When it comes to maintaining and optimizing the performance of your cutting tool, a comprehensive grasp of its various elements is essential. Each component plays a vital role in ensuring efficiency and longevity, contributing to the overall functionality of the equipment.

Exploring the intricate assembly of these machines can unveil crucial insights into their operation. By examining the individual parts, one can identify potential issues and streamline repair processes, ultimately enhancing the tool’s effectiveness.

In this section, we will delve into the essential elements of your equipment, providing a detailed overview that highlights their interconnections and significance. Understanding these components will empower you to make informed decisions regarding maintenance and upgrades, ensuring your cutting tool remains in top-notch condition.

Understanding the Stihl MS270 Chainsaw

Exploring the mechanics and components of a popular power tool reveals its efficiency and versatility in various cutting tasks. This particular model is designed to deliver optimal performance, making it a favorite among both professionals and enthusiasts. Understanding its structure can greatly enhance the user experience and maintenance practices.

Key Features

This machine boasts several notable attributes that contribute to its functionality. Users can expect a reliable engine, robust construction, and ease of handling, all of which play a crucial role in achieving desired outcomes in wood cutting.

Essential Components

| Component | Description |

|---|---|

| Engine | Powerful and efficient for high-performance cutting. |

| Guide Bar | Designed for precision and control during operation. |

| Chain | Specially crafted for durability and sharpness. |

| Handle | Ergonomically designed for comfort and stability. |

Key Features of MS270 Model

This model is renowned for its robust design and efficiency, making it a favorite among both professionals and hobbyists. Its standout attributes enhance performance and user experience, ensuring reliable operation in various tasks.

- Powerful Engine: Designed for maximum output, it provides exceptional cutting capabilities.

- Lightweight Construction: The body is crafted for easy maneuverability, reducing fatigue during extended use.

- Advanced Air Filtration: This feature ensures cleaner air intake, prolonging engine life and performance.

- User-Friendly Controls: Intuitive design makes it accessible for users of all skill levels.

- Vibration Reduction System: Minimizes discomfort, allowing for longer work sessions without strain.

These elements collectively contribute to the overall effectiveness and satisfaction experienced by users, making it an ultimate choice for various cutting tasks.

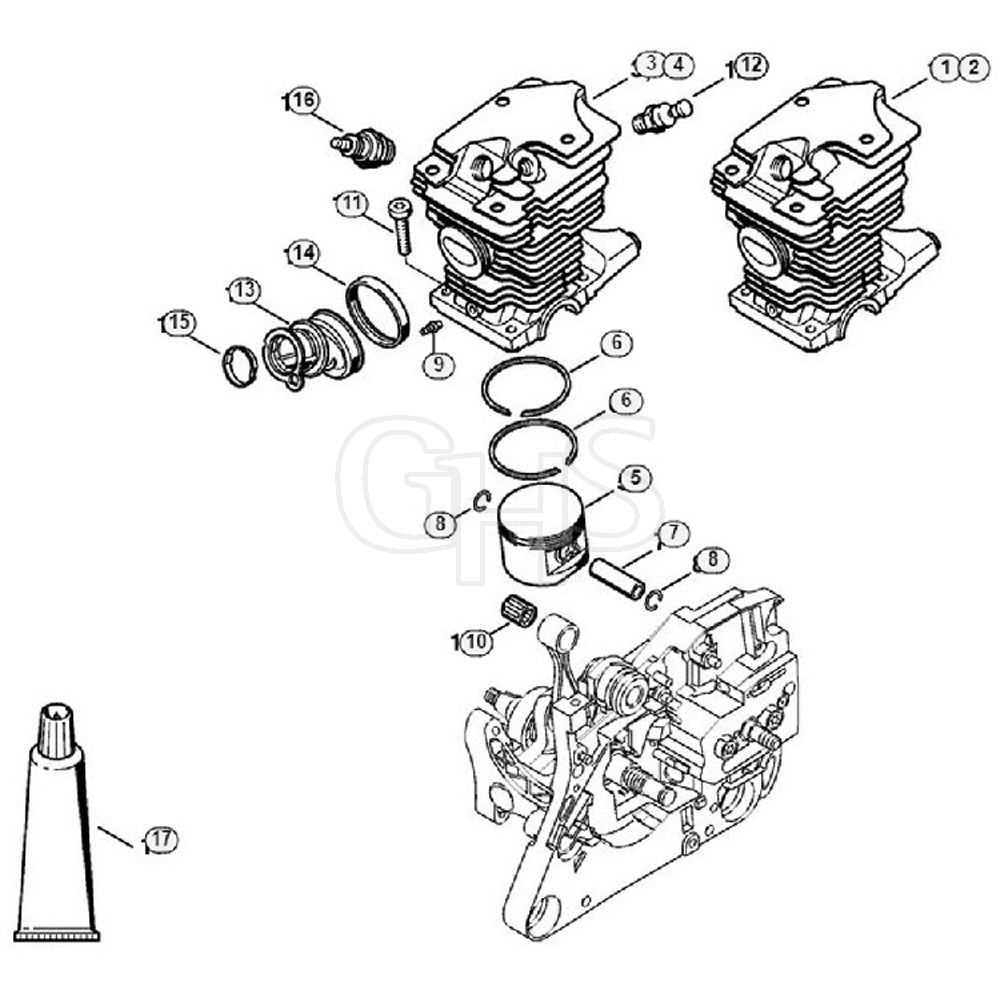

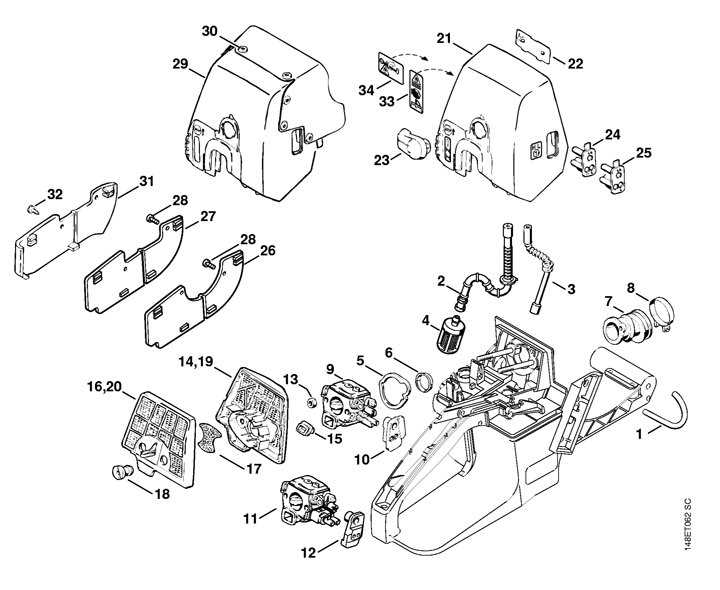

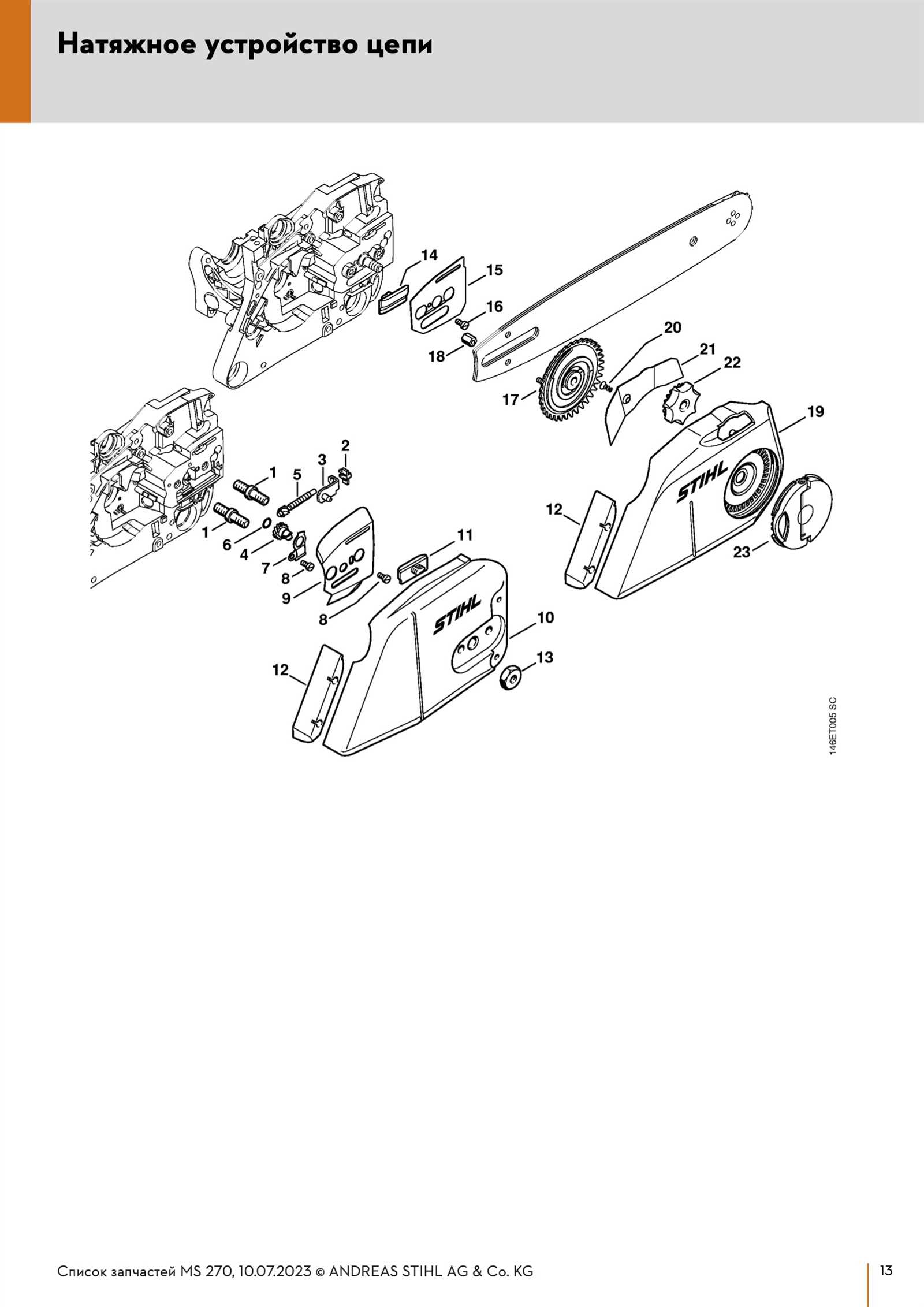

Importance of a Parts Diagram

A visual representation of components is crucial for understanding the assembly and functionality of machinery. This tool aids users in identifying individual elements, facilitating easier maintenance and repair processes.

- Enhances understanding of complex systems

- Streamlines maintenance efforts

- Prevents misassembly and errors

- Serves as a reference for replacements

By utilizing such representations, users can delve deeper into the mechanics, ultimately ensuring better performance and longevity of their equipment.

How to Use the Parts Diagram

Understanding a schematic representation of components can greatly enhance your maintenance and repair skills. By visualizing each element, you can easily identify what you need and how everything fits together, facilitating efficient troubleshooting and restoration.

Steps to Effectively Utilize the Schematic

- Locate the appropriate illustration for your model.

- Familiarize yourself with the labels and corresponding numbers.

- Cross-reference with the service manual for detailed descriptions.

- Identify any worn or damaged items for replacement.

- Keep the diagram handy during disassembly and reassembly.

Tips for Success

- Take notes as you examine each section.

- Use a high-quality printout for clarity.

- Ask for help from forums or communities if needed.

- Regularly update your knowledge with new resources.

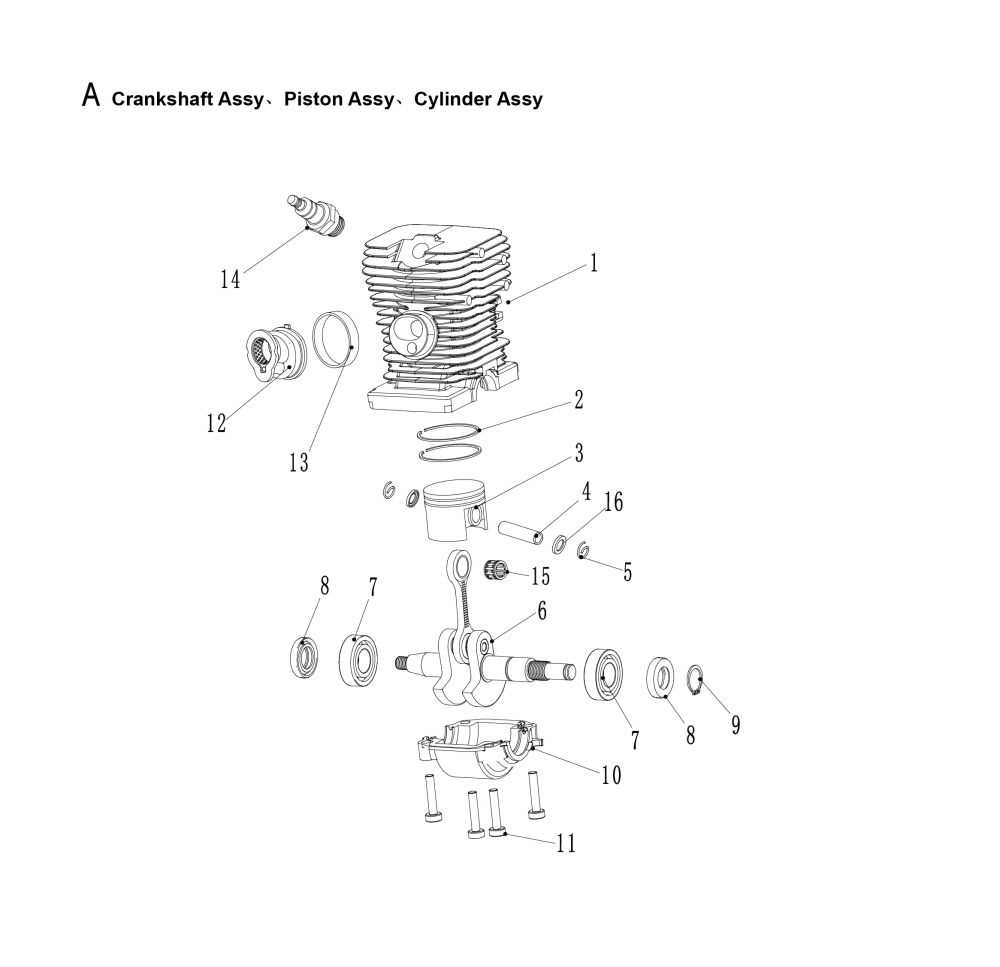

Common MS270 Replacement Parts

When it comes to maintaining outdoor power equipment, certain components are frequently subject to wear and tear. Understanding which elements typically need to be replaced can enhance the longevity and performance of your machine.

- Air Filter: Essential for keeping dirt and debris out of the engine.

- Fuel Filter: Ensures that contaminants do not clog the fuel system.

- Chain: A critical element for cutting efficiency; regular replacement is necessary.

- Sprocket: Works in conjunction with the chain, requiring periodic changes to maintain smooth operation.

- Spark Plug: Vital for ignition; replacing it helps maintain optimal engine performance.

- Bar: The part that guides the chain; wear can lead to reduced cutting efficiency.

Regular maintenance of these components can lead to improved functionality and extended life for your equipment.

Identifying Parts by Number

Understanding component identification through numerical references is essential for effective maintenance and repair. Each part is designated a unique identifier, allowing users to easily locate and order the correct items needed for their equipment.

Why Use Numbers for Identification?

- Facilitates accurate ordering

- Reduces confusion between similar components

- Streamlines inventory management

How to Find Component Numbers

- Refer to the equipment manual for a comprehensive list.

- Check manufacturer websites for updated catalogs.

- Utilize online forums or communities for user-shared insights.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor power equipment requires consistent upkeep and attention to detail. Proper maintenance not only extends the life of your machinery but also enhances performance and efficiency.

Regular Cleaning

- Remove debris after each use.

- Check and clean air filters periodically.

- Inspect spark plugs and clean as needed.

Lubrication and Inspection

- Apply lubricant to moving parts to prevent wear.

- Inspect cables and hoses for signs of damage.

- Replace any worn components promptly.

Adhering to these maintenance practices will help ensure your equipment remains in optimal condition for years to come.

Where to Find Genuine Parts

Finding authentic components for your machinery is crucial for maintaining performance and safety. Reliable sources ensure that you receive high-quality replacements that meet manufacturer specifications. Below are several avenues to explore when searching for legitimate items.

Authorized Dealers

One of the most reliable options is to visit authorized retailers. These establishments are certified by the manufacturer and typically offer a wide selection of original items. Additionally, staff members are usually well-trained and can provide expert advice on which components you need for optimal operation.

Online Marketplaces

Another convenient method is browsing reputable online platforms. Many websites specialize in selling genuine components and often feature customer reviews, helping you gauge the reliability of the seller. Always verify that the website guarantees authenticity and offers secure transactions to protect your purchase.

In summary, whether you choose brick-and-mortar stores or online shops, ensuring the authenticity of your components is essential for the longevity of your equipment.

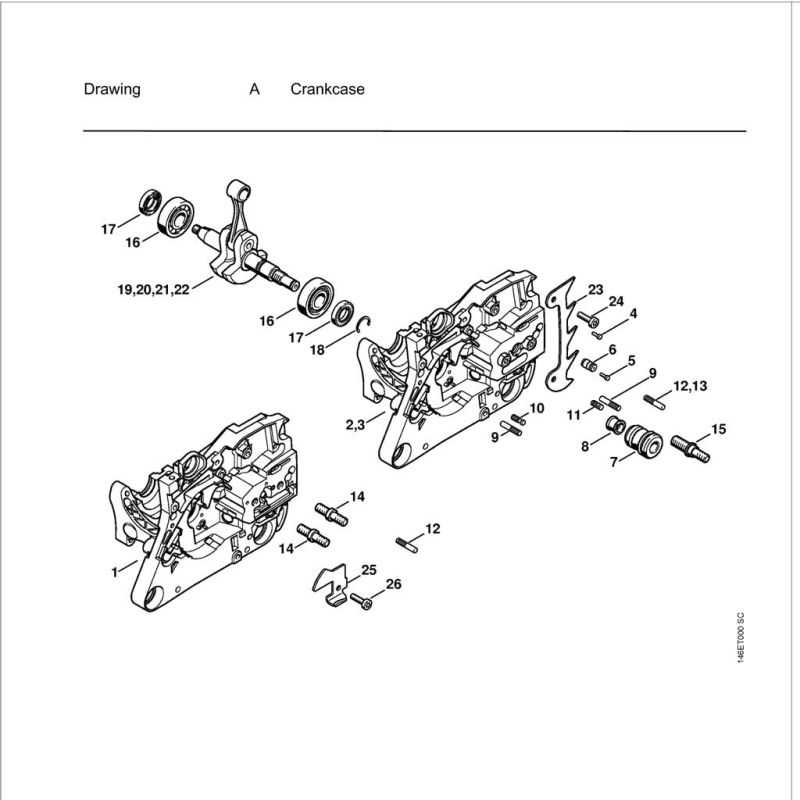

DIY Repairs for MS270 Chainsaw

Maintaining your cutting tool can enhance its performance and longevity. Tackling minor repairs on your own not only saves money but also boosts your confidence in handling equipment. From tuning the engine to replacing worn components, engaging in these tasks can be fulfilling and practical.

Understanding Common Issues: Many users encounter similar problems, such as difficulty starting or chain issues. Identifying these challenges early on can prevent further damage and ensure smooth operation.

Essential Tools: Before beginning any repair, gather the necessary tools. A basic toolkit, including screwdrivers, wrenches, and safety gear, is vital for safe and effective work.

Step-by-Step Guidance: Consult user manuals or reliable online resources for specific instructions. Following a structured approach helps in addressing issues methodically.

Safety First: Always prioritize safety. Ensure the tool is powered off and unplugged during repairs. Wear protective gear to minimize risks.

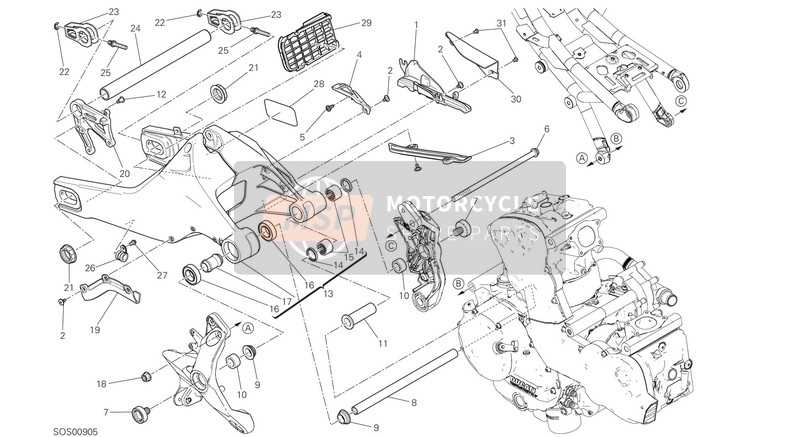

Tools Needed for Disassembly

When tackling a disassembly project, having the right equipment is crucial for efficiency and safety. A well-prepared toolkit ensures that every component can be accessed and removed without causing damage.

Essential items include various sizes of screwdrivers, a wrench set, and pliers. Additionally, an impact driver can be invaluable for loosening stubborn fasteners. Don’t forget a torque wrench to ensure proper reassembly.

Consider using organizers to keep small parts in order during the process, as this will help streamline the reassembly phase. Having these tools at your disposal will ultimately lead to a smoother and more efficient disassembly experience.

Safety Precautions During Repairs

Ensuring safety during maintenance and repair tasks is essential to prevent accidents and injuries. Adhering to specific guidelines not only protects the individual performing the work but also safeguards equipment and surroundings. Prior preparation and awareness of potential hazards can significantly enhance overall safety.

Essential Safety Gear

- Wear protective goggles to shield eyes from debris.

- Use gloves to protect hands from sharp edges and chemicals.

- Put on sturdy footwear to prevent foot injuries.

- Consider ear protection if working with loud machinery.

Safe Work Practices

- Always disconnect power sources before starting repairs.

- Keep the workspace organized and free of clutter.

- Use tools correctly and check for any damage before use.

- Maintain proper lighting to enhance visibility.

Common Issues and Solutions

When operating outdoor power equipment, users often encounter a range of challenges that can hinder performance. Understanding these common problems and their solutions can greatly enhance the longevity and efficiency of the machinery. Addressing issues promptly can save both time and money in maintenance.

Engine Performance Problems

A frequent concern is engine stalling or difficulty starting. This may result from fuel quality or blockage in the fuel system. Ensure to use fresh, clean fuel and inspect filters for any obstructions. Regular maintenance checks can also help identify potential issues before they escalate.

Chain and Bar Issues

Another common issue involves the cutting mechanism, such as a dull chain or improper tension. A dull chain can lead to inefficient cutting and increased wear. Regular sharpening and correct tension adjustments are essential for optimal performance and safety during operation.

Upgrading Components for Performance

Enhancing the efficiency and capability of outdoor power tools can significantly improve their functionality and longevity. By focusing on specific elements, users can achieve optimal performance, making tasks easier and more efficient.

One of the most impactful upgrades involves improving the air filtration system. A higher-quality filter can ensure better airflow and reduce engine strain, resulting in improved power output.

Additionally, consider upgrading the ignition system. A more advanced spark plug can lead to more efficient combustion, enhancing overall engine responsiveness and reliability.

Lastly, exploring options for a premium fuel system can yield benefits such as increased fuel efficiency and smoother operation, allowing for longer working periods without interruptions.