This section aims to provide a comprehensive overview of the essential elements that make up a drive mechanism. Each component plays a critical role in ensuring the smooth operation and efficiency of the entire system. By familiarizing yourself with these key elements, you can enhance your understanding and maintenance of the drive assembly.

In the following paragraphs, we will explore the various sections of the drive mechanism, highlighting their functions and interrelations. This knowledge is invaluable for anyone seeking to troubleshoot issues or perform upgrades, as it allows for a clearer grasp of how each part contributes to overall performance.

Whether you are a novice or an experienced user, having a clear representation of these components will aid in your projects. Gaining insight into their configurations and interactions will empower you to make informed decisions regarding repairs and enhancements.

Understanding Comet Clutch Functionality

This section delves into the operation of a vital component in various mechanical systems. The primary role of this assembly is to facilitate smooth transitions between power delivery and disengagement. By leveraging a series of interconnected elements, it ensures that motion is both effective and responsive to user input.

At its core, the mechanism relies on friction to engage and disengage, allowing for controlled acceleration and deceleration. When the driving force is applied, the system activates, transferring energy efficiently to the output. Conversely, when the force is reduced, the mechanism disengages, preventing unnecessary wear and enhancing overall durability.

Understanding the intricacies of this assembly can significantly improve performance. Regular maintenance and correct adjustments are crucial for ensuring optimal functionality, which ultimately leads to improved efficiency and longevity of the entire system.

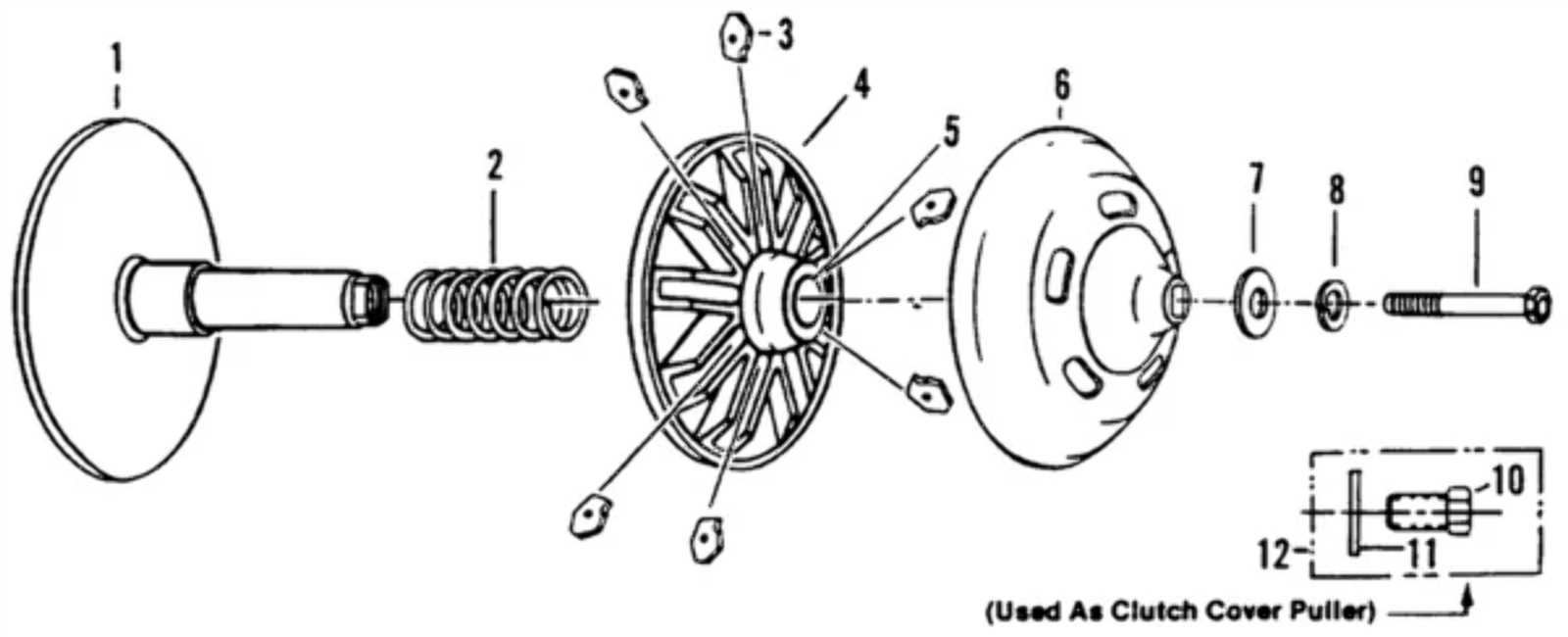

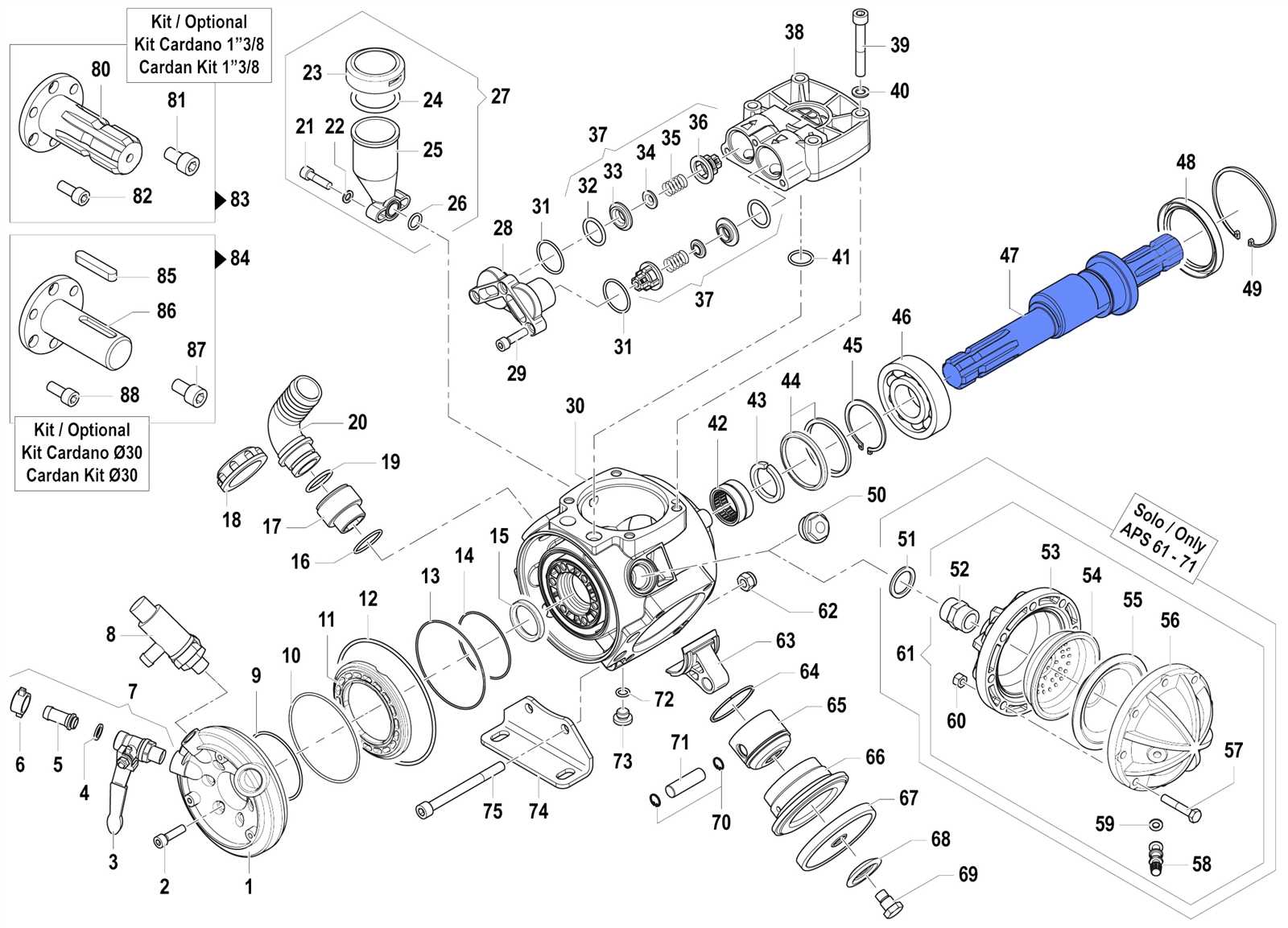

Components of the Clutch Assembly

The assembly responsible for engagement and disengagement in a transmission system comprises various elements that work in harmony to ensure smooth operation. Each component plays a crucial role in facilitating the transfer of power, allowing for efficient performance and control.

The primary element is a circular disc that interacts with the drive mechanism, creating the necessary friction for engagement. Adjacent to this, a pressure plate applies force to maintain contact, ensuring stability during operation. The release mechanism, often activated by a lever, disengages the system when needed, allowing for seamless shifting.

Diagram Overview and Its Importance

Understanding the layout of mechanical components is crucial for effective maintenance and operation. A well-illustrated representation provides a clear view of how different elements interact within a system, ensuring that users can identify each segment’s function and role.

Such visual aids serve not only as a reference tool but also enhance troubleshooting capabilities. By grasping the arrangement and connections, one can swiftly pinpoint issues and streamline repairs, ultimately leading to improved performance and longevity.

In addition, familiarity with these visuals fosters better communication among technicians, enabling them to discuss and share insights more effectively. This collaborative approach can significantly enhance problem-solving efficiency in various mechanical tasks.

Key Features of Comet Clutches

This section explores the distinctive characteristics that define high-performance mechanisms designed for efficient power transfer in various applications. Understanding these elements can enhance both functionality and reliability in operational settings.

Durability and Reliability

Robust construction ensures long-lasting performance, allowing these devices to withstand challenging conditions. This durability translates into fewer replacements and maintenance requirements, enhancing overall productivity.

Efficiency in Power Transfer

Designed to optimize the transfer of energy, these mechanisms minimize power loss. This efficiency is crucial in achieving peak performance across various systems.

| Feature | Description |

|---|---|

| Material Quality | High-grade materials are utilized for enhanced strength and longevity. |

| Design Precision | Engineered for exact fit, ensuring seamless integration into various systems. |

| Adaptability | Can be customized for different applications, providing versatility. |

Common Applications for Clutch Systems

These mechanisms play a crucial role in various vehicles and machinery, allowing for efficient power transfer and control. Their versatility makes them suitable for a wide range of applications across different industries.

- Automobiles: Essential for smooth gear transitions and engine power management.

- Motorcycles: Provide effective control for acceleration and deceleration.

- Agricultural Equipment: Enable the operation of heavy machinery, enhancing productivity in farming tasks.

- Industrial Machinery: Allow for precise control in manufacturing processes, ensuring optimal performance.

- Marine Applications: Facilitate smooth operation in boats and ships, contributing to better maneuverability.

Overall, these systems are integral to the functionality and efficiency of various transport and industrial applications, highlighting their importance in everyday operations.

How to Interpret the Diagram

Understanding the layout of mechanical components is crucial for effective assembly and maintenance. This section will guide you through the essential aspects of reading and making sense of these representations.

- Familiarize with Symbols: Recognize the common symbols used to represent various elements. This knowledge will enhance your ability to quickly identify each part’s function.

- Follow Connections: Pay attention to the lines connecting different parts. These indicate relationships and flow, helping you understand how components interact.

- Refer to Annotations: Annotations often provide valuable information about measurements, materials, or specifications. Review them thoroughly for a complete understanding.

- Use a Reference Guide: If available, consult a reference guide that explains each symbol and line in detail. This can be especially helpful for beginners.

By mastering these elements, you will gain confidence in interpreting the layout and successfully working with the assembly.

Maintenance Tips for Clutch Parts

Proper upkeep of essential components in your vehicle’s transmission system is crucial for optimal performance and longevity. Regular maintenance not only enhances functionality but also prevents costly repairs down the line. Adopting a proactive approach ensures that all elements work harmoniously.

Here are some valuable tips to keep in mind:

| Tip | Description |

|---|---|

| Regular Inspection | Frequently check for wear and tear. Look for signs of damage or excessive friction. |

| Lubrication | Ensure all moving parts are adequately lubricated to minimize wear and enhance performance. |

| Clean Components | Remove dirt and debris from surfaces to prevent contamination that can lead to malfunction. |

| Monitor Usage | Keep an eye on how often and how hard you use the system to anticipate maintenance needs. |

| Seek Professional Help | When in doubt, consult a qualified technician to assess the condition and perform necessary repairs. |

Troubleshooting Common Clutch Issues

Understanding the typical challenges associated with the engagement mechanism can significantly enhance performance and reliability. Identifying these problems early can prevent more serious complications, ensuring a smoother operation.

Here are some common issues you might encounter:

- Slipping Mechanism: This can occur when the engagement system does not fully engage, often due to wear or improper adjustment.

- No Engagement: If the system fails to respond when activated, it may indicate a failure in the activation mechanism or misalignment.

- Unusual Noises: Any grinding or clicking sounds can suggest worn components or lack of lubrication.

- Excessive Heat: Overheating can result from prolonged use or inadequate cooling, leading to potential damage.

To address these issues, consider the following steps:

- Inspect all connections and ensure proper alignment.

- Check for any signs of wear or damage on the components.

- Verify that all lubricants are applied correctly and are in good condition.

- Consult the manufacturer’s guidelines for any specific troubleshooting techniques.

By following these steps, you can effectively diagnose and resolve the most common issues, ensuring optimal performance.

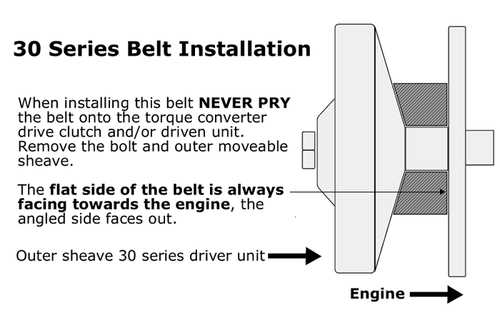

Installation Guidelines for Clutch Components

Proper assembly of essential elements is crucial for ensuring optimal performance and longevity of the system. Following specific steps and guidelines can help achieve a seamless integration, reducing the likelihood of future issues.

Before beginning, ensure all necessary tools and components are at hand. Start by carefully inspecting each item for any signs of wear or damage. It’s important to follow the manufacturer’s recommendations for alignment and torque specifications during the installation process.

When positioning the components, ensure they fit snugly without any obstructions. This can help prevent unnecessary friction and ensure smooth operation. Additionally, double-check all connections to confirm they are secure and properly oriented.

Once the elements are installed, conduct a thorough test to verify functionality. Monitoring the system during initial use can help identify any adjustments needed for optimal performance. Regular maintenance checks are also advised to prolong the lifespan of the assembly.

Performance Enhancements for Clutch Systems

Optimizing the efficiency and responsiveness of transmission components can significantly elevate overall vehicle performance. Various strategies can be employed to enhance these systems, providing improved engagement, reduced slippage, and increased durability.

- Upgraded Materials: Utilizing advanced materials in the construction of these components can enhance strength and longevity, allowing for better performance under demanding conditions.

- Improved Design: Adopting innovative design modifications can lead to more efficient power transfer and smoother operation, reducing wear and tear over time.

- Precision Engineering: Ensuring that components are manufactured to tighter tolerances can minimize play and enhance the engagement process, resulting in a more responsive experience.

- Heat Dissipation: Incorporating better cooling mechanisms can prevent overheating, which is crucial for maintaining performance during prolonged use.

Implementing these enhancements can lead to a significant improvement in vehicle handling and acceleration, making for a more enjoyable driving experience.

Comparative Analysis with Other Clutches

This section provides an examination of the functional elements and mechanisms found in various engagement systems, highlighting the distinctions and similarities between different types. Understanding these variations can enhance the selection process for specific applications and performance needs.

Performance Characteristics

When assessing performance, key factors such as responsiveness, durability, and ease of installation come into play. Certain systems may offer superior engagement speed, while others excel in longevity under high-stress conditions. Evaluating these traits can lead to informed choices based on the demands of the intended use.

Design and Construction

The design approaches across different models reveal a spectrum of engineering philosophies. Some utilize advanced materials for weight reduction and strength, while others focus on traditional components for reliability. By analyzing these constructions, one can appreciate how engineering choices affect overall performance and maintenance requirements.

Frequently Asked Questions About Clutches

This section addresses common inquiries regarding a crucial component in various mechanical systems. Understanding these elements can enhance performance and longevity, ensuring smooth operation in different applications.

What is the primary function of this component?

Its main role is to engage and disengage the connection between two rotating shafts, allowing for controlled power transfer and enabling smoother starts and stops.

How do I know when it needs replacement?

Signs of wear include slipping during operation, unusual noises, or difficulty in engaging or disengaging. Regular maintenance checks can help identify these issues early.

Can I install it myself?

While some may choose to undertake the installation process, it requires specific tools and knowledge. It’s often recommended to consult a professional to ensure proper alignment and functionality.

What factors affect its lifespan?

Several elements influence durability, including operating conditions, maintenance frequency, and the quality of materials used. Keeping the system clean and well-lubricated can significantly extend its life.