In the realm of farming equipment, the intricate assembly of various elements plays a crucial role in ensuring optimal functionality and efficiency. Recognizing how these components interact can significantly enhance maintenance and repair processes.

For operators and enthusiasts alike, having access to a visual representation of these mechanisms fosters a deeper comprehension of their structure. This knowledge not only simplifies troubleshooting but also aids in identifying potential upgrades or replacements that can improve overall performance.

Ultimately, diving into the specifics of these assemblies empowers users to take charge of their machinery, leading to more effective management and longevity of the equipment. By exploring this topic, one can unlock the secrets to maintaining a well-oiled agricultural operation.

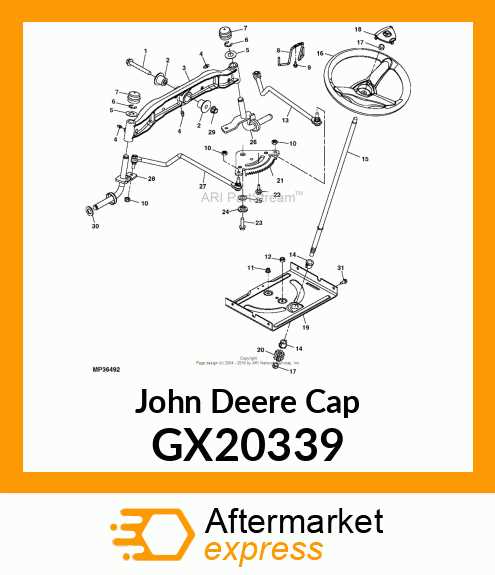

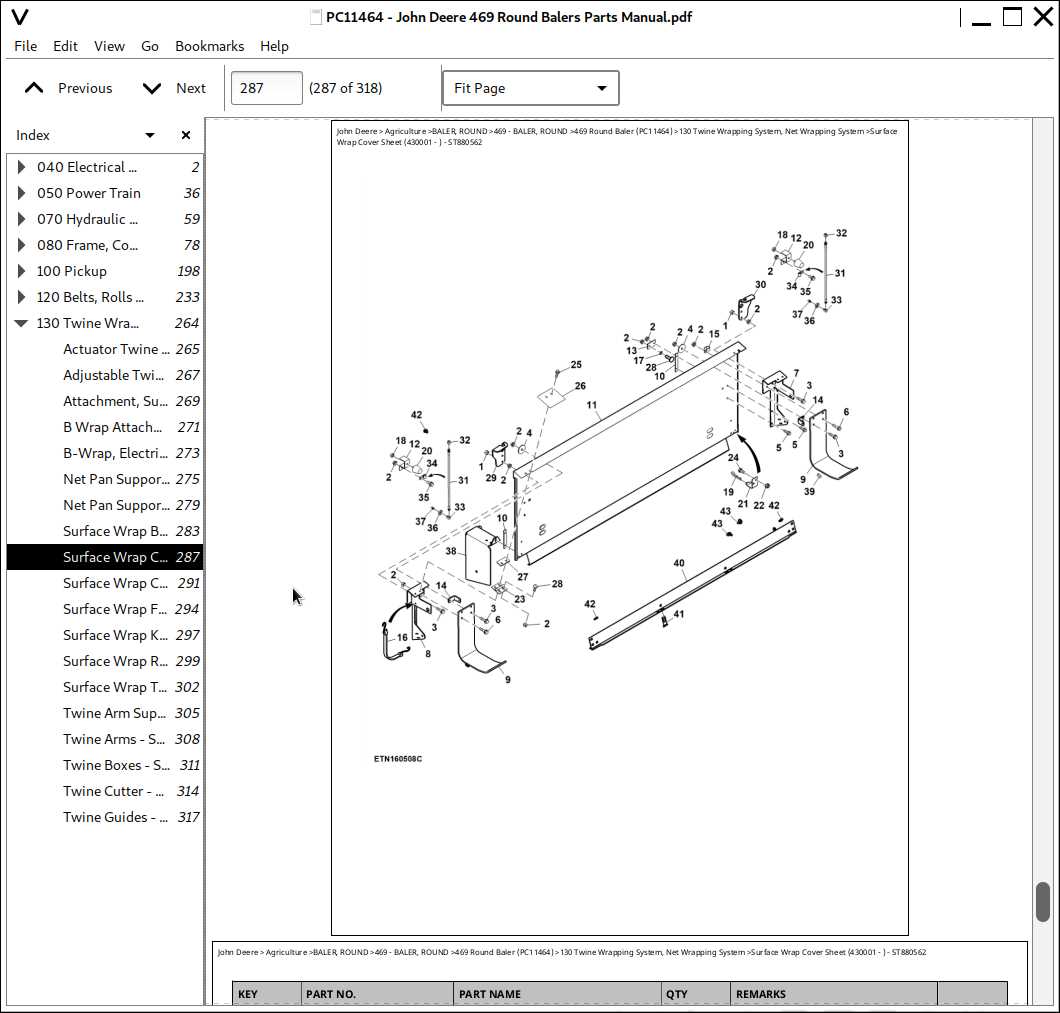

Understanding John Deere 130 Parts

This section aims to provide a comprehensive overview of the components involved in a specific agricultural machinery model. Familiarity with these elements can enhance maintenance and repair processes, ensuring optimal performance in various tasks.

Key Components

- Engine assembly

- Transmission system

- Cutting deck

- Steering mechanism

- Wheels and tires

Maintenance Tips

- Regularly check fluid levels.

- Inspect belts and cables for wear.

- Clean air filters periodically.

- Replace worn components promptly.

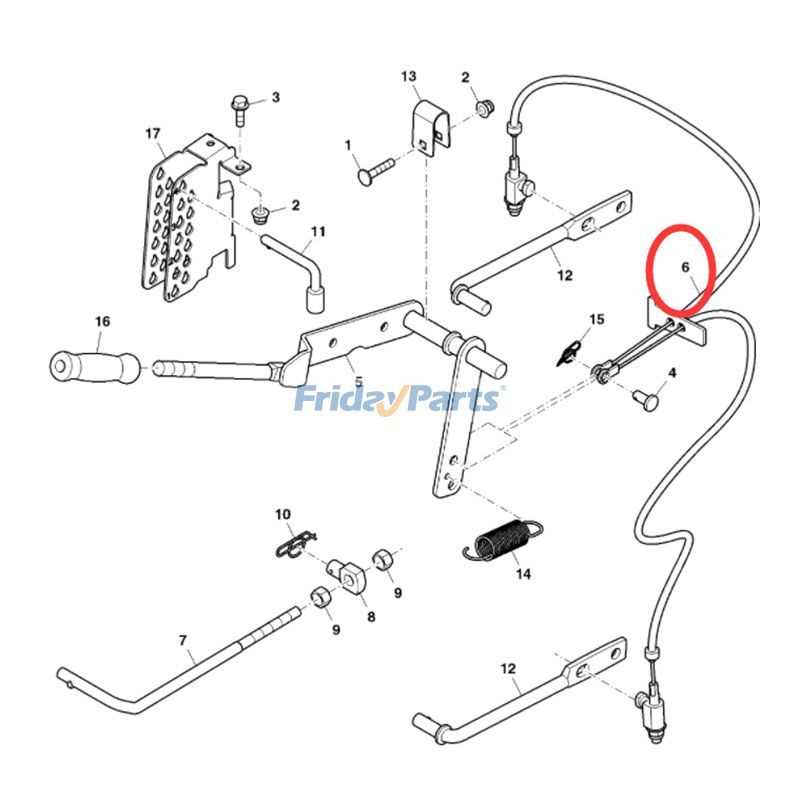

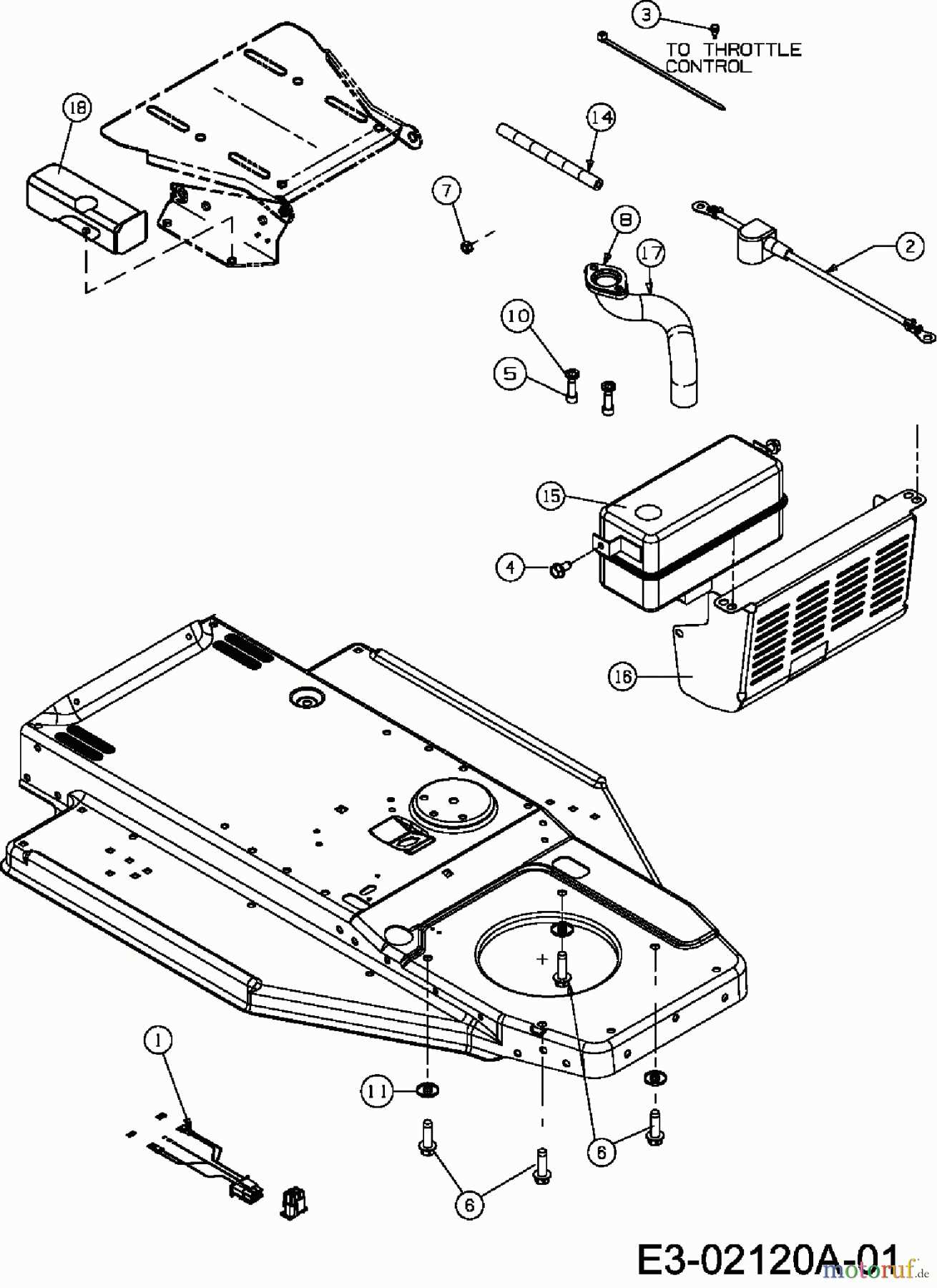

Importance of Accurate Diagrams

Having precise visual representations is crucial for effective maintenance and repair tasks. These illustrations serve as vital tools that guide users through complex processes, ensuring that every component is correctly identified and assembled.

Enhancing Understanding

Accurate visual aids improve comprehension of machinery functionality and assembly. They provide clarity, helping users to:

- Identify individual components easily

- Understand the relationship between parts

- Minimize errors during installation

Boosting Efficiency

Using reliable visual references can significantly speed up maintenance procedures. Key benefits include:

- Reduced downtime for repairs

- Streamlined workflows

- Increased productivity and accuracy

Common Issues with John Deere 130

When dealing with a popular lawn maintenance machine, operators often encounter several typical problems that can affect performance and efficiency. Understanding these issues can help in timely troubleshooting and maintenance, ensuring that the equipment runs smoothly.

Frequent Challenges

- Engine Difficulties: Common signs include hard starting or stalling, which may indicate fuel or ignition issues.

- Cutting Quality: Uneven or inconsistent cutting can result from dull blades or improper deck height adjustments.

- Transmission Problems: Slipping gears or difficulty shifting may point to low fluid levels or worn components.

- Electrical Failures: Symptoms like dead batteries or malfunctioning lights often stem from faulty wiring or corroded connections.

Maintenance Tips

- Regularly check and replace the air filter to ensure optimal airflow to the engine.

- Sharpen or replace blades at the start of each season to maintain cutting efficiency.

- Inspect belts and cables for wear and tear to prevent unexpected breakdowns.

- Keep the fuel system clean by using quality fuel and regularly changing fuel filters.

How to Source Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. This section outlines effective strategies to help you locate the necessary items with ease and confidence.

- Identify Your Needs: Before beginning your search, ensure you have a clear understanding of the specific items required. Consider making a list based on functionality or area of the machine.

- Consult the Manual: Refer to the equipment’s manual for detailed information on specifications and compatible alternatives. This document often contains crucial details that will aid in your search.

- Visit Authorized Dealers: Seek out certified retailers who specialize in your brand. They typically offer genuine items and can provide valuable insights on compatibility and quality.

- Explore Online Marketplaces: Websites dedicated to machinery components can be excellent resources. Use search filters to narrow down options and read reviews to ensure reliability.

- Consider Used Components: Look into second-hand options. Many platforms offer refurbished or gently used items that can be more affordable while still maintaining quality.

- Join Online Forums: Engage with communities dedicated to your type of equipment. Members often share recommendations and can point you to trustworthy sources.

lessCopy code

By employing these strategies, you can successfully navigate the process of sourcing the right components, ensuring your machinery operates smoothly for years to come.

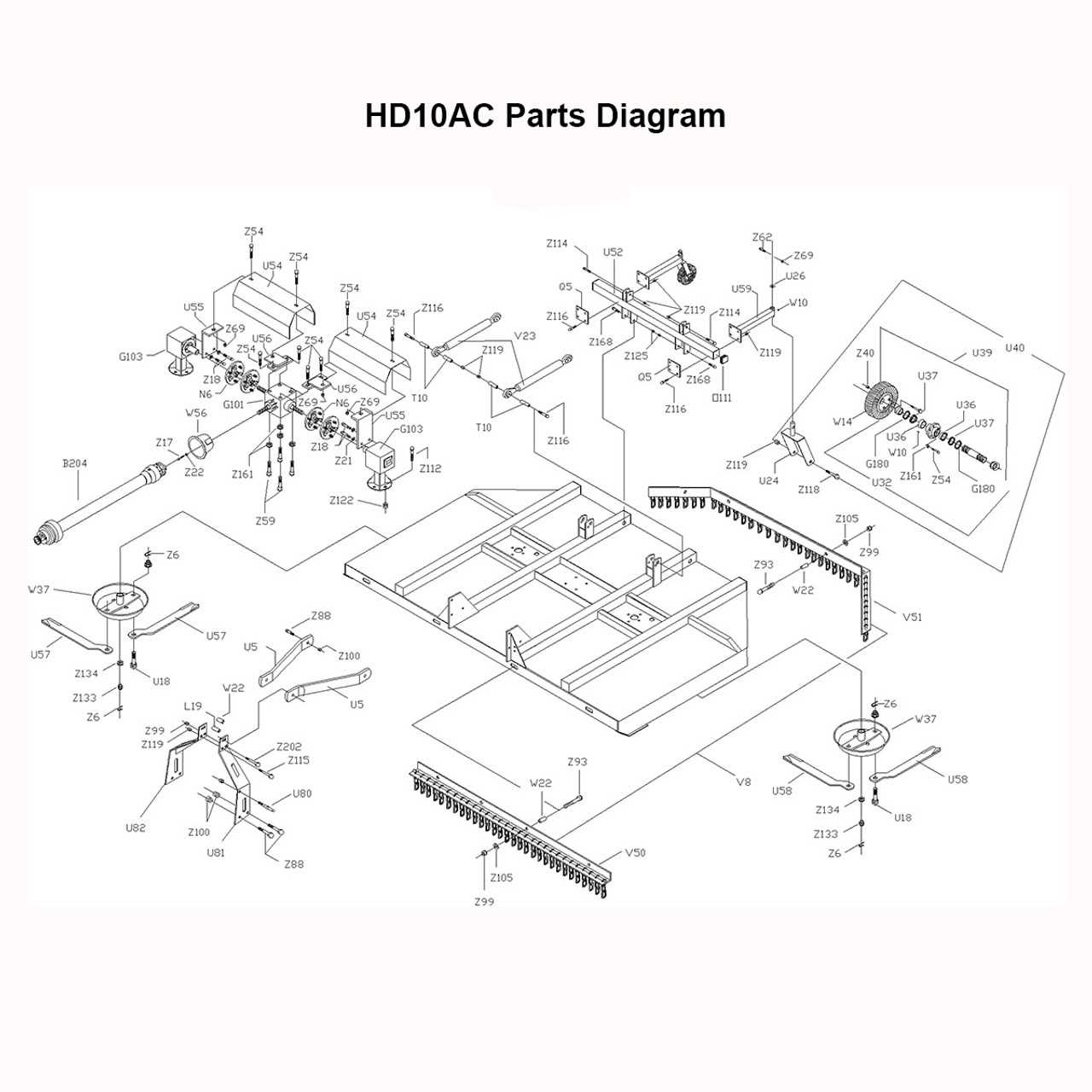

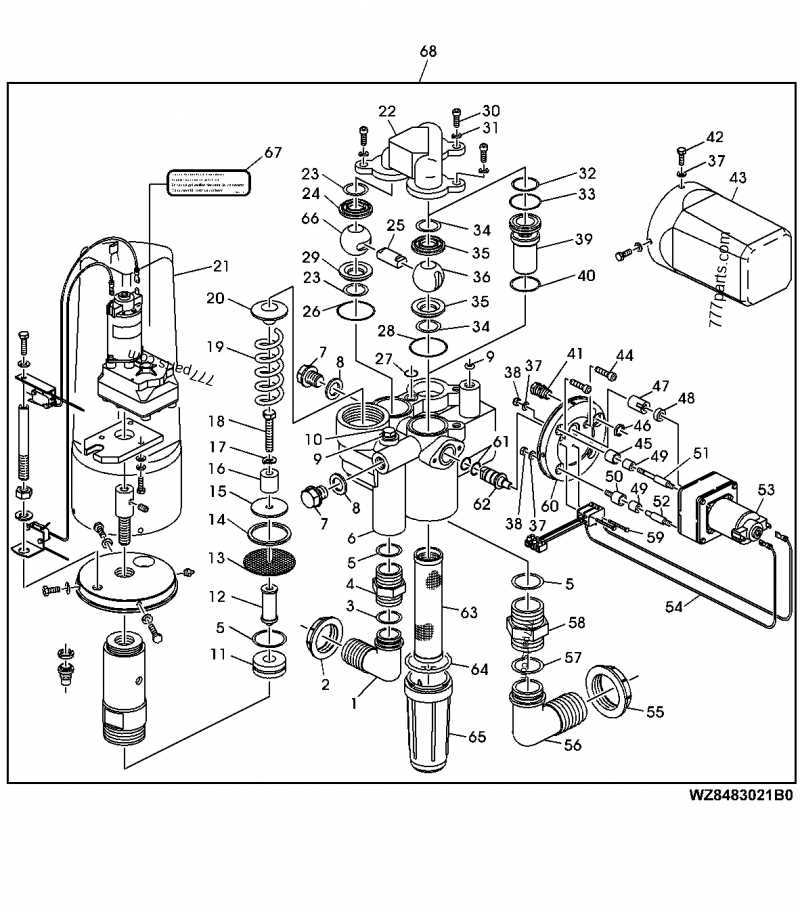

Identifying Key Components in Diagrams

Understanding the intricate details of technical illustrations is essential for effective maintenance and repairs. These visuals often serve as a roadmap, guiding users through the various elements that comprise complex machinery. By familiarizing oneself with the essential parts depicted in these graphics, one can enhance both comprehension and efficiency in addressing mechanical issues.

Familiarity with Symbols: Recognizing common symbols and notations is crucial. Each icon typically represents a specific component, and understanding these can streamline the identification process. For instance, gears may be denoted with unique shapes, while connectors might have standardized markings.

Interpreting Relationships: Analyzing how different elements interact is equally important. Many illustrations highlight connections between components, indicating how they work together within the system. Grasping these relationships can provide insights into potential points of failure and maintenance needs.

Reference Guides: Utilizing reference materials can further aid in deciphering complex visuals. Manuals or online resources often include glossaries that explain various symbols and their meanings. These guides serve as valuable tools for anyone seeking to deepen their understanding of machinery layouts.

Ultimately, the ability to effectively interpret technical illustrations not only enhances problem-solving capabilities but also fosters greater confidence in handling machinery.

Maintenance Tips for John Deere 130

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. Implementing a few straightforward strategies can help you maintain its efficiency and prevent potential issues down the line. Here are some vital tips to keep your machine in peak condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace the engine oil and filter to ensure proper lubrication and prevent wear. |

| Air Filter Check | Every 25 hours | Inspect and clean or replace the air filter to maintain airflow and engine performance. |

| Blade Sharpening | As needed | Keep blades sharp for a clean cut, which promotes healthier grass growth. |

| Tire Pressure | Monthly | Check and adjust tire pressure to improve traction and reduce wear. |

| Battery Maintenance | Seasonally | Inspect battery terminals for corrosion and ensure a full charge for reliable starts. |

By following these guidelines, you can significantly enhance the performance and durability of your machinery, ensuring it serves you well for many seasons to come.

Comparing Models: John Deere 130 vs Others

This section explores the similarities and differences among various models in the same category, focusing on performance, features, and user experience. By examining these elements, we can provide insights into which model might best suit specific needs.

When comparing different models, several key factors should be considered:

- Engine Power: Assessing the horsepower and torque can help determine suitability for various tasks.

- Cutting Width: A wider cutting deck may enhance efficiency, especially for larger areas.

- Durability: Evaluating the materials used in construction can indicate long-term reliability.

- Maintenance Requirements: Understanding the upkeep involved is crucial for ownership experience.

- Comfort Features: Ergonomic design and ease of operation can significantly impact user satisfaction.

Here are some notable models to consider:

- Model A: Known for its robust engine and efficient cutting capabilities, making it ideal for extensive lawns.

- Model B: Features a compact design suited for smaller spaces, offering agility and ease of maneuverability.

- Model C: This variant emphasizes comfort with enhanced seating and controls, perfect for extended use.

By weighing these factors and comparing various options, potential buyers can make informed decisions tailored to their specific landscaping requirements.

Tools Needed for Repairs

When undertaking maintenance or repair tasks on machinery, having the right tools is essential for ensuring efficiency and accuracy. Each repair job requires specific implements to facilitate the process, minimize damage, and enhance safety. Whether you are a professional or a hobbyist, equipping yourself with the proper instruments can significantly impact the quality of your work.

Essential Hand Tools

Hand tools are fundamental for most repair tasks. Wrenches, screwdrivers, and pliers are critical for loosening, tightening, and manipulating various components. Additionally, having a reliable set of sockets can make accessing hard-to-reach areas much simpler. A comprehensive tool kit that includes these essentials will prepare you for a wide range of repairs.

Power Tools and Accessories

In many cases, power tools can expedite the repair process. Drills, impact wrenches, and grinders offer increased efficiency and precision, especially for tougher jobs. It is also advisable to have a variety of drill bits and attachments to accommodate different materials and tasks. Investing in quality power tools will not only save time but also enhance the overall outcome of your repair efforts.

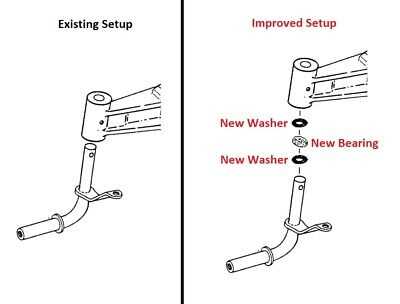

Expert Advice on Parts Replacement

When it comes to maintaining machinery, understanding the intricacies of component replacement is essential. Whether you’re a seasoned operator or a novice, knowing how to effectively swap out elements can prolong the lifespan of your equipment and ensure optimal performance. Proper guidance can make this process more efficient and less daunting.

Assessing Wear and Damage

Before embarking on any replacement, it’s crucial to evaluate the condition of the components in question. Look for signs of wear, corrosion, or any irregularities that could affect functionality. Regular inspections can help you identify potential issues before they escalate, allowing for timely interventions that save both time and resources.

Choosing Quality Alternatives

When sourcing new components, always opt for high-quality alternatives that meet or exceed manufacturer specifications. While it may be tempting to choose cheaper options, investing in reliable replacements ensures longevity and enhances the overall efficiency of your machinery. Research trusted suppliers and read reviews to make informed choices that will serve you well in the long run.

Online Resources for Parts Diagrams

Accessing comprehensive resources online can significantly enhance the experience of finding components for various machinery. Numerous platforms provide detailed visuals and information, making it easier for users to identify and source the necessary elements for maintenance and repairs.

Official Manufacturer Websites often serve as the most reliable source, offering up-to-date visuals and specifications directly related to their products. These sites usually include user-friendly search functions and downloadable content.

Third-Party Retailers also contribute valuable resources, often featuring expansive catalogs with images and descriptions. These platforms can help users compare prices and availability across different suppliers.

Online Forums and Communities provide a space for enthusiasts and professionals to share insights. Users can post inquiries and receive guidance on identifying specific elements, as well as recommendations on sourcing.

Utilizing these online platforms can ultimately streamline the process of locating the right components, ensuring that machinery remains in optimal condition.

Understanding Warranty on Replacement Parts

When it comes to sourcing components for machinery, comprehending the warranty associated with these replacements is crucial. A solid warranty not only provides assurance of quality but also serves as a safeguard for investment.

Key Aspects of Warranties

- Coverage Duration: Warranties typically specify how long the coverage lasts.

- Types of Defects: It’s essential to know which defects are included in the warranty.

- Limitations: Understand any limitations that might apply to the warranty claims.

Importance of Keeping Records

Maintaining thorough documentation of purchases and warranty details is vital. This can expedite the claims process and ensure that you receive the ultimate support when needed.