The functionality of a multi-purpose rotary instrument is significantly influenced by its individual elements. Each component plays a crucial role in enhancing the overall performance, making it essential for users to familiarize themselves with these integral parts. A thorough comprehension of these components not only aids in effective utilization but also fosters maintenance and troubleshooting capabilities.

In this section, we will delve into the various elements that contribute to the operation of this versatile device. By examining each section, users can gain insights into how these components interact and function together, enabling a smoother experience during use. Understanding the layout and purpose of each part can enhance the efficiency of projects and prolong the lifespan of the instrument.

Whether one is a novice or an experienced user, recognizing the intricacies of these components can prove invaluable. Knowledge of the device’s structure allows for more informed decisions when it comes to selecting attachments or accessories. Ultimately, this foundational understanding empowers users to maximize the potential of their rotary instrument.

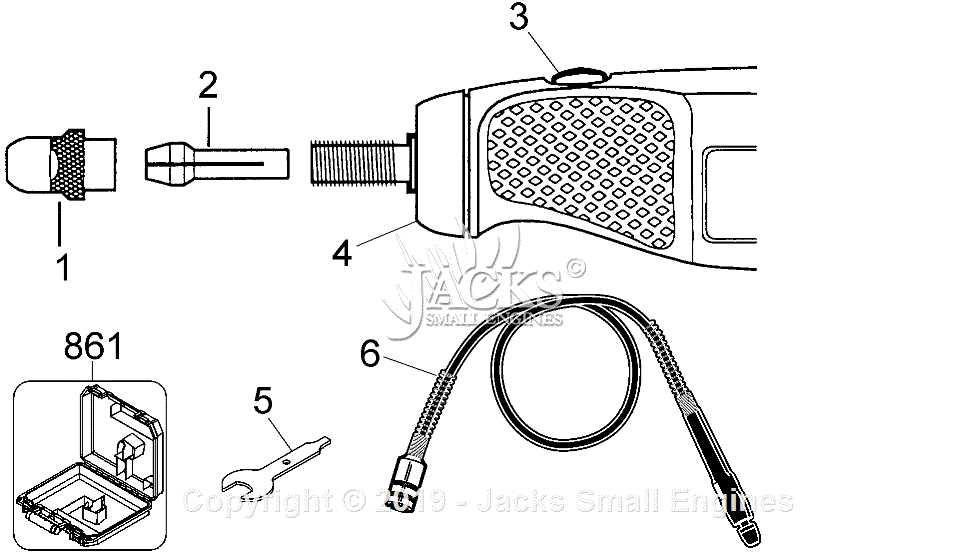

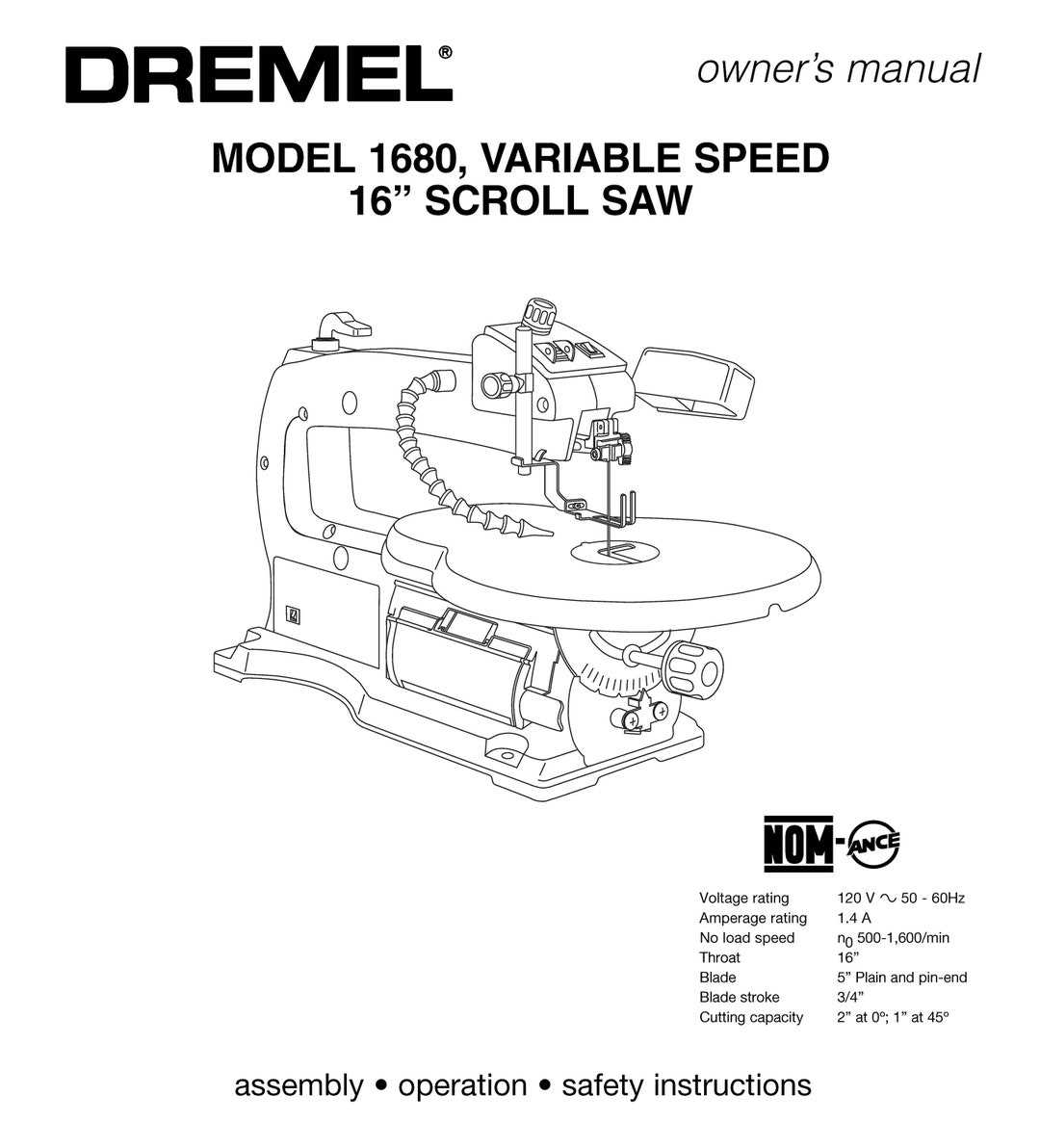

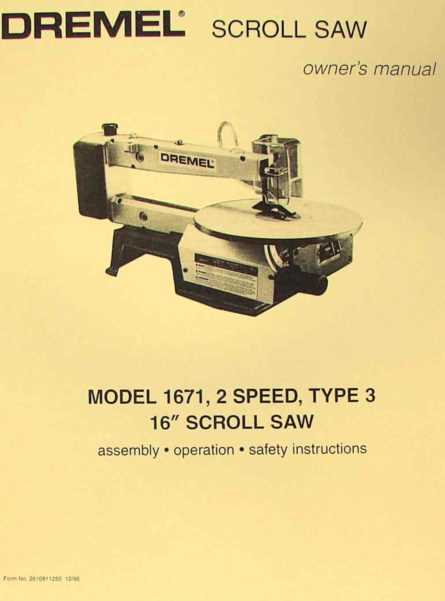

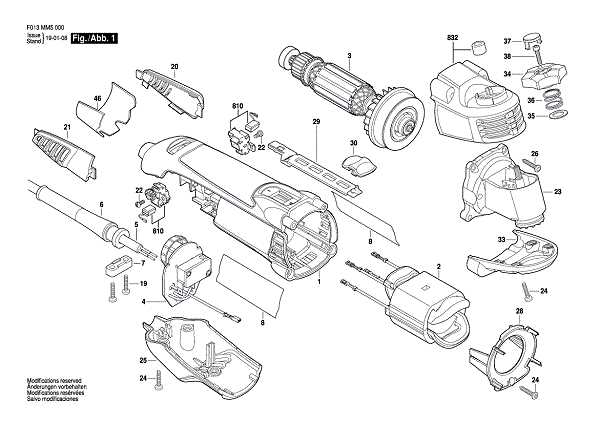

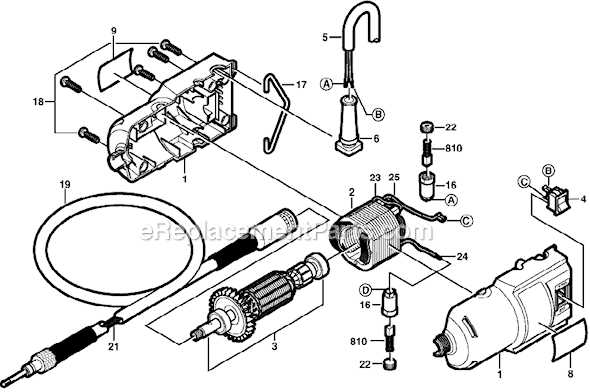

Dremel Tool Parts Diagram

This section provides an overview of the components involved in a versatile handheld rotary instrument. Understanding the various elements that make up this device enhances the user experience and facilitates maintenance, troubleshooting, and replacement. Each component plays a vital role in the overall functionality and effectiveness of the equipment.

Key Components

The assembly consists of several essential features, including the motor housing, speed control, and collet. The motor housing houses the engine, ensuring durability and stability during operation. The speed control allows users to adjust the rotation rate for different tasks, while the collet secures the attachments in place, enabling seamless operation.

Maintenance and Troubleshooting

Regular inspection and understanding of these components can significantly improve longevity. For instance, checking the motor for wear and ensuring the collet is free from debris will help maintain performance. If issues arise, identifying the specific segment causing the malfunction will lead to more effective solutions.

Understanding Dremel Tool Components

Familiarizing oneself with the various elements of a versatile rotary instrument enhances its effective use and maintenance. Each component plays a crucial role in ensuring optimal performance, allowing for a wide range of applications from cutting to polishing. Grasping the functionality of these elements can significantly improve the user experience and extend the lifespan of the device.

Main Functional Elements

The primary components of a rotary device can be categorized based on their functions. Understanding these categories helps users select the appropriate attachments and settings for different tasks. Below are some essential elements and their purposes:

| Component | Function |

|---|---|

| Motor | Drives the rotation of the attached accessories, providing power for various applications. |

| Shaft | Connects the motor to the accessories, facilitating smooth rotation and transfer of power. |

| Collet | Holds the accessories in place securely, ensuring stability during operation. |

| Speed Control | Allows users to adjust the rotational speed according to the requirements of the task. |

Attachments and Accessories

The variety of accessories available for the device expands its capabilities considerably. Each attachment is designed for specific functions, making it essential to choose the right one for the job at hand. Understanding the different types of attachments enhances efficiency and effectiveness in various projects.

Importance of Each Part Explained

Understanding the significance of each component in an intricate device enhances overall performance and efficiency. Each segment plays a crucial role in the functionality and versatility of the instrument, contributing to the precision and quality of work. Recognizing these elements not only aids in effective usage but also informs maintenance practices, ensuring longevity and optimal performance.

Key Components and Their Functions

Each element has a specific function that contributes to the tool’s overall operation. For instance, the motor is responsible for providing the necessary power, enabling high-speed rotations essential for various applications. Similarly, the housing protects the internal mechanisms while providing a comfortable grip for users, ensuring ease of handling during tasks.

Impact on Performance and Maintenance

The efficiency of the device is heavily reliant on the condition of each individual component. Regular inspection and timely replacement of worn-out parts can prevent malfunctions and enhance performance. Understanding how each part interacts with others enables users to troubleshoot issues effectively, leading to a smoother experience and greater satisfaction with the device.

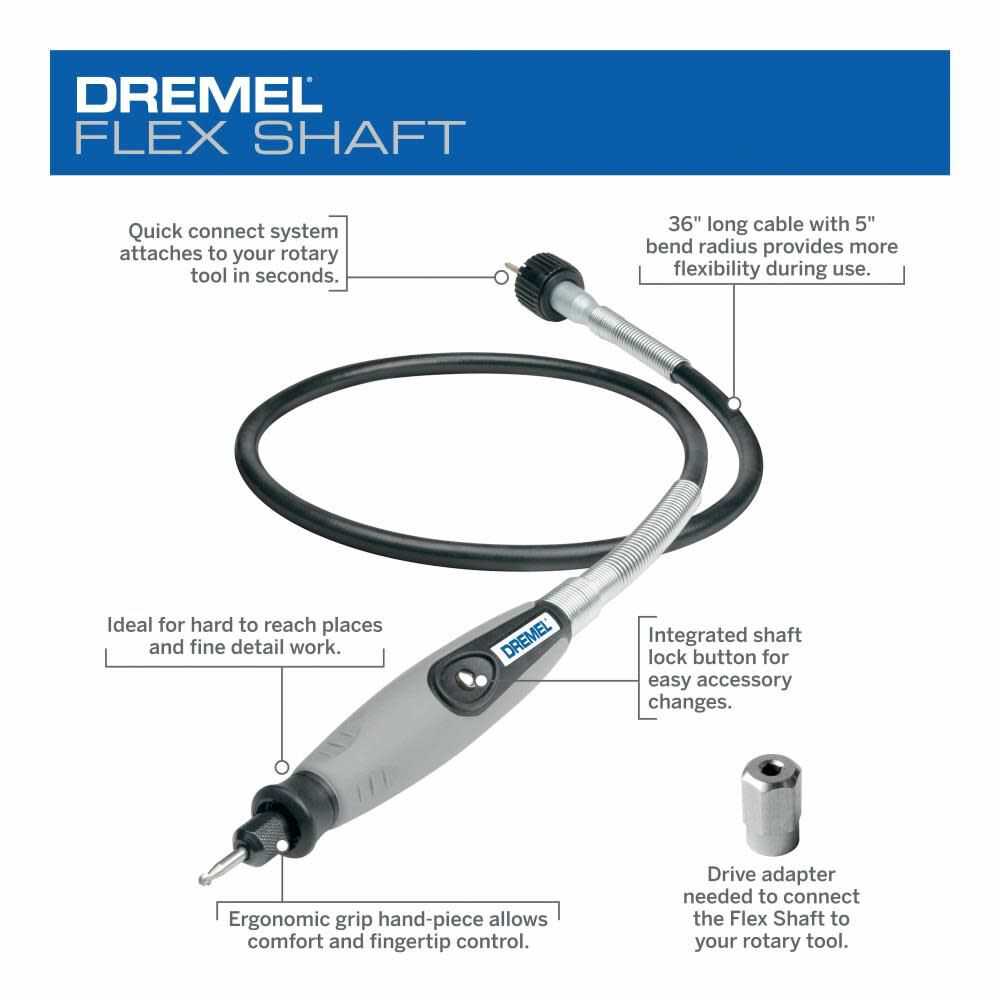

Common Dremel Attachments Overview

Various attachments enhance the functionality of handheld rotary devices, making them versatile for a range of tasks. These accessories cater to different applications, allowing users to achieve specific results efficiently. Understanding the available options can significantly improve project outcomes.

Types of Attachments

- Cutting Discs: Ideal for slicing through materials like metal, plastic, and wood.

- Sanding Drums: Perfect for smoothing surfaces and edges.

- Grinding Stones: Used for shaping and refining materials, particularly metals.

- Polishing Wheels: Useful for achieving a high-gloss finish on various surfaces.

- Carving Bits: Designed for detailed engraving and decorative work.

Choosing the Right Accessory

Selecting the appropriate attachment depends on the specific task at hand. Here are some factors to consider:

- Material Type: Different attachments perform better on various materials.

- Desired Finish: Choose attachments based on the finish required for your project.

- Speed Settings: Some attachments work best at particular speed settings, influencing the choice.

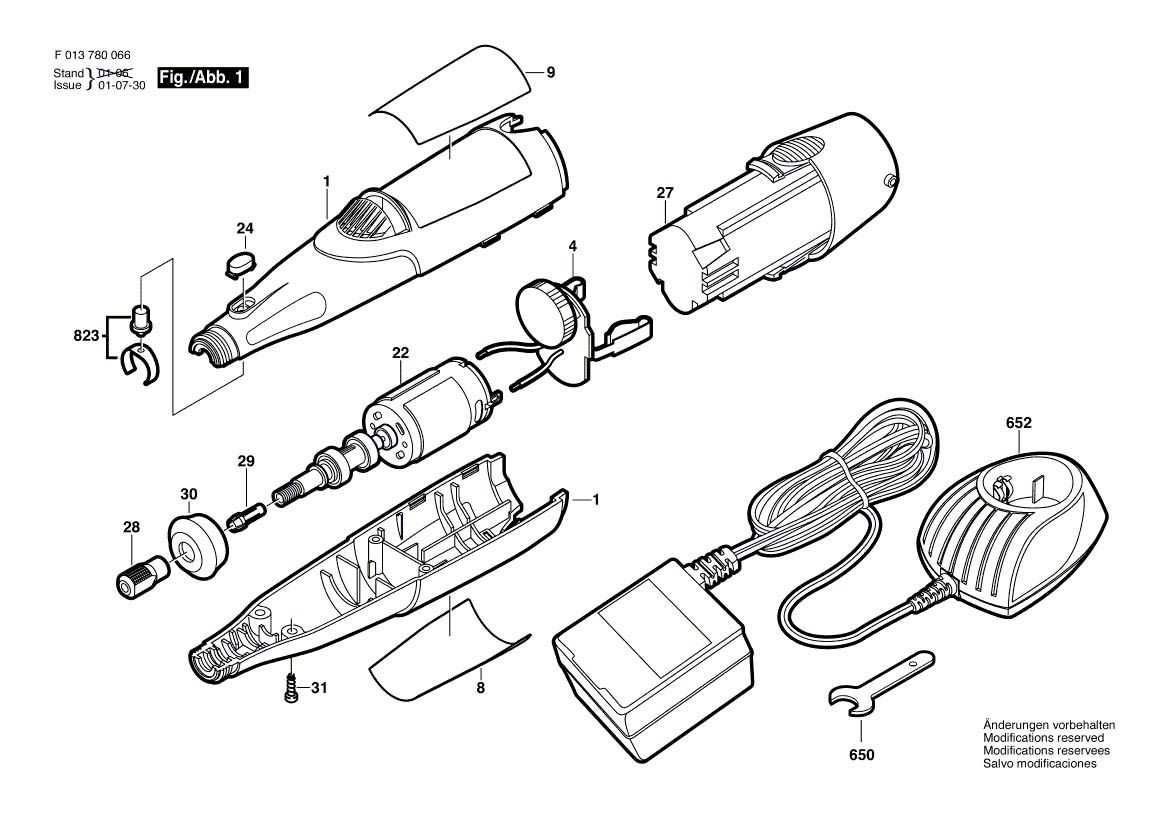

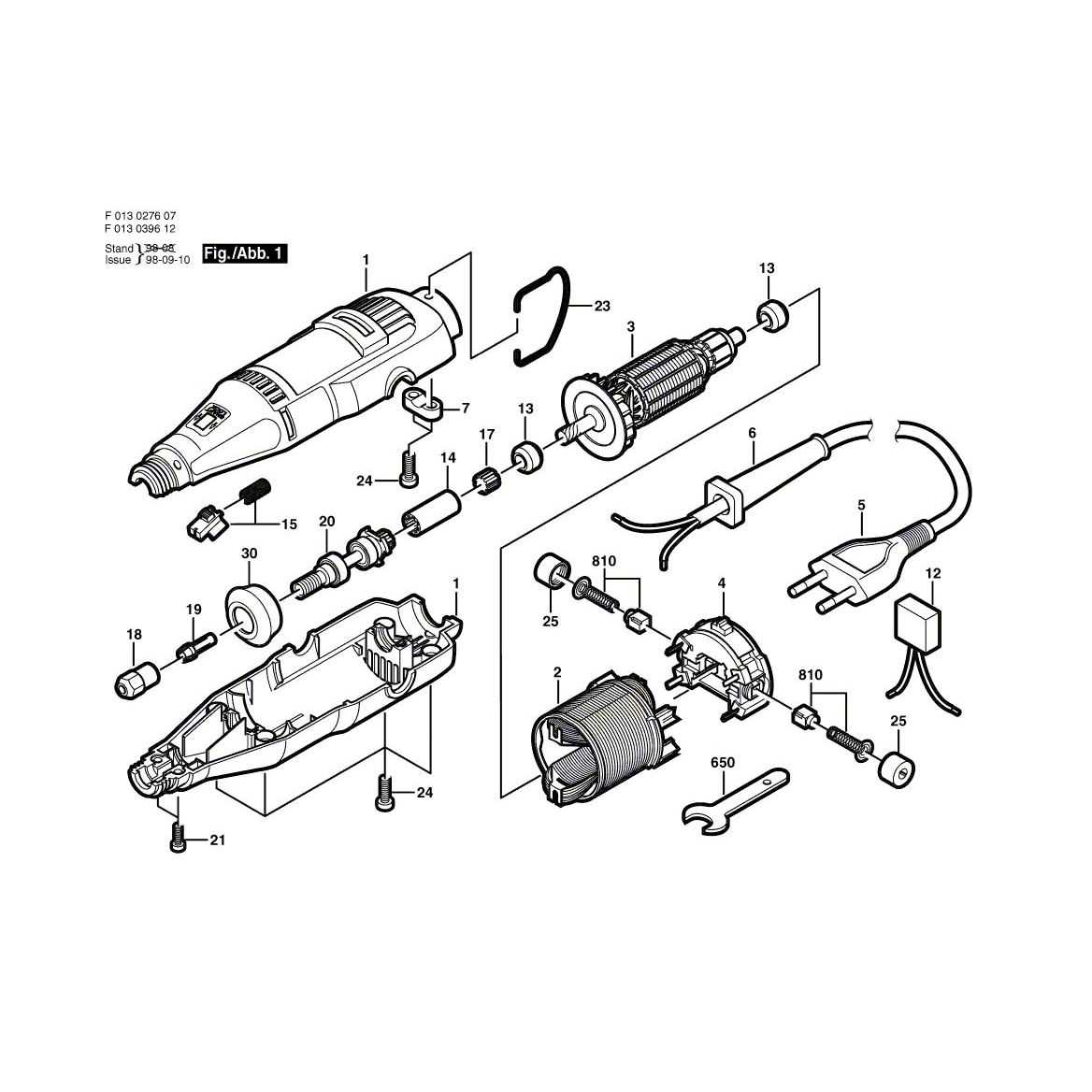

Identifying Parts in Diagrams

Understanding the components of a device is essential for effective maintenance and troubleshooting. Visual representations can greatly aid in recognizing the individual elements and their functions. By familiarizing oneself with these visuals, users can navigate the assembly or disassembly process more efficiently, ensuring a smoother experience in handling the equipment.

Common Components to Recognize

When examining a visual representation, look for the most frequently encountered elements. These may include the following:

- Motor: The heart of the device, responsible for driving its operation.

- Housing: The outer shell that encases and protects the internal mechanisms.

- Switch: A control mechanism that allows the user to operate the device.

- Attachments: Various accessories that can enhance functionality for specific tasks.

Utilizing Visual Aids for Assembly

Employing visual aids can significantly enhance the understanding of how components interact. Pay close attention to labeling and numbering, which provide insights into the order of assembly and the relationship between elements. This knowledge is crucial for both novice and experienced users looking to optimize their approach to maintenance or upgrades.

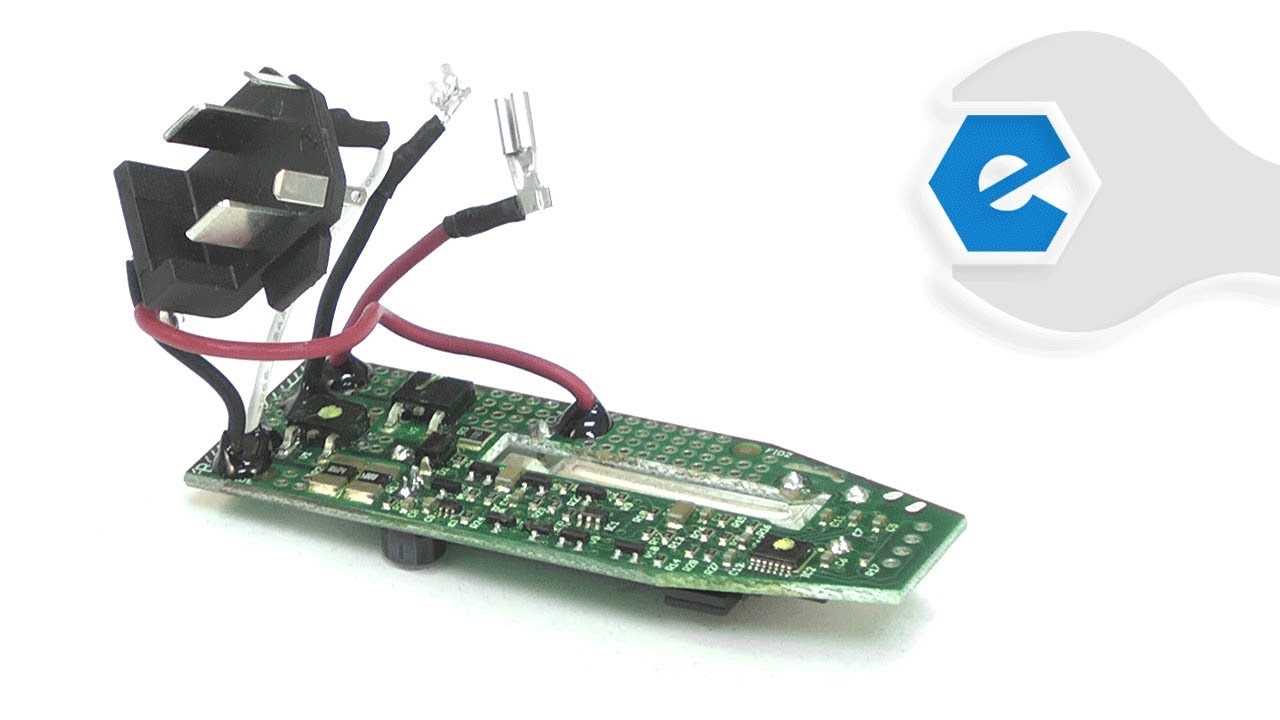

How to Read Dremel Schematics

Understanding the layout of an electrical device can significantly enhance your ability to troubleshoot and maintain it. Familiarity with the schematic representation allows users to identify various components and their interconnections, enabling efficient repairs and modifications.

When approaching a schematic, consider the following steps:

- Familiarize Yourself with Symbols: Each component is represented by a unique symbol. Knowing what these symbols stand for is crucial.

- Trace the Connections: Follow the lines between symbols to understand how different elements are interconnected. This helps in visualizing the flow of electricity.

- Identify Key Components: Look for crucial parts like switches, resistors, and capacitors. Recognizing their functions will aid in diagnostics.

- Refer to a Legend: Many schematics include a legend or key that explains the symbols and colors used. Always check this for clarification.

- Understand Circuit Functions: Grasp the overall function of the circuit to appreciate how each part contributes to the device’s operation.

By following these guidelines, you can effectively read and interpret schematic representations, empowering you to handle repairs with confidence.

Maintenance of Dremel Tool Parts

Proper upkeep of your rotary device is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents potential malfunctions that may arise from wear and tear. Understanding the key components and how to care for them is crucial for any user.

Cleaning is the first step in maintaining your rotary instrument. Dust and debris can accumulate in various areas, affecting functionality. Use a soft brush or cloth to remove particles, paying special attention to the ventilation areas to avoid overheating.

Next, lubrication of moving elements is vital. Apply a light machine oil to bearings and shafts to ensure smooth operation. This practice minimizes friction, extending the lifespan of the device.

Additionally, check for wear and damage regularly. Inspect attachments and fittings for signs of deterioration. Replacing worn components promptly can prevent more significant issues and ensure safe usage.

Finally, storage plays a significant role in maintenance. Keep the instrument in a dry, cool environment, and utilize a protective case to safeguard against impacts and moisture. This proactive approach will maintain the integrity of the device for years to come.

Replacing Worn Out Components

Maintaining the functionality of your equipment is crucial for optimal performance. Over time, certain elements may wear down due to frequent use or exposure to various conditions. Identifying and replacing these worn components is essential to ensure the longevity and efficiency of your device. This section will guide you through the process of assessing and replacing these parts effectively.

Identifying Worn Components

Before proceeding with any replacements, it’s important to recognize which components are no longer functioning at their best. Look for signs of damage such as cracks, excessive wear, or unusual noises during operation. Regular inspections will help you catch issues early and prevent more extensive damage.

Steps for Replacement

Once you have identified the components that need replacing, follow these steps for a successful replacement:

- Gather necessary tools and replacement parts.

- Ensure the device is unplugged and safe to work on.

- Carefully remove the damaged component, taking note of how it is attached.

- Install the new part, ensuring a secure fit and alignment.

- Test the device to confirm that it operates smoothly.

By replacing worn components promptly, you not only enhance the efficiency of your device but also extend its lifespan, ensuring that it remains a reliable asset for your projects.

Upgrading Your Dremel Accessories

Enhancing the versatility and performance of your handheld rotary device can significantly improve your crafting and DIY experiences. By selecting high-quality attachments and components, you can expand the functionality of your equipment, allowing for a wider range of tasks and improved results. Understanding which accessories to upgrade can make a notable difference in both efficiency and effectiveness.

Choosing the Right Attachments

When considering upgrades, it’s essential to evaluate your specific needs and the types of projects you undertake. Various attachments, such as cutting wheels, sanding bands, and grinding bits, are designed for different applications. Opting for premium options can enhance durability and performance, providing smoother results and a longer lifespan.

Compatibility and Versatility

Ensure that the accessories you choose are compatible with your device model. Some components may offer universal fitment, but others might be tailored for specific machines. Versatile attachments that can be used for multiple functions will maximize your investment and reduce clutter in your workspace.

Finding Compatible Replacement Parts

When it comes to maintaining your equipment, locating suitable replacement components is crucial for ensuring optimal performance. Identifying the right elements can enhance functionality and extend the lifespan of your device.

Here are some key steps to consider when searching for compatible replacements:

- Consult the Manual: Start by reviewing the user guide or manual that came with your device. It often contains specifications and part numbers.

- Research Online: Utilize online resources and forums dedicated to equipment maintenance. Users often share insights about compatible components.

- Visit Local Retailers: Check with local hardware stores or specialized shops. Staff can assist you in finding the right replacements.

- Consider Aftermarket Options: Many manufacturers offer third-party alternatives that may be compatible. Ensure these options meet quality standards.

- Contact Customer Support: Reach out to the manufacturer’s customer service for assistance in finding suitable replacements.

By following these guidelines, you can effectively locate compatible elements, ensuring your device remains in peak condition.

Tips for Assembly and Disassembly

Assembling and disassembling equipment can be a meticulous task that requires attention to detail and a systematic approach. Understanding the correct order of operations, as well as the necessary components involved, can greatly enhance efficiency and prevent damage during the process.

Here are some practical tips to consider:

| Tip | Description |

|---|---|

| 1. Organize Your Workspace | Ensure your area is clean and well-lit. Arrange all necessary components and tools within easy reach to streamline the process. |

| 2. Refer to Manuals | Consult any available guides or manuals to familiarize yourself with the assembly order and specific instructions for the equipment. |

| 3. Take Notes | While disassembling, jot down notes or take photos to document the order and orientation of components for easier reassembly. |

| 4. Use the Right Tools | Ensure that you have the correct tools at hand to prevent stripping screws or damaging parts during assembly or disassembly. |

| 5. Handle Components Carefully | Be gentle when removing or installing parts to avoid bending or breaking them, which can affect performance. |

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and their functionalities. Understanding the intricacies of these elements can enhance your experience and ensure efficient usage.

- What types of components are available?

Various types of components can be found, each designed for specific applications, such as:

- Attachments for enhanced versatility

- Replacement elements for maintenance

- Accessories to improve performance

- How do I know which component to use?

Choosing the right element depends on your intended application. Always refer to the specifications and recommendations for optimal performance.

- Can I replace components myself?

Yes, most components can be replaced with basic tools. Follow the guidelines provided in user manuals for safe and effective replacement procedures.

- Where can I find replacement elements?

Replacement elements can be purchased from:

- Authorized retailers

- Online marketplaces

- Official service centers

- Are there any warranties on components?

Most components come with a warranty, but terms may vary. Always check the warranty details at the time of purchase.

Resources for Dremel Tool Users

Having access to reliable information and resources is essential for anyone engaged in crafting and precision work. Whether you are a novice or an experienced individual, a variety of materials can enhance your understanding and improve your skills. Below are valuable resources that can assist in maximizing the potential of your equipment.

- Official Manuals: Always refer to the user manuals for comprehensive guidance on operation and safety. These documents provide essential insights into the features and functionalities of your equipment.

- Online Tutorials: Numerous websites and platforms offer instructional videos and tutorials. These resources can help you learn new techniques and improve your proficiency.

- Community Forums: Engaging with other enthusiasts through online forums can provide practical tips and solutions. You can share experiences, ask questions, and find inspiration.

- Workshops and Classes: Local workshops often offer hands-on experience and expert guidance. Participating in such events can deepen your understanding and introduce you to new techniques.

- Replacement Parts Suppliers: Knowing where to find spare components is crucial. Many suppliers offer a wide range of accessories that can enhance your work.

- Safety Equipment Guides: Understanding safety practices is vital. Look for resources that provide information on protective gear and safe operating procedures.

Utilizing these resources can greatly enhance your experience and outcomes. Continuous learning and community engagement will lead to greater mastery and enjoyment of your projects.