The functionality and safety of any vehicle heavily rely on the efficiency of its stopping mechanism. Understanding the intricate elements that contribute to this system is essential for both enthusiasts and professionals alike. This section delves into the various components that play a critical role in ensuring effective deceleration and stability during operation.

Each element within this system serves a distinct purpose, working harmoniously to provide reliable performance. From the initial engagement to the final halt, these components interact seamlessly, showcasing the complexity and engineering behind modern automotive design. A comprehensive overview will enhance your knowledge and appreciation of how these mechanisms function together.

In exploring the different elements, we aim to clarify their roles and significance. This understanding not only assists in maintenance and troubleshooting but also contributes to informed decisions regarding upgrades and modifications. By examining these components, readers can gain insights into optimizing the overall performance and safety of their vehicles.

Overview of Rear Brake Components

The mechanisms responsible for deceleration play a crucial role in vehicle safety and performance. Understanding these essential elements is vital for effective maintenance and troubleshooting. This section aims to provide a comprehensive look at the various components that contribute to the overall functionality of the stopping system at the back of a vehicle.

Key Elements in the Stopping Mechanism

Several critical elements work in unison to ensure effective deceleration. These include devices that facilitate friction and energy transfer, ensuring that the vehicle slows down efficiently. Additionally, various supportive structures are involved, aiding in the distribution of force and enhancing overall stability during operation.

Importance of Regular Inspection

Frequent examination of these components is essential for maintaining optimal performance. Regular checks can prevent premature wear and potential failure, contributing to a safer driving experience. Understanding the signs of wear or malfunction can help in timely repairs and ensure reliable operation over time.

Functionality of Brake Parts

This section explores the essential components involved in the deceleration system of a vehicle, highlighting their roles in ensuring safe and effective stopping power.

Key Components

- Calipers: These elements exert pressure on the friction material, enabling the slowing of the wheel.

- Friction Material: This surface is crucial for creating the necessary grip to halt motion.

- Rotors: These circular components provide a surface for the calipers to press against, facilitating the stopping process.

- Master Cylinder: This device generates hydraulic pressure to engage the stopping mechanism when the pedal is pressed.

Working Mechanism

- The driver applies force to the pedal.

- The master cylinder generates hydraulic pressure.

- The calipers engage the friction material against the rotors.

- Friction between the surfaces slows the rotation of the wheels.

Common Types of Rear Brakes

This section explores the various configurations utilized for the stopping mechanism at the back of vehicles. Different designs serve unique functions and contribute to overall performance and safety.

Understanding these configurations can help in identifying their advantages and applications in different types of automobiles.

| Type | Description | Advantages |

|---|---|---|

| Drum | Utilizes a cylindrical design where shoes press against the inner surface to create friction. | Typically more affordable and effective in certain driving conditions. |

| Disc | Features a flat disc that is squeezed by pads to generate stopping force. | Offers superior heat dissipation and consistent performance under stress. |

| Integrated | A combination of both drum and disc mechanisms in a single assembly. | Provides versatility and enhanced efficiency for various driving styles. |

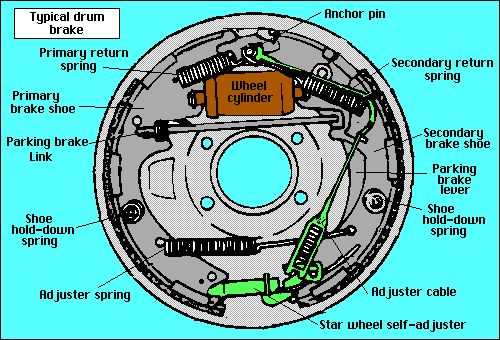

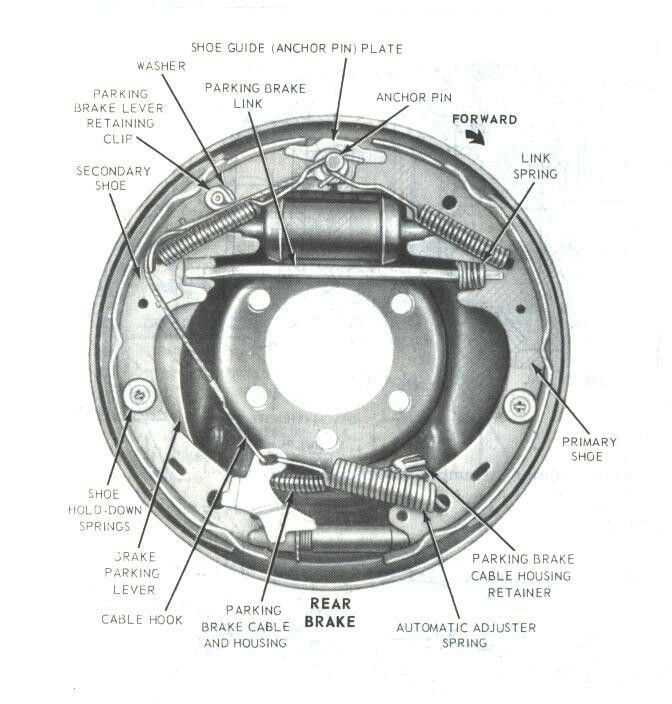

Understanding Brake Diagrams

Comprehending visual representations of stopping mechanisms is essential for anyone involved in vehicle maintenance or repair. These illustrations offer insights into the components and their interrelationships, aiding in troubleshooting and enhancement of performance.

Analyzing these visuals can reveal crucial information about how various elements function together. By breaking down the schematic, one can identify critical components, their placements, and the flow of energy within the system.

Moreover, gaining familiarity with these representations empowers individuals to execute repairs more effectively. A thorough understanding fosters confidence in diagnosing issues, ensuring that every element is operating optimally.

Maintenance Tips for Brake Systems

Ensuring the longevity and reliability of your stopping mechanisms is essential for vehicle safety. Regular attention to various components can significantly enhance performance and prevent costly repairs. Here are some fundamental practices to maintain these critical systems.

| Tip | Description |

|---|---|

| Regular Inspections | Frequent checks can identify wear and tear before they become serious issues. |

| Fluid Replacement | Changing the hydraulic fluid periodically helps maintain optimal function. |

| Clean Components | Keeping all elements free from debris ensures smooth operation and reduces friction. |

| Monitor Performance | Pay attention to any changes in responsiveness or unusual noises during use. |

| Professional Servicing | Having a qualified technician perform maintenance can catch hidden issues. |

Diagnosing Brake Issues

Identifying problems within the stopping mechanism is crucial for maintaining vehicle safety. Symptoms such as unusual noises or diminished responsiveness can indicate underlying issues that require immediate attention. Understanding these signs can help in effectively troubleshooting and ensuring optimal functionality.

Common indicators to look for include vibrations during operation, squeaking sounds, or a soft pedal feel. Each of these may suggest specific malfunctions that need to be addressed. Regular checks can prevent further complications and ensure a safe driving experience.

In some cases, visual inspections of the system may reveal wear or damage. It is essential to assess components thoroughly to determine the root cause of the problem, thereby facilitating appropriate repairs and replacements.

Importance of Quality Brake Parts

Ensuring safety in any vehicle largely depends on the components that manage deceleration. High-quality elements are crucial for maintaining optimal performance and preventing potential hazards on the road. The reliability of these components directly affects driving stability and overall security.

Investing in superior components can lead to enhanced longevity and better functionality. Quality materials and craftsmanship contribute to effective operation, reducing the likelihood of unexpected failures. Below is a comparison of various types of components and their impact on performance.

| Component Type | Quality Impact |

|---|---|

| Standard | Shorter lifespan, less efficiency |

| Premium | Longer lifespan, improved efficiency |

| Aftermarket | Variable quality, potential risks |

Choosing high-grade components not only ensures better performance but also enhances the overall driving experience. Prioritizing quality over cost can save money in the long run by reducing maintenance and replacement needs.

Upgrading Rear Brake Systems

Enhancing the stopping mechanism of your vehicle can significantly improve safety and performance. This section discusses various methods to enhance the functionality and reliability of the stopping components, focusing on modern advancements and best practices.

Benefits of Enhanced Systems

Upgrading the stopping components offers numerous advantages, including improved response times, increased longevity, and better heat dissipation. These enhancements can lead to a more enjoyable driving experience, especially in demanding conditions.

Components to Consider

When contemplating upgrades, several elements should be evaluated to ensure optimal performance. Here are the key components to consider:

| Component | Description | Benefits |

|---|---|---|

| Pads | Friction material that engages with the rotor. | Improved stopping power and reduced fade. |

| Rotors | Disc that the pads clamp down on to create friction. | Increased durability and better heat management. |

| Calipers | Holds the pads and applies pressure to the rotor. | Enhanced responsiveness and modulation. |

Brake Fluid and Its Role

This section explores the essential fluid that plays a crucial role in the functionality of stopping mechanisms in vehicles. Its primary purpose is to transfer force from the pedal to the stopping components, ensuring effective deceleration and safety during operation.

The significance of this fluid extends beyond mere functionality; it also contributes to the overall performance and reliability of the entire system. Key aspects to consider include:

- Hydraulic Properties: The fluid must possess the ability to transmit force effectively under varying conditions.

- Temperature Resistance: High-temperature stability is crucial to prevent vaporization during intense usage.

- Corrosion Prevention: The formulation should safeguard against rust and damage to internal components.

Understanding the characteristics and maintenance of this vital fluid can enhance the longevity and efficiency of stopping systems, promoting safer driving experiences.

Installation Process for Rear Brakes

This section outlines the essential steps involved in fitting the components necessary for effective stopping mechanisms on the rear axle. Proper installation ensures safety and optimal performance during operation.

Preparation Steps

- Gather all necessary tools and materials.

- Ensure the vehicle is on a stable surface and securely lifted.

- Remove any obstructions that may hinder access to the area.

Installation Steps

- Detach the existing components carefully to avoid damage.

- Inspect the new items for defects or irregularities.

- Align the new components with the mounting points.

- Securely fasten all connections, ensuring they are tightened to the manufacturer’s specifications.

- Reassemble any removed parts and lower the vehicle.

After installation, perform a thorough check to confirm everything is functioning correctly. Regular maintenance will prolong the lifespan of these components and enhance overall safety.

Safety Considerations When Replacing Brakes

Ensuring safety during the replacement of crucial components is vital for both the individual and the vehicle’s performance. Proper precautions can prevent accidents and ensure effective functioning.

Here are some key safety measures to consider:

- Always use protective gear, including gloves and safety goggles.

- Ensure the vehicle is securely lifted and supported on jack stands.

- Disconnect the battery to prevent any electrical mishaps.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

Following these guidelines will help maintain a safe working environment and promote successful completion of the task.