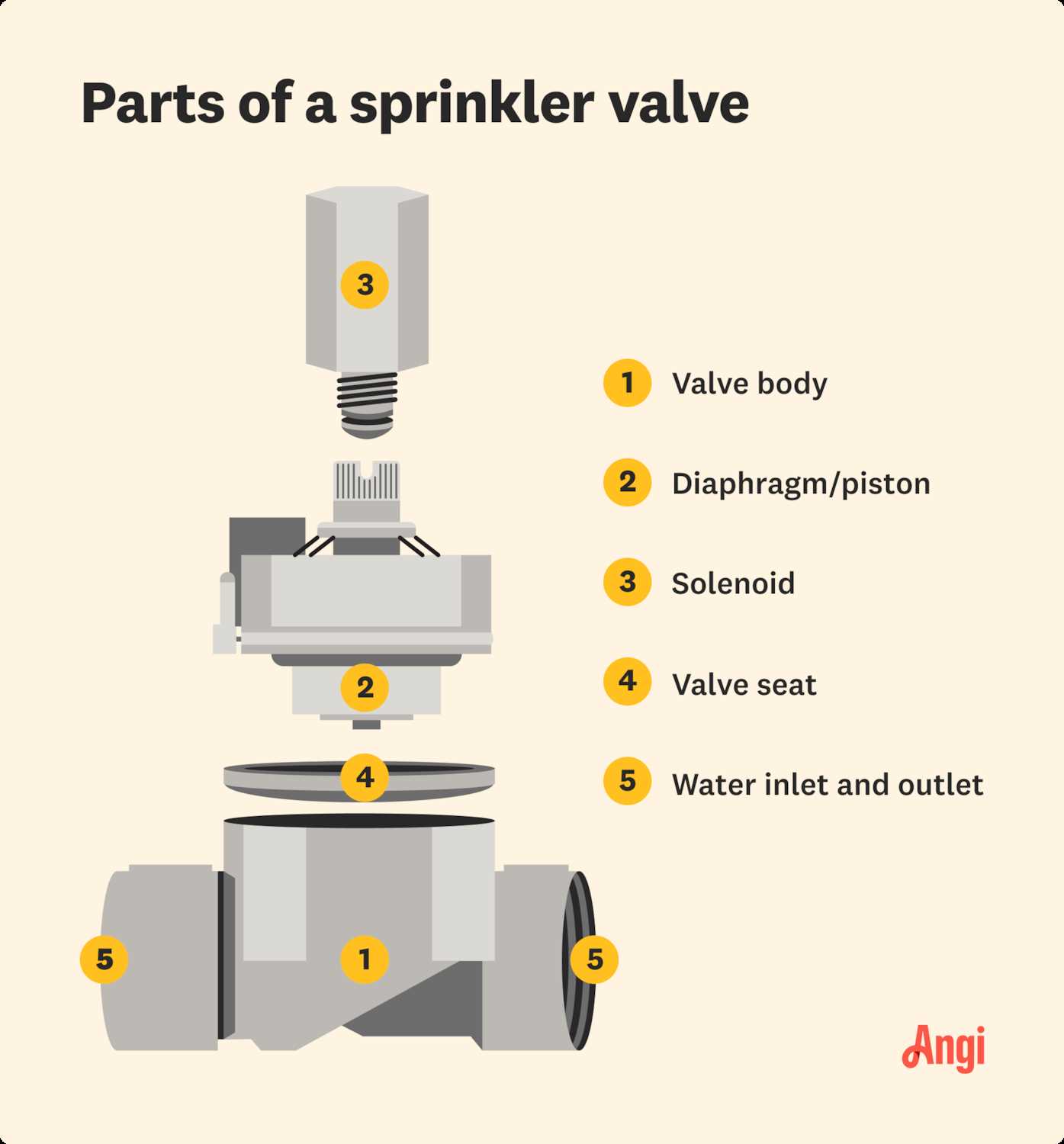

Choosing the Right Orbit Valve Parts

When it comes to selecting components for your irrigation system, understanding the available options is crucial for ensuring optimal functionality and efficiency. Each element plays a vital role in the overall performance, and making informed choices can significantly impact the system’s effectiveness.

One of the primary considerations is compatibility with existing equipment. It’s essential to assess the specifications and design of the components to guarantee they work seamlessly together. Additionally, evaluating the durability and material quality can lead to a more reliable setup, reducing the need for frequent replacements.

Another aspect to consider is the specific requirements of your landscape or agricultural needs. Factors such as water pressure, flow rate, and coverage area will influence the selection process. Opting for elements that meet these criteria will enhance performance and conserve resources.

Finally, consulting with professionals or utilizing resources such as manuals and guides can provide valuable insights into making the right choices. Investing time in understanding the options available will ultimately lead to a more efficient and sustainable irrigation solution.