Clean any di

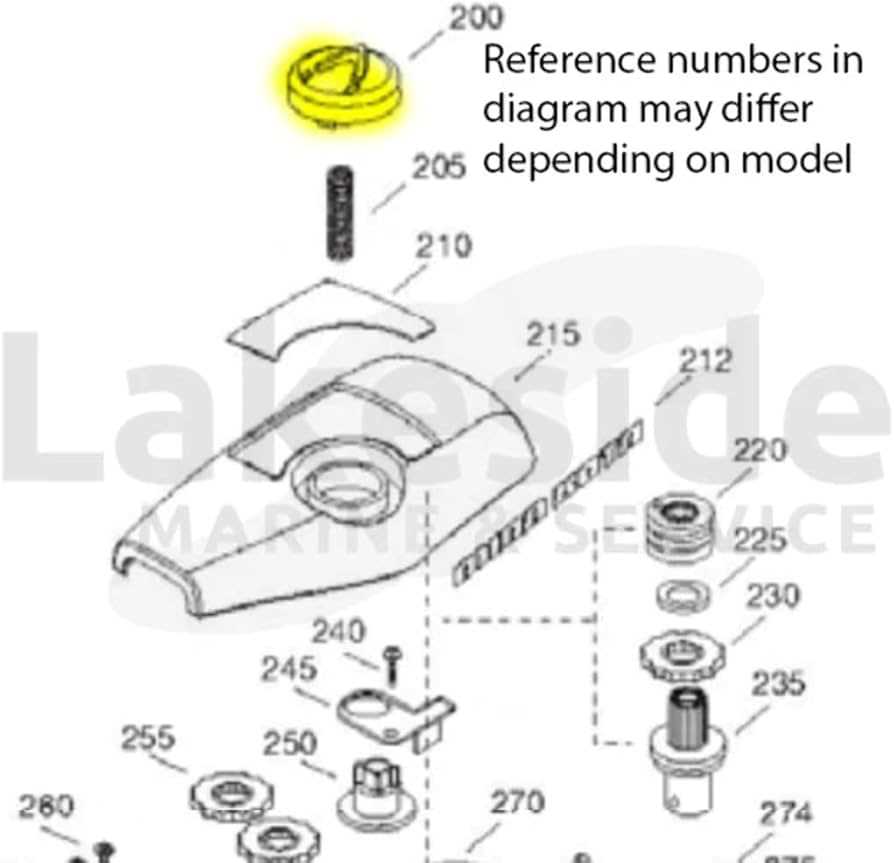

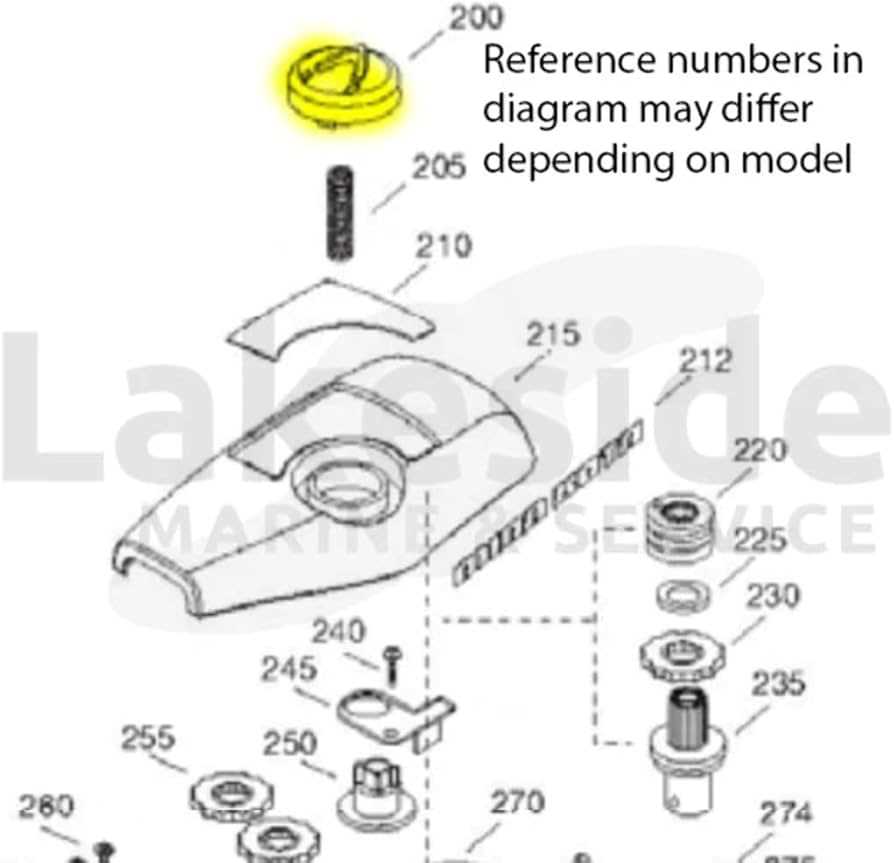

Mount Assembly: A Detailed Overview

This section provides an in-depth look at the components and functions involved in the mounting mechanism of a specific model. Understanding the assembly is crucial for ensuring proper installation and maintenance, which contributes to optimal performance and longevity.

Key Components

The mount assembly consists of several essential parts that work together to support the overall structure. Each component plays a unique role in enhancing stability and functionality.

| Component Name |

Description |

| Base Plate |

This part serves as the foundation for the assembly, providing a sturdy surface for mounting. |

| Pivot Arm |

Facilitates movement, allowing for adjustments in angle and positioning. |

| Locking Mechanism |

Ensures that the assembly remains securely in place during operation. |

| Mounting Brackets |

These parts attach the assembly to the main structure, providing additional support. |

Installation Tips

For effective setup, it is important to follow a few guidelines. First, ensure that all components are compatible and in good condition. Proper alignment during installation is vital to prevent any potential issues. Regular checks and maintenance can also help maintain functionality over time.

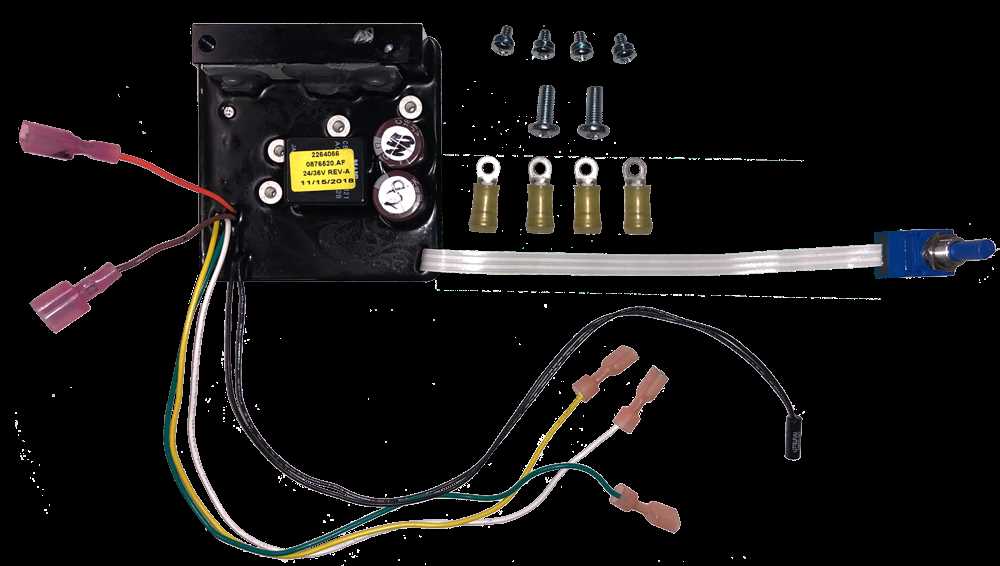

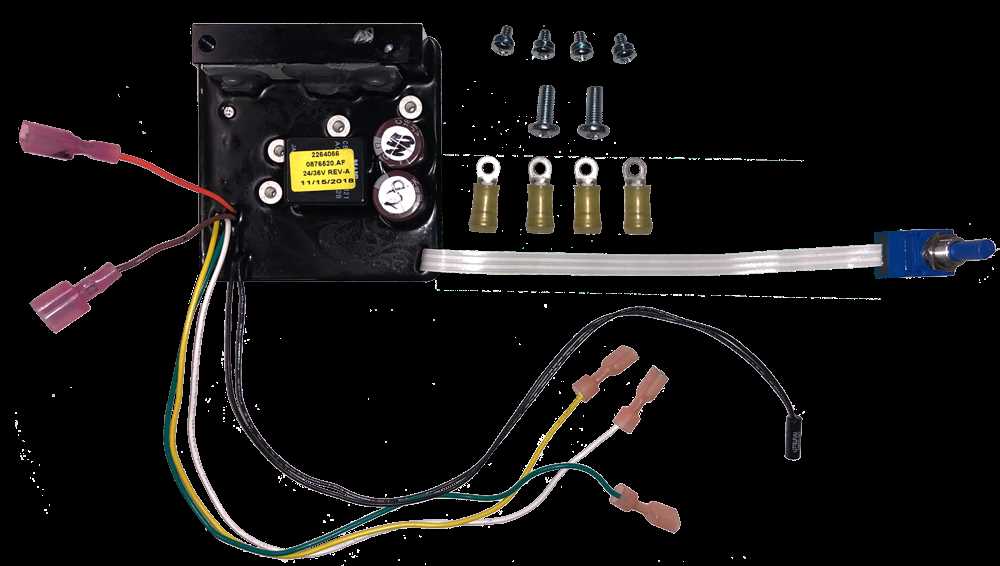

Fortrex Control Board Layout

The control board is a vital component that manages the operation of the system, ensuring seamless functionality. Understanding its layout is essential for efficient maintenance and troubleshooting. This section provides an overview of the key features and arrangements found on the control panel.

Typically, the layout includes various elements such as connectors, switches, and indicator lights, each serving a specific purpose. Recognizing the positioning of these components can facilitate easier diagnostics and repairs. Moreover, familiarity with the arrangement aids in identifying potential issues and optimizing performance.

Propeller Mechanism and Adjustments

The propeller system plays a crucial role in the overall functionality of a motorized vessel. Understanding its components and the adjustments required for optimal performance is essential for achieving the best results on the water. This section will explore the mechanism of the propeller and the necessary modifications that can enhance its efficiency.

Understanding the Propeller Components

A propeller consists of several key elements that work together to create thrust and maneuverability. The main components include:

- Blades: The angled surfaces that push water backward, generating forward movement.

- Hub: The central part that connects the blades to the motor shaft.

- Nut: A fastening device that secures the propeller to the shaft.

Making Adjustments for Optimal Performance

To ensure the propeller operates effectively, various adjustments may be necessary. Consider the following:

- Pitch Adjustment: Modifying the angle of the blades can affect speed and torque.

- Height Adjustment: Positioning the propeller at the correct height can enhance efficiency and reduce drag.

- Blade Inspection: Regularly checking for damage or wear can prevent performance issues.

By understanding the mechanics of the propeller and implementing the right adjustments, users can significantly improve their vessel’s performance on the water.

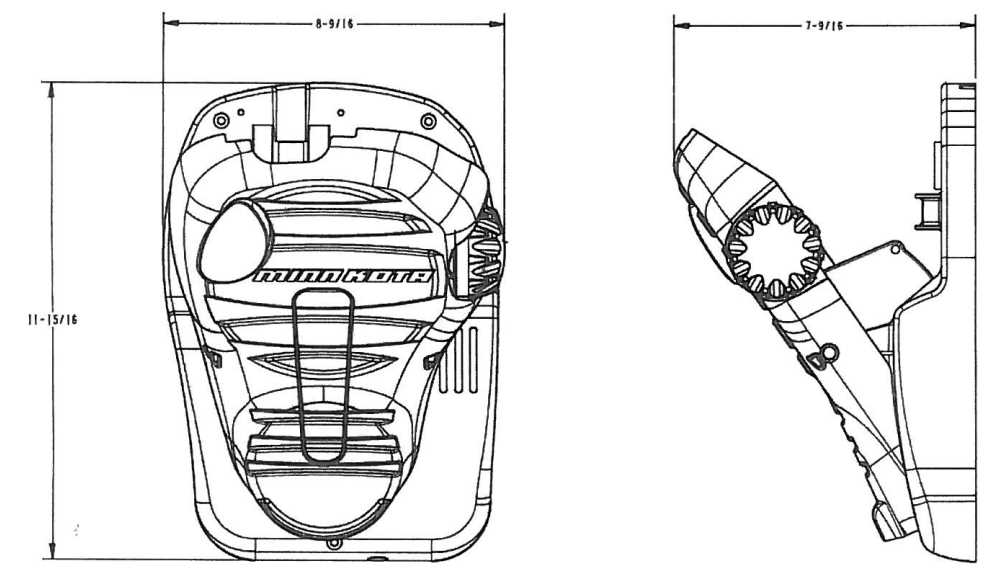

Foot Pedal Functionality and Setup

The foot-operated control mechanism serves as a vital interface for managing various aspects of a boat’s movement and maneuverability. This section explores the essential features and configuration of this tool, highlighting how it enhances user experience and operational efficiency.

Understanding the Controls: The foot pedal typically includes multiple buttons and switches, allowing the operator to adjust speed, direction, and other functions seamlessly. Each control is designed for intuitive use, enabling quick reactions to changing conditions on the water.

Setup Process: To properly configure the foot-operated unit, it is crucial to connect it securely to the power source and ensure that all components are functioning correctly. Following the manufacturer’s guidelines for installation will facilitate optimal performance.

Tuning for Optimal Performance: Adjusting the sensitivity and response settings can greatly enhance the overall effectiveness of the foot pedal. Experimenting with these settings allows users to find the perfect balance that meets their specific needs while navigating.

Maintenance Tips: Regular inspections and cleaning of the foot pedal ensure longevity and reliability. Keeping the connections free from corrosion and ensuring that all moving parts are well-lubricated will prevent malfunctions during use.

Handle and Lift Assist Features

The design of modern towing mechanisms incorporates advanced features that enhance usability and convenience. These components are crafted to facilitate the operation of lifting and maneuvering, making them essential for efficient handling during various tasks.

Ergonomic handles play a crucial role in providing a comfortable grip, ensuring that users can operate the device with ease. The thoughtful placement and design of these handles allow for minimal strain on the hands and wrists, promoting longer usage without discomfort.

Additionally, the lift assist functionality significantly reduces the effort required to raise and lower the mechanism. This feature is particularly beneficial in situations where frequent adjustments are necessary, allowing for smoother transitions and improved control. Overall, these elements work together to enhance the overall experience, making tasks more manageable and efficient.

Replacing Worn-Out Fortrex Parts

Over time, components of a boat’s propulsion system may experience wear and tear, leading to reduced performance. Timely replacement of these elements is essential to maintain efficiency and ensure smooth operation on the water. Understanding which parts require attention and how to replace them effectively can enhance the longevity of your equipment.

Identifying Worn Components

Recognizing signs of wear is crucial for effective maintenance. Look for unusual noises, decreased speed, or instability during operation. Regular inspections can help pinpoint areas that need replacement. Keep an eye out for frayed cables, rusted fittings, or damaged housing, as these are common indicators that it’s time for an upgrade.

Steps for Replacement

Once you’ve identified the components that need replacing, follow these steps for a successful upgrade:

- Gather Necessary Tools: Ensure you have all required tools handy before starting the replacement process.

- Follow Manufacturer Guidelines: Consult the manual for specific instructions related to the components being replaced.

- Test the New Components: After installation, conduct a thorough test to ensure everything functions correctly.

By staying proactive in maintaining your equipment, you can enjoy seamless adventures on the water without unnecessary interruptions.

Ordering Compatible Replacement Components

When seeking to acquire suitable substitute elements for your equipment, it is essential to ensure compatibility with existing components. This process not only enhances performance but also prolongs the lifespan of your device. Understanding the specifications and requirements of the parts you need will help streamline your purchasing experience.

Identifying Required Components

Begin by examining your current setup to determine which elements require replacement. Make a list of the components that are not functioning optimally or have been damaged. It is advisable to reference the user manual or manufacturer’s guidelines to confirm the specifications needed for each part.

Where to Purchase

There are numerous avenues for acquiring compatible replacements. Authorized dealers, online retailers, and specialty shops often provide a wide selection of components. Ensure that you purchase from reputable sources to avoid subpar quality. Additionally, checking for customer reviews can offer insights into the reliability of the components offered.