In the realm of agricultural equipment, having a clear grasp of the various elements that contribute to machinery functionality is crucial. Knowledge of these components not only enhances maintenance practices but also aids in the efficient operation of these machines. A comprehensive overview of each section can significantly improve the performance and longevity of the equipment.

Exploring the intricate layout of these essential items provides valuable insights into their interrelations and individual roles. Recognizing the significance of each part empowers operators to make informed decisions during repairs or upgrades. Furthermore, a detailed representation serves as a reliable reference, ensuring that the machinery runs smoothly and effectively.

By familiarizing oneself with the layout and function of these elements, one can optimize machinery performance and troubleshoot issues with confidence. The exploration of such diagrams fosters a deeper understanding of the equipment, ultimately leading to enhanced productivity and reduced downtime.

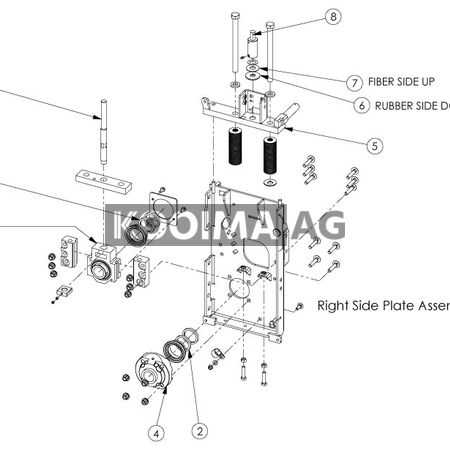

Precision in visual representations is crucial for effective understanding and maintenance of machinery. These illustrations serve as essential tools that aid users in identifying components, understanding assembly, and facilitating repairs.

Accurate visuals provide numerous advantages, including:

- Clarity: Clear representations help in the quick identification of specific elements.

- Efficiency: Users can save time during maintenance or repairs by having detailed visuals at hand.

- Reduced Errors: Precise illustrations minimize the likelihood of mistakes, leading to better outcomes.

- Training Aid: These visuals are invaluable in training new personnel, ensuring they understand the machinery layout.

In summary, the role of precise illustrations extends beyond mere representation; they are vital in enhancing understanding, efficiency, and overall operational effectiveness.

Identifying Common Replacement Parts

Understanding the various components of heavy machinery is essential for effective maintenance and repair. Familiarity with the common elements that may require substitution helps in ensuring optimal performance and longevity of the equipment. This section will guide you in recognizing these key components, their functions, and how to identify when they need replacement.

Key Components to Monitor

Among the most crucial elements to observe are the hydraulic systems, filters, and belts. These components play significant roles in the overall operation and efficiency of the machinery. Regular inspections can help detect wear and tear, ensuring timely replacements are made.

Signs of Wear and Necessary Actions

Common indicators of wear include unusual noises, decreased performance, or visible damage. Addressing these signs promptly by replacing affected components can prevent further complications. Keeping a record of maintenance and replacements can also aid in tracking the condition of the machinery over time.

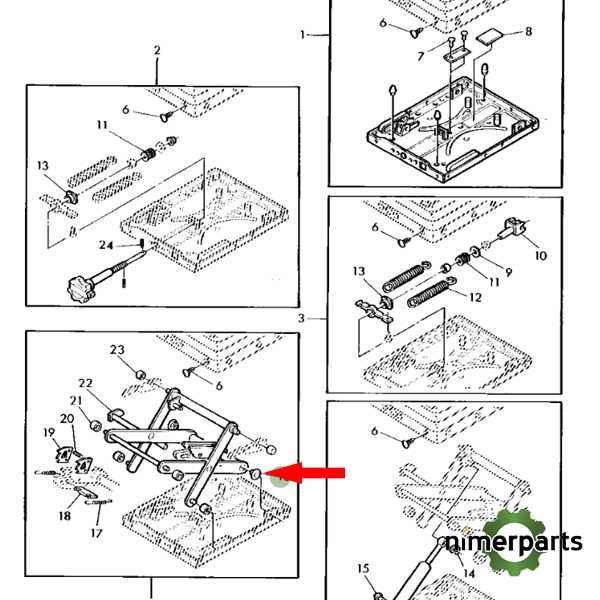

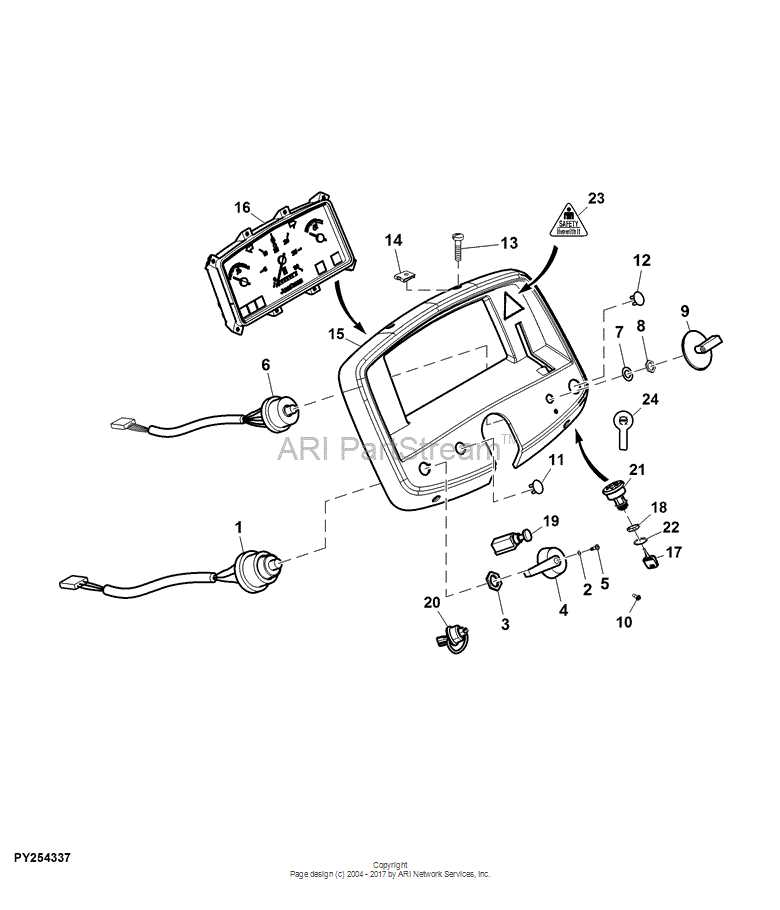

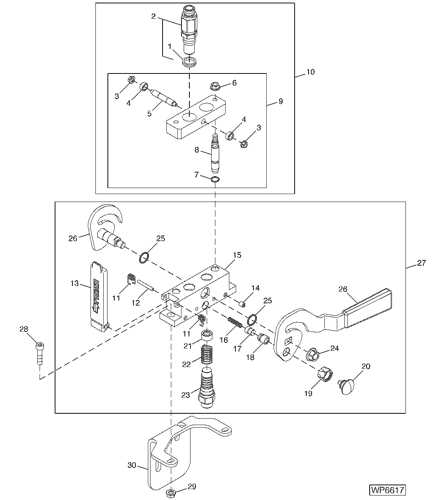

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repairs of machinery. These visual representations provide essential information about components, their relationships, and the overall structure of the equipment. Familiarity with these visuals can streamline troubleshooting and parts identification, ultimately enhancing efficiency in maintenance tasks.

To begin, it is important to recognize the various symbols and labels used in these illustrations. Each element typically corresponds to a specific component, often accompanied by a reference number. Studying the key or legend provided can help decipher the meaning behind these symbols, enabling users to identify individual pieces accurately.

Additionally, observing the arrangement of components can provide insight into how they interact within the system. Pay attention to the layout, as it often indicates the order of assembly or disassembly. Understanding this sequence can prevent mistakes during repairs and ensure proper reassembly. Taking the time to familiarize oneself with these visuals can lead to more successful maintenance outcomes and a better grasp of the machinery’s inner workings.

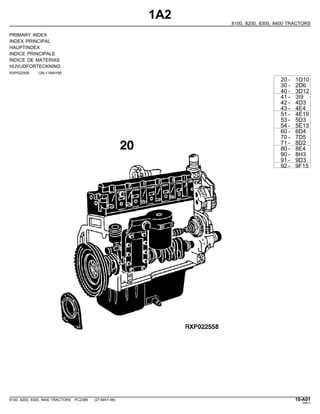

Visual Guide to Engine Components

Understanding the various elements of an engine is crucial for effective maintenance and troubleshooting. This section provides a comprehensive overview of the key components found within a typical power unit, highlighting their functions and significance.

Engines consist of several essential parts, each playing a vital role in overall performance. Familiarity with these components can aid in recognizing issues and optimizing functionality.

- Cylinder Block: The main structure housing the cylinders, providing support for various components.

- Pistons: Moving elements within the cylinders that convert fuel energy into mechanical power.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, driving the vehicle.

- Camshaft: Controls the timing of valve openings and closings, essential for engine efficiency.

- Valves: Regulate the intake of air and fuel, as well as the expulsion of exhaust gases.

- Timing Belt/Chain: Synchronizes the movement of the crankshaft and camshaft to ensure proper operation.

By familiarizing yourself with these components, you can better understand how an engine operates and maintain its optimal performance.

Transmission and Drive System Components

The transmission and drive system of agricultural machinery play a crucial role in ensuring efficient operation and effective power transfer. Understanding the components involved in this system is essential for maintaining optimal performance and addressing any potential issues that may arise during usage. This section outlines the key elements that contribute to the seamless functionality of the transmission and drive systems in heavy equipment.

| Component | Description |

|---|---|

| Gearbox | A mechanical device that alters the speed and torque of the engine output, enabling the vehicle to adapt to various tasks. |

| Clutch | Facilitates the engagement and disengagement of the engine from the drive system, allowing for smooth transitions between gears. |

| Driveshaft | Transfers rotational power from the engine to the wheels, ensuring that the vehicle moves effectively. |

| Torque Converter | Enhances the efficiency of the transmission by multiplying engine torque, especially during acceleration. |

| Axles | Support the vehicle’s weight and facilitate the movement of wheels, playing a vital role in stability and control. |

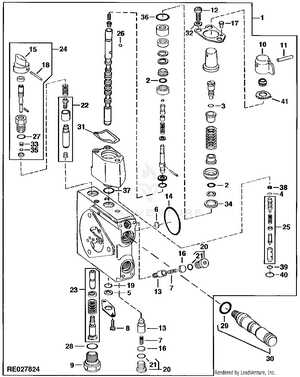

Hydraulic System Components Explained

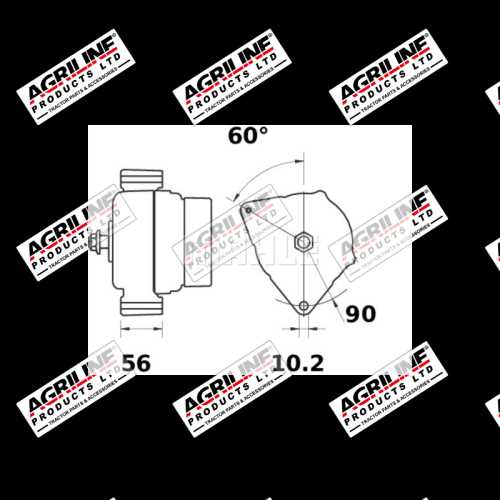

The hydraulic system plays a crucial role in the operation of heavy machinery, providing the necessary force and control for various functions. Understanding the components involved in this system is essential for effective maintenance and troubleshooting.

Key components of hydraulic systems include:

- Pumps: These devices convert mechanical energy into hydraulic energy, generating fluid flow to power the system.

- Actuators: Responsible for converting hydraulic energy back into mechanical energy, allowing movement or operation of different parts.

- Valves: Control the direction and flow of hydraulic fluid, ensuring that the system operates efficiently and safely.

- Hoses and Tubes: These convey hydraulic fluid between components, maintaining the necessary pressure for effective system performance.

- Reservoirs: Store hydraulic fluid, providing a supply for the system and helping to dissipate heat generated during operation.

Each component serves a specific purpose, contributing to the overall functionality of the hydraulic system. Regular inspection and maintenance of these parts are vital for ensuring optimal performance and longevity.

Electrical System Overview

The electrical framework of modern agricultural machinery plays a crucial role in ensuring efficient operation and functionality. This intricate network is responsible for powering various components, including lighting, ignition, and essential control systems. Understanding the structure and flow of electricity within this system is vital for effective troubleshooting and maintenance.

The components within the electrical system can be categorized into several key sections. Power generation is typically handled by the alternator, which converts mechanical energy into electrical energy, ensuring that the battery remains charged and operational. Wiring harnesses distribute electrical power to various systems, connecting essential parts and enabling communication between them.

Additionally, fuses and relays serve protective functions, safeguarding sensitive components from overloads and ensuring that power is directed appropriately. Understanding the role of each element within this system allows for better maintenance practices and enhances the overall reliability of the equipment. Regular checks and diagnostics can prevent unexpected failures and prolong the lifespan of critical machinery.

Maintenance Tips for Long-Lasting Parts

Ensuring the longevity of machinery components requires regular care and attention. Adopting preventive measures can significantly enhance the lifespan of various elements, reducing the need for frequent replacements and improving overall performance.

Here are some essential practices to consider for maintaining machinery components:

- Regular Inspections: Conduct routine checks to identify any wear or damage early.

- Proper Lubrication: Use appropriate lubricants to minimize friction and prevent premature wear.

- Cleanliness: Keep all components free of dirt and debris to ensure optimal functioning.

- Timely Replacements: Replace worn-out items promptly to avoid further damage to other elements.

- Storage Conditions: Store components in a dry and safe environment to prevent corrosion and deterioration.

Implementing these strategies will help maintain the functionality and efficiency of your machinery, ensuring that all components serve you well over time.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for maintaining optimal performance and longevity. There are several reliable sources that ensure you receive high-quality replacements suited for your specific model. Consider the following options:

- Authorized Dealers: Official dealerships are often the best option for sourcing genuine items. They typically carry a comprehensive inventory and can provide expert advice.

- Manufacturer Websites: Visiting the official website of the equipment manufacturer can lead you to a dedicated section for replacement components, often with detailed information about compatibility.

- Online Marketplaces: Reputable e-commerce platforms frequently offer genuine items from trusted sellers. Look for products that have verified reviews to ensure authenticity.

- Local Repair Shops: Many local service centers specialize in specific brands and may stock or order original components. They can also provide installation services if needed.

Ensuring that you source genuine replacements not only enhances the performance of your machinery but also preserves its value over time. Investing in authentic components is a wise choice for any operator.

Resources for Further Learning

For those seeking to expand their knowledge and expertise in machinery maintenance and repair, various resources are available. These materials can provide valuable insights into equipment functionality, troubleshooting techniques, and component replacement strategies.

Books and Manuals

Several comprehensive books and manuals focus on machinery upkeep and operational efficiency. These resources often include detailed explanations and illustrations, making them accessible for both beginners and experienced technicians.

Online Courses and Webinars

Numerous online platforms offer courses and webinars tailored to machinery operation and maintenance. These interactive learning opportunities allow participants to engage with experts and gain practical knowledge.

| Resource Type | Examples |

|---|---|

| Books | Maintenance Basics, Equipment Repair Techniques |

| Online Courses | Machinery Operation 101, Advanced Repair Strategies |

| Webinars | Expert Talks on Equipment Efficiency |