In the world of marine engineering, the intricate mechanisms that power watercraft are vital to their performance and reliability. A comprehensive exploration of these components provides insights into their functionality and maintenance. By examining the various elements involved, one can appreciate the complexity and engineering prowess behind these systems.

Visual representation of these intricate assemblies serves as a crucial tool for both enthusiasts and professionals alike. Such illustrations enhance the understanding of each individual element, facilitating easier troubleshooting and repairs. By breaking down the construction, users can delve deeper into how these systems operate seamlessly on the water.

The ultimate goal of this exploration is to equip boat owners and technicians with the knowledge necessary to ensure optimal performance. With a solid grasp of the inner workings, they can make informed decisions regarding maintenance and upgrades, thereby prolonging the lifespan of their vessels.

Understanding Sterndrive Mechanisms

In the world of marine propulsion, certain systems play a crucial role in enhancing the performance and maneuverability of vessels. These mechanisms convert engine power into thrust, allowing boats to glide through water with efficiency. A deep understanding of these systems reveals their complexity and the engineering marvel behind their operation.

Components of the System

Key elements include the drive unit, which houses the gears and propeller, and the hydraulic components that facilitate steering and trim adjustments. Each part is designed to work harmoniously, ensuring optimal performance and longevity. Maintenance of these components is essential for reliable operation.

Operational Mechanics

These systems utilize a series of gears and levers to transmit power effectively. Adjustments in trim and angle can significantly impact handling and speed, demonstrating the intricate relationship between the parts. Understanding these mechanisms allows for better troubleshooting and enhancements.

Key Components of Volvo Penta Systems

Understanding the essential elements of marine propulsion and power systems is crucial for optimal performance and maintenance. These systems consist of various interconnected parts that work together to ensure smooth operation and reliability on the water. Each component plays a vital role, contributing to the overall efficiency and functionality of the setup.

Among the primary elements are the engine, which provides the necessary power, and the transmission system, responsible for transferring that power to the propeller. The cooling system is equally important, as it regulates temperatures to prevent overheating during operation. Additionally, the control mechanisms, including throttles and steering systems, allow for precise maneuverability and handling.

Moreover, components such as the exhaust system and fuel delivery network are critical for maintaining optimal engine performance and environmental compliance. Regular maintenance and inspection of these key parts can significantly enhance longevity and performance, ensuring that marine adventures are both enjoyable and safe.

Importance of Maintenance and Upkeep

Regular maintenance and diligent care of marine equipment are crucial for ensuring optimal performance and longevity. Neglecting these aspects can lead to unexpected failures, increased repair costs, and diminished safety. By prioritizing routine checks and upkeep, users can safeguard their investment and enhance the overall experience on the water.

Benefits of Routine Care

Engaging in consistent maintenance practices offers numerous advantages. From preventing major breakdowns to ensuring efficient operation, these efforts can significantly reduce downtime and enhance reliability. Additionally, well-maintained machinery often results in better fuel efficiency, translating to cost savings over time.

Key Maintenance Tasks

To maintain optimal functionality, certain tasks should be regularly performed. The following table outlines essential upkeep activities:

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Oil Change | Every 100 hours | Reduces engine wear and enhances performance |

| Inspect Belts and Hoses | Monthly | Prevents leaks and ensures efficient operation |

| Clean Cooling System | Annually | Prevents overheating and maintains optimal temperature |

| Check Fuel System | Every 50 hours | Ensures proper fuel flow and prevents contamination |

By adhering to these essential maintenance practices, users can enjoy a safer, more efficient, and trouble-free experience on the water, ultimately leading to greater satisfaction and peace of mind.

Common Issues with Sterndrive Parts

Understanding frequent challenges related to marine propulsion systems is crucial for maintaining optimal performance. These issues can arise from wear and tear, environmental factors, or improper handling, leading to significant operational difficulties.

Typical Challenges

- Corrosion and Rust: Exposure to saltwater can lead to deterioration of metal components.

- Oil Leaks: Insufficient seals can result in fluid loss, affecting lubrication and functionality.

- Overheating: Insufficient cooling can cause critical failures, especially during prolonged use.

Signs of Malfunction

- Unusual Noises: Grinding or clunking sounds may indicate mechanical issues.

- Poor Handling: Difficulty steering or reduced responsiveness could suggest serious problems.

- Vibrations: Excessive shaking may point to misalignment or damage within the system.

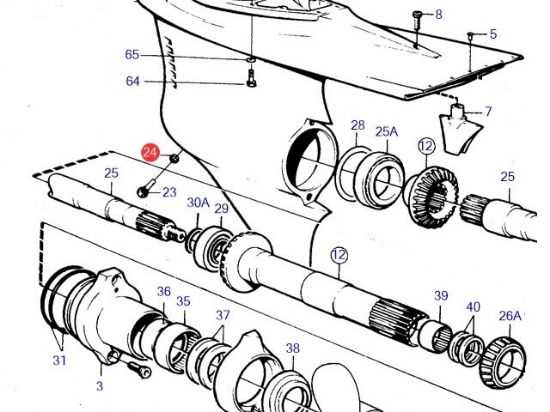

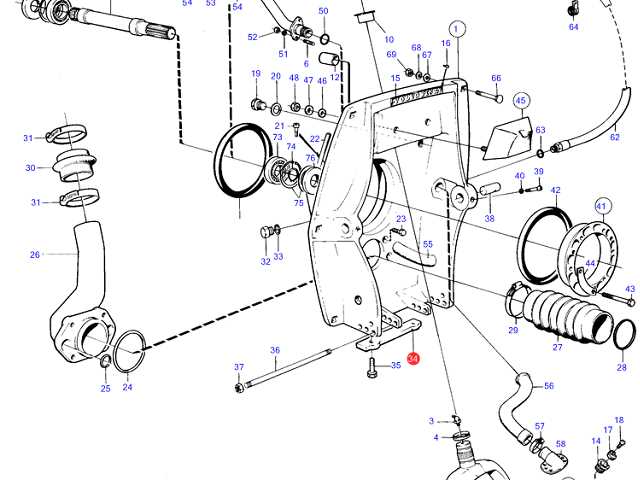

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to maintain and repair equipment. Familiarizing yourself with the layout and symbols used is crucial for effective interpretation.

- Identify Key Components: Look for labels that indicate the main elements within the illustration.

- Study the Legend: Most visuals come with a guide that explains the symbols and numbers used.

- Follow Connections: Observe how different parts are linked to understand their relationships.

- Note Assembly Order: Pay attention to any sequence that suggests how parts fit together.

- Refer to Supplementary Information: Check manuals or online resources for additional context.

By applying these strategies, you will ultimately enhance your understanding and efficiency in working with the visual guide.

Replacement Parts: What You Need

Ensuring the longevity and efficiency of your marine propulsion system relies on the timely replacement of essential components. Understanding which items require regular attention can help maintain performance and prevent costly repairs.

Common Components to Monitor

Several critical elements play a vital role in the overall functionality of your system. Regular inspection and timely replacement of these components can significantly enhance durability and performance.

| Component | Function | Replacement Frequency |

|---|---|---|

| Gaskets | Seals to prevent leaks | Every season |

| Propellers | Convert engine power into thrust | As needed |

| Belts | Transfer power between components | Every 2 years |

| Filters | Maintain fluid cleanliness | Every 100 hours |

Finding the Right Replacements

When seeking new components, consider quality and compatibility. Consulting with experts and utilizing trusted suppliers can lead to optimal choices, ensuring your system operates at its best.

Tools Required for Repairs

When undertaking maintenance tasks, having the right equipment is essential for efficiency and effectiveness. Various instruments are necessary to ensure that every component is handled correctly and safely. This section outlines the primary tools you will need for successful repairs.

Socket Wrench Set: A diverse range of socket sizes will allow you to tackle different bolts and fasteners effectively.

Screwdriver Set: Both flathead and Phillips screwdrivers are crucial for loosening and tightening screws.

Pliers: These are invaluable for gripping, twisting, and cutting wires or small parts.

Torque Wrench: To ensure that bolts are tightened to the specified limits, a torque wrench is vital for precision.

Multimeter: This device is essential for diagnosing electrical issues and ensuring all components are functioning properly.

Cleaning Supplies: Proper maintenance often involves cleaning; therefore, brushes, cloths, and suitable solvents are necessary.

By gathering these tools, you will be well-equipped to delve into your repair tasks and achieve the ultimate results efficiently.

Steps for Sterndrive Disassembly

Disassembling a marine propulsion unit requires careful attention and systematic steps to ensure all components are handled correctly. Proper preparation and understanding of the assembly layout will facilitate a smoother process, minimizing the risk of damage to any parts.

Preparation

Before starting the disassembly, ensure you have the necessary tools and workspace organized. This includes wrenches, screwdrivers, and a clean surface to lay out components. It is advisable to consult the service manual for specific instructions related to the model in question.

Disassembly Process

Follow these steps for a successful disassembly:

| Step | Description |

|---|---|

| 1 | Disconnect the power supply and any related cables to ensure safety during the process. |

| 2 | Remove the mounting bolts securing the unit to the transom or hull. |

| 3 | Carefully detach the drive unit from the housing, ensuring not to force any connections. |

| 4 | Take off any additional covers or shields that may be protecting internal components. |

| 5 | Identify and remove individual parts, such as the gear mechanism and propeller assembly, noting their arrangement for reassembly. |

| 6 | Clean all components thoroughly and inspect for wear or damage. |

Choosing Quality Replacement Parts

When it comes to maintaining your marine engine, selecting high-grade components is crucial for ensuring optimal performance and longevity. Quality replacements not only enhance efficiency but also minimize the risk of future breakdowns. Understanding the key features and benefits of superior alternatives will guide you in making informed choices.

Look for materials that offer durability and resistance to corrosion, especially in harsh marine environments. Genuine or certified aftermarket options often provide better compatibility and reliability than generic choices. Additionally, consider the manufacturer’s reputation and warranty policies as indicators of product quality.

Thorough research can help you identify trusted suppliers who prioritize customer satisfaction. Reviews and recommendations from fellow enthusiasts can also be invaluable in your search for the best components. Ultimately, investing in top-notch replacements can save you time and money in the long run.

Tips for Efficient Installation Process

When undertaking the assembly of marine propulsion components, ensuring a smooth and effective installation is crucial. By following specific guidelines, you can minimize errors and enhance the overall efficiency of the process.

Preparation is Key: Before starting, gather all necessary tools and materials. Familiarize yourself with the components and their respective roles within the system.

Consult Documentation: Always refer to the manufacturer’s instructions. These guidelines provide essential insights into the correct procedures and specifications, helping you avoid common pitfalls.

Work Methodically: Approach the installation step-by-step. Break down the process into manageable segments, ensuring each part is correctly positioned and secured before moving on.

Check for Compatibility: Ensure that all components are compatible with each other. Mismatched elements can lead to inefficiencies and potential failures.

Test Thoroughly: After installation, conduct comprehensive checks. Testing the system under various conditions ensures everything operates smoothly and identifies any adjustments needed.