The intricate design of a renowned chainsaw model involves various essential elements working harmoniously together. Each component plays a pivotal role in ensuring optimal performance and reliability, making it crucial for users to comprehend their functions and interrelations.

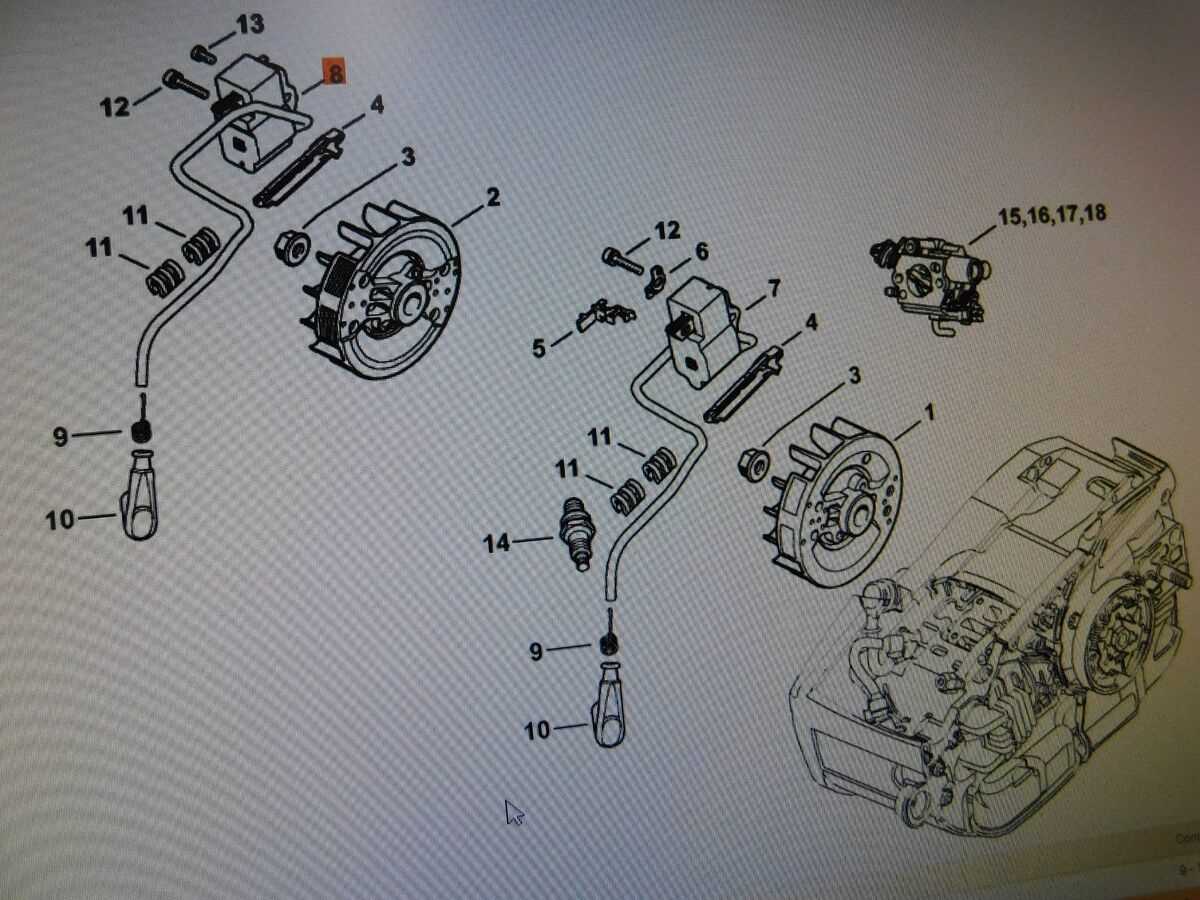

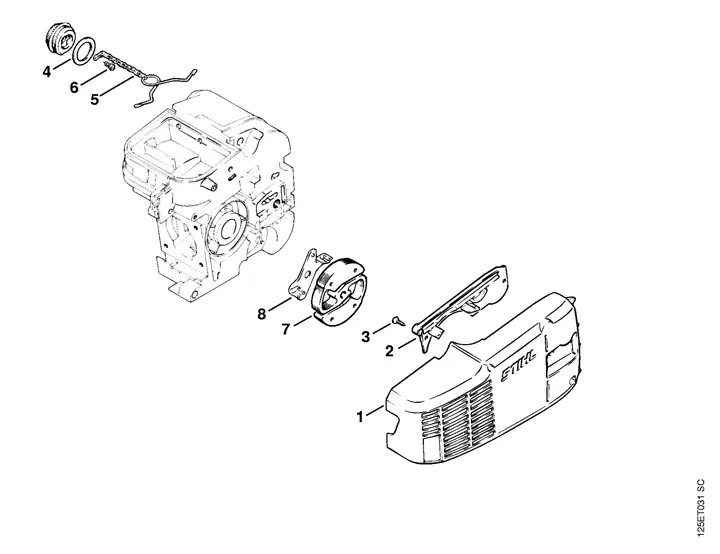

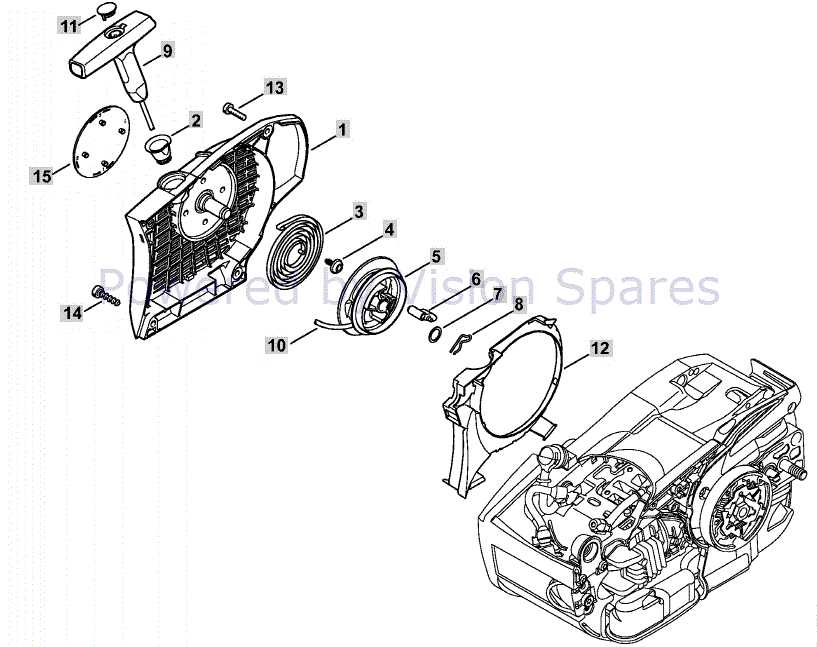

To enhance your experience and maintenance practices, a visual representation can prove invaluable. This resource serves as a guide, illustrating the different sections and parts that contribute to the overall efficiency of the machine.

Whether you are a novice or an experienced user, having a comprehensive understanding of these elements will ultimately empower you to make informed decisions regarding repairs and upgrades. Delve into the details to discover how each piece contributes to the chainsaw’s exceptional functionality.

Understanding the Stihl 201T Parts Diagram

Gaining insight into the components of your equipment is crucial for effective maintenance and troubleshooting. A clear representation of the various elements not only aids in identifying parts but also enhances your ability to perform repairs efficiently. This understanding fosters a deeper connection with the machinery and ensures optimal performance.

Each component plays a vital role in the overall function, contributing to the machine’s reliability and effectiveness. Familiarity with these individual elements allows for better assessment of issues that may arise, making it easier to pinpoint the source of a malfunction. Recognizing how these parts interact further enhances your problem-solving skills.

Utilizing a visual guide simplifies the process of locating specific components, streamlining repairs and replacements. By studying this representation, you can better appreciate the engineering behind your equipment and understand how to maintain it for long-lasting use.

Engaging with the intricacies of the machinery empowers users to take charge of their maintenance routines, leading to improved longevity and performance. Knowledge of each element equips you with the confidence needed to tackle repairs, ensuring that your equipment operates smoothly and efficiently.

Key Components of the 201T Model

The efficiency and performance of a professional-grade cutting tool rely heavily on its core elements. Understanding these crucial components is essential for optimal maintenance and operation. Each part plays a specific role in ensuring the machine functions smoothly and effectively in various tasks.

Engine: The heart of the device, the engine, provides the necessary power for cutting. Its design emphasizes fuel efficiency and reliability, allowing for extended use without frequent refueling.

Bar and Chain: The bar and chain are vital for the cutting action. The bar serves as a guide, while the chain, with its sharp teeth, performs the actual cutting. Proper tensioning and lubrication of these components are critical for performance and longevity.

Air Filter: An efficient air filter is essential for maintaining optimal airflow to the engine. It prevents debris from entering the combustion chamber, ensuring smooth operation and longevity of the engine.

Ignition System: This system is responsible for starting the engine. A reliable ignition mechanism ensures quick starts and consistent performance, even in challenging conditions.

Fuel System: The fuel system, including the carburetor, regulates the air-fuel mixture necessary for combustion. Proper maintenance of this system is crucial for efficient fuel consumption and optimal performance.

Handle and Controls: The ergonomic design of the handle and the placement of controls enhance user comfort and accessibility. This aspect is vital for safe and effective operation during extended use.

Understanding these key elements helps users maintain their equipment, ensuring reliability and performance in various cutting tasks.

Common Issues with Stihl 201T Parts

When operating a high-performance tool, it’s not uncommon to encounter various challenges related to its components. Understanding these common problems can help in maintaining efficiency and prolonging the lifespan of the equipment.

Here are some frequent issues that users might face:

- Wear and Tear: Components may degrade over time due to constant use, leading to reduced performance.

- Improper Assembly: Incorrect installation of parts can cause malfunction, resulting in safety hazards.

- Fuel System Problems: Clogged filters or damaged lines can hinder fuel flow, affecting engine performance.

- Electrical Failures: Wiring issues or faulty ignition components can lead to starting difficulties.

- Overheating: Insufficient lubrication or blocked cooling systems can cause overheating, risking damage.

Addressing these challenges promptly can ensure optimal performance and safety. Regular maintenance checks are essential to catch potential issues early.

Maintenance Tips for the 201T Chainsaw

Regular upkeep of your chainsaw is crucial for ensuring optimal performance and longevity. Implementing a consistent maintenance routine not only enhances efficiency but also guarantees safety during operation. Below are key strategies to keep your equipment in top shape.

Routine Cleaning

- After each use, remove debris and sawdust from the air filter and other components.

- Clean the chain and bar to prevent build-up that can lead to overheating.

- Inspect and clear the exhaust outlet to maintain proper airflow.

Regular Inspections

- Check the chain tension regularly to ensure proper operation.

- Examine the bar for signs of wear or damage; replace if necessary.

- Inspect fuel and oil levels before each use to prevent interruptions.

By following these maintenance tips, you can extend the life of your chainsaw and enhance its performance, making your cutting tasks more efficient and safer.

Where to Find Replacement Parts

When seeking components for maintenance or repair, it’s essential to know the best sources. Availability can vary, so exploring multiple options ensures you find the right pieces efficiently and at competitive prices.

Online Retailers

Numerous e-commerce platforms specialize in outdoor equipment. They often have extensive inventories and detailed descriptions, making it easier to locate what you need.

Local Dealers

Visiting authorized dealerships can provide access to original equipment and expert advice. This option supports local businesses and ensures you receive quality components.

| Source | Pros | Cons |

|---|---|---|

| Online Retailers | Wide selection, convenience | Shipping delays, potential mismatches |

| Local Dealers | Expert guidance, original quality | Higher prices, limited stock |

How to Read Parts Diagrams Effectively

Understanding schematic representations of components is crucial for anyone involved in maintenance or repair tasks. These visual aids provide a clear overview of individual elements and their relationships, making it easier to identify what is needed for a specific job. Mastering the art of interpreting these illustrations can save time and reduce frustration during assembly or troubleshooting.

Familiarize Yourself with Symbols

Each illustration often employs standardized symbols to represent various components. Take the time to familiarize yourself with these icons, as they can differ between manufacturers. Recognizing what each symbol stands for will enable you to navigate the layout with confidence, ensuring you can locate the required pieces without confusion.

Pay Attention to Labels and Numbers

Most visual guides include labels and numerical references that correspond to a parts list. These annotations provide vital information regarding specifications and compatibility. Carefully studying these details can enhance your understanding of how each element interacts with others, streamlining the selection process when sourcing replacements or upgrades.

Upgrading Your Stihl 201T Components

Enhancing the performance and longevity of your chainsaw can lead to improved efficiency and a better overall experience. Whether you are a professional arborist or a weekend warrior, upgrading certain elements can make a significant difference in how your equipment operates. In this section, we will explore various upgrades that can help elevate your tool to new heights.

Key Components to Consider

When looking to enhance your equipment, it’s essential to focus on the following components:

| Component | Benefits |

|---|---|

| Bar and Chain | Improved cutting efficiency and reduced friction. |

| Air Filter | Enhanced airflow for better combustion and performance. |

| Spark Plug | Reliable ignition for optimal engine performance. |

| Fuel System | Increased fuel efficiency and reduced emissions. |

Installation Tips

When upgrading components, always ensure you follow manufacturer guidelines for installation. Proper maintenance and regular inspections can also help you identify areas that need attention. Taking the time to upgrade will not only improve functionality but also prolong the life of your equipment.

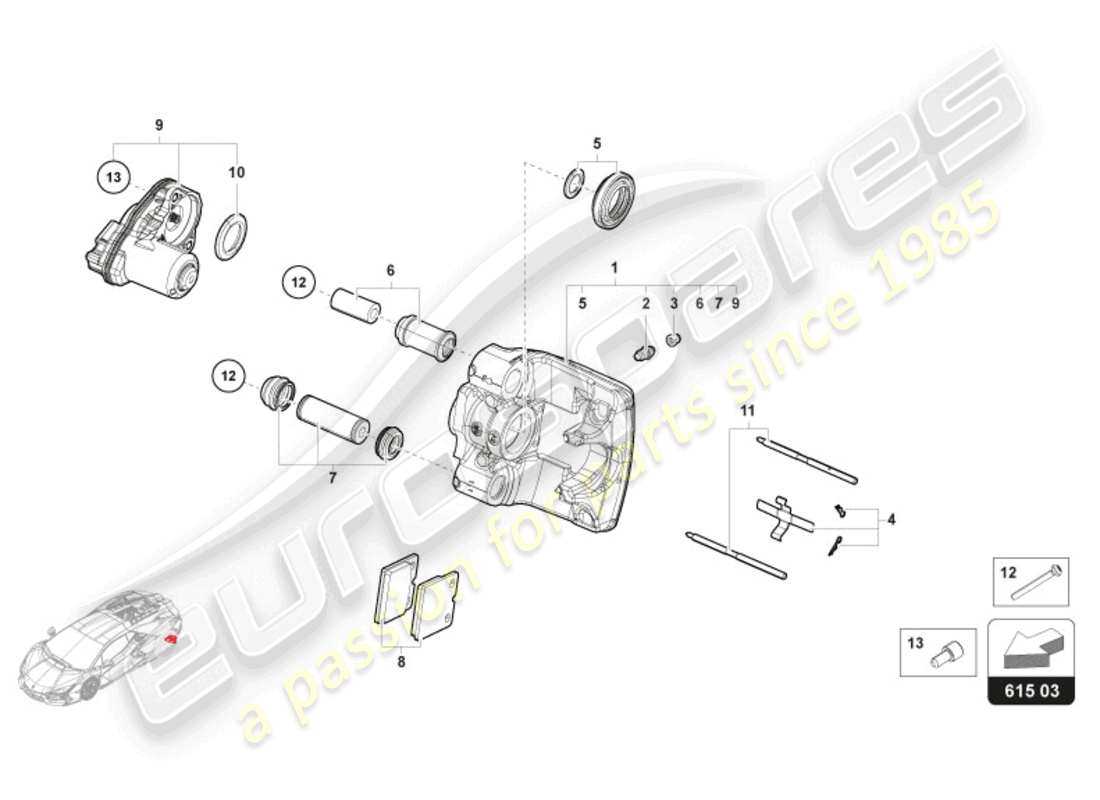

Comparing 201T Parts with Other Models

This section explores the differences and similarities among various components across different equipment models. By examining these variations, users can gain insights into compatibility, performance, and maintenance needs.

Understanding Compatibility: Each model may feature unique attributes that affect how components function together. Some elements might be interchangeable, while others are specifically designed for optimal performance.

Performance Analysis: Comparing components allows users to identify which designs enhance efficiency and longevity. Certain models may boast advanced technology that improves user experience compared to others.

Maintenance Considerations: Knowing the distinctions in parts can significantly impact maintenance routines. Models with more readily available components may offer easier upkeep, ensuring longevity and reliability.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and fixing of machinery. Whether tackling minor adjustments or more extensive repairs, a well-equipped toolkit enhances efficiency and ensures tasks are completed with precision.

Must-Have Tools

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: Necessary for various screws, available in different types and sizes.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Socket Set: Provides flexibility for various fastener sizes.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

Additional Equipment

- Multimeter: For electrical diagnostics and troubleshooting.

- Oil Can: Important for lubrication to prevent wear and tear.

- Cleaning Supplies: Brushes and cloths for maintaining cleanliness.

- Safety Gear: Gloves and goggles to protect against injuries.

Understanding Warranty on Components

Warranties play a crucial role in safeguarding consumers when acquiring essential machinery elements. They ensure that individuals receive quality and reliable products, promising repairs or replacements within a specified timeframe if defects arise under normal usage. Understanding these guarantees helps buyers make informed decisions and enhances confidence in their purchases.

Types of Warranties

There are typically two main categories of guarantees offered: limited and full warranties. Each type outlines specific conditions and coverage terms, affecting the consumer’s rights and responsibilities.

| Type | Coverage | Duration |

|---|---|---|

| Limited Warranty | Covers specific defects or issues | Varies, often 1-2 years |

| Full Warranty | Comprehensive coverage for defects | Usually 3 years or more |

Important Considerations

When evaluating these assurances, it’s vital to read the fine print, noting any exclusions or conditions that may apply. Keeping receipts and documentation will also facilitate any claims in the future, ensuring a smoother process if repairs or replacements become necessary.

Expert Advice on Stihl Products

When it comes to maintaining outdoor power equipment, having access to expert guidance can significantly enhance performance and longevity. Whether you’re a professional or a hobbyist, understanding the nuances of your tools is essential. This section provides valuable insights to ensure optimal use and care of your equipment.

Choosing the Right Equipment

Selecting the appropriate machinery for your specific tasks can make all the difference. Factors such as power requirements, weight, and intended use should guide your decision. Always consult with knowledgeable retailers or online forums for tailored recommendations that suit your unique needs.

Maintenance Tips for Longevity

| Task | Frequency | Benefits |

|---|---|---|

| Clean Air Filter | Every 10 hours of use | Improves airflow and engine performance |

| Sharpen Blades | As needed | Ensures clean cuts and reduces strain on the engine |

| Inspect Fuel System | Every month | Prevents clogs and maintains fuel efficiency |

| Check Spark Plug | Every 25 hours of use | Enhances ignition and overall engine performance |

By following these tips and staying informed, you can maximize the efficiency and lifespan of your outdoor equipment, ensuring reliable performance for years to come.