Line Feed Mechanism: This system controls how

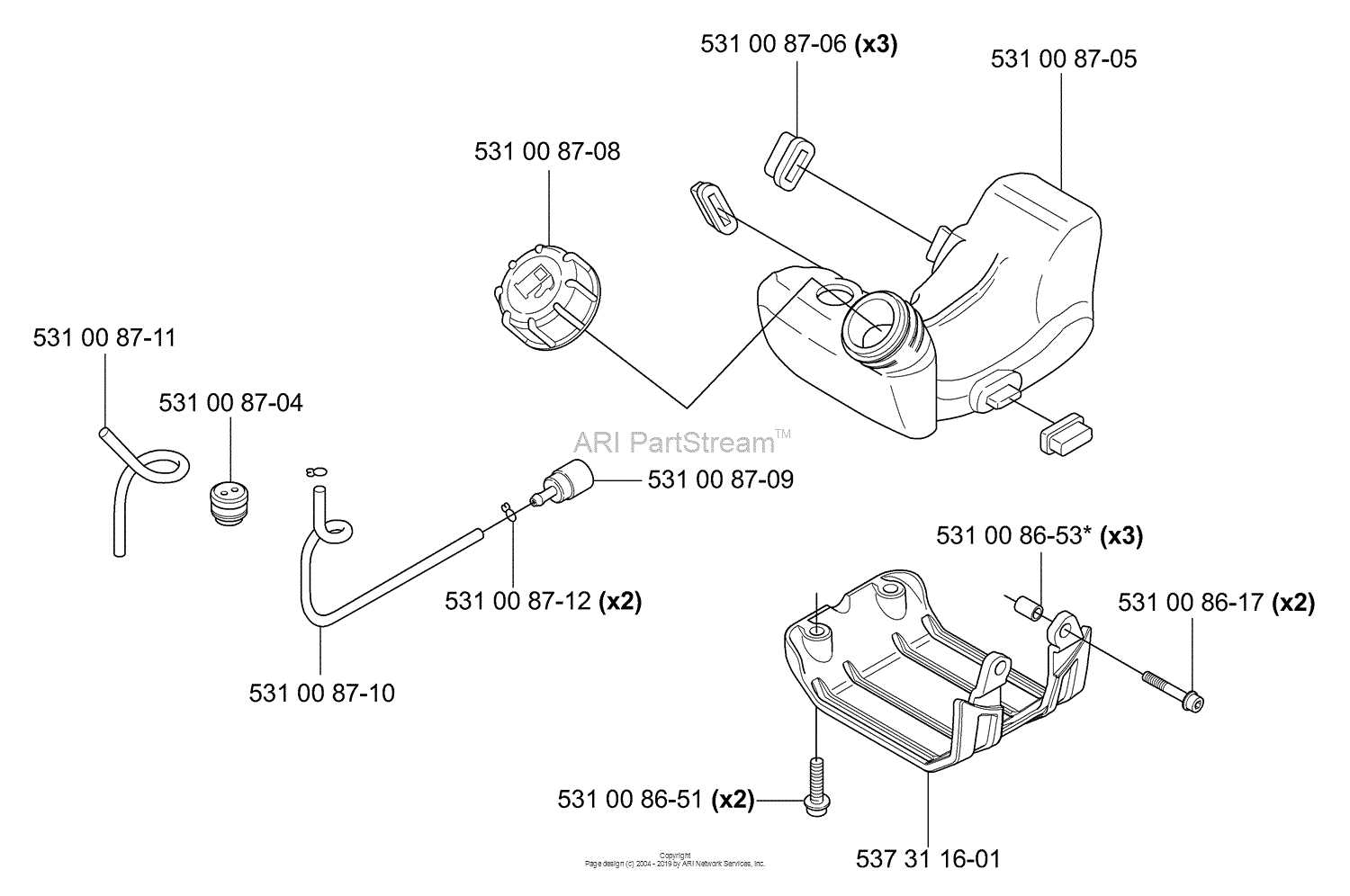

Throttle and Control Cable Diagram

This section provides an overview of the components related to the throttle and control cables, which are crucial for the proper functioning of various outdoor equipment. Understanding the arrangement and connection of these elements can enhance maintenance and repair efforts, ensuring optimal performance.

Key Components

The main elements involved in the throttle and control system include the cables, levers, and attachment points. Each part plays a specific role in regulating engine speed and operational control. The cables connect the control levers to the throttle mechanism, allowing for smooth adjustments while in use.

Installation and Maintenance Tips

When handling the cables, it’s important to check for wear and ensure they are properly aligned and secured. Regular inspections can prevent potential issues and enhance the longevity of the components. If any part shows signs of damage, timely replacement is recommended to maintain effective functionality.

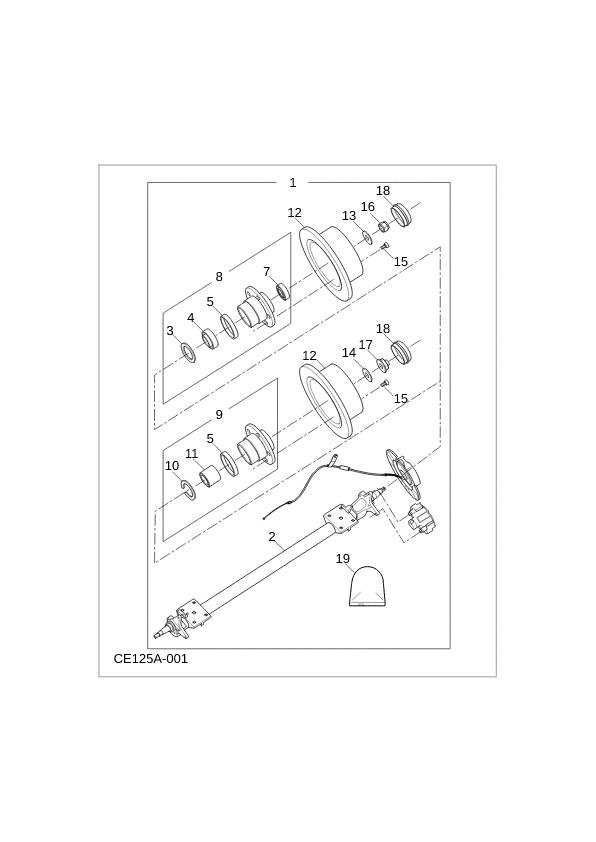

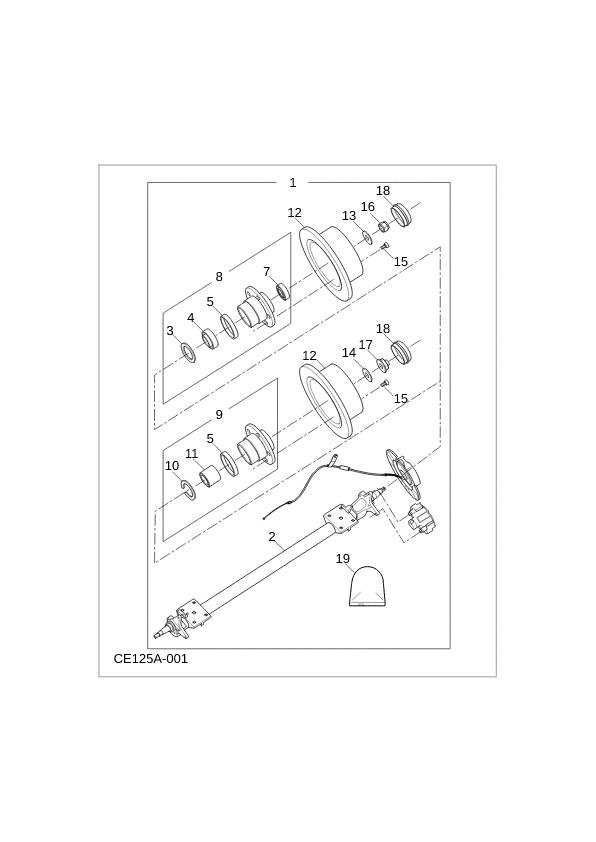

Drive Shaft Assembly and Operation

The drive shaft is a crucial component in various machines, facilitating the transfer of power from the engine to the cutting mechanism. Understanding its structure and functionality can enhance maintenance and operational efficiency. This section delves into the assembly of the drive shaft and its role in the overall performance of the equipment.

Assembly Components

The drive shaft assembly typically comprises several key elements, including the shaft itself, couplings, and bearing supports. Each part works together to ensure smooth rotation and power transmission. Proper alignment and secure fastening of these components are essential to avoid vibrations and premature wear. Regular inspections can help identify potential issues before they escalate.

Operational Mechanics

During operation, the drive shaft rotates, converting engine output into mechanical energy that drives the cutting head. This process involves a series of rotational forces that must be balanced to maintain optimal performance. Understanding the dynamics of how the drive shaft interacts with other components is vital for troubleshooting and enhancing the lifespan of the machine. Regular maintenance, such as lubricating bearings and checking for misalignments, can significantly improve efficiency and reliability.

Ignition System Parts and Connections

The ignition system plays a crucial role in ensuring the proper functioning of outdoor equipment. It consists of several components that work together to generate the spark necessary for engine operation. Understanding the connections and arrangement of these elements can aid in effective maintenance and troubleshooting.

Key Components

At the heart of the ignition system is the coil, which converts the battery’s low voltage into a high-voltage spark. This spark ignites the fuel-air mixture within the engine. Other vital elements include the spark plug, responsible for delivering the ignition spark, and the magneto, which generates electrical current. Each component is interconnected, forming a circuit that enables efficient ignition.

Connection Overview

Connections within the ignition assembly are critical for reliable performance. Wires link the coil to the spark plug, ensuring that the generated spark reaches the combustion chamber. Additionally, the magneto is typically connected to the ignition coil, creating a self-sustaining power source. Proper alignment and secure connections are essential to prevent misfires and ensure optimal engine operation.

Handlebar and Grip Components

The handlebar and grip elements are essential for maintaining control and comfort while using outdoor power tools. These components play a crucial role in the overall usability and maneuverability of the equipment. Understanding their construction and function can help users ensure proper maintenance and replacement when needed.

Construction and Materials

The structure of the handlebar typically consists of durable materials that provide strength and resistance to wear. Commonly used materials include various metals and high-quality plastics, which are designed to withstand environmental factors. Grips, on the other hand, are often made from rubber or foam to enhance comfort and reduce fatigue during extended use.

Functionality and Adjustments

These components not only facilitate steering but also house various controls that manage the operation of the equipment. Adjustments to the handlebar height and angle can significantly improve ergonomics, allowing users to customize their experience for optimal performance. Regular inspection of these elements is vital to ensure safety and efficiency during operation.

Clutch System Design and Purpose

The clutch system is a critical component in many mechanical devices, serving as a link between the engine and the driven parts. Its primary role is to engage and disengage power transmission, allowing for smooth operation and control. Understanding its design and functionality is essential for maintaining performance and efficiency.

This system typically consists of several key elements, each contributing to its overall effectiveness:

- Clutch Plate: This element provides the surface for engagement and disengagement, transferring power when engaged.

- Spring Mechanism: Springs are vital for maintaining tension, ensuring that the clutch plates remain in contact when necessary and separate when not.

- Lever Assembly: This component allows the operator to control the clutch, offering the ability to engage or disengage easily.

- Housing: The outer casing protects the internal components and ensures proper alignment during operation.

The design of the clutch system ensures that it can handle various operational demands while maintaining reliability. Proper adjustment and maintenance of these components are crucial for optimal performance, allowing for efficient power transfer and enhancing the overall functionality of the machine.

Muffler and Exhaust System Structure

The exhaust system is a critical component of any engine, serving to direct and manage the flow of gases produced during combustion. Its design not only enhances performance but also plays a vital role in minimizing noise and emissions, ensuring compliance with environmental standards.

At its core, the exhaust system typically consists of several key elements:

- Muffler: This component is designed to reduce the sound produced by the engine. It accomplishes this by using a series of chambers and baffles that disrupt the flow of exhaust gases.

- Exhaust Pipes: These tubes channel the gases from the engine to the muffler and then to the outside atmosphere. They must be designed to withstand high temperatures and corrosive elements.

- Headers: Often the first point of exhaust gas exit, headers optimize the flow of gases from the engine cylinders, enhancing efficiency and performance.

- Catalytic Converter: This essential part reduces harmful emissions by converting toxic gases into less harmful substances before they exit the exhaust system.

Overall, the assembly of these components contributes to the effective functioning of the exhaust system, promoting engine efficiency and reducing environmental impact.