In the realm of machinery and equipment, comprehending the intricate arrangement of individual elements is essential for seamless operation and maintenance. Such layouts provide valuable insights into how various parts interact and function together, ensuring optimal performance and longevity. By grasping these configurations, operators can identify potential issues, streamline repair processes, and enhance overall efficiency.

Detailed visual representations serve as indispensable tools for technicians and engineers alike. They illustrate the relationships between components, enabling a clearer understanding of how each part contributes to the system’s functionality. Moreover, these representations assist in troubleshooting by pinpointing specific areas that may require attention, thereby preventing prolonged downtime and unnecessary costs.

For anyone involved in the upkeep of machinery, familiarization with these illustrative layouts is not merely beneficial but crucial. By enhancing one’s ability to interpret these resources, maintenance can be executed with greater precision and confidence, ultimately leading to improved productivity and reliability. In the following sections, we will delve deeper into the specifics of these representations, equipping you with the knowledge necessary to navigate them effectively.

Understanding Hu625hwt Components Overview

This section provides a comprehensive overview of the various elements that make up a specific mechanical assembly. By examining the key components and their functions, users can gain insight into the overall operation and maintenance of the system. A well-structured understanding of these elements is crucial for effective troubleshooting and optimization.

Main Elements

- Engine Assembly

- Transmission Unit

- Cooling System

- Fuel Delivery Mechanism

Functional Roles

- Engine Assembly: Responsible for converting fuel into mechanical energy.

- Transmission Unit: Facilitates the transfer of power from the engine to the wheels.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Fuel Delivery Mechanism: Ensures a consistent supply of fuel to the engine for efficient operation.

Understanding these crucial elements allows for better comprehension of the system’s functionality, leading to improved performance and longevity.

Importance of Accurate Parts Diagram

Having precise visual representations of components is crucial for effective assembly, maintenance, and troubleshooting. These illustrations serve as essential guides, enabling users to comprehend the relationship between various elements and ensuring that each piece fits together seamlessly. Accurate depictions not only facilitate the repair process but also enhance the overall understanding of complex systems.

Enhancing Efficiency and Reducing Errors

When technicians and operators work with reliable visuals, they can significantly reduce the likelihood of mistakes during installation or repairs. Clear and detailed representations allow for quicker identification of necessary components, minimizing the time spent searching for the correct elements. This efficiency leads to faster turnaround times and improved productivity in various settings.

Supporting Safety and Compliance

Accurate visual guides are vital for ensuring safety standards are met. By clearly outlining the correct placement and orientation of each component, users can avoid potentially hazardous situations that may arise from improper assembly. Moreover, adherence to industry regulations often necessitates the use of detailed representations, making them indispensable in maintaining compliance and safeguarding both personnel and equipment.

Common Issues with Hu625hwt Units

Understanding the frequent challenges associated with these units can significantly enhance their longevity and performance. Users often encounter a variety of problems that can arise from improper maintenance, environmental factors, or component failures. Recognizing these issues early can lead to effective troubleshooting and prevent further complications.

Overheating Problems

One of the most prevalent issues is overheating, which can stem from blocked vents or malfunctioning cooling systems. When airflow is restricted, the internal components can become excessively warm, leading to decreased efficiency or even unit failure. Regular cleaning and inspections are essential to mitigate this risk.

Electrical Malfunctions

Another common challenge involves electrical failures, which may result from faulty wiring or component degradation. These malfunctions can cause erratic performance or complete shutdowns. Routine checks of the electrical connections and timely replacement of worn-out components can help maintain consistent operation.

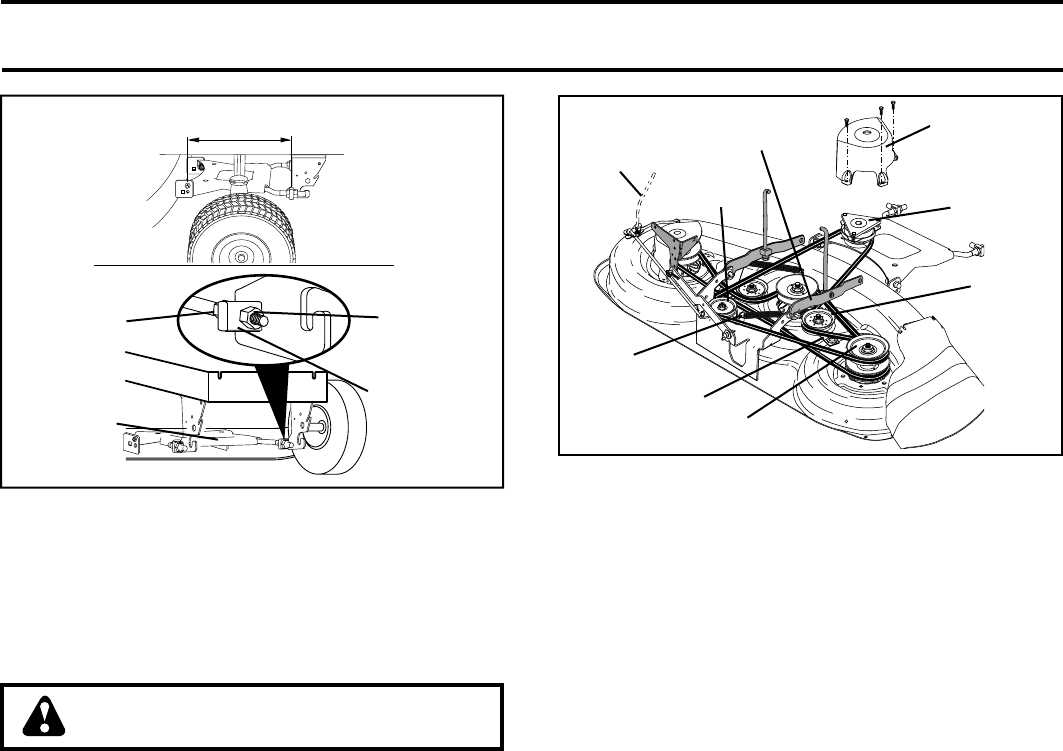

Step-by-Step Assembly Instructions

Assembling your equipment can be an enjoyable and rewarding experience when approached methodically. This section provides clear, sequential guidelines to help you efficiently piece together the components. Following these instructions will ensure a smooth assembly process and enhance your understanding of the device’s structure.

Begin by gathering all necessary components in a well-lit workspace. Ensure that you have all the required tools at hand to facilitate the assembly process. Refer to the provided list to verify that no items are missing.

Start with the base unit. Carefully position the foundation component on a flat surface, ensuring it is stable. Proceed to attach the side elements, securing them with the appropriate fasteners. Ensure each connection is tight to maintain overall integrity.

Once the sides are in place, move on to the upper sections. Align them with the pre-drilled holes, then insert screws or bolts to secure them firmly. It is essential to follow the prescribed order for assembly to avoid any misalignment.

Next, install any internal mechanisms, making sure they fit snugly within their designated areas. Double-check that each part operates smoothly before sealing the enclosure. This step is crucial for the functionality of the entire assembly.

Finally, complete the process by attaching any external features or covers. Take your time to ensure everything aligns correctly and fits well. Once finished, review the assembled unit to confirm that all components are secured and that the assembly meets quality standards.

With careful attention to detail and adherence to these instructions, you will successfully assemble your equipment, ready for use and capable of performing its intended functions efficiently.

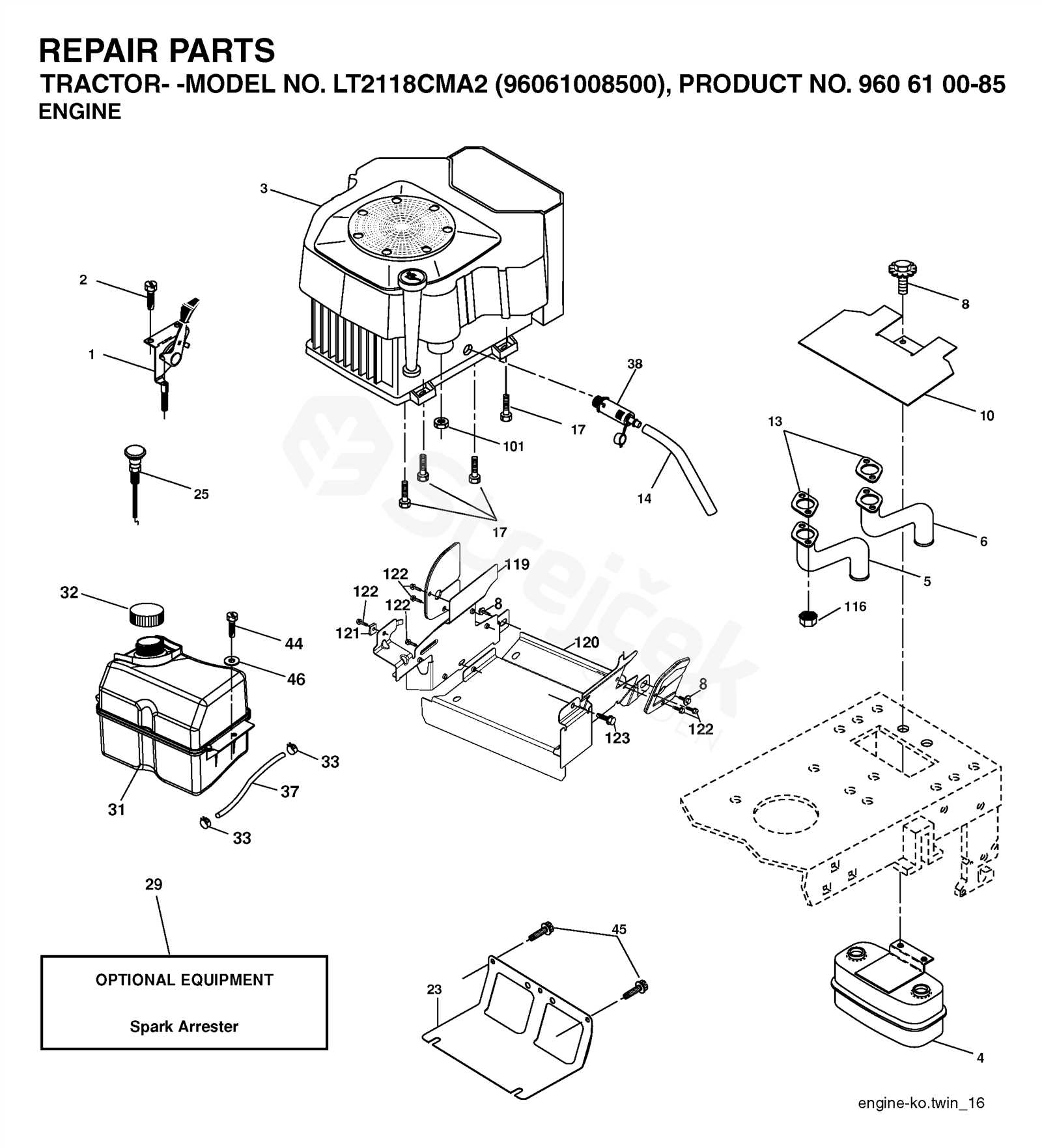

Identifying Hu625hwt Spare Parts

Understanding the components of this model is essential for maintaining its performance and longevity. Proper identification ensures that replacements and repairs are done correctly, preventing further damage and extending the life of the machine. By recognizing key elements, users can efficiently address issues, whether they involve wear and tear or mechanical failures.

Key elements are typically divided into several categories, including essential mechanical pieces and additional functional units. Each piece serves a unique role, contributing to the overall operation. Recognizing these elements can help streamline the replacement process.

Detailed analysis of each individual section allows for a more comprehensive understanding of the system. Careful attention to markings and specifications will guide you in choosing the right replacements for each specific component.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring that mechanical equipment operates smoothly and efficiently for years to come. By following specific maintenance practices, you can significantly extend the service life of your machine and avoid costly repairs or unexpected breakdowns.

Regular Cleaning and Inspection

Dirt and debris can accumulate over time, leading to wear and tear. Consistent cleaning and visual inspections help prevent minor issues from escalating. Check for any unusual noises, vibrations, or signs of wear that could indicate a potential problem.

- Wipe down surfaces regularly to remove dust and grime.

- Inspect moving parts for signs of wear or damage.

- Lubricate components according to manufacturer guidelines.

Scheduled Maintenance Intervals

Performing maintenance at regular intervals is key to keeping your equipment in top condition. Following a set schedule can help catch issues early, ensuring optimal performance over time.

Repair Techniques for Hu625hwt Equipment

Effective maintenance of complex machinery requires a deep understanding of its inner mechanisms and potential areas of failure. When addressing mechanical issues, a systematic approach ensures both precision and durability. The goal is to restore optimal functionality while minimizing the risk of recurring problems.

One of the first steps in resolving mechanical failures is conducting a thorough inspection to identify wear or damage in critical components. Once the issue is pinpointed, it’s important to use high-quality replacement materials and follow manufacturer guidelines during disassembly and reassembly. This ensures not only a successful repair but also prolongs the overall lifespan of the equipment.

In addition, regular preventive care can significantly reduce the likelihood of breakdowns. Lubrication, tightening of loose components, and checking for proper alignment are simple yet effective practices to avoid unexpected malfunctions. Keeping a maintenance log also helps track previous repairs and predict future needs, contributing to smoother operation over time.

Where to Purchase Replacement Parts

When it comes to maintaining your equipment, finding the right components is essential for ensuring longevity and performance. You want reliable options that fit seamlessly with your machine and are readily available for quick replacement when needed. In this section, we explore the best sources where you can buy these essential components and how to choose suppliers that offer quality and reliability.

Authorized Retailers

One of the most dependable ways to find the components you need is by purchasing from official or authorized sellers. These retailers ensure that you are getting original products directly from the manufacturer, which guarantees compatibility and quality. Most official stores provide warranties and support services, making them a secure option for both businesses and individuals.

Online Marketplaces

Online platforms are another popular choice for sourcing components, especially when you’re looking for a wide variety of options. Many online sellers offer both new and used products, often at competitive prices. However, it’s crucial to verify the seller’s reputation, check customer reviews, and ensure that the products are genuine to avoid counterfeit items.

| Source | Advantages |

Comparing Hu625hwt to Similar Models

When evaluating this unit alongside other available options, it is crucial to examine the design features, functionality, and performance capabilities that set them apart. While each model may appear similar at first glance, closer inspection reveals key distinctions that influence their suitability for different tasks and environments. Design and Build QualityOne of the primary factors to consider is the overall construction quality. Some comparable models are built with lighter materials, which may reduce durability but enhance portability. Others are more robust, designed for extended use in demanding settings.

Performance and EfficiencyPerformance often depends on the specific features integrated into each model. Different units may offer varied engine capacities, speed settings, or fuel Expert Recommendations for UsersFor optimal performance and long-term efficiency, it’s important to follow certain best practices. These guidelines will help ensure reliable operation, minimize potential issues, and extend the lifespan of your equipment.

Adhering to these expert suggestions will help users maintain seamless functionality while reducing the likelihood of costly downtime or significant repairs. |

|---|