Extractor:

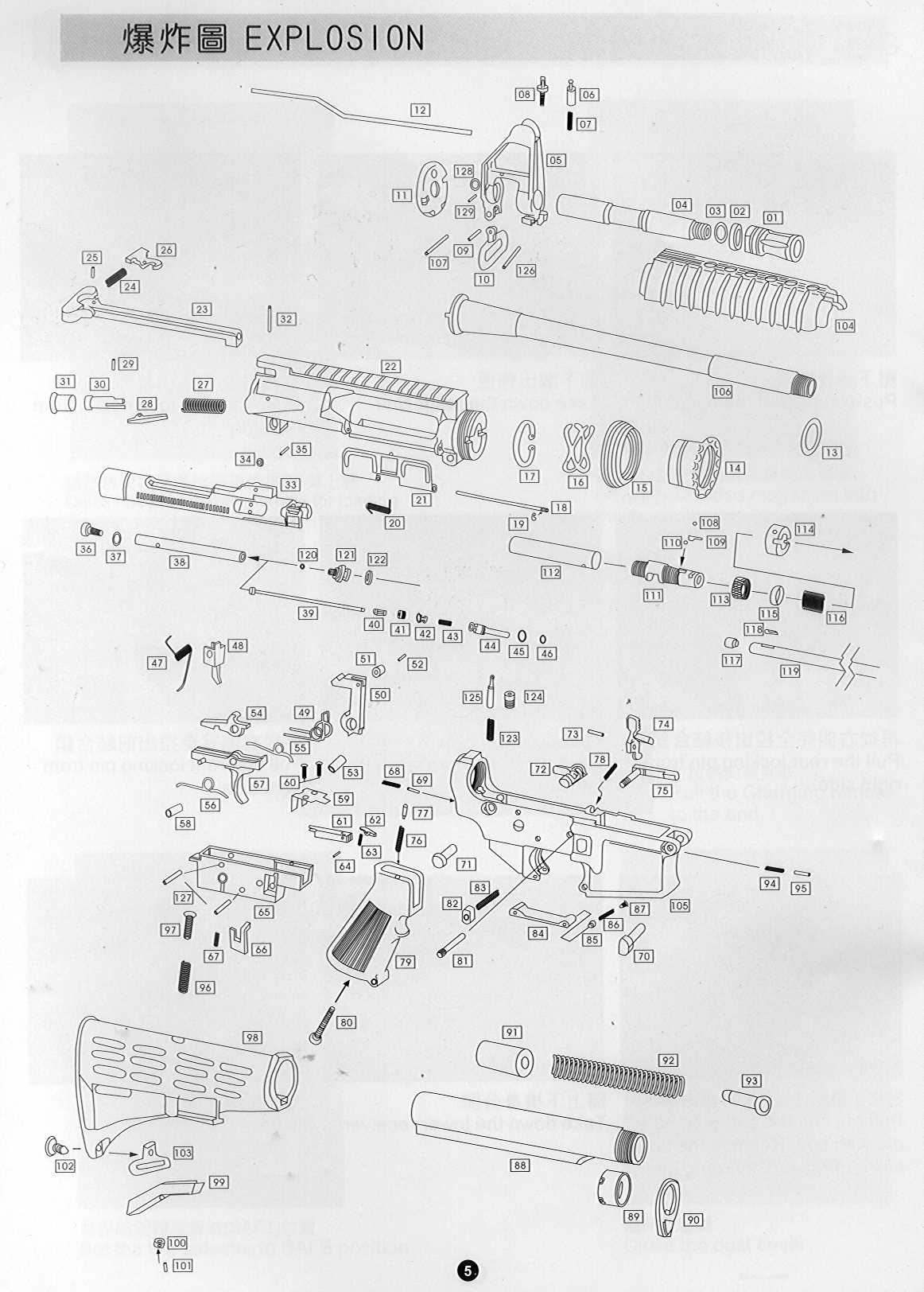

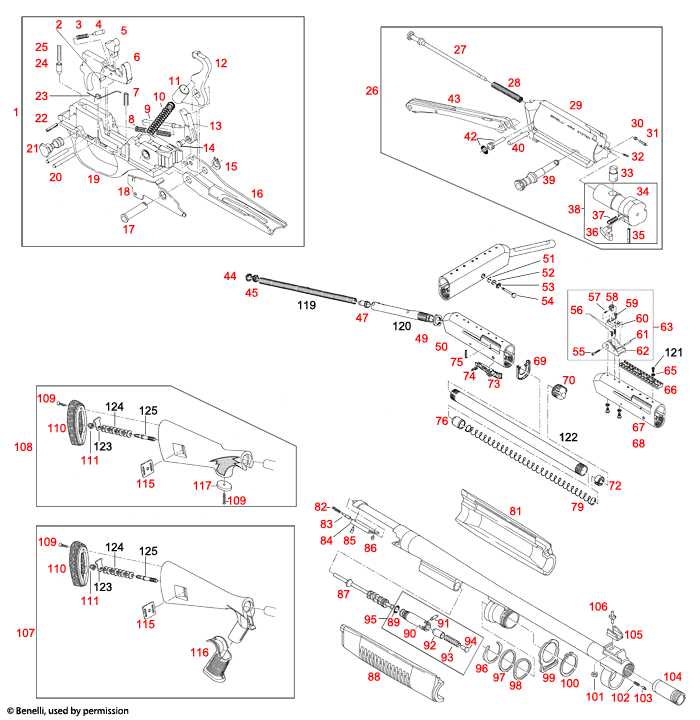

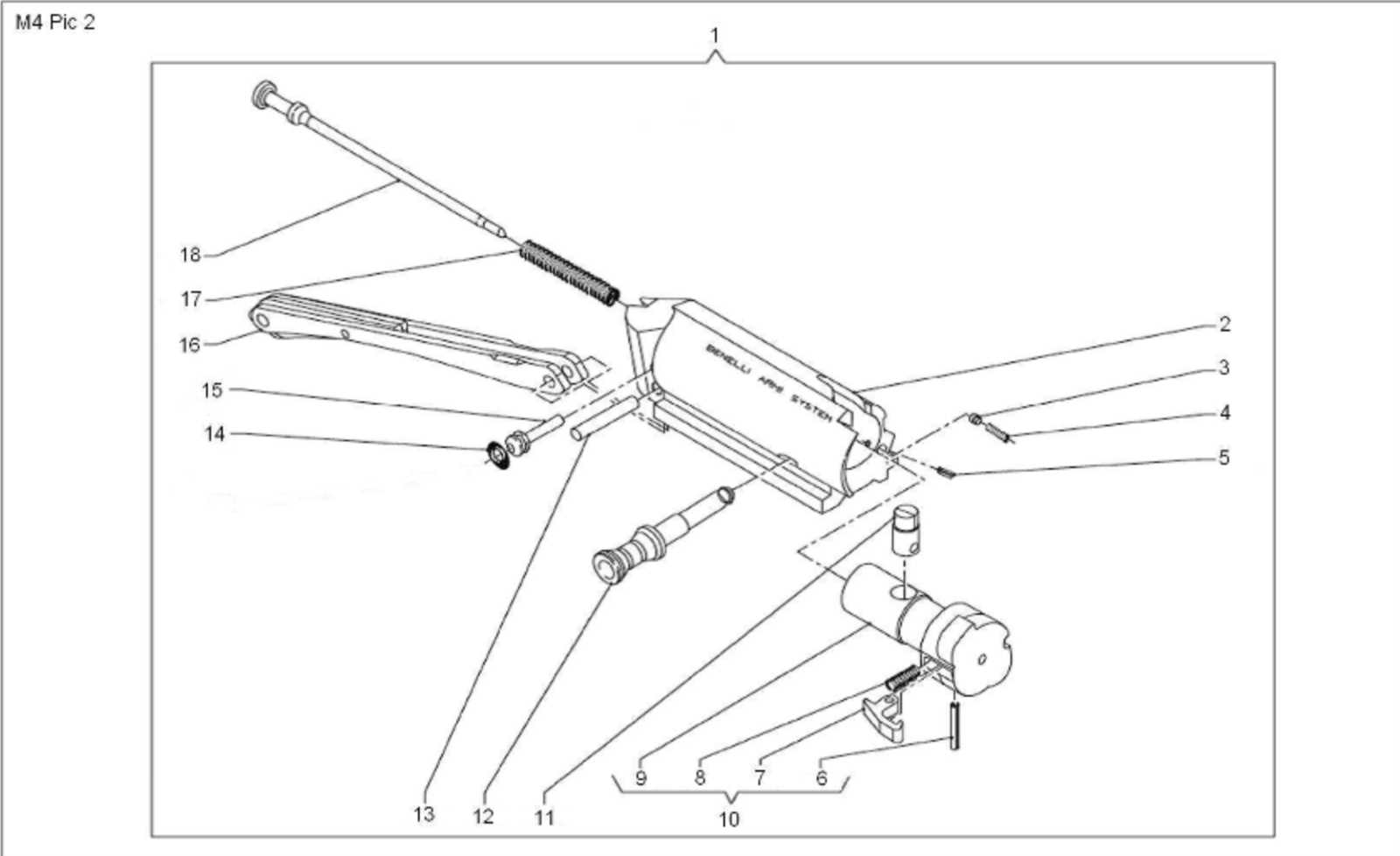

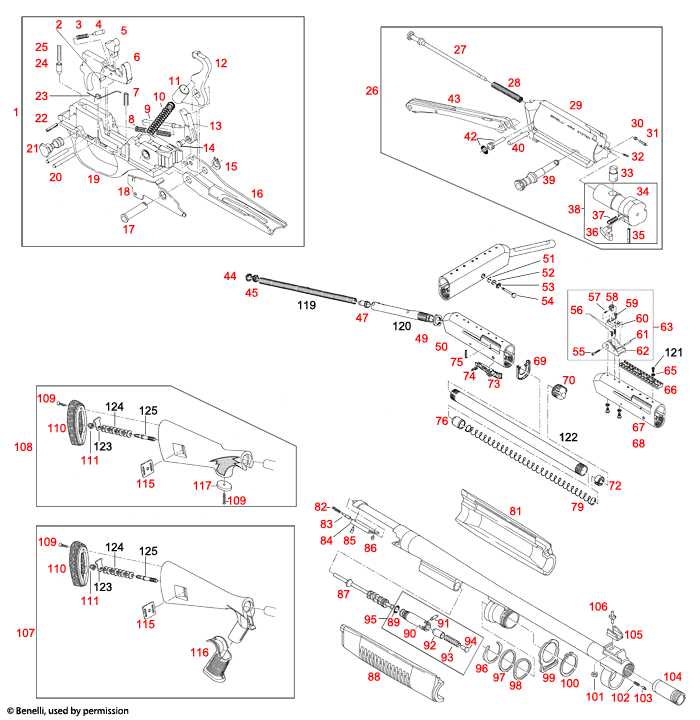

Trigger Group Components Breakdown

This section provides a detailed examination of the essential elements within the firing mechanism of a shotgun. Understanding these components is crucial for effective maintenance and functionality.

Key Elements of the Firing Mechanism

- Trigger: The part responsible for initiating the firing sequence.

- Sear: Engages with the hammer to hold it in a cocked position until the trigger is pulled.

- Hammer: The component that strikes the firing pin to ignite the shell.

- Disconnector: Ensures that the firearm only fires once per trigger pull.

Maintenance and Care Tips

- Regularly clean each component to prevent buildup of dirt and debris.

- Check for wear and replace any parts that show signs of damage.

- Lubricate moving parts to ensure smooth operation.

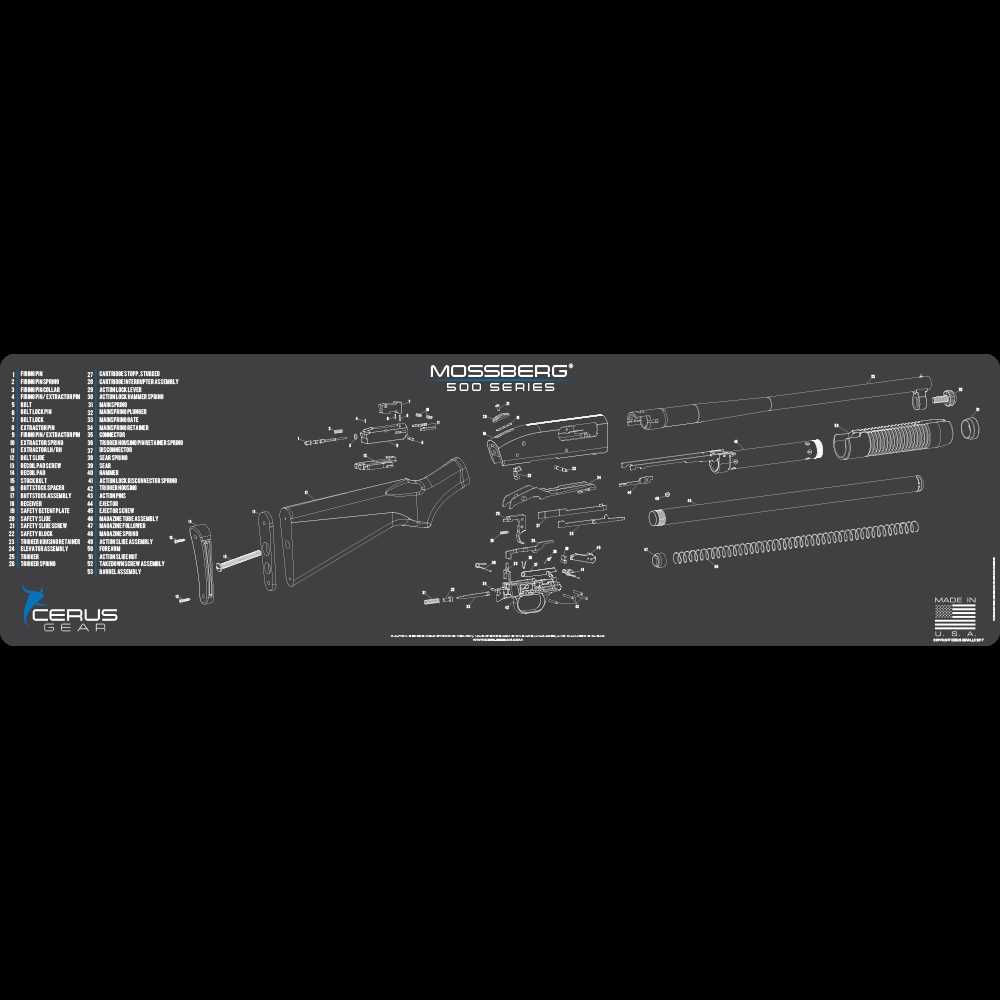

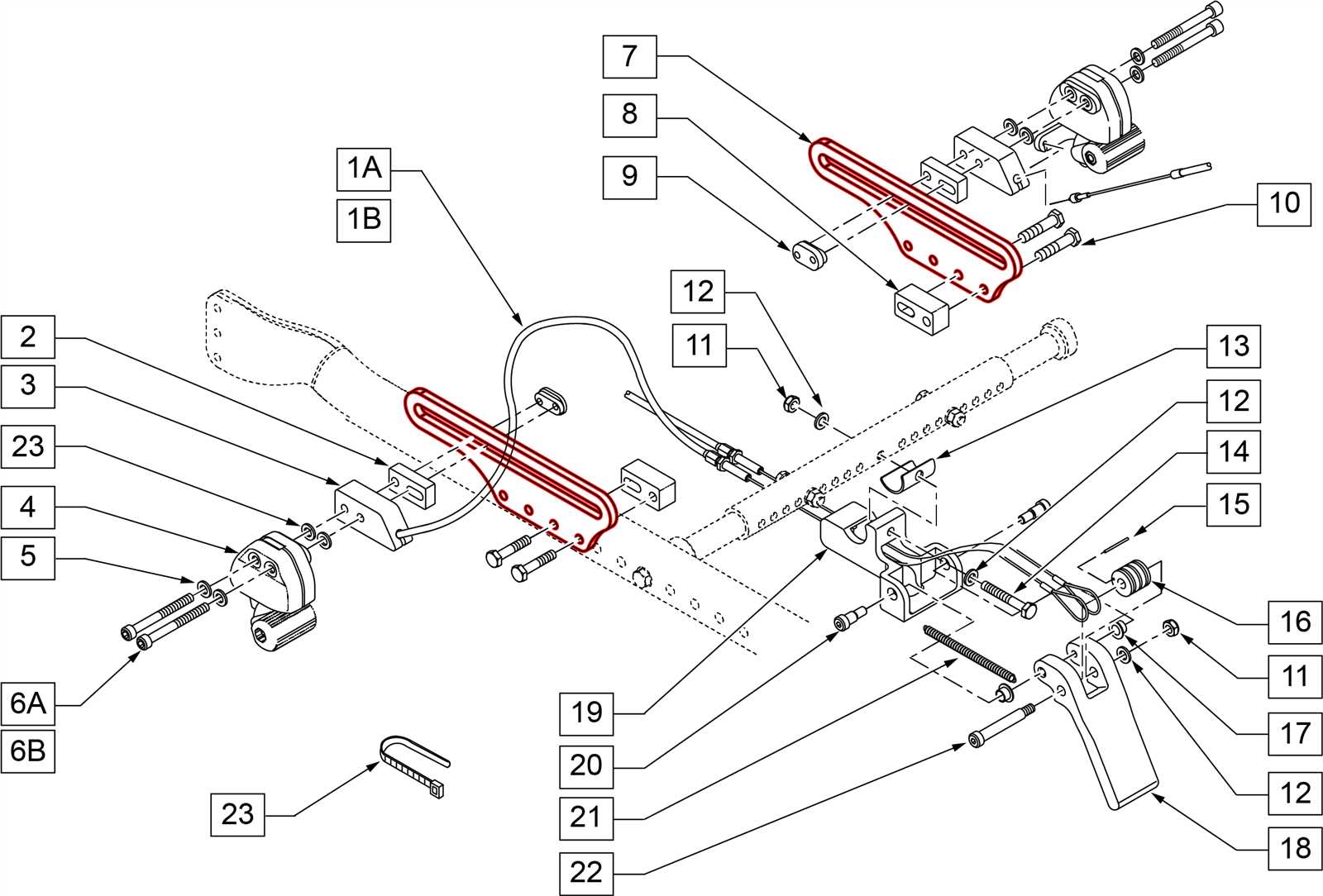

Magazine Tube and Feeding Mechanism

The magazine tube and feeding mechanism are crucial components that ensure the reliable operation of a shotgun. These elements work together to store and deliver ammunition efficiently, allowing for quick reloads and consistent performance during use.

| Component |

Description |

| Magazine Tube |

A cylindrical chamber that holds cartridges ready for feeding into the action. |

| Follower |

A device that pushes the ammunition upward as rounds are fired or removed. |

| Spring |

A component that provides the necessary force to elevate the follower and maintain cartridge position. |

| Feeding Ramp |

A sloped surface that guides cartridges from the magazine into the chamber smoothly. |

| Loading Port |

The opening through which ammunition is inserted into the magazine tube. |

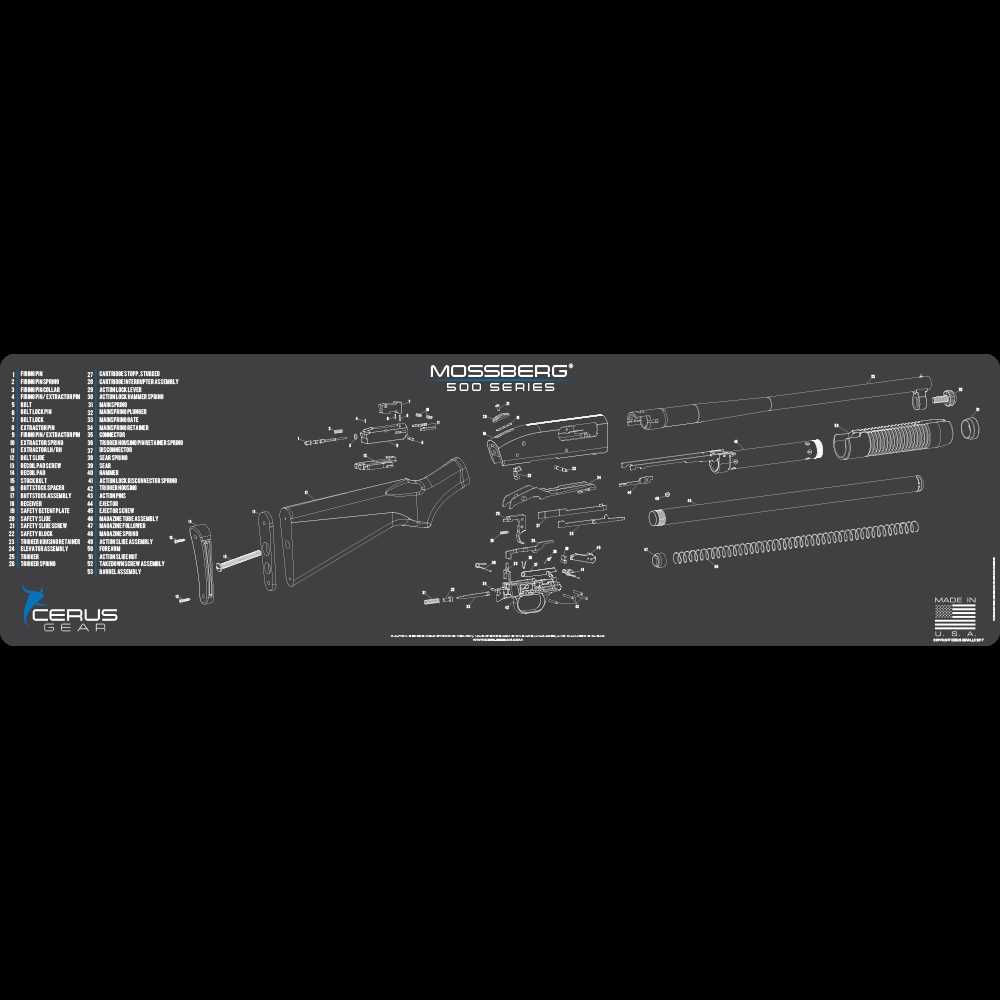

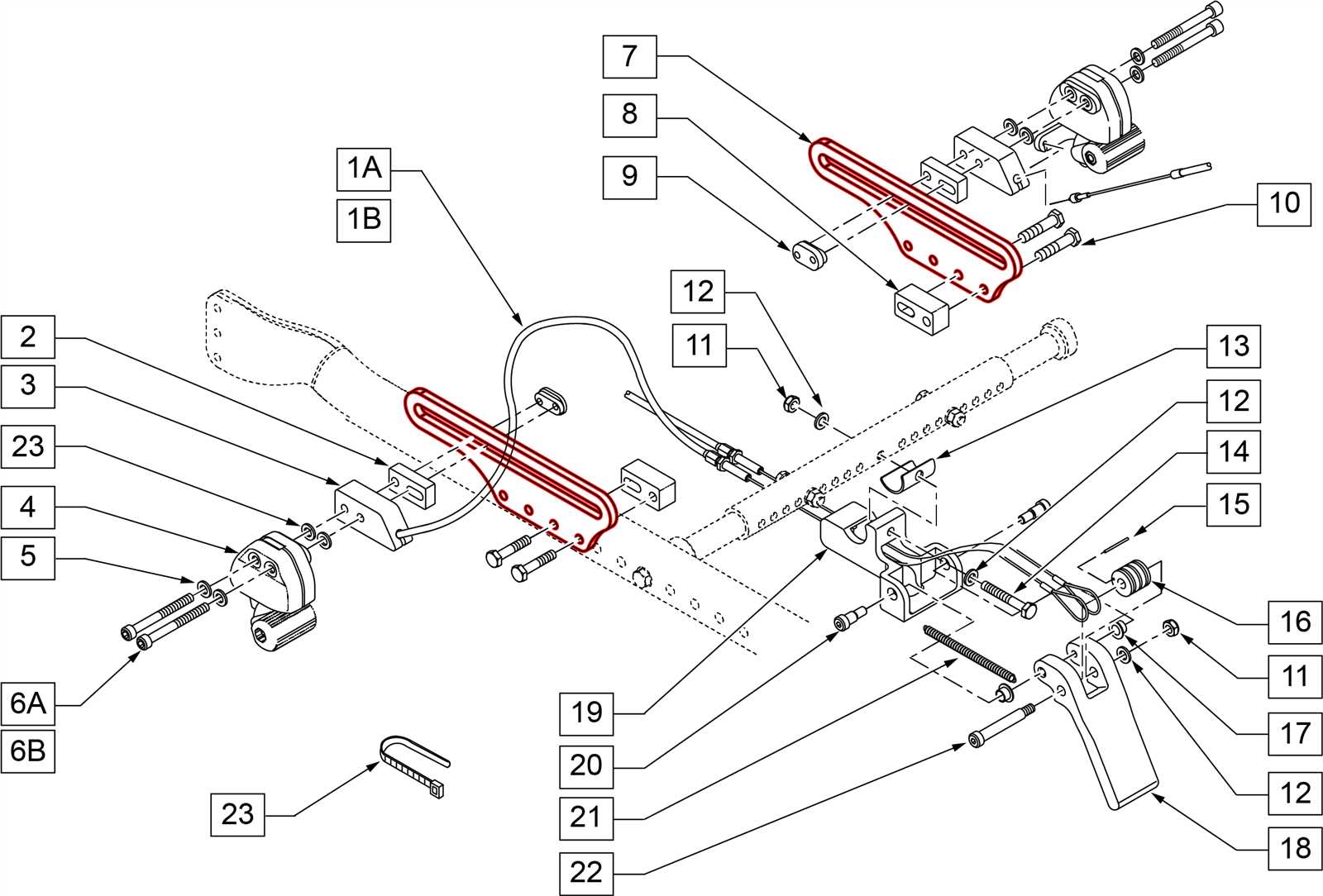

Stock and Recoil Management Features

The design and functionality of a firearm’s stock significantly influence its handling and user experience. Features aimed at managing recoil not only enhance comfort but also improve accuracy during use. By integrating innovative materials and ergonomic shapes, manufacturers strive to create components that allow for smoother operation and reduced fatigue.

Ergonomic Design

An ergonomic stock design ensures that the firearm fits comfortably against the shoulder, facilitating better control and aiming. This is crucial for maintaining stability during repetitive use, particularly in high-caliber models. The contours and materials used can make a significant difference in user experience.

Recoil Absorption Mechanisms

Modern firearms often incorporate advanced recoil absorption technologies. These systems work by dissipating the energy generated upon firing, reducing the impact felt by the shooter. Such mechanisms may include specialized cushioning materials and adjustable features to accommodate various shooting styles.

| Feature |

Description |

| Adjustable Stock |

Allows customization of length and fit for optimal comfort. |

| Shock Absorbing Pad |

Provides cushioning against recoil, minimizing discomfort. |

| Cheek Rest |

Enhances alignment with sights for improved accuracy. |

| Textured Grip |

Ensures secure handling, especially in adverse conditions. |

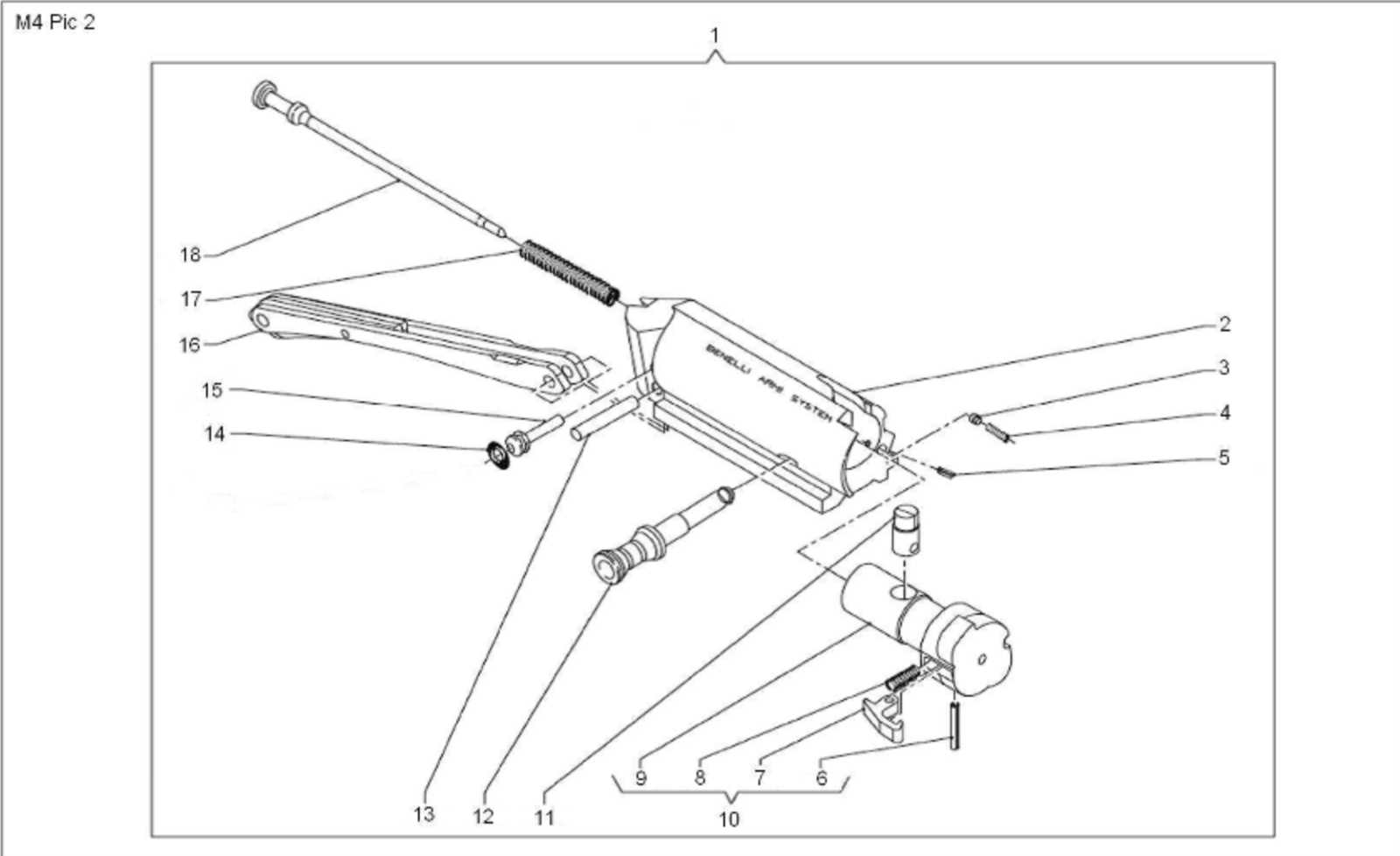

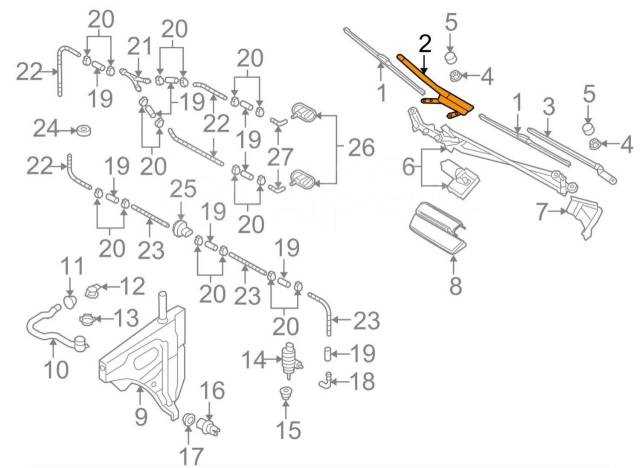

Barrel and Choke Tube Compatibility

This section explores the compatibility between barrels and choke tubes, focusing on how these components interact to influence the performance of a shotgun. Understanding this relationship is essential for optimizing shooting experiences and ensuring reliable operation.

When selecting a barrel, it is crucial to consider the choke system that will be used. Different barrel designs may accommodate various choke tube styles, which can significantly affect shot patterns and overall accuracy. Compatibility between these components ensures that the firearm functions efficiently and meets the shooter’s specific needs.

Furthermore, when upgrading or replacing components, verifying compatibility is vital to maintaining the integrity of the firearm. Users should consult manufacturer specifications or trusted resources to ensure that the chosen barrel and choke tubes work harmoniously, thereby enhancing performance and versatility.

Forearm Design and Functionality

The forearm is a critical component that plays a significant role in the overall handling and control of a firearm. Its design not only enhances the aesthetic appeal but also contributes to the stability and comfort during use. A well-crafted forearm allows the user to maintain a secure grip, facilitating better aim and precision while shooting.

Material Selection: The choice of materials in forearm construction greatly affects its durability and weight. Common materials include high-strength polymers and lightweight metals, which provide resilience without compromising maneuverability.

Ergonomic Features: An effective forearm design incorporates ergonomic elements that conform to the user’s hand. Textured surfaces and contoured shapes can improve grip and reduce slippage, especially in adverse conditions.

Attachment Points: Many forearms come with integrated attachment points for accessories such as lights or grips. These features enhance versatility, allowing users to customize their setup according to personal preferences and operational needs.

In summary, the forearm’s design and functionality are pivotal in optimizing the user’s experience with the firearm. A thoughtful design not only ensures comfort and control but also supports the effective use of various accessories, making it an essential aspect of the overall system.

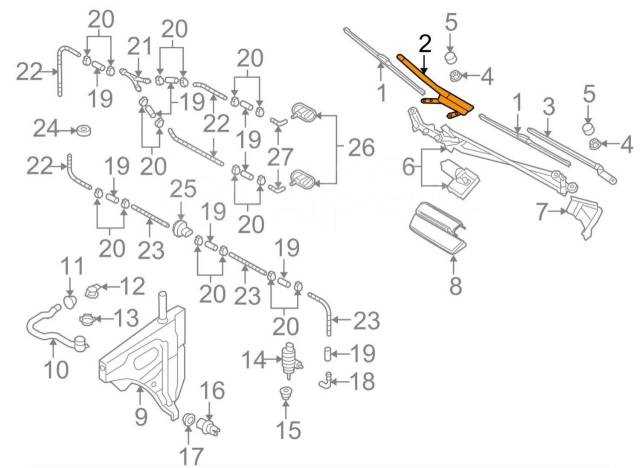

Sight System and Adjustments

The sighting mechanism plays a crucial role in achieving precision and accuracy in shooting. Proper alignment and adjustment of this system are essential for optimal performance, ensuring that the user can effectively target and hit their intended mark.

To maintain the effectiveness of the sighting system, regular checks and adjustments may be necessary. These adjustments can help compensate for environmental factors or any changes in the shooter’s technique. Below is a table summarizing the main components involved in the sighting system and their functions:

| Component |

Function |

| Front Sight |

Helps in aligning the target with the shooter’s eye. |

| Rear Sight |

Provides a reference point for the front sight to ensure accuracy. |

| Windage Adjustment |

Allows lateral adjustments to compensate for wind or drift. |

| Elevation Adjustment |

Enables vertical adjustments to account for distance to the target. |

| Optics |

Enhances visibility and precision in targeting. |

Maintenance Tips for Internal Parts

Proper upkeep of internal components is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances reliability but also minimizes the risk of malfunctions during operation. Understanding the importance of cleanliness and timely inspections can greatly improve the overall functionality of your equipment.

Begin by regularly cleaning the internal mechanisms to prevent the buildup of dirt and debris. Use appropriate cleaning solutions that are safe for the materials involved. Ensure that all moving elements are free of obstruction and can operate smoothly without hindrance.

Lubrication is another critical aspect of maintenance. Applying the right lubricant to the designated areas helps reduce friction and wear, prolonging the life of the components. Be sure to follow the manufacturer’s recommendations for suitable products and application frequencies.

Additionally, conduct routine inspections to identify any signs of wear or damage. Look for unusual noises or changes in performance that could indicate a need for adjustments or replacements. Addressing minor issues promptly can prevent more significant problems in the future.

Lastly, keeping a record of all maintenance activities will aid in tracking performance and identifying patterns that may require attention. This proactive approach to care will ensure that the internal systems function at their best for years to come.

Aftermarket Options for Upgrades

Enhancing firearm performance and customization is a common pursuit among enthusiasts. There are various aftermarket solutions available that cater to different preferences, allowing users to tailor their weapon to meet specific needs and improve functionality.

Enhanced Accessories

Upgrading components can lead to significant improvements in handling and accuracy. Options such as improved sights, ergonomic grips, and adjustable stocks provide a personalized shooting experience. These enhancements can also enhance comfort during prolonged use.

Performance-Boosting Modifications

In addition to accessories, certain modifications can elevate the overall performance of the firearm. Upgrading internal mechanisms or utilizing specialized ammunition can result in better reliability and efficiency. Investing in quality aftermarket products ensures optimal functionality and longevity.