When dealing with complex machinery, a clear representation of its various elements is essential for effective maintenance and repair. This overview highlights the critical aspects of a specific model, enabling users to identify and manage components efficiently.

Knowledge of individual pieces enhances the overall functionality and longevity of your equipment. Recognizing how each part contributes to the operation allows for informed decision-making during servicing and troubleshooting.

By exploring the intricacies of the various elements, operators can ensure that their machinery operates at peak performance. This guide aims to simplify the process, providing clarity and insight into essential components.

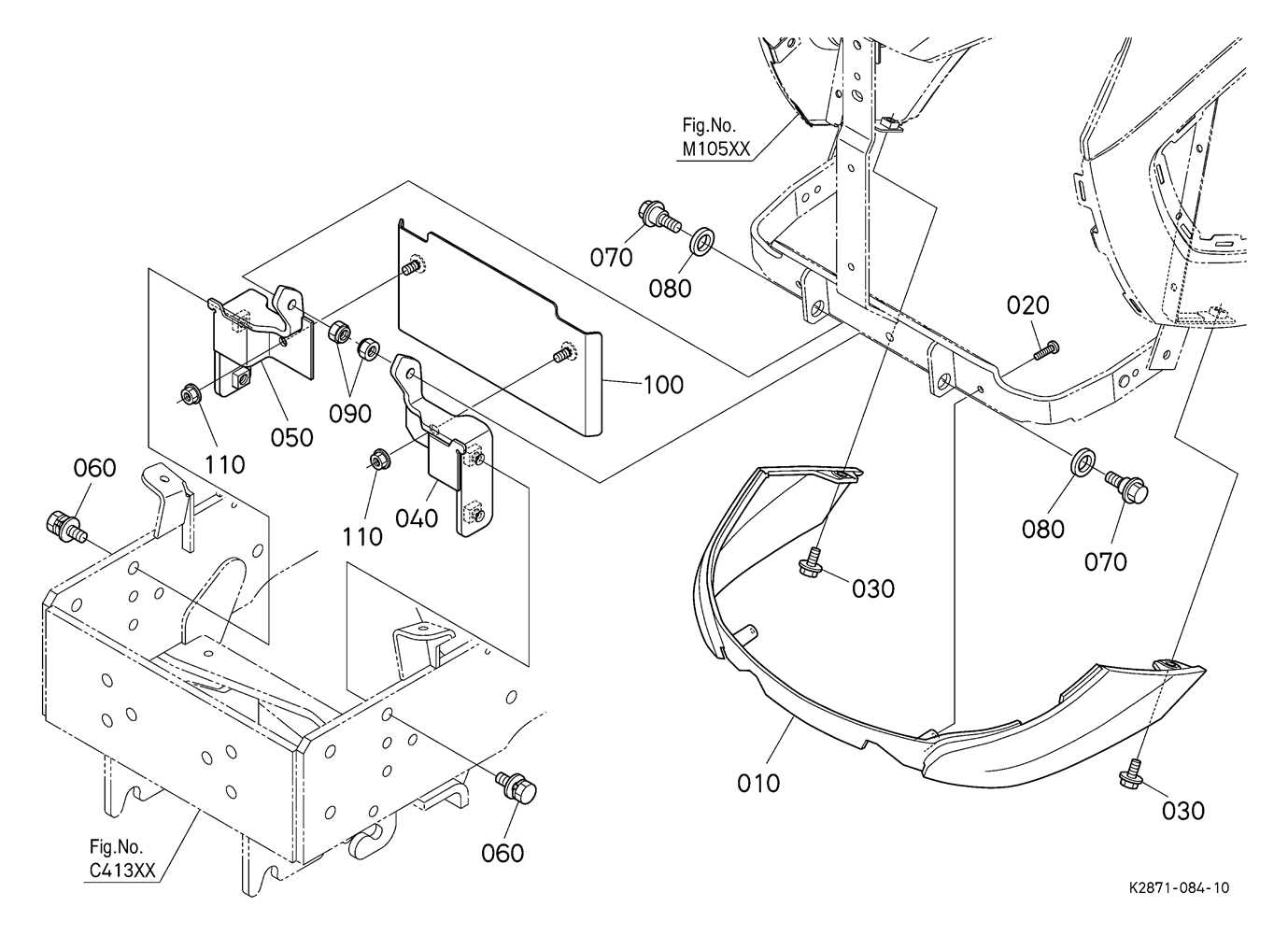

Overview of Component Layout

This section provides an insightful examination of the arrangement and interrelations of various elements in a compact utility machine. Understanding how these components fit together is essential for effective maintenance and troubleshooting, ensuring optimal performance in various tasks.

Importance of Understanding Configuration

Grasping the configuration of each part is crucial for operators and technicians alike. Familiarity with this layout aids in identifying potential issues and streamlining repair processes, ultimately enhancing the machine’s longevity and efficiency.

Exploring the Assembly

Analyzing the assembly reveals how each section contributes to the overall functionality. A well-organized layout not only simplifies repairs but also facilitates upgrades, making it easier to adapt the machine for diverse applications. Comprehensive knowledge of this structure empowers users to maximize their investment and maintain operational excellence.

Key Components of BX23S

This section explores the essential elements that contribute to the functionality and performance of the machine. Understanding these components is crucial for effective maintenance and optimal operation.

| Component | Description |

|---|---|

| Engine | Powerful unit providing the necessary force for operation. |

| Hydraulic System | Facilitates movement and operation of various attachments. |

| Transmission | Transmits power from the engine to the wheels, ensuring smooth operation. |

| Chassis | The structural framework that supports all components. |

| Control Panel | Interface for managing various functions and settings. |

Understanding the Hydraulic System

The hydraulic system is a vital component in many machinery, providing the necessary force and motion to perform various tasks efficiently. This system operates on the principle of fluid mechanics, allowing the transmission of power through pressurized liquid. Understanding its components and functionality is essential for effective maintenance and troubleshooting.

Key Components

Several critical elements work together to form the hydraulic system:

- Hydraulic Pump: Converts mechanical energy into hydraulic energy.

- Hydraulic Fluid: Transmits power and provides lubrication.

- Actuators: Convert hydraulic energy back into mechanical motion.

- Valves: Control the flow and direction of the hydraulic fluid.

Common Functions

This system performs several essential functions, including:

- Powering attachments and implements.

- Facilitating lifting and lowering actions.

- Enabling steering and maneuvering capabilities.

Understanding these elements and their functions will greatly aid in the effective use and maintenance of the machinery’s hydraulic system.

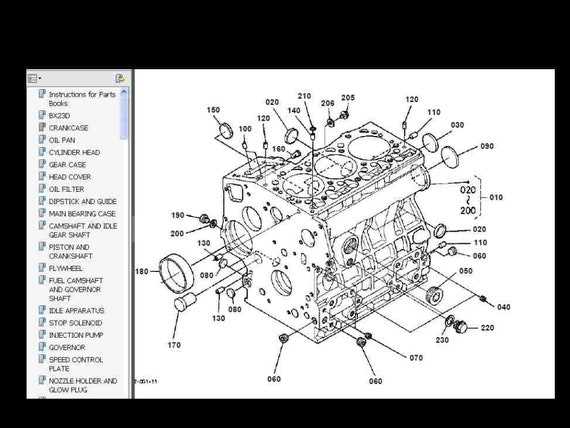

Engine Assembly Details

This section provides an overview of the components and their arrangement within the engine unit. Understanding the assembly is crucial for maintenance and repair tasks, ensuring optimal performance and longevity of the machine.

Key Components

- Crankshaft: Central to the engine’s operation, it converts linear motion into rotational motion.

- Piston: Moves within the cylinder, generating power through combustion.

- Connecting Rod: Links the piston to the crankshaft, facilitating movement transfer.

- Cylinder Head: Houses the combustion chamber and contains valves for air and fuel intake.

- Oil Pump: Circulates lubricant throughout the engine to minimize friction.

Assembly Process

- Begin by securing the crankshaft in the engine block.

- Attach the connecting rod to the piston, ensuring proper alignment.

- Insert the piston into the cylinder, followed by the installation of the cylinder head.

- Connect the oil pump to the designated port for optimal lubrication.

- Perform a final inspection to ensure all components are correctly positioned and secured.

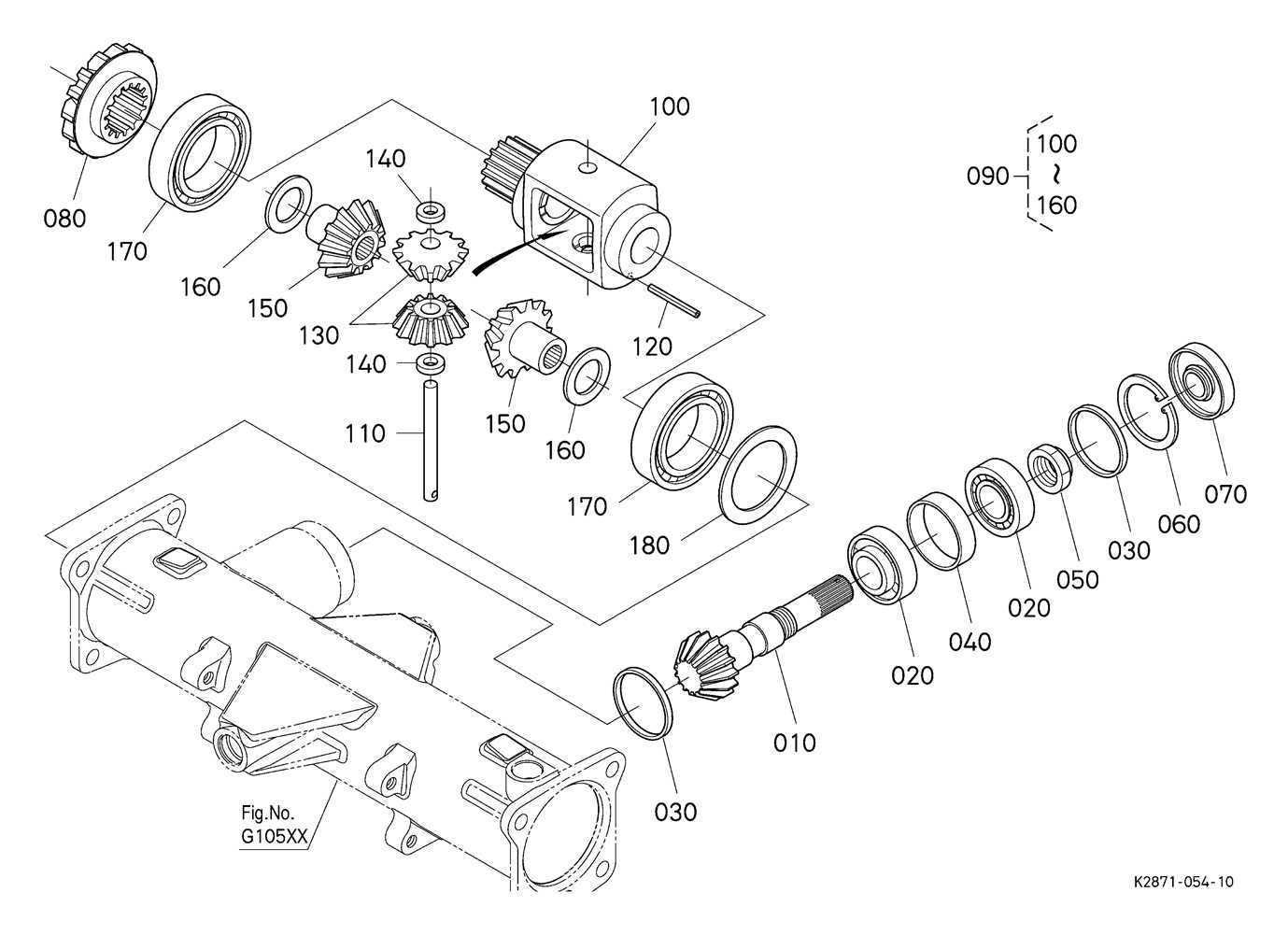

Transmission and Drive Parts

The efficiency of any machinery heavily relies on its transmission and drive components, which play a crucial role in power transfer and performance. Understanding the arrangement and function of these elements can greatly enhance maintenance and operational knowledge.

Key components include gears, belts, and axles, each contributing to the overall effectiveness of the system. Gears facilitate the appropriate speed and torque adjustment, while belts provide flexibility and dampening between different parts. Axles support the weight and enable the movement of the machine, ensuring a smooth operation.

Regular inspection of these components is essential for preventing potential failures. Identifying wear and tear early can significantly reduce repair costs and downtime. Proper lubrication and alignment are also vital practices to maintain the longevity and efficiency of the drive system.

Electrical System Layout

This section provides an overview of the arrangement and functionality of the electrical components in a compact utility vehicle. Understanding this layout is crucial for efficient troubleshooting and maintenance.

The electrical system comprises several key elements that work together to ensure optimal performance:

- Power Source: The battery supplies energy to all electrical components.

- Wiring Harness: A network of wires connects different parts, facilitating communication and power distribution.

- Control Units: These units manage various functions, from starting the engine to controlling lights and attachments.

Regular inspection of these components is essential to identify any potential issues. Below are some maintenance tips:

- Check for any frayed or damaged wires.

- Ensure connections are clean and secure.

- Test the battery regularly to confirm its charge capacity.

By maintaining a clear understanding of the electrical system layout, operators can enhance the longevity and reliability of their vehicle.

Chassis and Frame Components

The foundation of any vehicle is crucial for its stability and performance. In this section, we will explore the essential elements that constitute the undercarriage and structural framework of a compact machine. Understanding these components is vital for ensuring optimal operation and longevity.

Key elements of the chassis and frame include:

- Main Frame: The primary structure providing support and rigidity.

- Subframe: Auxiliary framework that helps distribute weight and enhance stability.

- Cross Members: Horizontal supports that maintain the integrity of the main frame.

- Mounting Brackets: Connectors that secure various components to the chassis.

- Rear Axle Housing: A critical component that houses the axle and facilitates movement.

- Transmission Mounts: Supports that secure the transmission and reduce vibrations.

Each of these components plays a pivotal role in the overall functionality and durability of the equipment. Regular maintenance and inspection of these parts are recommended to prevent wear and ensure safe operation.

Implement Attachments Explained

Understanding various implements is essential for enhancing the functionality of compact machinery. These attachments enable operators to perform a wide range of tasks, from digging and lifting to grading and moving materials.

Each implement serves a specific purpose, allowing for increased versatility and efficiency in various applications. For instance, a loader attachment can simplify material handling, while a backhoe provides exceptional digging capabilities. Adapting the right tool to the job can significantly improve productivity.

When selecting implements, consider factors such as compatibility, weight distribution, and operational requirements. Properly matched attachments not only optimize performance but also ensure safety during operation. Investing in quality implements can lead to long-term benefits and enhanced capabilities for your machinery.

Maintenance Parts and Accessories

Ensuring optimal performance of machinery involves regular upkeep and the use of suitable components. The right accessories play a crucial role in enhancing functionality and extending the lifespan of equipment.

To maintain efficiency, consider the following essential items:

- Filters: Regular replacement of air and oil filters is vital for smooth operation.

- Batteries: High-quality batteries are necessary for reliable starting and operation.

- Fluids: Utilizing appropriate lubricants and coolants prevents overheating and wear.

- Belt systems: Inspecting and replacing belts ensures proper power transmission.

- Lighting: Upgrading lighting improves visibility and safety during operation.

Additionally, the following accessories can enhance performance:

- Attachments: Various implements can increase versatility for different tasks.

- Tool kits: A comprehensive set of tools aids in timely repairs and adjustments.

- Protective covers: Using covers safeguards against environmental elements.

Regular attention to these components not only promotes longevity but also ensures efficient operation, ultimately leading to better productivity.

Fuel System Breakdown

The fuel system is a crucial component that ensures optimal performance and efficiency of the machinery. Understanding its various elements helps in maintaining and troubleshooting potential issues effectively.

Key Components: The fuel system typically comprises a fuel tank, filter, pump, and injectors. Each part plays a significant role in delivering the necessary fuel to the engine, ensuring smooth operation.

Maintenance Tips: Regular inspection of the fuel filter and tank can prevent clogging and contamination. Additionally, ensuring proper fuel quality is essential for the longevity of the system.

Cooling System Components

The cooling system plays a vital role in maintaining optimal operating temperatures within the machinery. This system ensures that excessive heat generated during operation is effectively dissipated, preventing overheating and potential damage to engine components.

Key elements of this system include:

- Radiator: A crucial component that dissipates heat from the coolant, allowing it to cool before recirculating through the engine.

- Water Pump: This component circulates the coolant throughout the system, ensuring an efficient flow and heat exchange.

- Thermostat: A device that regulates the temperature of the coolant, maintaining it within a specific range for optimal performance.

- Cooling Hoses: Flexible conduits that transport the coolant between various components of the cooling system.

Understanding these components helps in maintaining the efficiency and longevity of the machinery, allowing for effective troubleshooting and replacement when necessary.

Wheels and Tire Specifications

This section provides an overview of the essential characteristics and requirements for the rolling components of compact machinery. Understanding these specifications is crucial for optimal performance and safety during operation.

Wheel Dimensions

The dimensions of the wheels play a significant role in the overall functionality of the equipment. Key factors include:

- Diameter: Typically measured in inches, it affects ground clearance and stability.

- Width: Influences traction and load distribution.

- Offset: Determines the alignment and spacing from the machine’s chassis.

Tire Specifications

Tires are critical for ensuring grip and maneuverability. The following specifications should be considered:

- Tread Pattern: Impacts traction on various surfaces, such as mud, grass, or gravel.

- Load Rating: Indicates the maximum weight the tires can support safely.

- Inflation Pressure: Essential for maintaining proper performance and wear characteristics.

Choosing the Right Components

Selecting appropriate wheels and tires is vital for enhancing the machine’s efficiency. When making a choice, consider:

- Intended Use: Identify the primary tasks to ensure the right grip and durability.

- Surface Conditions: Analyze the terrain type to select suitable tread designs.

- Manufacturer Recommendations: Always refer to guidelines for optimal compatibility.

Safety Features and Equipment

Ensuring the highest level of safety while operating machinery is paramount. Various mechanisms and tools are designed to protect users from potential hazards and enhance overall operational security. Understanding these features is crucial for maintaining a safe working environment.

Essential Safety Mechanisms

Modern equipment incorporates several essential safety mechanisms, including:

- Emergency Stop Systems: These systems allow for immediate halting of operations in case of unexpected situations.

- Guarding Structures: Protective barriers are strategically placed to prevent access to moving parts, minimizing the risk of injury.

- Stability Control: Features that enhance the machine’s balance, ensuring stability during operation on various terrains.

Personal Protective Equipment

The use of personal protective equipment (PPE) is equally important. Operators should always wear:

- Helmets to protect against falling objects.

- Gloves to prevent injuries from sharp edges or rough surfaces.

- Steel-toed boots to safeguard feet from heavy loads.