Understanding the intricate layout of a utility vehicle is essential for effective maintenance and repair. This section will provide insights into the various elements that make up such a vehicle, facilitating a deeper appreciation for its design and functionality.

In this overview, readers will discover the different sections and components that contribute to the overall performance and usability of the vehicle. Each element plays a critical role, and comprehending their arrangement can significantly enhance operational efficiency.

Furthermore, gaining familiarity with the configuration of these components allows enthusiasts and technicians alike to troubleshoot issues more effectively. By delving into this subject, one can uncover the ultimate potential of the vehicle, ensuring it remains in optimal condition for years to come.

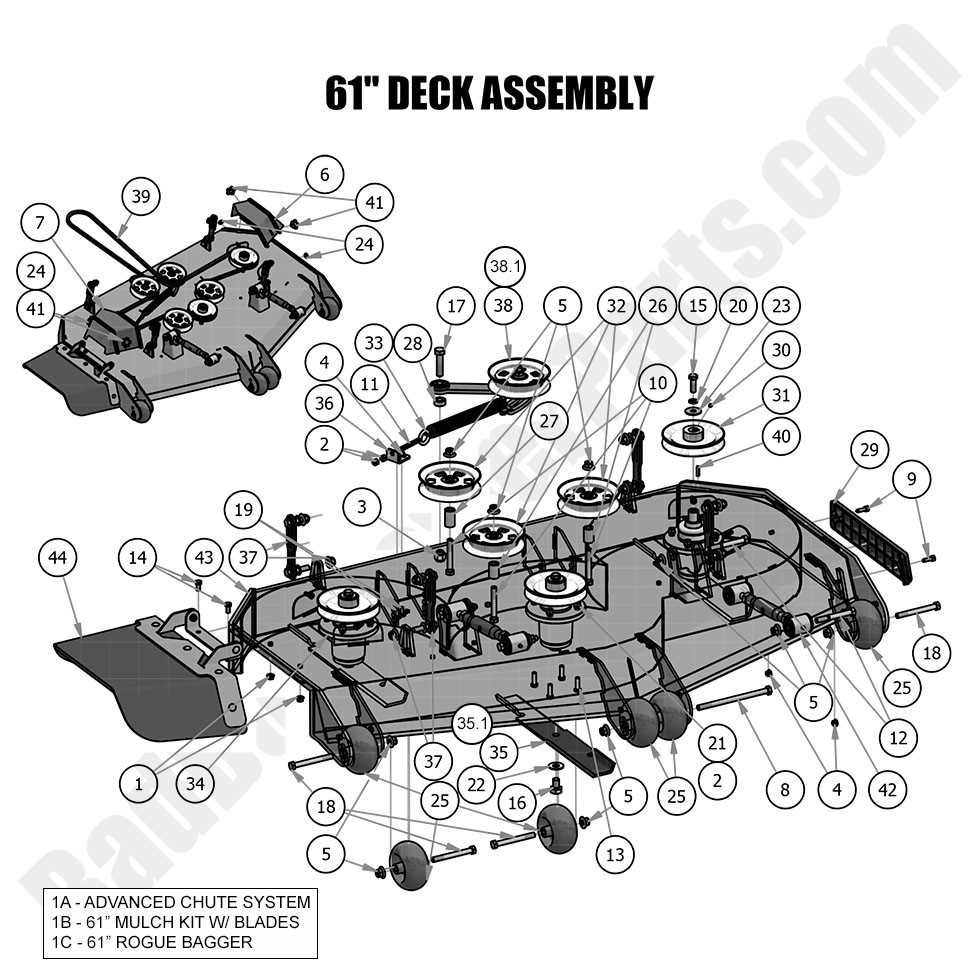

Understanding the Encore Prowler 61 Components

This section delves into the various elements that make up a specific model, highlighting their functions and significance in the overall design. Each component plays a crucial role in ensuring optimal performance, contributing to the system’s efficiency and reliability. Recognizing these parts will enhance comprehension and facilitate better maintenance practices.

The following table outlines key components, their functions, and their relevance:

| Component | Function | Importance |

|---|---|---|

| Chassis | Provides structural support | Ensures durability and stability |

| Engine | Generates power for operation | Critical for performance |

| Transmission | Transfers power to the wheels | Vital for movement control |

| Suspension System | Absorbs shocks and maintains balance | Enhances ride comfort |

| Braking System | Enables stopping and slowing down | Essential for safety |

Understanding these components and their interactions is fundamental for anyone looking to optimize usage and troubleshoot issues effectively.

Key Features of Encore Prowler 61

This section highlights the essential characteristics of a notable model in its category. Understanding these attributes helps users appreciate its capabilities and make informed decisions regarding usage and maintenance.

- Robust Construction: Designed for durability, ensuring longevity even in challenging conditions.

- Advanced Performance: Offers impressive efficiency and reliability, making it suitable for various tasks.

- User-Friendly Design: Engineered for ease of use, with intuitive controls that enhance the user experience.

- Versatile Applications: Adaptable for multiple environments, catering to diverse needs and preferences.

- Enhanced Safety Features: Incorporates mechanisms that prioritize user safety during operation.

These features collectively contribute to its reputation, making it a valuable choice for enthusiasts and professionals alike.

Importance of Accurate Parts Diagrams

Detailed representations of components are essential for effective maintenance and repairs. These visuals serve as crucial references, guiding users through complex systems with ease. Their accuracy ensures that every element is correctly identified and understood, leading to smoother operations and fewer errors.

Having precise representations can significantly enhance the efficiency of repair processes. Here are some key benefits:

- Reduced Downtime: Quick identification of components allows for faster troubleshooting, minimizing operational interruptions.

- Improved Safety: Accurate visuals help prevent improper handling or installation, reducing the risk of accidents.

- Cost-Effectiveness: Correctly identifying components prevents unnecessary purchases and helps in budgeting for repairs.

- Enhanced Understanding: Clear representations provide users with a better grasp of how different elements interact within the system.

In summary, precise visual aids are indispensable tools for anyone involved in maintenance or repairs. They not only streamline processes but also contribute to overall safety and cost efficiency.

Common Issues with Prowler 61 Parts

Understanding typical challenges associated with components of this model can enhance the experience for users and maintainers. Familiarity with frequent problems allows for timely interventions and effective solutions, ensuring the equipment operates efficiently.

Frequent Component Failures

One of the most common difficulties faced involves the deterioration of key elements over time. Wear and tear can lead to malfunctions, resulting in decreased performance. Regular inspection is essential to identify and rectify these issues early on.

Compatibility Concerns

Another area of concern is the compatibility of replacement components. Using parts that are not designed for this specific model can lead to improper functionality and additional complications. It is crucial to verify that replacements meet the required specifications for optimal performance.

| Issue | Description | Recommended Action |

|---|---|---|

| Wear and Tear | Components may degrade over time, affecting performance. | Regularly inspect and replace worn items. |

| Compatibility | Using incorrect replacements can cause malfunctions. | Ensure replacements match specifications. |

| Installation Errors | Improper installation may lead to operational failures. | Follow installation guides carefully. |

Maintenance Tips for Encore Prowler 61

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By following a few straightforward guidelines, you can keep everything running smoothly and prevent potential issues down the line.

Routine Inspections: Conducting frequent checks is crucial. Look for signs of wear and tear, and address any minor issues before they escalate. Pay attention to moving components, ensuring they are properly lubricated and free of debris.

Cleaning: Maintaining cleanliness is vital for efficient operation. Remove dust, dirt, and any foreign objects that may hinder functionality. Use appropriate cleaning agents to ensure all surfaces are in good condition without causing damage.

Fluid Levels: Regularly monitor fluid levels, including oils and lubricants. Keeping these at the recommended levels is essential for reducing friction and preventing overheating.

Consult Manuals: Always refer to the manufacturer’s guidelines for specific maintenance tasks. This will provide you with important insights on intervals and necessary procedures to maintain peak efficiency.

By incorporating these maintenance practices, you can significantly extend the lifespan and enhance the reliability of your equipment, ensuring it remains in excellent working condition for years to come.

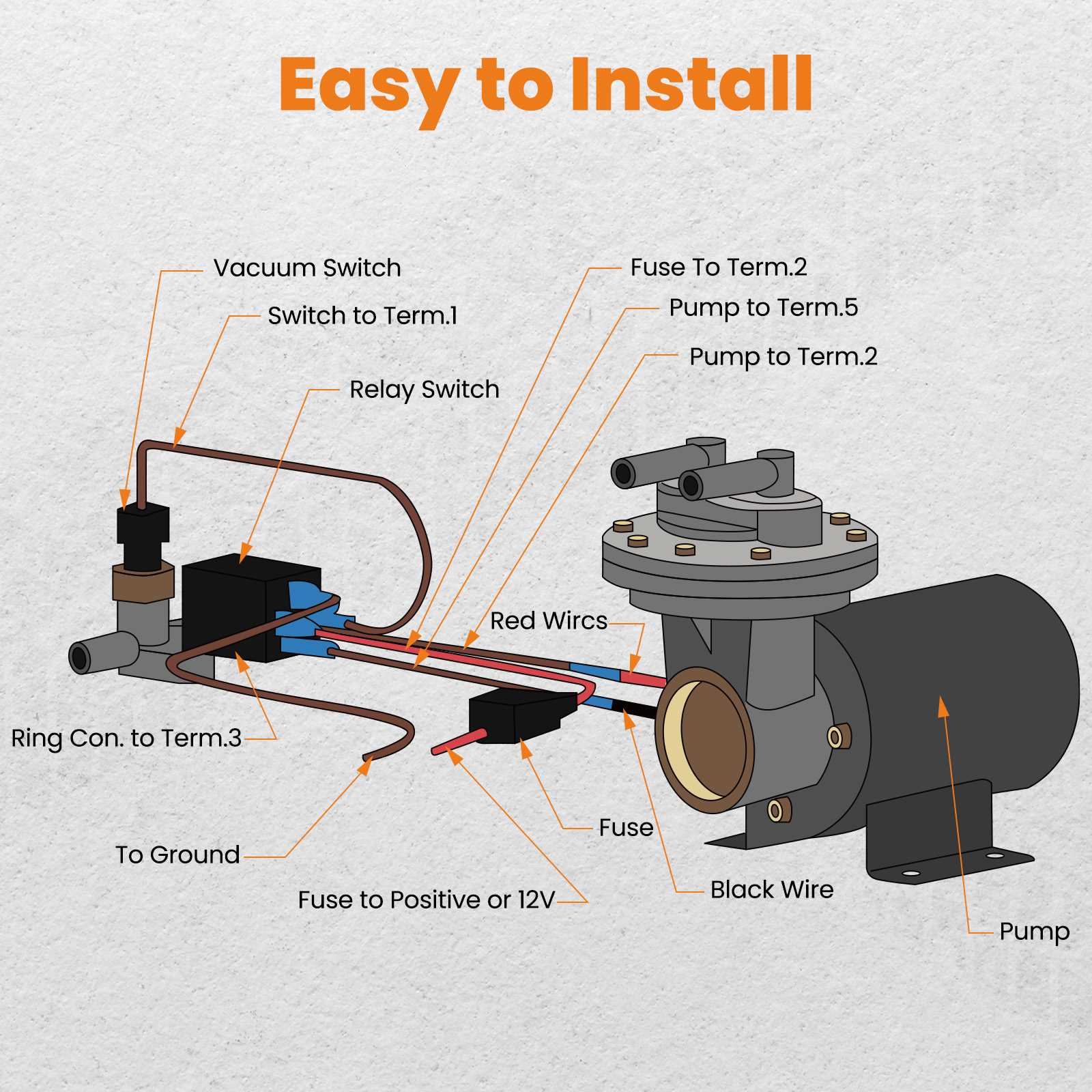

Identifying Components in the Diagram

This section aims to provide insights into recognizing various elements within the visual representation. Understanding how these components interact is crucial for effective analysis and troubleshooting.

Key Elements to Recognize

- Connectors: Essential for linking different parts together.

- Fasteners: Used to secure components in place.

- Wiring: Indicates how power and signals flow between elements.

Steps to Identify Components

- Examine the visual closely for labels or markings.

- Trace the connections to understand the layout.

- Cross-reference with documentation for clarification.

Where to Source Replacement Parts

Finding suitable components for your machinery can significantly enhance its performance and longevity. Various sources provide quality replacements, ensuring that your equipment remains in optimal working condition.

Online Retailers

- Major e-commerce platforms often carry a wide selection of components, making it easy to compare prices and options.

- Specialized websites focus on specific equipment and may offer detailed specifications.

Local Suppliers

- Hardware stores often stock essential items and can assist in finding compatible alternatives.

- Local dealers may provide expert advice and might have exclusive deals on specific items.

Exploring both online and local resources can help you identify the best options for your needs.

Comparing Prowler 61 with Similar Models

This section aims to explore how a specific model stacks up against its counterparts in terms of functionality, design, and user experience. By analyzing various characteristics, we can identify both unique features and common elements that influence performance and user satisfaction.

Design and Build Quality

When assessing the aesthetic appeal and structural integrity, it becomes clear that many models share similar dimensions and materials. However, subtle differences in design can affect overall durability and ease of use. Notably, some variants may prioritize lightweight construction while others focus on robustness, appealing to different consumer preferences.

Performance and Features

In terms of operational efficiency, variations in engine power and technology often lead to distinct performance profiles. While one model may excel in speed and agility, another might offer superior fuel efficiency or enhanced control systems. Understanding these differences helps consumers make informed decisions based on their specific needs.

DIY Repairs for Encore Prowler 61

Engaging in self-repairs can be a rewarding endeavor for those looking to maintain their equipment efficiently. Understanding the basic components and their functionalities is essential for effective troubleshooting. This section aims to guide enthusiasts through common repair tasks, enhancing their skills while saving on service costs.

Common Issues and Solutions

Several frequent challenges may arise during the operation of your device. By identifying these problems, you can implement straightforward solutions. Below is a table summarizing some typical issues along with recommended fixes:

| Issue | Possible Solution |

|---|---|

| Equipment not powering on | Check the power source and replace any faulty connectors. |

| Unusual noises during operation | Inspect for loose components and tighten as needed. |

| Performance inconsistencies | Clean filters and ensure all moving parts are lubricated. |

Tools You May Need

Before starting any repair work, gather the necessary tools to ensure a smooth process. Having the right equipment at hand can make a significant difference in the efficiency of your repairs.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws. |

| Pliers | To grip and twist components. |

| Multimeter | For checking electrical connections and voltage levels. |

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components used in various models, aiming to clarify typical concerns and provide helpful insights for users.

- What should I consider when selecting components?

- Compatibility with existing systems

- Quality and durability

- Cost and availability

- How do I identify the right components for my model?

- Refer to the user manual for specifications

- Consult online resources or community forums

- Seek assistance from local experts or retailers

- Are there any tips for maintaining components?

- Regularly clean and inspect for wear

- Store in a dry, controlled environment

- Follow manufacturer guidelines for usage

- Where can I find replacement components?

- Authorized dealers and retailers

- Online marketplaces and auctions

- Specialty shops focusing on specific models

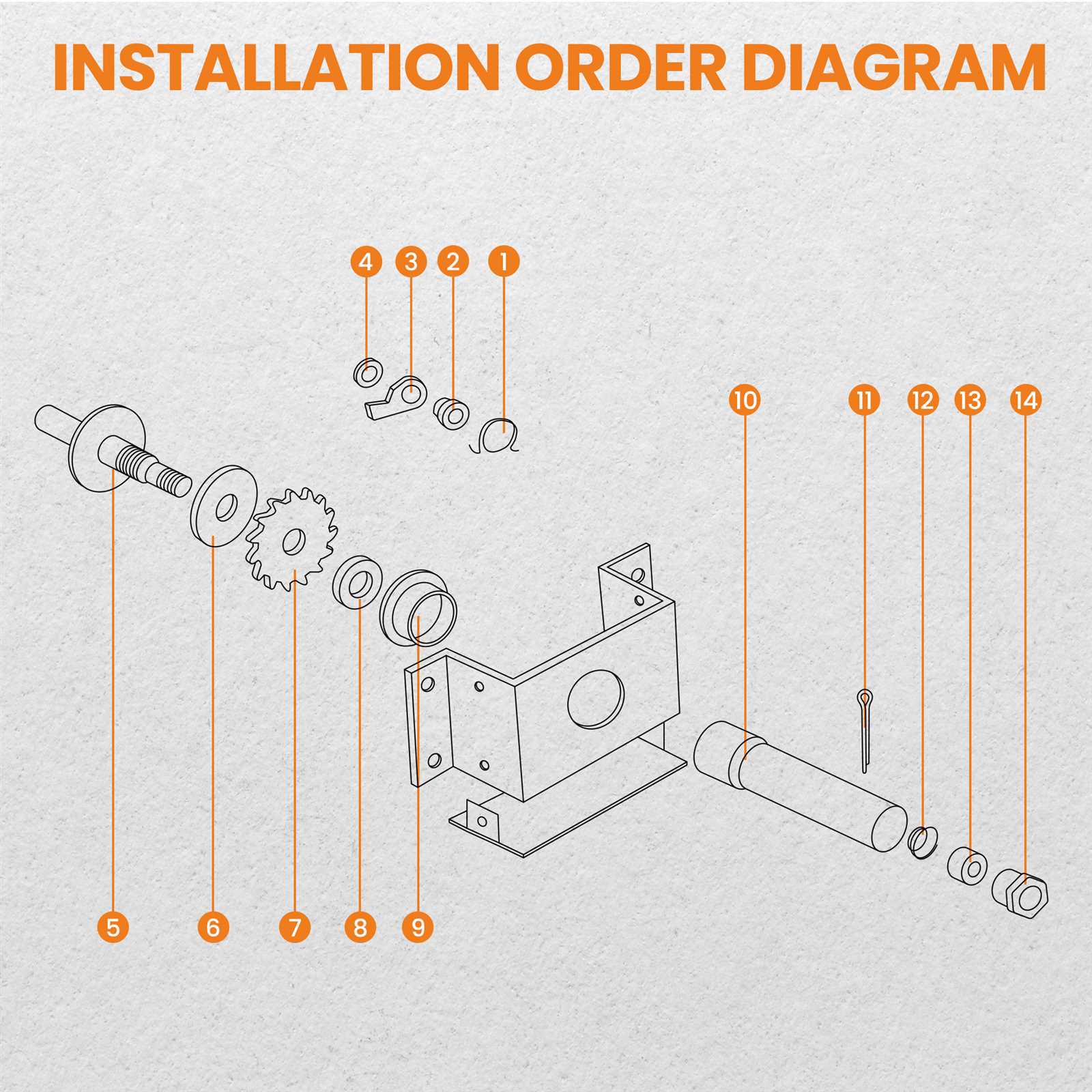

Understanding Assembly and Disassembly

This section explores the essential steps for assembling and disassembling components in a systematic manner. Grasping these procedures can enhance efficiency and ensure that each part functions optimally within the system.

Key Steps for Assembly

- Organize all components and tools before starting.

- Follow the sequence of steps to prevent errors.

- Ensure that each element is securely attached to avoid malfunction.

Tips for Disassembly

- Document the process to aid reassembly later.

- Handle parts with care to prevent damage.

- Keep small components in a designated area to avoid loss.

Enhancing Performance with Upgrades

Improving functionality and efficiency can significantly transform the overall experience. By integrating high-quality enhancements, users can achieve better responsiveness and reliability in their systems. These upgrades not only elevate performance but also extend the lifespan of the equipment.

Key Areas for Improvement

Focus on upgrading components that directly influence operation. For instance, enhancing the power supply and optimizing the control mechanisms can lead to substantial gains in efficiency. Additionally, revising the interface can streamline user interaction and improve usability.

Benefits of Quality Components

Utilizing superior materials and components can drastically enhance performance. Durability and efficiency are crucial, as quality upgrades reduce maintenance needs and ensure long-term reliability. Prioritizing these elements in your enhancements will yield the best results.