In every mechanical system, the proper arrangement of various elements plays a crucial role in ensuring functionality and reliability. These elements must work in harmony to deliver optimal performance, which can often be enhanced by understanding their structure and organization.

Exploring the design and function of interconnected systems offers insight into how individual sections contribute to the overall efficiency. By focusing on how each piece interacts with others, one can gain a deeper appreciation of the mechanical framework and its practical applications.

This guide will delve into the various aspects of component placement, helping you to better comprehend the intricate web of connections that form the foundation of any technical system.

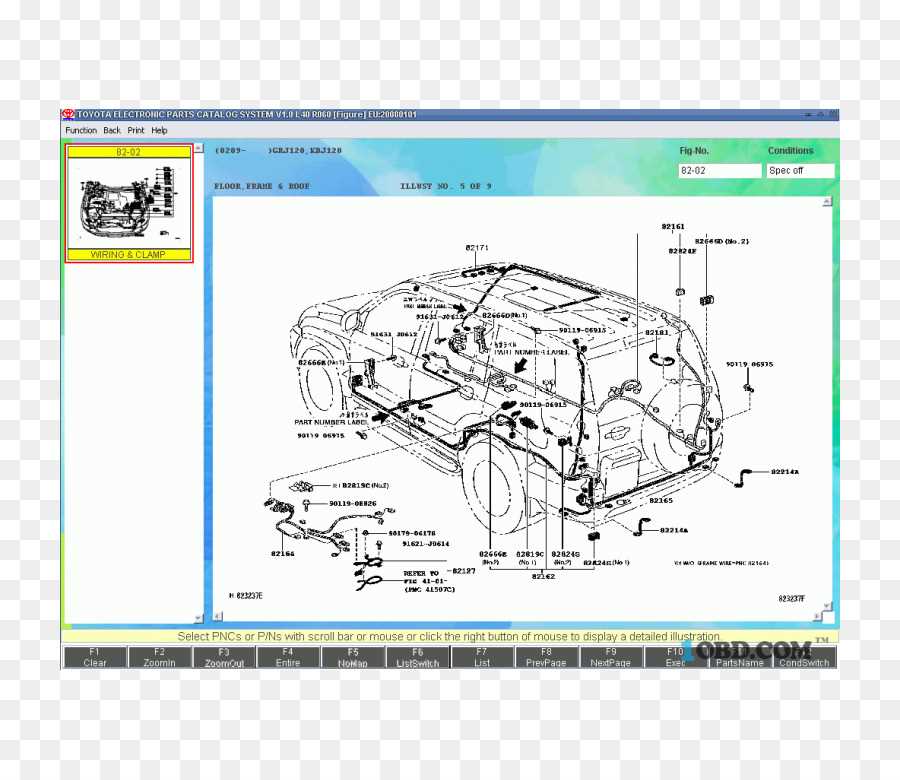

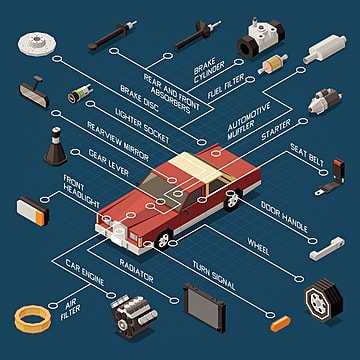

Car Part Diagram Overview

Understanding the inner workings of a vehicle’s components is essential for anyone looking to maintain, repair, or upgrade their machine. These detailed visual representations offer a clear and organized view of various systems, allowing for precise identification of specific elements within each assembly. Whether it’s the engine, electrical wiring, or suspension, this type of illustration provides a comprehensive breakdown, guiding users through each connection and mechanism.

Main Sections of the Layout

Each schematic is typically divided into multiple sections, focusing on distinct systems like the drivetrain, cooling, or braking. These segments allow technicians or enthusiasts to zero in on individual components without confusion, ensuring accurate installation or troubleshooting.

Benefits of Understanding These Schematics

By mastering the layout and placement of different assemblies, users can efficiently diagnose issues, order the correct

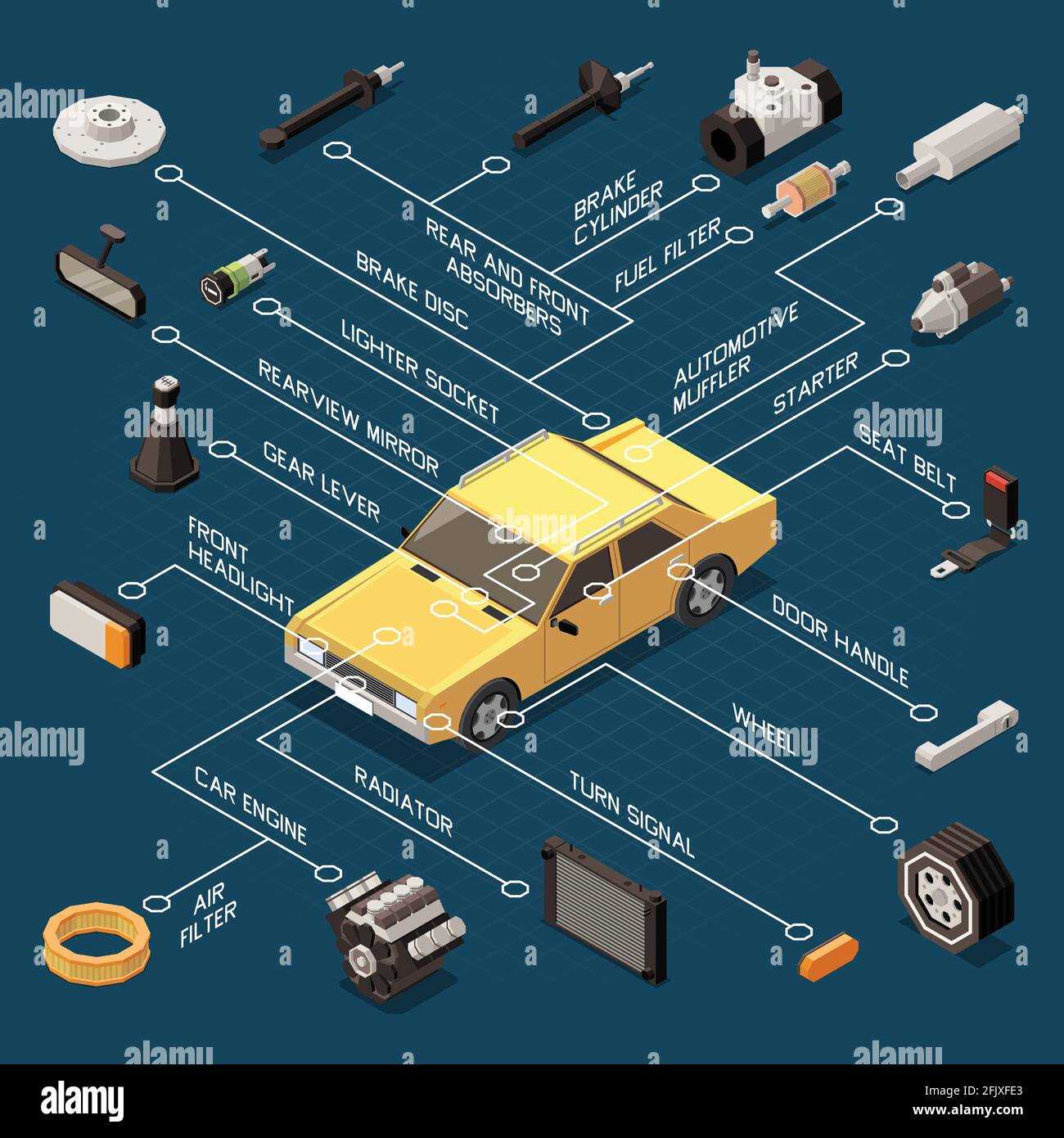

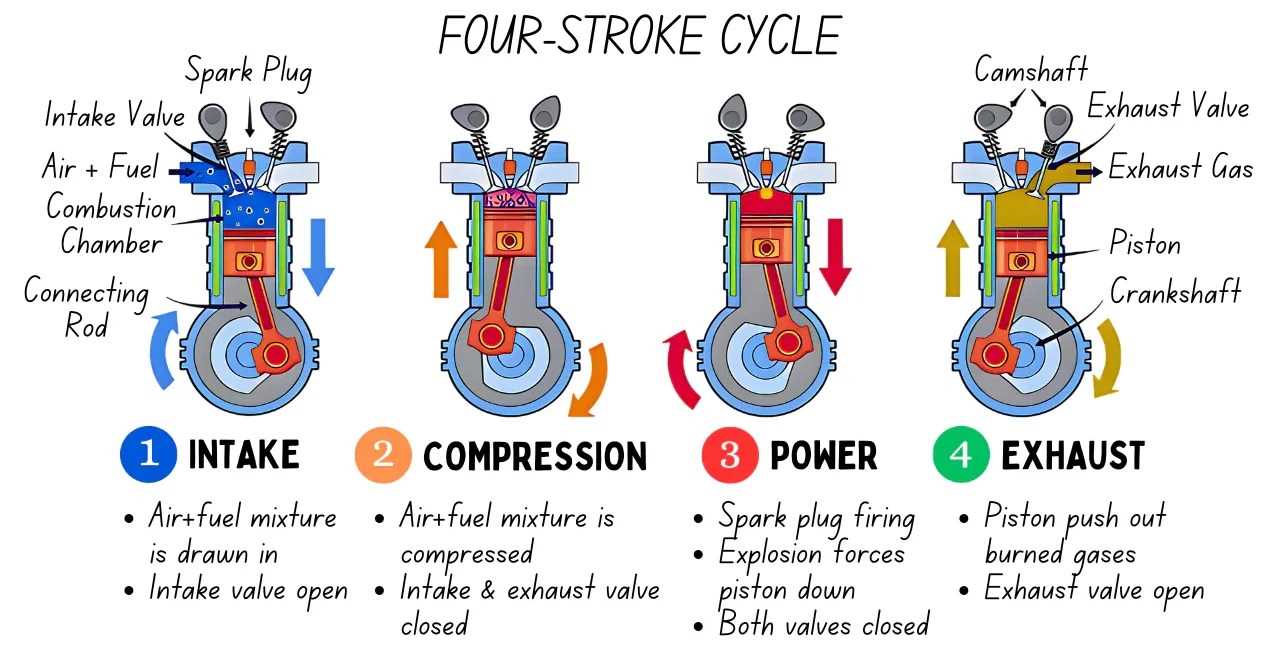

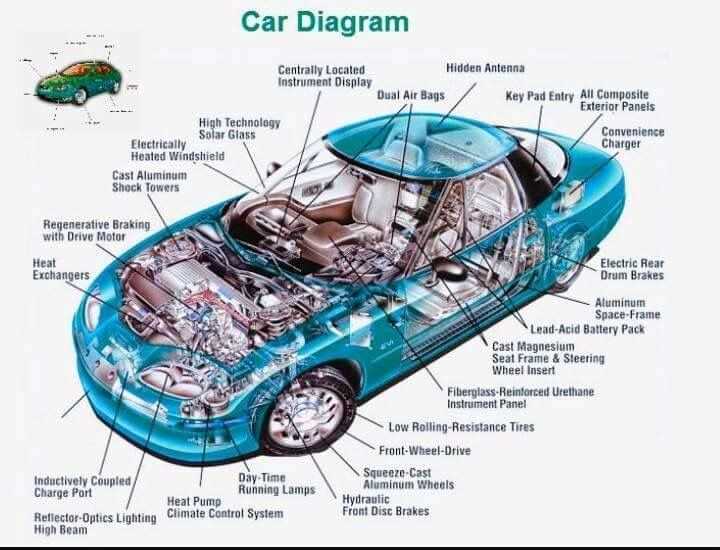

Understanding Automotive Components and Systems

Every vehicle relies on a variety of interconnected elements working together to ensure smooth operation. These elements function as part of a larger system, where each unit plays a crucial role in ensuring the functionality, safety, and efficiency of the machine. By comprehending how these systems operate, one can gain valuable insights into their purpose and maintenance.

Key systems, such as those responsible for movement, energy generation, and control, collaborate seamlessly to create a reliable and responsive driving experience. Each mechanism is designed with precision, enabling the machinery to operate under different conditions and demands. Understanding these configurations is essential for diagnosing issues and enhancing overall performance.

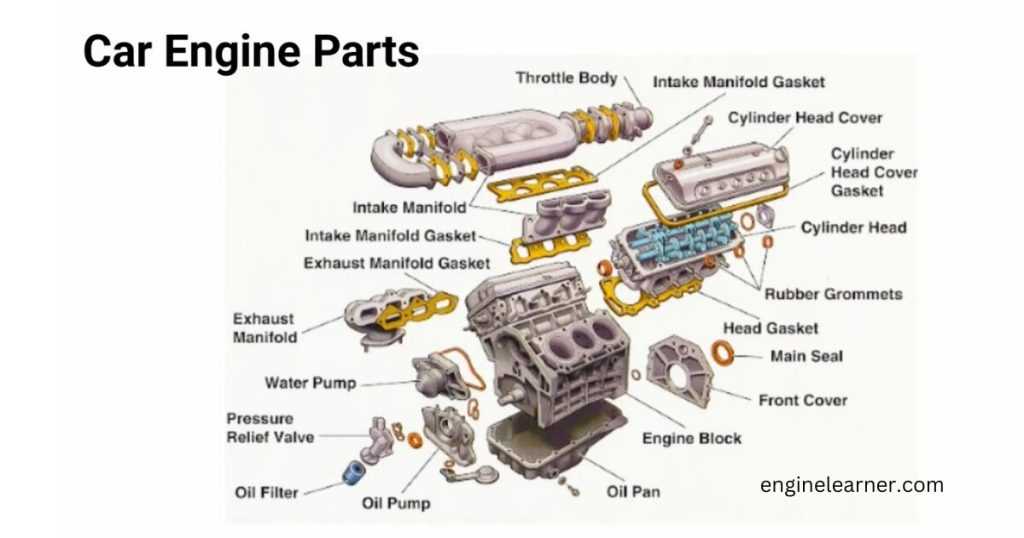

Visual Guide to Engine Components

The intricate structure under the hood is composed of numerous interconnected elements, each playing a pivotal role in ensuring optimal performance. Understanding the layout and functionality of these elements can significantly enhance maintenance skills and troubleshooting efficiency.

Main Structural Elements

Among the core elements, various systems collaborate to ensure smooth operation. The primary elements focus on providing power, regulating temperature, and delivering necessary fluids. These include essential mechanisms responsible for combustion, air intake, and the cooling process.

Supporting Systems and Functions

Apart from the core mechanisms, additional systems focus on reducing emissions, managing electrical power, and enhancing fuel efficiency. These supporting structures work in harmony to ensure that

Decoding Electrical Wiring Layouts

Understanding the intricate pathways of electrical connections is key to ensuring proper functionality. These configurations are a detailed representation of how power and signals flow through various components, offering insight into the relationships between different elements. By examining these layouts, technicians can troubleshoot issues or optimize the system for better performance.

Identifying key elements in the setup involves recognizing power sources, ground connections, and signal routes. Each element is carefully mapped to ensure seamless interaction between all components, which helps in avoiding potential malfunctions or inefficiencies.

To effectively interpret the wiring, one must focus on the logical flow and the intended outcomes of each connection. Careful analysis of these configurations not only simplifies maintenance but also contributes to the longevity and reliability of the entire system.

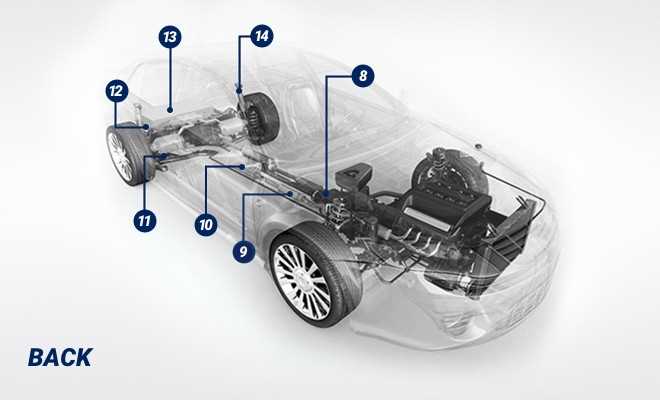

Exploring Suspension and Steering Diagrams

Understanding the layout and function of the components responsible for ride stability and directional control is essential for ensuring a smooth and safe driving experience. These systems are designed to manage various forces, providing both comfort and precision while navigating different terrains. A closer examination of these mechanisms reveals the complexity and interdependence of each element, which work together to maintain balance and responsiveness.

Suspension plays a critical role in absorbing shocks and keeping the vehicle’s frame steady during movement. Key elements within this system are designed to handle vertical forces, ensuring that the wheels remain in contact with the ground. This contributes to a smoother ride and better handling, especially when encountering uneven surfaces.

Steering mechanisms, on the other hand, focus on translating the driver’s input into directional movement. The various linkages and joints involved work together to ensure that the front wheels respond accurately to the

How Brake System Components Connect

In every vehicle, the efficiency of the braking system relies on the seamless integration of various elements. These elements work in unison to ensure that force is transmitted effectively, enabling the slowing or stopping of the motion. Understanding how these elements interact is key to maintaining and optimizing performance.

The hydraulic and mechanical mechanisms serve as the core structure. Pipes and cylinders guide the movement of fluids, while pedals and levers initiate the entire process. Through precise pressure regulation and smooth transitions, these components translate driver input into responsive action.

Each unit is linked to the other through a network of channels, allowing for synchronized movement. This careful alignment ensures that when pressure is applied, it is evenly distributed, resulting in a reliable and consistent response from the system as a whole.

Mapping Out Exhaust System Parts

The exhaust assembly plays a crucial role in the overall functionality of a vehicle’s engine, facilitating the safe expulsion of gases produced during combustion. Understanding the various components within this system is essential for effective maintenance and upgrades, ensuring optimal performance and compliance with emission standards.

Key Components of the Exhaust Assembly

Several vital elements make up this system, each serving a specific function. The manifold captures exhaust gases from the engine’s cylinders and directs them into the piping. Following this, the catalytic converter reduces harmful emissions through a series of chemical reactions, while the muffler minimizes noise produced by these gases before they exit through the tailpipe.

Importance of Proper Configuration

Proper arrangement and connection of these components ensure efficient gas flow, which can significantly impact engine performance. For instance, a well-designed exhaust layout can enhance horsepower and torque while improving fuel efficiency. Regular inspections and replacements of worn-out sections are essential to maintain the integrity of the system and avoid potential issues related to emissions and noise pollution.

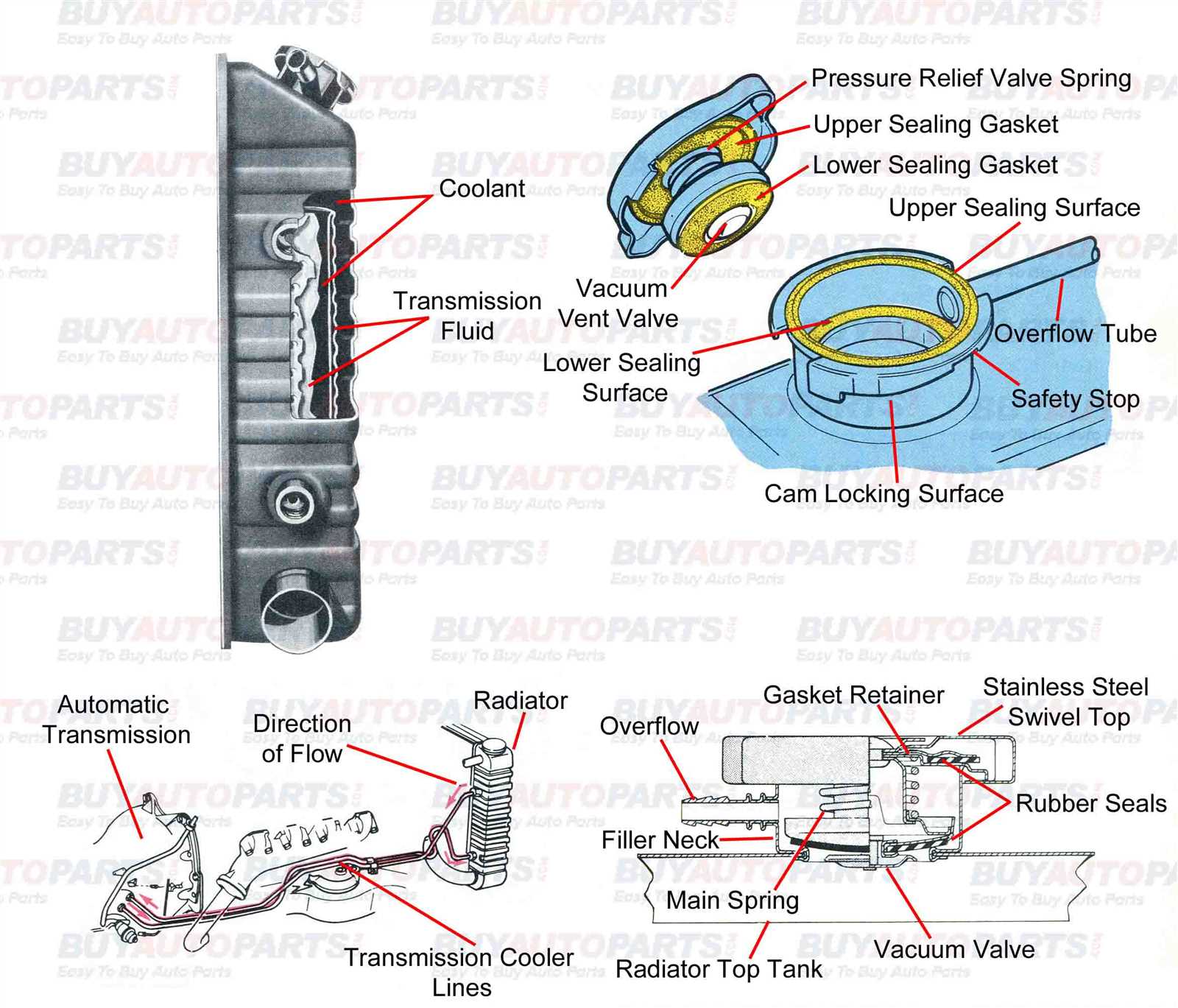

Detailed Layout of Transmission Assembly

The intricate arrangement of the transmission assembly plays a crucial role in the overall functionality of the vehicle’s drivetrain. This section explores the components and their interactions, highlighting the significance of each element within the system.

Key Components and Their Functions

- Gearbox: This unit houses various gears, allowing for smooth changes in speed and torque.

- Clutch: Engages and disengages the engine from the drivetrain, enabling smooth transitions during gear shifts.

- Torque Converter: Converts rotational energy from the engine to the transmission, enhancing acceleration and performance.

- Shift Linkage: Connects the gear lever to the transmission, facilitating manual or automatic shifting.

- Fluid Pump: Circulates transmission fluid, ensuring adequate lubrication and cooling of components.

Understanding the Assembly Layout

- Identify the primary components listed above and their respective locations within the assembly.

- Examine the relationship between the clutch and gearbox to appreciate how power is transferred.

- Analyze the role of the torque converter in managing engine output and vehicle acceleration.

- Consider the importance of transmission fluid and its distribution through the system.

Each element within this assembly works in concert, allowing for efficient power delivery and a seamless driving experience. Understanding this layout is essential for diagnosing issues and performing maintenance on the drivetrain system.

Breaking Down Fuel System Structure

The fuel delivery system is a critical component of any vehicle, responsible for supplying the necessary energy to the engine. Understanding its layout and functionality is essential for effective maintenance and troubleshooting. This section will explore the various elements that constitute this intricate network, ensuring optimal performance and efficiency.

Key Components of the Fuel Delivery System

At the heart of the fuel delivery mechanism lies the fuel tank, which stores the liquid energy. From there, the fuel pump facilitates the transfer of fuel towards the engine. An important element, the fuel filter, ensures that impurities are removed before reaching the engine, protecting it from damage. Lastly, the fuel injectors play a crucial role in atomizing the fuel for optimal combustion within the engine cylinders.

Understanding the Flow Process

Fuel flows from the tank through a series of lines and filters, propelled by the pump. As the fuel travels, it passes through the filter, which captures contaminants and prevents them from entering the engine. Once filtered, the fuel is delivered to the injectors, where it is atomized and mixed with air before entering the combustion chamber. This precise process is vital for maximizing engine efficiency and reducing emissions.

Cooling System Components Explained

The efficient operation of an engine relies heavily on the proper functioning of its thermal regulation system. This system plays a crucial role in maintaining optimal temperatures, preventing overheating, and ensuring the longevity of the engine. Various elements work together seamlessly to facilitate effective cooling, each serving a specific purpose within the assembly.

Key Elements of the Cooling System

- Radiator: This component dissipates heat from the coolant, allowing it to return to a lower temperature before circulating back to the engine.

- Water Pump: This pump circulates the coolant throughout the system, ensuring a constant flow to maintain temperature balance.

- Thermostat: A crucial valve that regulates the coolant flow based on the engine’s temperature, allowing for efficient heating and cooling cycles.

- Cooling Fans: These electric or mechanical fans enhance airflow through the radiator, especially when the vehicle is stationary or moving at low speeds.

- Coolant Reservoir: This tank stores extra coolant to ensure that the system remains filled, providing a buffer for expansion during heating.

Functionality and Maintenance

Each element contributes to the overall efficiency of the thermal regulation system, ensuring that the engine operates within safe temperature limits. Regular inspections and maintenance are essential for identifying potential issues, such as leaks or blockages, which can disrupt the cooling process. A well-maintained assembly not only promotes optimal performance but also extends the life of the engine.

Understanding these components and their roles is vital for any enthusiast or technician looking to ensure reliability and longevity in engine performance.

Interpreting HVAC System Diagrams

Understanding the intricate layouts associated with heating, ventilation, and air conditioning systems is essential for effective troubleshooting and repair. These schematics provide a visual representation of the components and their interconnections, allowing technicians to navigate through complex systems with ease.

When analyzing HVAC layouts, it is crucial to grasp the following key aspects:

- Component Identification: Familiarize yourself with symbols representing various elements, such as compressors, evaporators, and condensers. Knowing what each symbol signifies helps streamline the diagnostic process.

- Flow Direction: Pay attention to arrows indicating the flow of refrigerant and air. This information is vital for understanding how the system operates and where potential issues may arise.

- Electrical Connections: Review electrical schematics to identify power sources and control systems. This knowledge aids in pinpointing electrical faults and ensuring proper functionality.

To effectively interpret these layouts, follow these steps:

- Begin by familiarizing yourself with the overall layout. Identify the main components and their arrangement.

- Study the flow directions and connections. Understanding how each part interacts with others is crucial for effective repairs.

- Cross-reference the schematic with manufacturer documentation to clarify any uncertainties regarding component specifications and functions.

By mastering the interpretation of HVAC layouts, technicians can enhance their diagnostic skills, leading to more efficient repairs and improved system performance.

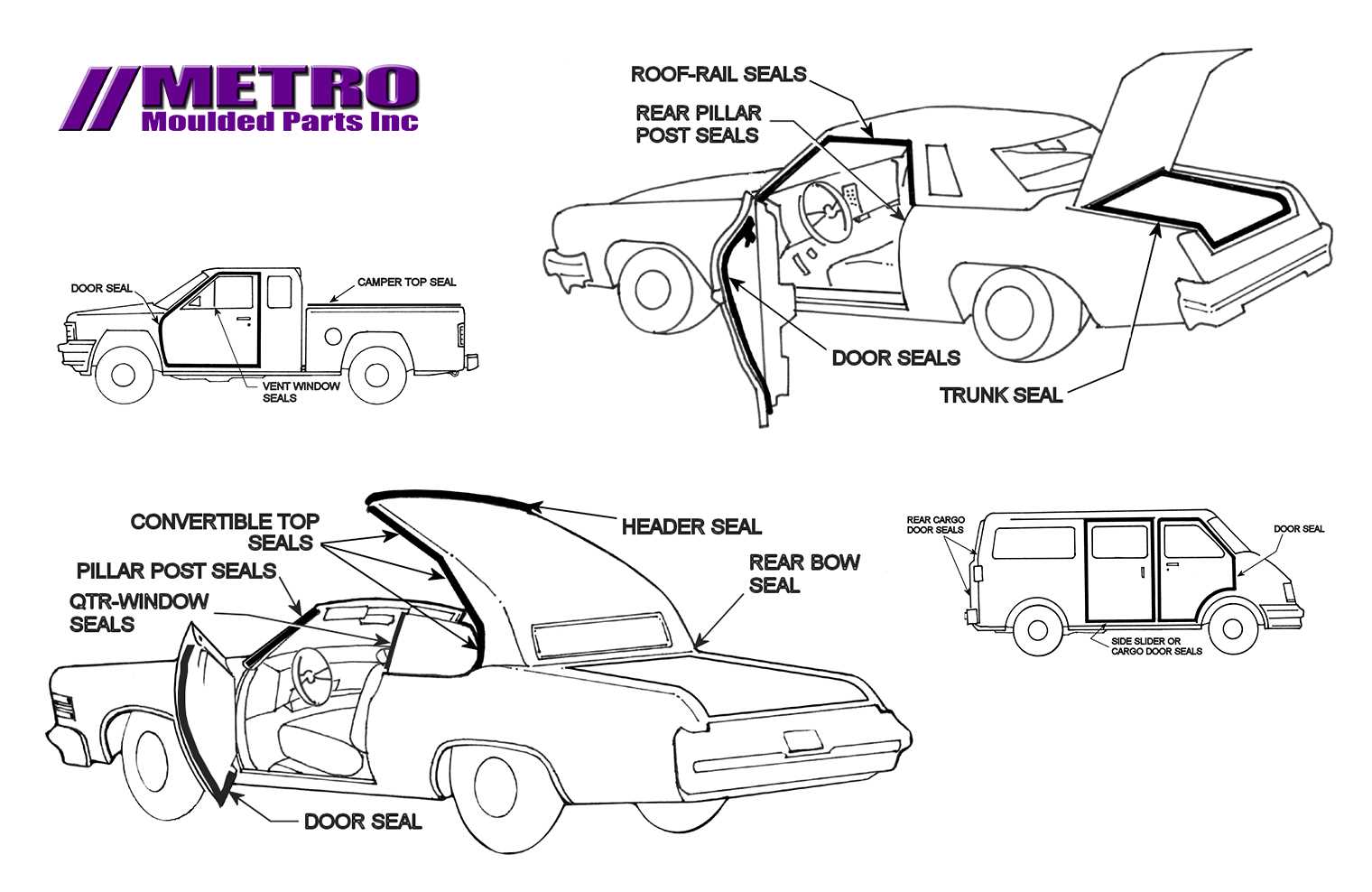

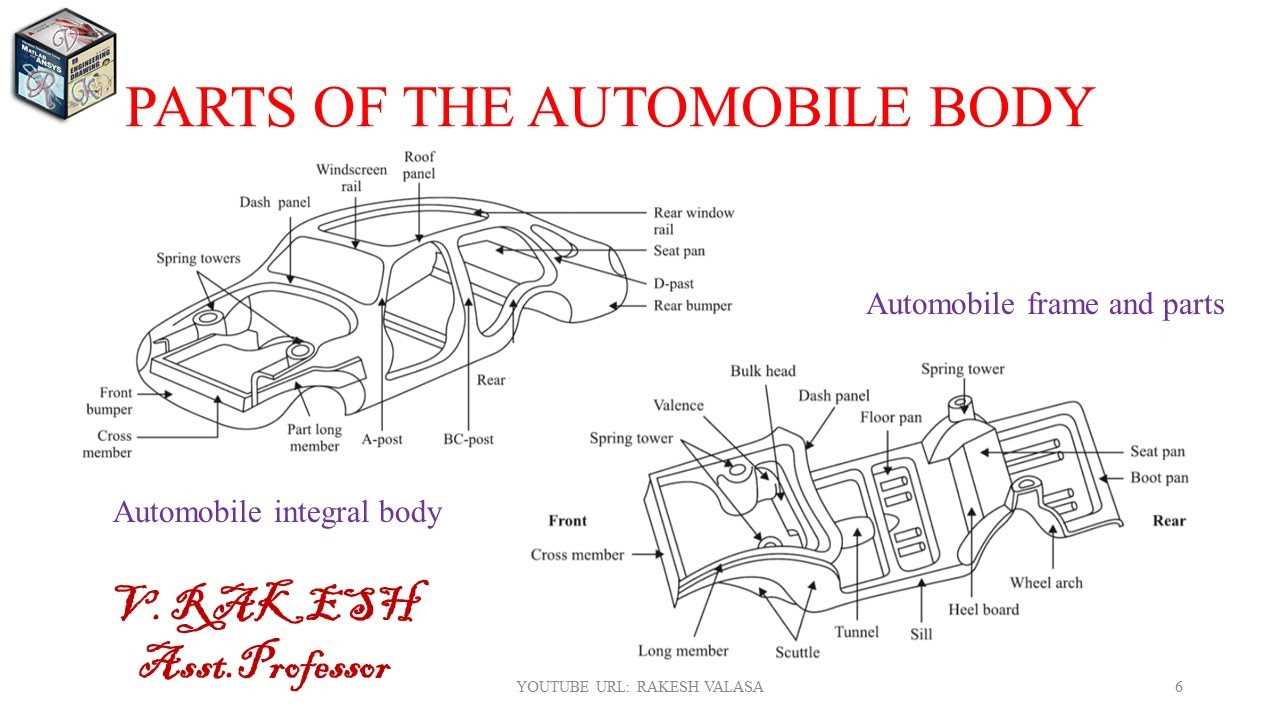

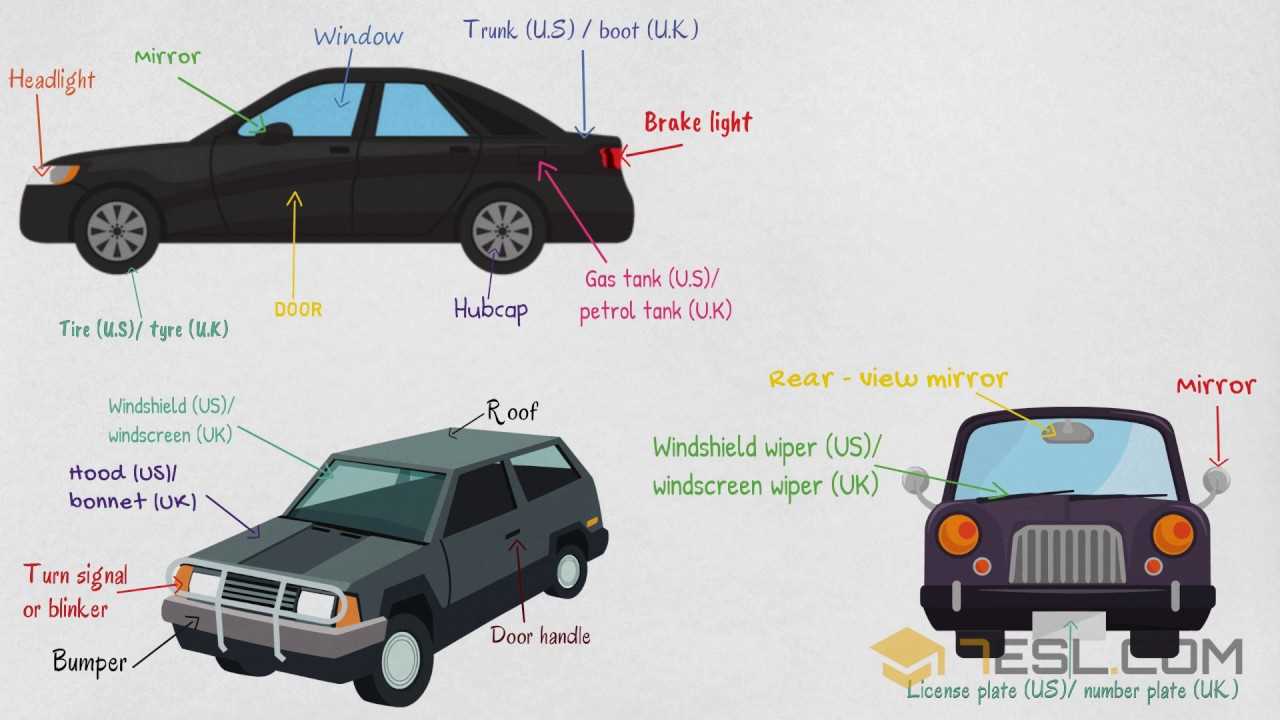

Body Panels and Frame Layout

The structure of any vehicle plays a crucial role in its overall performance and safety. Understanding the arrangement and functions of exterior components is essential for both enthusiasts and professionals. This section explores the key elements that contribute to the framework and outer coverings of vehicles, highlighting their significance in design and functionality.

Key Components

- Fenders: These protective panels cover the wheels, preventing debris from being thrown into the air.

- Hoods: The hinged cover over the engine compartment allows for easy access to the engine and essential components.

- Doors: Vital for entry and exit, they also provide structural support and enhance safety.

- Rooftops: These sections contribute to the vehicle’s aerodynamics and provide protection from the elements.

- Trunk Lids: Enclosing the storage area, they also assist in maintaining the vehicle’s aerodynamic profile.

Frame Structure

The frame serves as the backbone of the vehicle, supporting various components and ensuring stability. Here are some key points regarding frame layouts:

- Monocoque: A design where the body and frame are integrated, enhancing rigidity and reducing weight.

- Body-on-Frame: A traditional method where the body is mounted on a separate frame, often used in trucks for increased durability.

- Subframe: A secondary structure that supports specific components like the engine and suspension, adding strength to critical areas.

Understanding the interplay between body panels and frame layouts aids in appreciating vehicle design and maintenance, ensuring that enthusiasts can make informed decisions when modifying or repairing their vehicles.

Comprehensive Guide to Drivetrain Schematics

The intricacies of the drivetrain system are pivotal to the overall performance and functionality of any vehicle. Understanding the various components and their interconnections can greatly enhance troubleshooting and maintenance efforts. This section aims to provide a detailed overview of drivetrain layouts, highlighting essential elements and their roles within the entire assembly.

Key Components of the Drivetrain

At the core of the drivetrain are several fundamental elements that work in harmony to transmit power from the engine to the wheels. The major players include the transmission, driveshaft, differential, and axles. Each component has a unique function, yet they collectively contribute to the efficiency and smooth operation of the vehicle. Recognizing how these parts interact can significantly aid in diagnosing issues and performing repairs.

Understanding the Interconnection

Properly grasping the relationship between the various drivetrain components is essential for effective maintenance. Transmission serves as the primary conduit for power transfer, while the driveshaft connects the transmission to the differential, facilitating torque delivery. Additionally, the differential plays a crucial role in distributing power to the wheels, enabling smoother turns and improved handling. Studying these interactions allows for better insight into performance enhancements and potential modifications.